Conveying device used for machining chase mortises of wood floor

A technology of groove and tenon processing and conveying device, which is applied in the field of wood processing, can solve the problems of low efficiency, imperfection and low precision of groove and tenon processing of wooden floors, and achieves the effect of improving the controllability and wide application of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

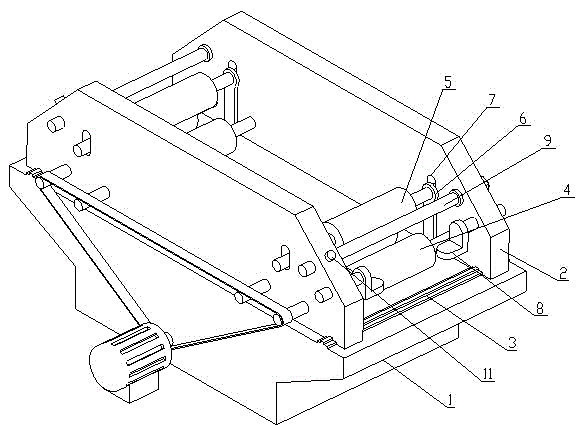

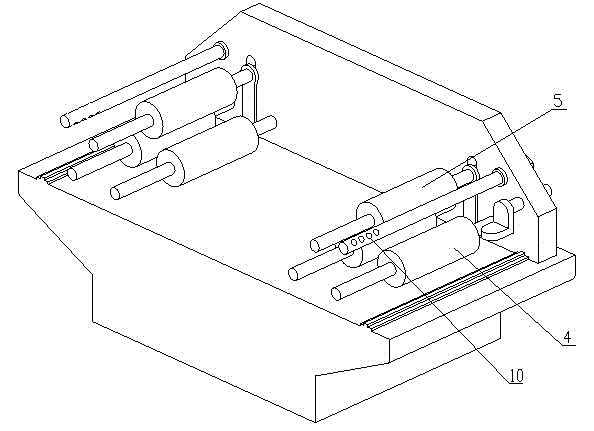

[0016] Embodiment 1 of the present invention: a conveying device for wood floor groove and tenon processing, such as figure 1 and figure 2 As shown, it includes a base 1, a body 2, a slide rail 3, a conveying roller 4, a pressure roller 5, a lifting plate 6 and a limit hole 7, the body 2 is arranged on the base 1, the slide rail 3 is arranged on the base 1, and the body 2 Adapted to the slide rail 3, the body 2 can slide on the slide rail 3, the conveying roller 4 is set at the lower part of the body 2, the lifting plate 6 is set on the base 1, and the driving device on the base 1 can make the lifting plate 6 go up and down, press The roller 5 is arranged on the lifting plate 6, the pressure roller 5 rises and falls together with the lifting plate 6, the limit hole 7 is arranged on the body 2, the limit hole 7 is adapted to the pressure roller 5, and the limit hole 7 limits the pressure roller 5 only Move vertically.

[0017] In particular, a guide block 8 is provided on th...

Embodiment 2

[0020] Embodiment 2 of the present invention: a conveying device for wood floor groove and tenon processing, including a base 1, a body 2, a slide rail 3, a conveying roller 4, a pressure roller 5, a lifting plate 6 and a limit hole 7, and the body 2 Set on the base 1, the slide rail 3 is set on the base 1, the body 2 is adapted to the slide rail 3, the body 2 can slide on the slide rail 3, the conveying roller 4 is set on the lower part of the body 2, and the lifting plate 6 is set on the base 1 Above, the driving device on the base 1 can lift the lifting plate 6 up and down, the pressure roller 5 is arranged on the lifting plate 6, the pressure roller 5 rises and falls together with the lifting plate 6, the limit hole 7 is arranged on the body 2, the limit hole 7 Adapted to the pressure roller 5, the limiting hole 7 restricts the pressure roller 5 to move only in the vertical direction.

[0021] In particular, a guide block 8 is provided on the machine body 2, and the guide ...

Embodiment 3

[0022] Embodiment 3 of the present invention: a conveying device for wood floor groove and tenon processing, including a base 1, a body 2, a slide rail 3, a conveying roller 4, a pressure roller 5, a lifting plate 6 and a limit hole 7, and the body 2 Set on the base 1, the slide rail 3 is set on the base 1, the body 2 is adapted to the slide rail 3, the body 2 can slide on the slide rail 3, the conveying roller 4 is set on the lower part of the body 2, and the lifting plate 6 is set on the base 1 Above, the driving device on the base 1 can lift the lifting plate 6 up and down, the pressure roller 5 is arranged on the lifting plate 6, the pressure roller 5 rises and falls together with the lifting plate 6, the limit hole 7 is arranged on the body 2, the limit hole 7 Adapted to the pressure roller 5, the limiting hole 7 restricts the pressure roller 5 to move only in the vertical direction.

[0023] The use method of the present invention: the wooden floor is sent to the conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com