Flat chamfering machine

A technology of chamfering machine and flat plate, which is used in metal processing machinery parts, clamping, supporting and other directions, can solve the problems of flat plate deviation, the guide wheel cannot be actively rotated, and the accuracy of work is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

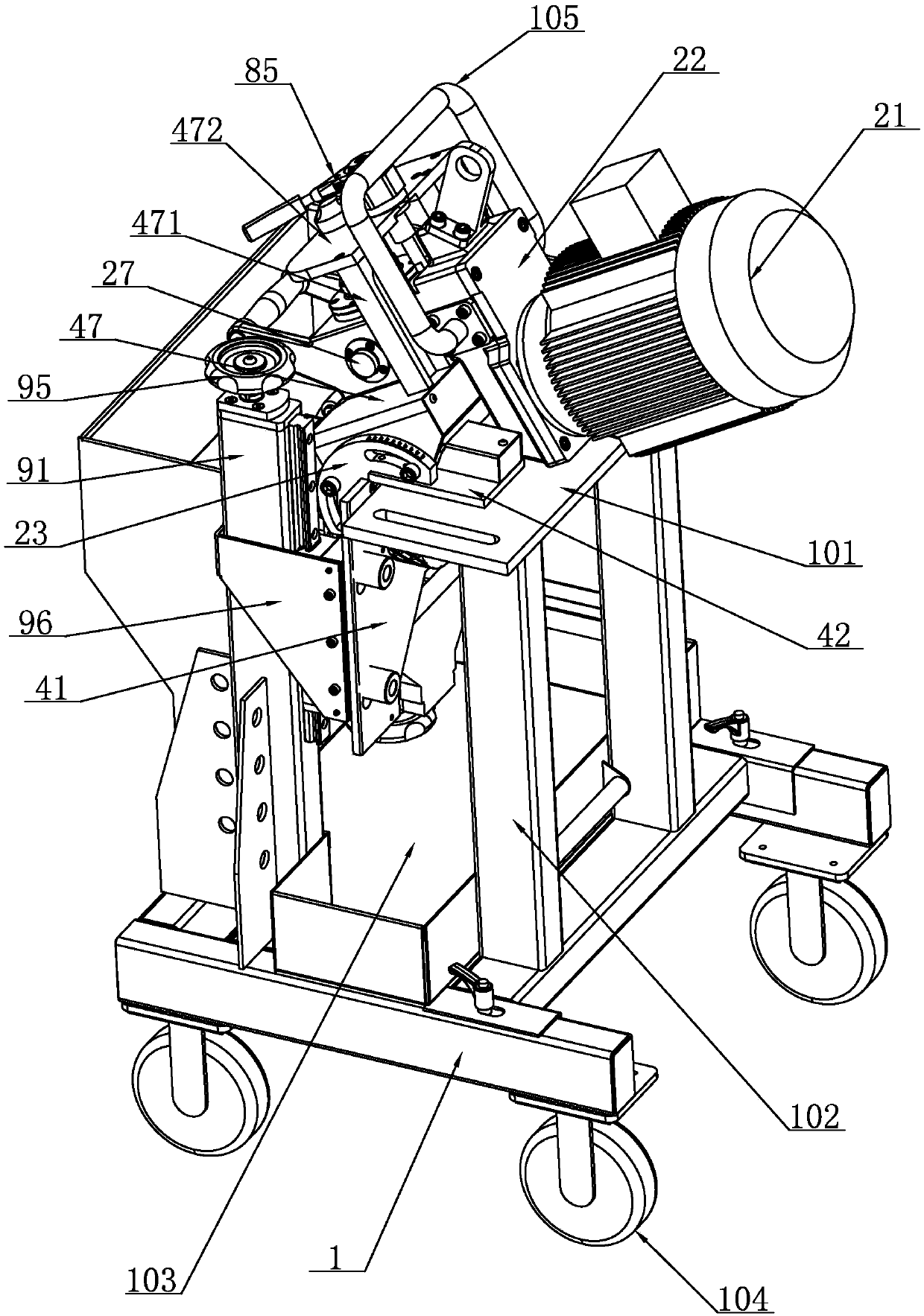

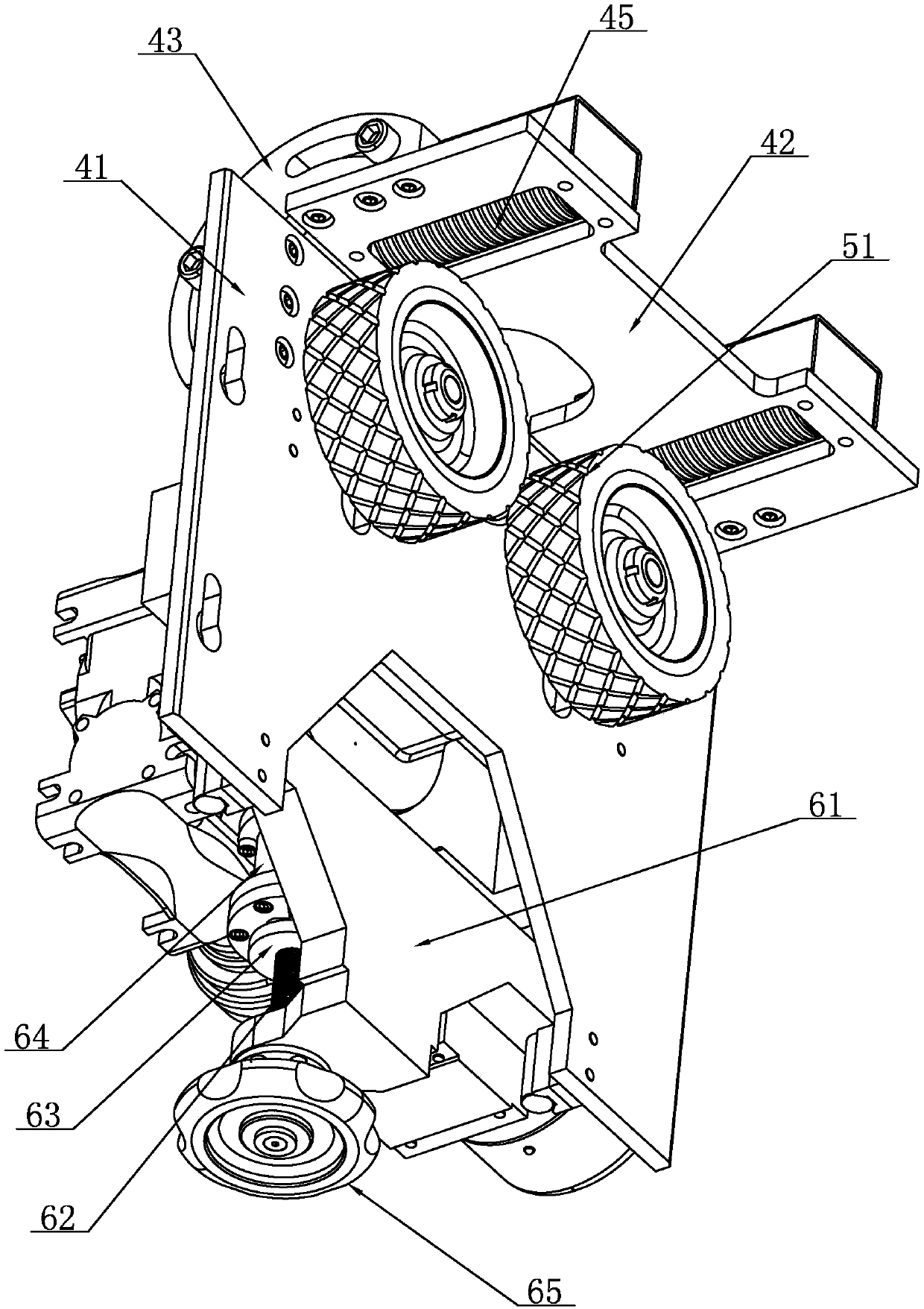

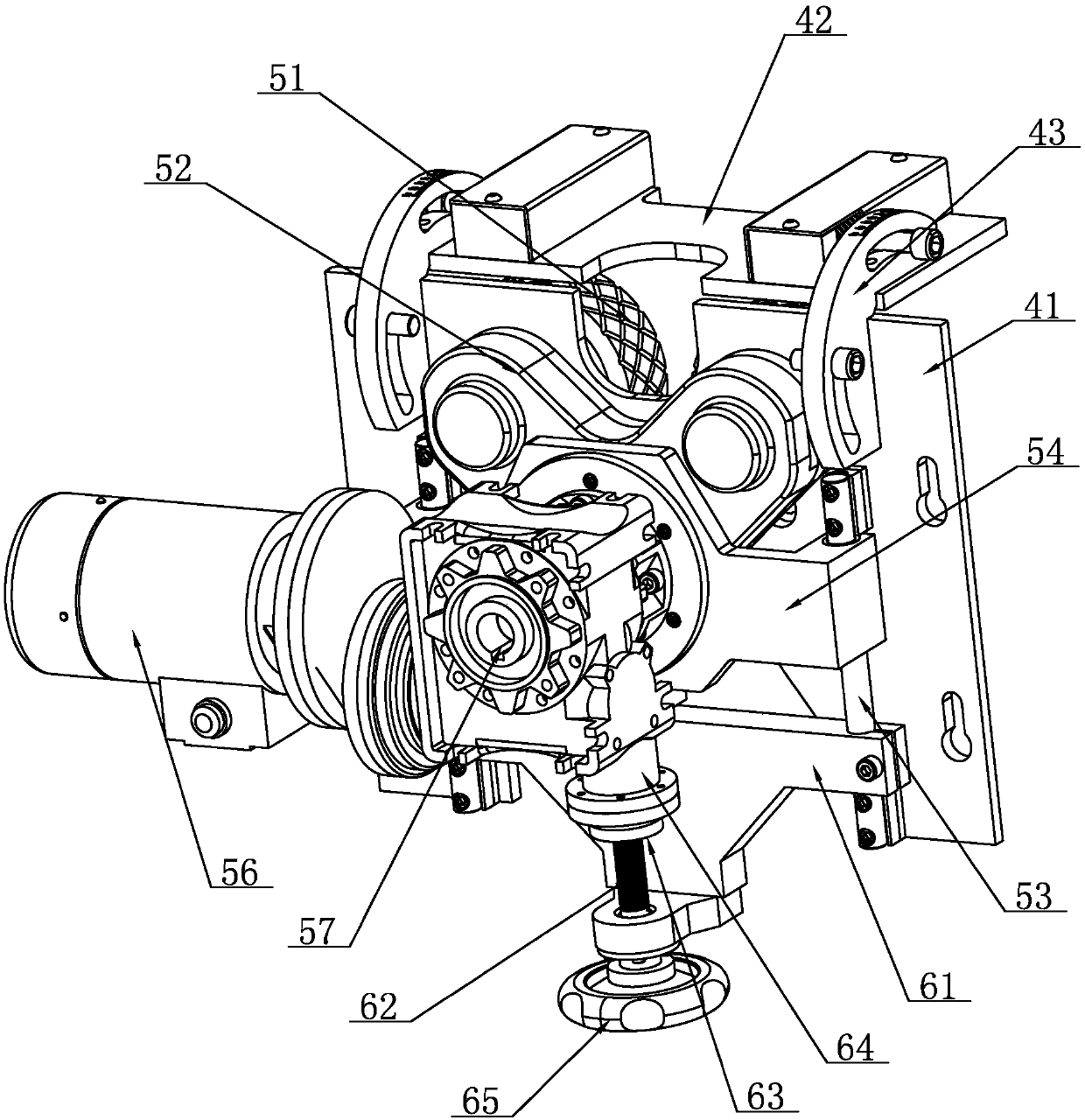

[0037] Such as Figure 1-Figure 12 As shown, a flat chamfering machine includes a frame 1, a first motor 21 and a chamfering knife 3, the first motor 21 is arranged on the frame 1 through a motor mount 22, and the chamfering knife 3 is rotated and installed on the motor On the seat 22, the output shaft of the first motor 21 is linked with the chamfering knife 3. The frame 1 is provided with a positioning plate 41 and a guide plate 42. The positioning plate 41 is installed on the frame 1, and the positioning plate 41 and the guide plate 42 are fixed. Connected, the first motor 21 is located above the guide plate 42, the end of the chamfering knife 3 extends between the positioning plate 41 and the guide plate 42, the motor mounting seat 22 is reversibly arranged on the positioning plate 41, and the positioning plate 41 is provided with There is a roller assembly for conveying flat plates, the roller assembly includes a first roller 51 and a roller seat 52, the first roller 51 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com