Turning, grinding and polishing all-in-one machine device for rubber roller

An all-in-one machine and rubber roller technology, applied in the fields of lathes, polishing machine tools, grinders, and rubber rollers to achieve the effect of changing the contact position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

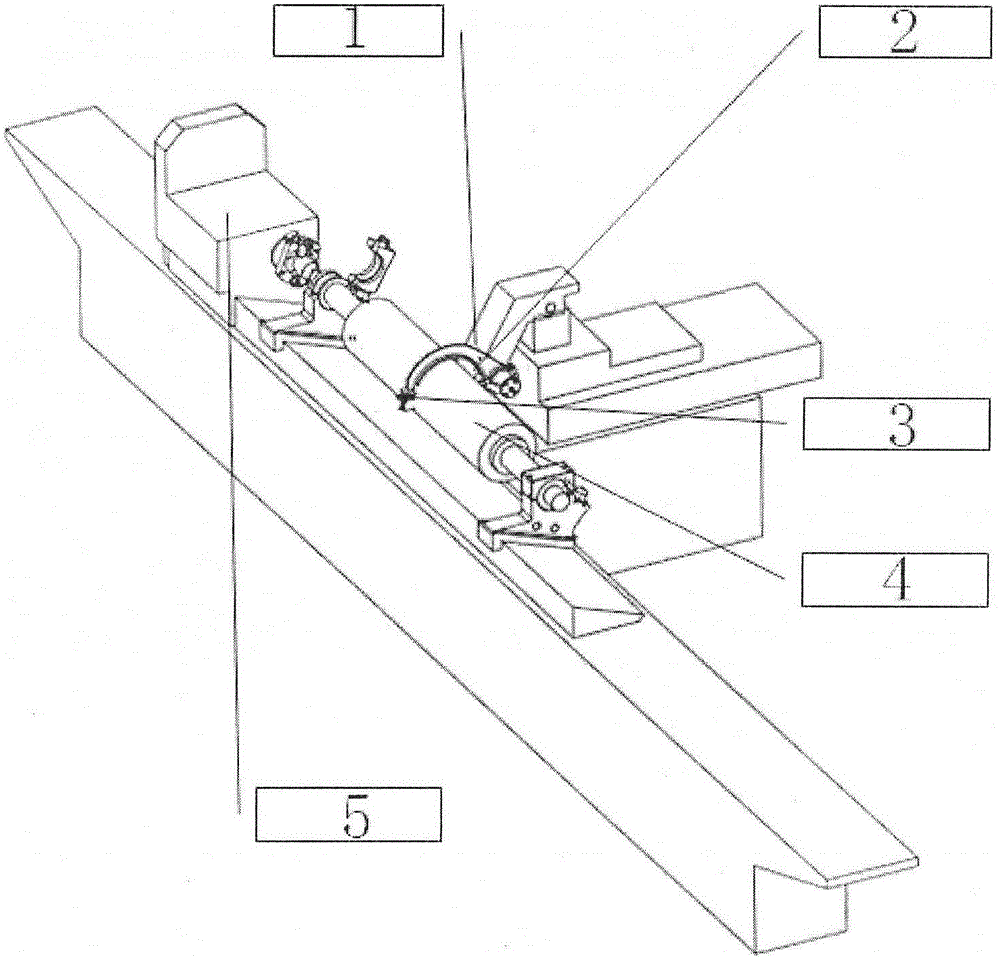

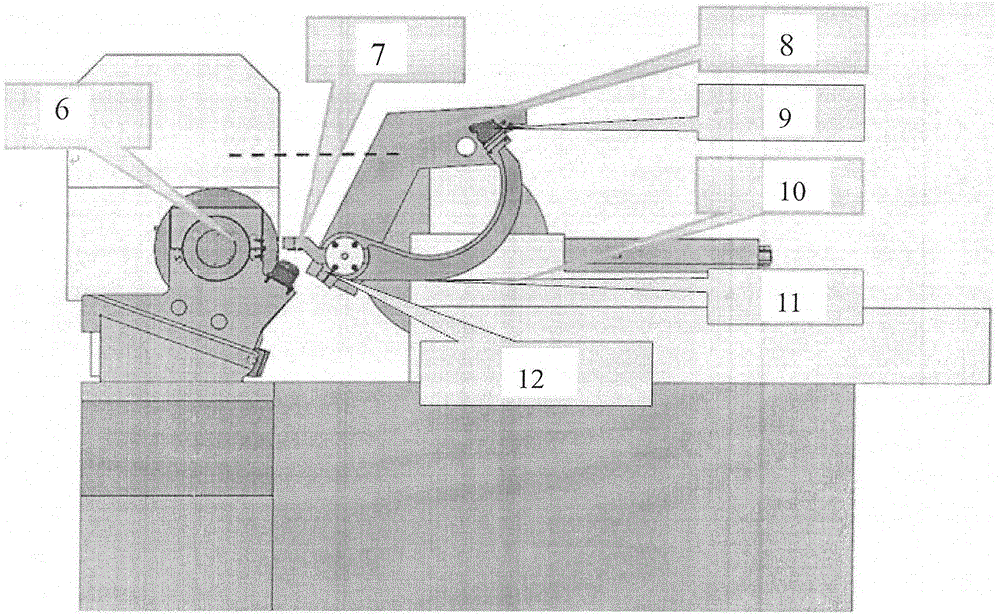

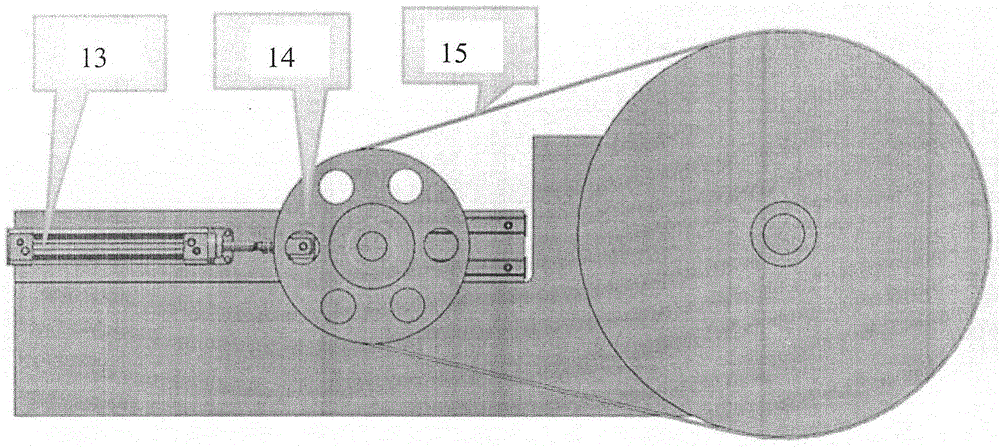

[0019] as attached Figure 1-2 As shown, a rubber roller turning, grinding and polishing integrated machine device includes a bed, an internal grinding device 1, a turning tool device 2, a grinding wheel device, an abrasive belt polishing device, and a measuring system 3.

[0020] The bed is an integral structure, and the internal ribs are arranged in a box shape. The bed is made of low-alloy high-strength inoculated cast iron to meet the requirements of high-efficiency and high-precision equipment for basic parts.

[0021] One end of the bed is equipped with a power bed head that rotates the workpiece, and the other end is equipped with a bed end. The head of the bed is provided with a main shaft, one end of the main shaft is connected with the chuck, and the other end is connected with the power unit; the top of the fixed workpiece is arranged on the end of the bed, and the main shaft of the head of the bed and the top of the end of the bed are on the same center line.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com