Disc-like workpiece automatic perforating device for machining

A technology of mechanical processing and drilling devices, which is applied in the direction of driving devices, metal processing machinery parts, feeding devices, etc., can solve problems such as safety accidents, reduce work efficiency, and cumbersome drilling operations, and achieve a high degree of automation and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

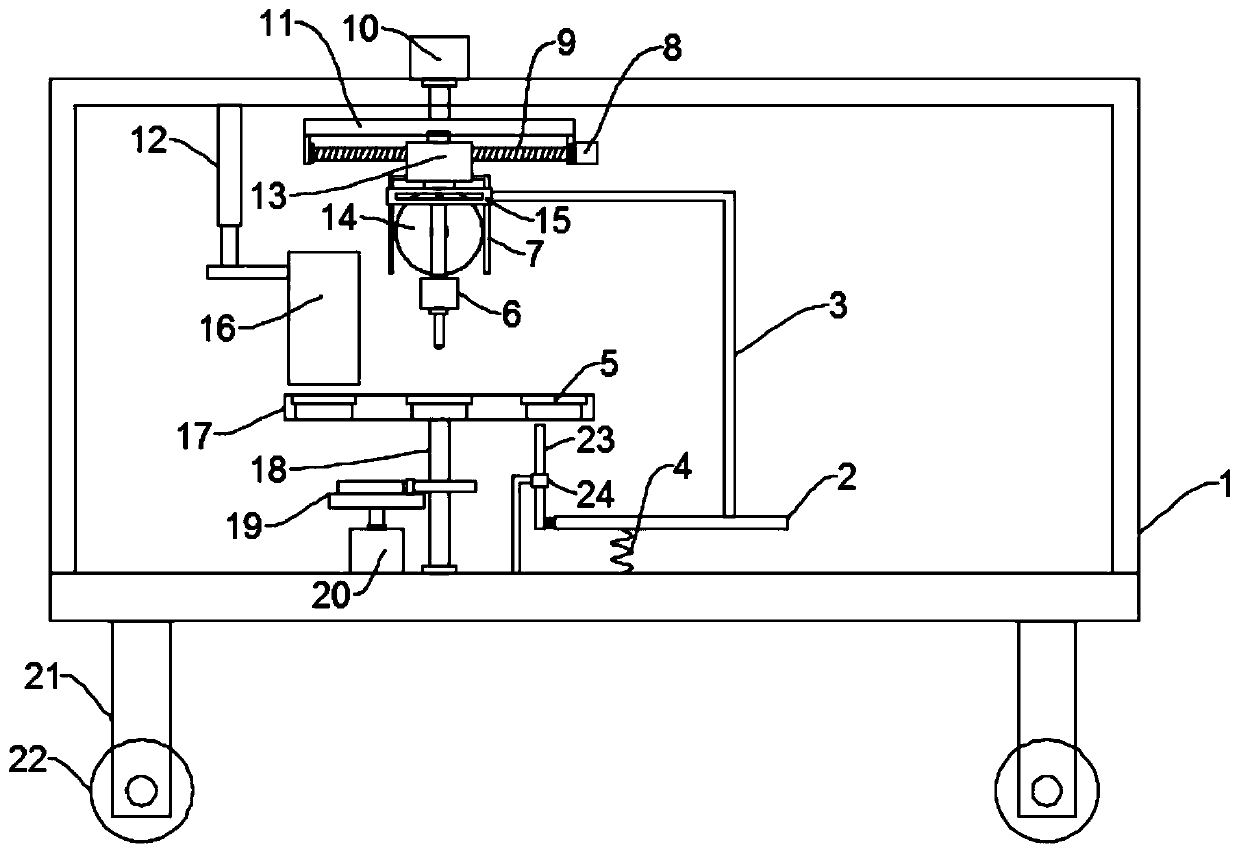

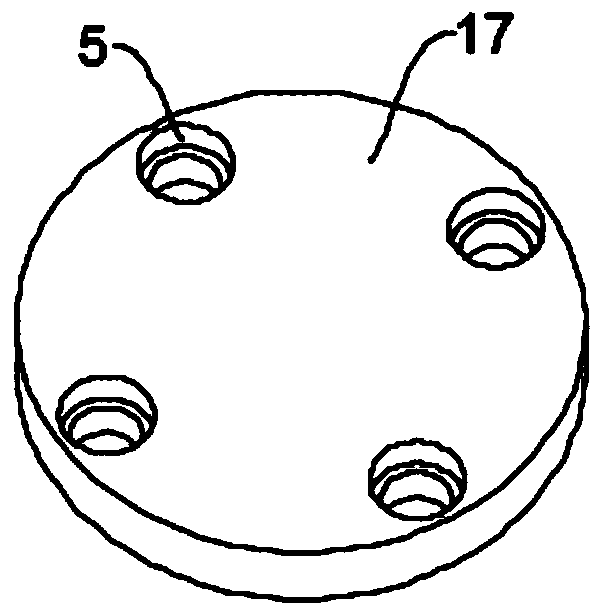

[0025] see Figure 1~2 , in an embodiment of the present invention, an automatic punching device for a disc-shaped workpiece for mechanical processing, comprising a frame 1, a drilling mechanism and a workbench 17, the bottom of the frame 1 is uniformly and symmetrically fixedly equipped with support legs 21, and the support legs 21 bottom end is equipped with roller 22, and described roller 22 is self-locking type roller, and the movement of convenience device, described frame 1 is equipped with workbench 17, and the frame 1 is positioned at the top of workbench 17 and is equipped with drilling mechanism, The workbench 17 is mounted on the frame 1 through the rotating shaft 18. The workbench 17 is provided with a plurality of stepped through holes 5 at equidistant intervals