Heat-conducting silicone grease composition with low oil separation degree and preparation method thereof

A technology of thermal conductive silicone grease and oil separation, which is applied in the field of low oil separation thermal conductive silicone grease composition and its preparation, can solve the problems of easy migration of base oil, increase working stability and service life, reduce thermal resistance, The effect of easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

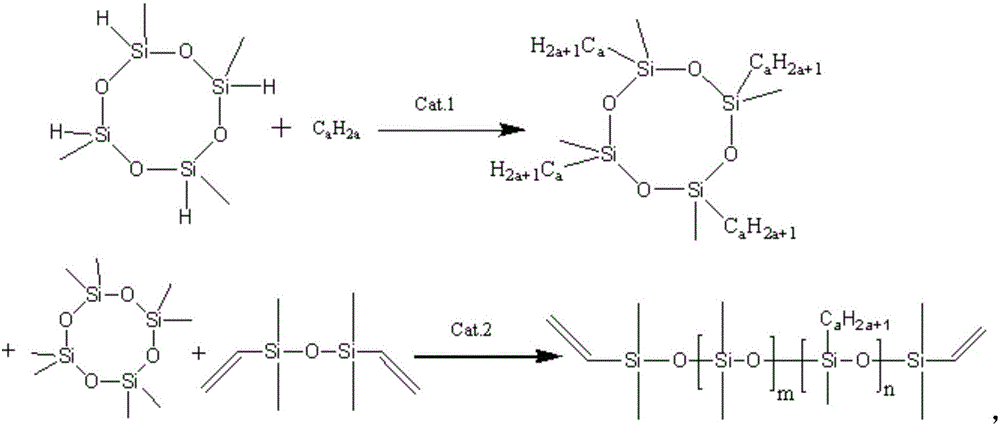

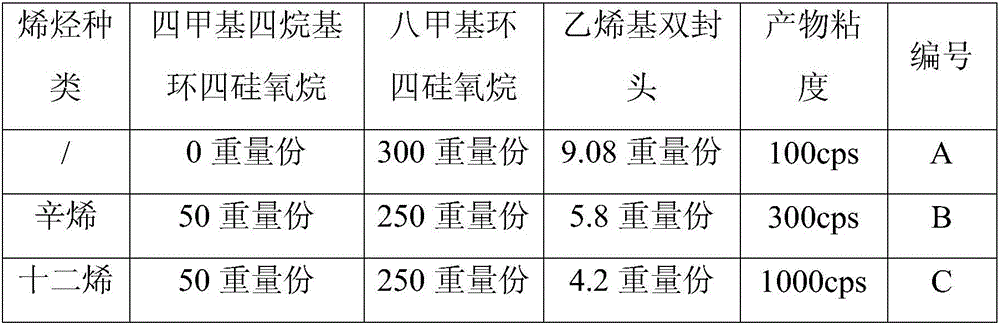

Method used

Image

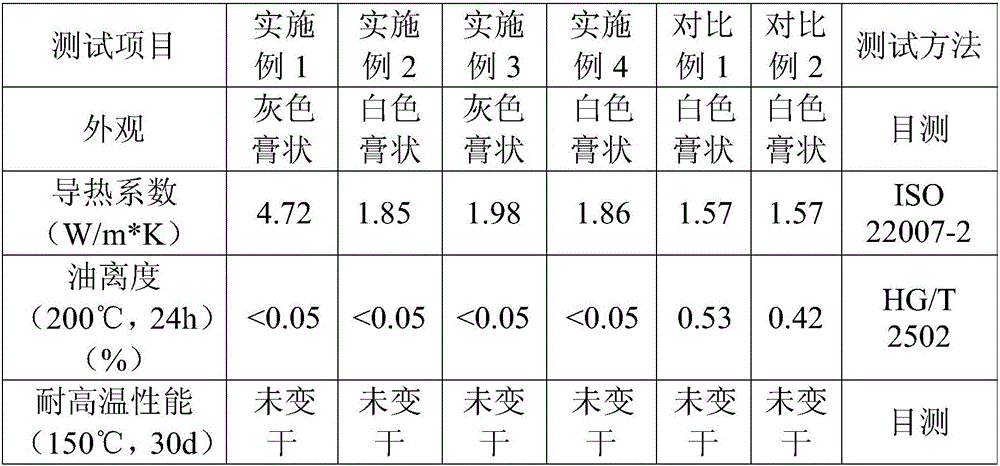

Examples

Embodiment 1

[0061] 30 parts by weight A;

[0062] 1 part by weight of hydrogen-containing silicone oil with a viscosity of 20 cps and a hydrogen content of 0.02 wt %;

[0063] 0.05 parts by weight methyl butynol;

[0064] 0.02 parts by weight of a platinum-vinylsiloxane complex with a platinum content of 2000ppm;

[0065] Put the above materials into a plastic jar, stir well, then add the following materials:

[0066] 100 parts by weight of alumina with a particle size of 5 μm;

[0067] 150 parts by weight of aluminum powder with a particle size of 1 μm;

[0068] 150 parts by weight of copper powder with a particle size of 10 μm;

[0069] Then put the jar into a high-speed centrifugal agitator, and centrifuge at a speed of 1000-1200r / min for 2 minutes, then take out the jar, open the bottle cap, and peel off the undispersed powder filler from the bottle wall to the bottom of the bottle. Stir moderately, and then centrifuge at a speed of 1500-1800r / min for 3-5min to prepare the sample...

Embodiment 2

[0071] 30 parts by weight B;

[0072] 0.2 parts by weight of hydrogen-containing silicone oil with a viscosity of 30 cps and a hydrogen content of 0.15 wt %;

[0073] 0.1 parts by weight of ethynyl cyclohexanol;

[0074] 0.02 parts by weight of a platinum-vinylsiloxane complex with a platinum content of 3000ppm;

[0075] Put the above materials into a plastic jar, stir well, then add the following materials:

[0076] 120 parts by weight of quartz powder with a particle size of 5 μm and hydrophobic treatment on the surface;

[0077] 120 parts by weight of aluminum oxide with a particle size of 1 μm and a hydrophobic treatment on the surface;

[0078] Then put the jar into a high-speed centrifugal agitator, and centrifuge at a speed of 1000-1200r / min for 2 minutes, then take out the jar, open the bottle cap, and peel off the undispersed powder filler from the bottle wall to the bottom of the bottle. Stir moderately, and then centrifuge at a speed of 1500-1800 r / min for 3-5 m...

Embodiment 3

[0080] 40 parts by weight C;

[0081] 0.1 parts by weight of hydrogen-containing silicone oil with a viscosity of 20 cps and a hydrogen content of 0.3 wt %;

[0082] 0.07 parts by weight of 3,7,11-trimethyldodeyn-3-alcohol;

[0083] 0.02 parts by weight of a platinum-vinylsiloxane complex with a platinum content of 1000ppm;

[0084] Put the above materials into a plastic jar, stir well, then add the following materials:

[0085] 120 parts by weight of zinc oxide with a particle size of 1 μm and hydrophobic treatment on the surface;

[0086] 120 parts by weight of aluminum powder with a particle size of 5 μm;

[0087] Then put the jar into a high-speed centrifugal agitator, and centrifuge at a speed of 1000-1200r / min for 2 minutes, then take out the jar, open the bottle cap, and peel off the undispersed powder filler from the bottle wall to the bottom of the bottle. Stir moderately, and then centrifuge at a speed of 1500-1800r / min for 3-5min to prepare the sample of Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com