Laser plasma dual-use cutting machine

A plasma and cutting machine technology, used in plasma welding equipment, laser welding equipment, welding/cutting auxiliary equipment, etc. Good dust effect, solve the effect of laser instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

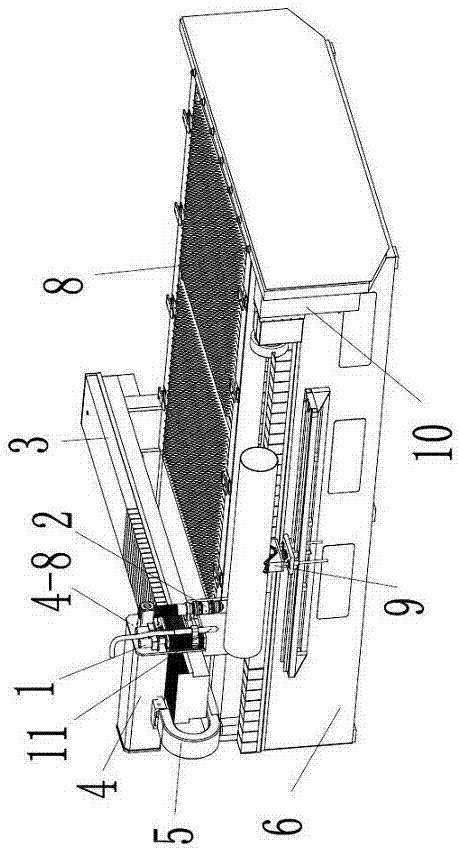

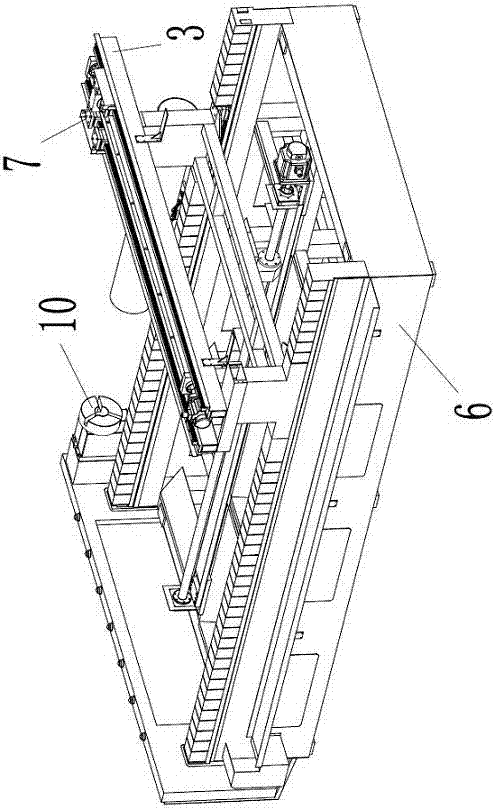

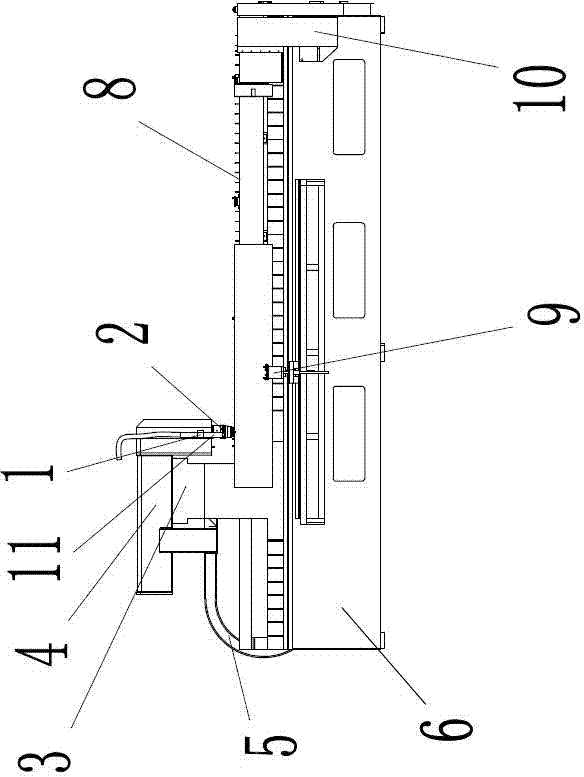

[0034] see figure 1 , 2 3. A laser and plasma dual-purpose cutting machine, comprising a bed 6, the bed 6 is connected with a beam 3, the beam 3 is connected with a drag plate 7, and the bed 6 is also fixedly connected with a workbench 8 and a drag Chain 5, its innovation lies in:

[0035] see figure 1 , 3 , 6, 7, 8, said carriage 7 is provided with a YAG solid-state laser generator 4, and the YAG solid-state laser generator 4 is provided with a light-emitting support plate 4-8, and said light-exit support plate 4-8 is equipped with two sets of Lifting mechanism 1, wherein one set of lifting mechanism 1 is connected with the double focal length laser cutting head 2, and the other set of lifting mechanism 1 is connected with plasma cutting torch 11;

[0036] see figure 1 , 2 , 3, 4, 5, the bed 6 is also provided with a rotary pipe cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com