Method for packaging sensitized optical fiber grating temperature sensor

A technology of temperature sensor and optical fiber grating, which is applied in the field of sensors, can solve the problems that the computer cannot automatically record data, cannot realize long-distance signal transmission, and is susceptible to electromagnetic radiation interference, so as to eliminate temperature-strain cross-sensitivity and increase temperature Sensitivity, the effect of high installation survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

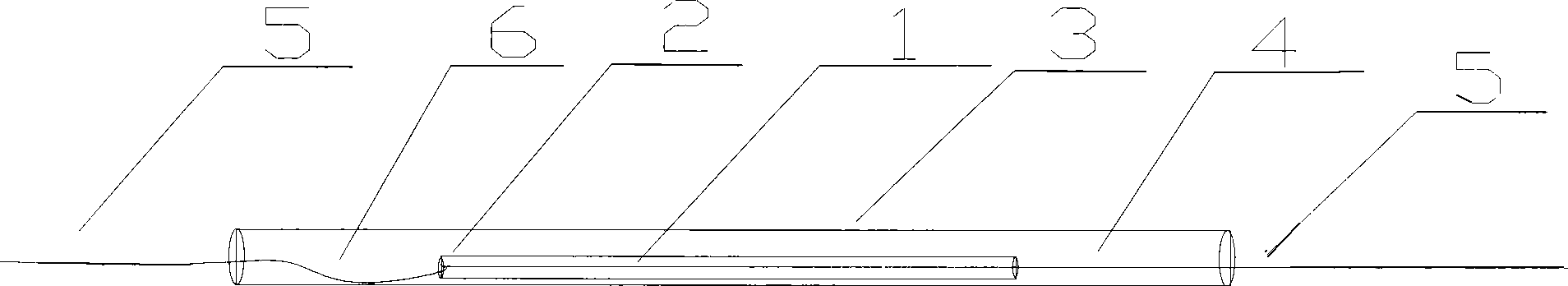

[0012] The best embodiment of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0013] Peel off the 5mm coating layer on both sides of the gate area of the fiber grating 1 to expose the bare fiber, and clean it with acetone, then insert the fiber grating 1 into a metal capillary tube 2 with an inner diameter of 0.5 mm and an outer diameter of 1 mm, and place it on the fiber grating A constant tension is applied on both sides of the fiber grating 1 to redshift the reflection wavelength of the fiber grating 1 by about 1nm, and then the two ends of the metal capillary 2 are firmly bonded to the exposed part of the optical fiber with metal glue. Put the above-mentioned metal capillary into a stainless steel tube 3 with an inner diameter of 2mm and an outer diameter of 3mm, and then fill it with thermally conductive silicone grease 4, connect both ends of the optical fiber sheath 7 and stick it firmly with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com