Thermal transfer ribbon and preparation method thereof

A thermal transfer and carbon ribbon technology, applied in printing, ink ribbon, coating, etc., can solve the problem of low energy consumption, lack of corrosion resistance and peelability, and low durability of wax-based thermal transfer ribbon printing. problem, to achieve the effect of high peelability, good product cost performance and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

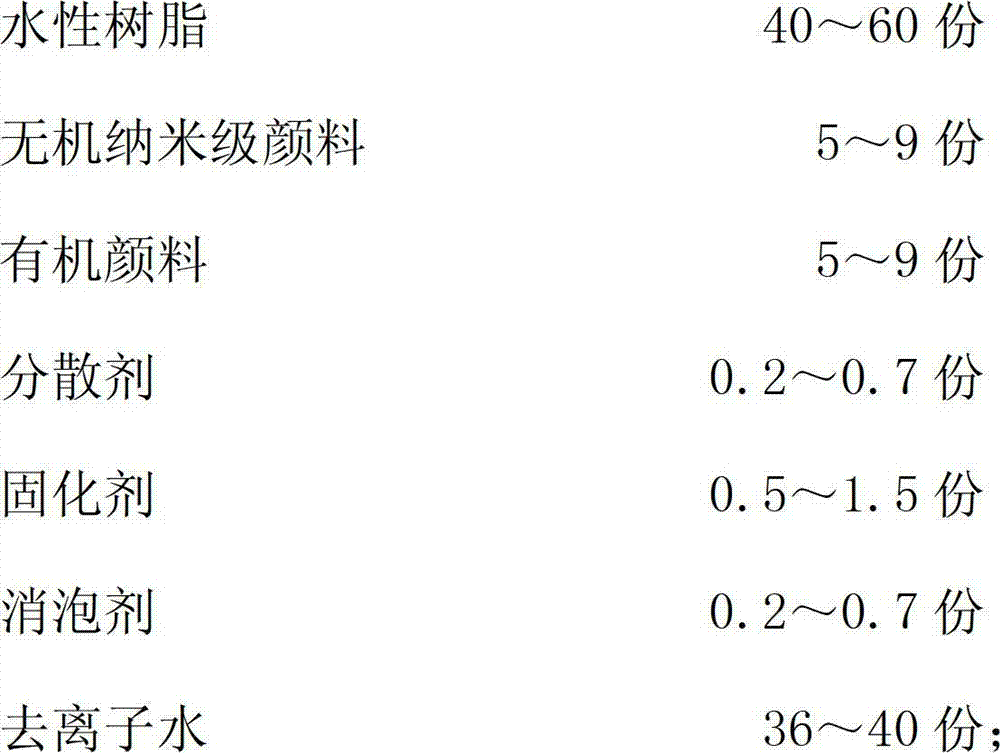

Embodiment 1

[0037] 6 parts of inorganic nano-scale pigments, 6 parts of organic pigments, 0.4 parts of dispersant, 1 part of curing agent, 0.5 parts of defoamer, 45 parts of water-based resin, 1.5 parts of talcum powder, 28 parts of silicone resin, 38 parts of water-based wax emulsion, 88 parts of polyester film, 9 parts of thermal grease, 18 parts of fluorocarbon, 48 parts of silicone resin, 92 parts of deionized water.

[0038] The preparation process of the present invention: first, 6 parts of inorganic nano-scale pigments, 6 parts of organic pigments, and 0.5 parts of dispersant are added to 38 parts of deionized water, stirred for 1.5 hours at a speed of 2000r / min to form ink base material, and then Add 45 parts of water-based resin to the ink base, stir for 0.5 hours, then add 1 part of curing agent and 0.4 parts of defoamer, and stir thoroughly for 0.5 hours to form an ink coating emulsion; then add 1.5 parts of talcum powder to 27 parts of Stir in deionized water for 1 hour at a s...

Embodiment 2

[0040] 7 parts of inorganic nano-scale pigments, 7 parts of organic pigments, 0.5 parts of dispersant, 1 part of curing agent, 0.5 parts of defoaming agent, 50 parts of water-based resin, 2 parts of talcum powder, 30 parts of silicone resin, 40 parts of water-based wax emulsion, 90 parts of polyester film, 10 parts of thermal grease, 20 parts of fluorocarbon, 50 parts of silicone resin, 95 parts of deionized water.

[0041]The preparation process of the present invention: first, 7 parts of inorganic nano-scale pigments, 7 parts of organic pigments, and 0.5 parts of dispersant are added to 38 parts of deionized water, stirred for 1.5 hours at a speed of 2000r / min to form ink base material, and then Add 50 parts of water-based resin to the ink base, stir for 0.5 hours, then add 1 part of curing agent and 0.5 parts of defoamer, and stir thoroughly for 0.5 hours to form an ink coating emulsion; then add 2 parts of talcum powder to 27 parts to remove Stir in deionized water for 1 h...

Embodiment 3

[0043] 8 parts of inorganic nano-scale pigments, 8 parts of organic pigments, 0.6 parts of dispersants, 1.2 parts of curing agents, 0.6 parts of defoamers, 55 parts of water-based resins, 2.5 parts of talcum powder, 28 parts of silicone resins, 38 parts of water-based wax emulsions, 92 parts of polyester film, 11 parts of thermal grease, 22 parts of fluorocarbon, 52 parts of silicone resin, 98 parts of deionized water.

[0044] The preparation process of the present invention: first, 8 parts of inorganic nano-scale pigments, 8 parts of organic pigments, and 0.6 parts of dispersant are added to 38 parts of deionized water, stirred for 1.5 hours at a speed of 2000r / min to form ink base material, and then Add 55 parts of water-based resin to the ink base, stir for 0.5 hours, then add 1.2 parts of curing agent and 0.6 parts of defoamer, and stir thoroughly for 0.5 hours to form an ink coating emulsion; then add 2.5 parts of talcum powder to 28 parts of In ionized water, stir for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com