Ultra-low thermal-resistance heat-conducing silicon grease and preparation method thereof

A technology of resisting heat conduction and ultra-low heat, applied in the field of ultra-low thermal resistance heat-conducting silicone grease and its preparation, which can solve the problems of easy leakage of silicone oil, poor heat transfer effect, pollution of other components, etc., and achieve good electrical insulation performance and dielectric performance. , The effect of good high temperature resistance and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

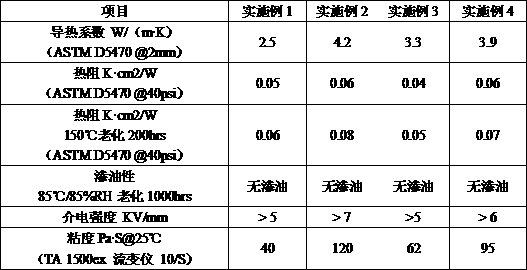

Examples

Embodiment 1

[0028] First of all, pretreatment of raw materials, including: (a) drying aluminum oxide and zinc oxide at a drying temperature of 120°C and a drying time of 100 minutes to remove moisture; (b) drying polydimethylsiloxane Alkanes (viscosity 500mPa·S (25°C)) are added to the double planetary mixer with heating jacket and vacuum equipment, and then 150°C heating oil is passed into the heating jacket, and the vacuum equipment is started to clean the inside of the double planetary mixer. Vacuumize (the absolute pressure inside the dual planetary mixer is 500Pa after vacuuming), and stir (stirring speed is 200 rpm, stirring time is 60 minutes), and cool to 25°C after stirring.

[0029] Then, follow the steps below to prepare ultra-low thermal resistance thermal grease:

[0030] (1) By weight, take 100 parts of polydimethylsiloxane, 20 parts of polyphenylmethylsiloxane (its viscosity is 50 mPa·S (25°C)), 1000 parts of alumina, 20 parts of oxide Zinc (the median particle size D50 is...

Embodiment 2

[0037] First of all, pretreatment of raw materials, including: (a) drying aluminum oxide and zinc oxide at a drying temperature of 120°C and a drying time of 80 minutes to remove moisture; (b) drying polydimethylsiloxane Alkanes (with a viscosity of 50mPa·S (25°C)) are added to the double planetary mixer with heating jacket and vacuum equipment, and then 150°C heating oil is passed into the heating jacket, and the vacuum equipment is started to adjust the double planetary mixer. Vacuumize inside (the absolute pressure inside the double planetary mixer is 200Pa after vacuuming), and stir (stirring speed is 400 rpm, stirring time is 60 minutes), and cool to 30°C after stirring.

[0038] Then, follow the steps below to prepare ultra-low thermal resistance thermal grease:

[0039] (1) By weight, take 100 parts of polydimethylsiloxane, 40 parts of polyphenylmethylsiloxane (with a viscosity of 50 mPa·S (25°C)), 2600 parts of alumina, 20 parts of oxide Zinc (the median particle size...

Embodiment 3

[0046] First, carry out raw material pretreatment, including: (a) drying aluminum oxide and zinc oxide at a drying temperature of 110°C and a drying time of 100 minutes to remove moisture; (b) drying polydimethylsiloxane Alkanes (with a viscosity of 200mPa·S (25°C)) are added to the double planetary mixer with heating jacket and vacuum equipment, and then 140°C heating oil is passed into the heating jacket, and the vacuum equipment is started to adjust the double planetary mixer. Vacuumize inside (the absolute pressure inside the double planetary mixer is 300Pa after vacuuming), and stir (stirring speed is 300 rpm, stirring time is 80 minutes), and cool to 20°C after stirring.

[0047] Then, follow the steps below to prepare ultra-low thermal resistance thermal grease:

[0048] (1) By weight, take 100 parts of polydimethylsiloxane, 20 parts of polyphenylmethylsiloxane (with a viscosity of 200 mPa·S (25°C)), 1600 parts of alumina, 40 parts of oxide Zinc (the median particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com