Smashing type food stirring cup

A mixing cup and pulverizing technology, which is applied in the field of pulverizing food mixing cups, can solve the problems of inability to achieve universal effects, inconvenient storage, complex structure, etc., and achieve the effects of improving versatility and practicability, convenient cleaning and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

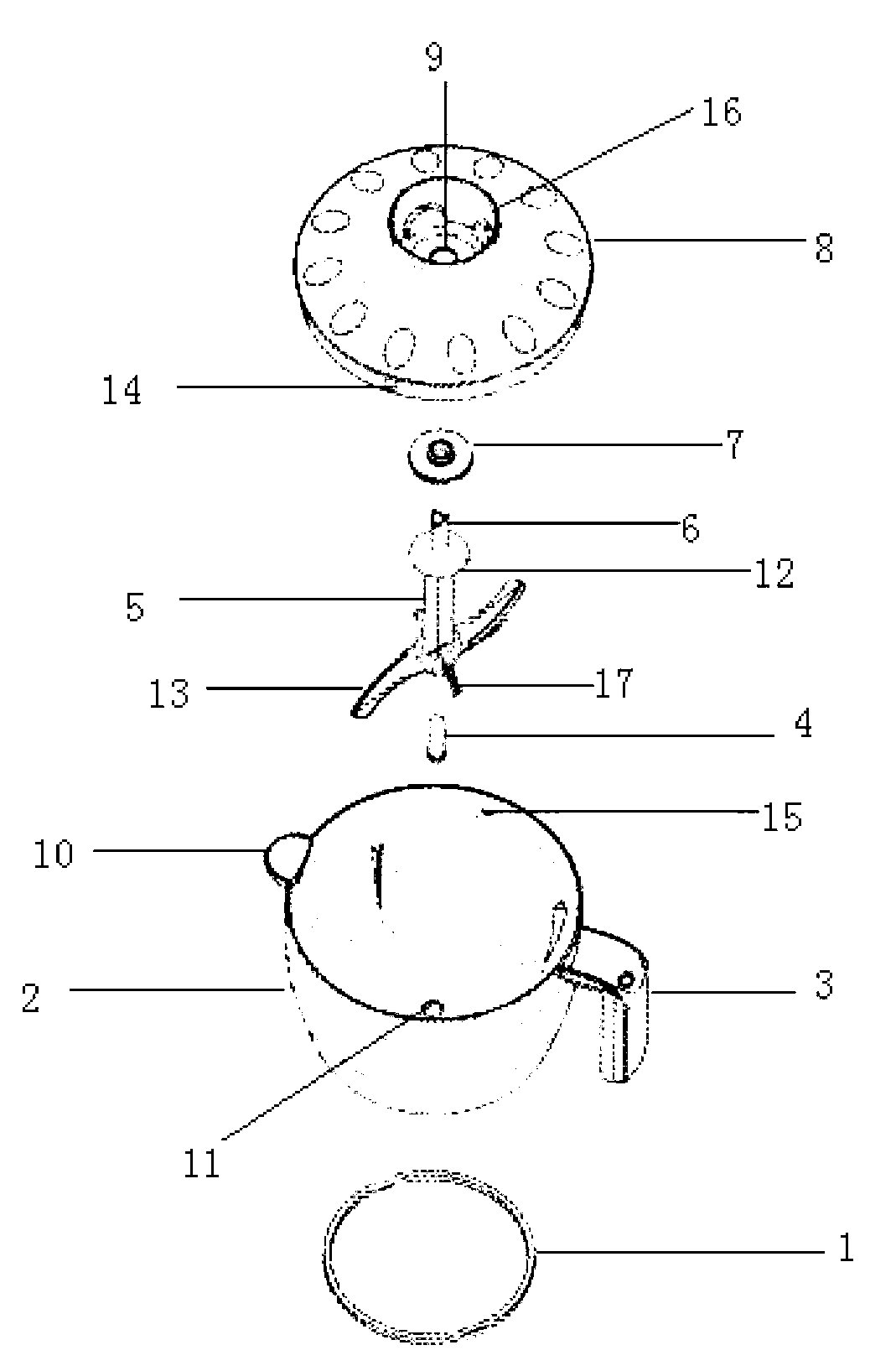

[0009] The main structure of this embodiment includes a cup bottom rubber 1, a cup body 2, a handle 3, a column 4, a crushing knife 5, a rotating shaft 6, a bearing 7, a cup cover 8, a rotating shaft hole 9, a discharge nozzle 10, and a fixing hole 11 , support plate 12, blade 13, convex card 14, card slot 15, power chamber 16 and short arm 17; cup body bottom rubber 1 is pasted and fixed in the outer bottom end groove of round box type cup body 2, cup body 2 One side of the top of the cup body is formed with a handle 3 with a downward bending structure, and the center of the inner bottom of the cup body 2 is fixed with a column 4 through a fixing hole 11. The upper end is shaped on a circular support plate 12 and a rotating shaft 6, the upper end of the rotating shaft 6 is a groove structure so as to facilitate the snap-fit docking with the external electric power, the rotating shaft 6 is covered with a bearing 7 and passes through the center of the cup cover 8 The shaft ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com