Needle machine for processing carbon fiber products

A technology of needle loom and carbon fiber, which is applied in the direction of needle looms, textiles, papermaking, non-woven fabrics, etc. It can solve problems such as instability, interference with the processing process, and unevenness of the needle fiber mat, so as to simplify operations and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] For the purpose of full disclosure, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described below are only used to explain the present invention, and are not used to limit the protection scope of the present invention.

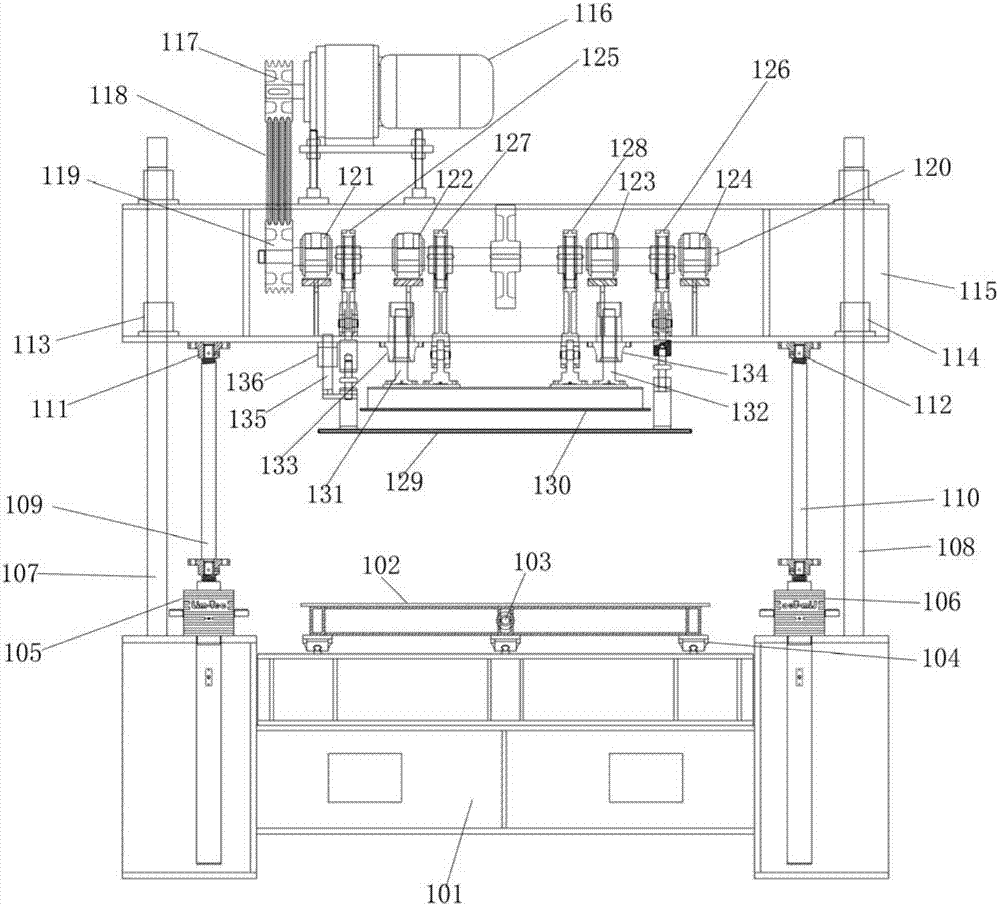

[0027] figure 1 A schematic diagram showing the overall structure of the needling machine of the present invention. Such as figure 1 As shown, the acupuncture machine of the present invention includes mechanical components and a control system, wherein the mechanical components include five parts: a machine base 101, a feeding mechanism installed on the machine base 101, and a height adjustment mechanism installed on the machine base 101 , the needle beam 115 supported on the height adjustment mechanism, and the acupuncture mechanism installed on the needle beam.

[0028] Such as figure 1 As shown in , the feeding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com