in the circumferential direction. The driving mechanism on which the table 17 rotates intermittently. In this embodiment, the driving mechanism includes a second motor 20 and a sheave mechanism 19. The sec...

Embodiment 2

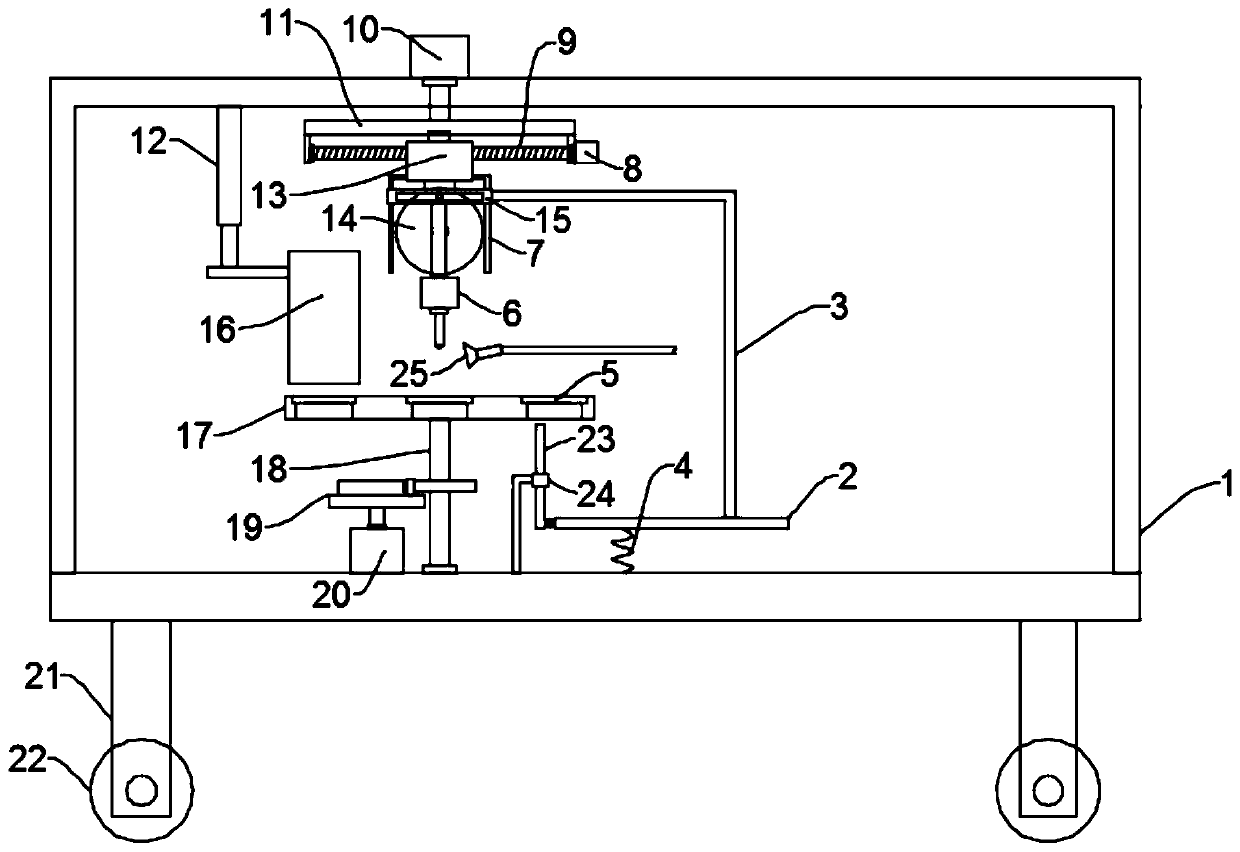

[0028] see image 3 The difference between this embodiment of the present invention and Embodiment 1 is that, further, a nozzle 25 is installed on one side of the processing station above the workbench 17, and the nozzle 25 is connected to the cutting fluid supply pipeline for lubrication and cooling during drilling , Protect the drill bit and the workpiece, and improve the processing efficiency.

[0029] The working principle of the present invention is: when the present invention is in use, the disc-shaped workpiece in the barrel 16 falls into a stepped hole on the workbench 17, and then the driving mechanism drives the workbench 17 to rotate so that the disc-shaped workpiece is located below the drilling mechanism After stopping, the power mechanism drives the drilling assembly 6 to move downward to drill holes. After the drilling is completed, the power mechanism drives the drilling assembly 6 to move upward, and then the workbench 17 rotates again, and the disc-shaped wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com