Evaporator for cooling chip and manufacture method thereof

An evaporator and chip technology, applied in electric solid devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as deterioration and insignificant strengthening effect, and achieve strong cooling capacity, low pipeline resistance, and manufacturing process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention should not be limited thereby.

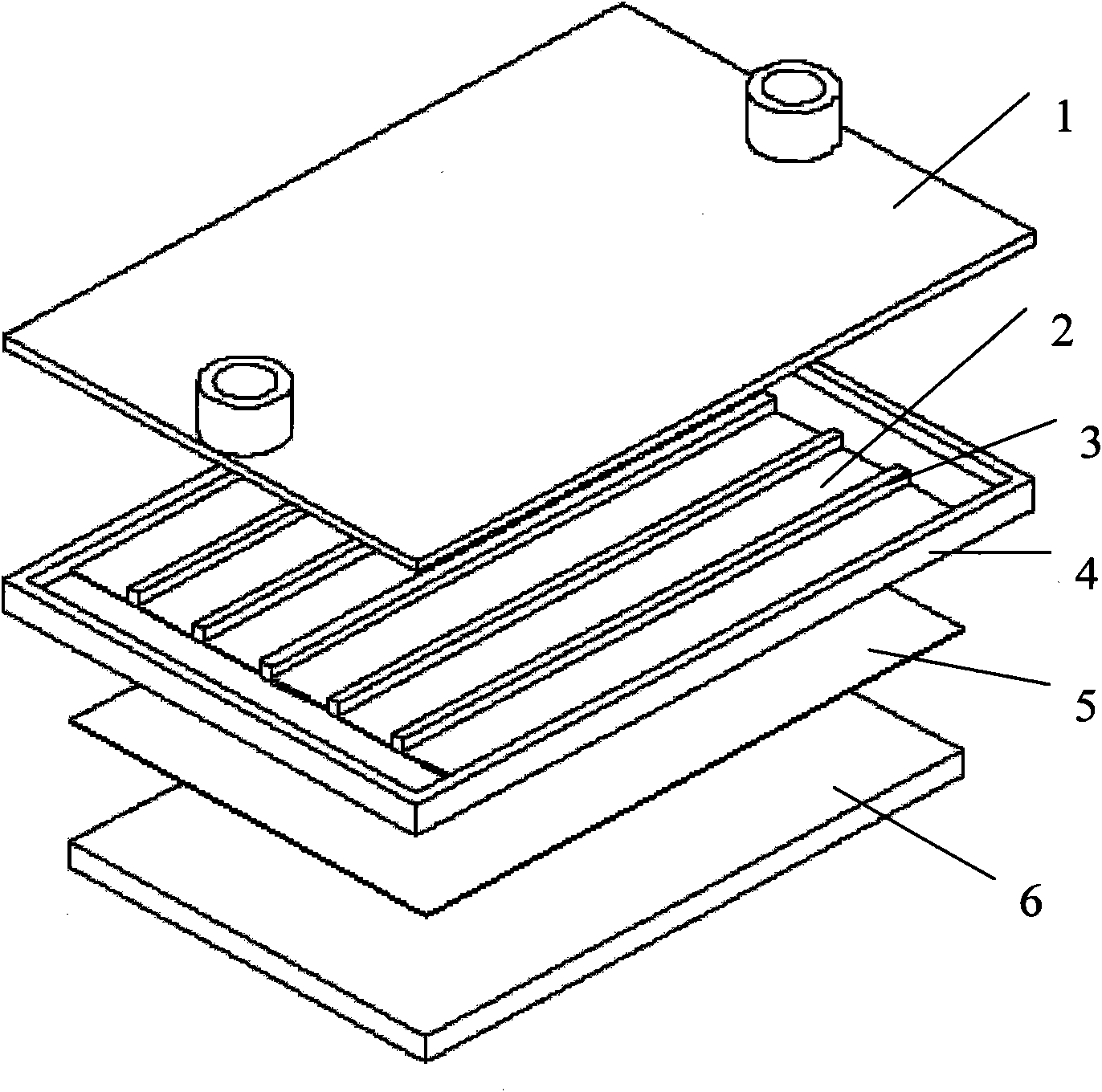

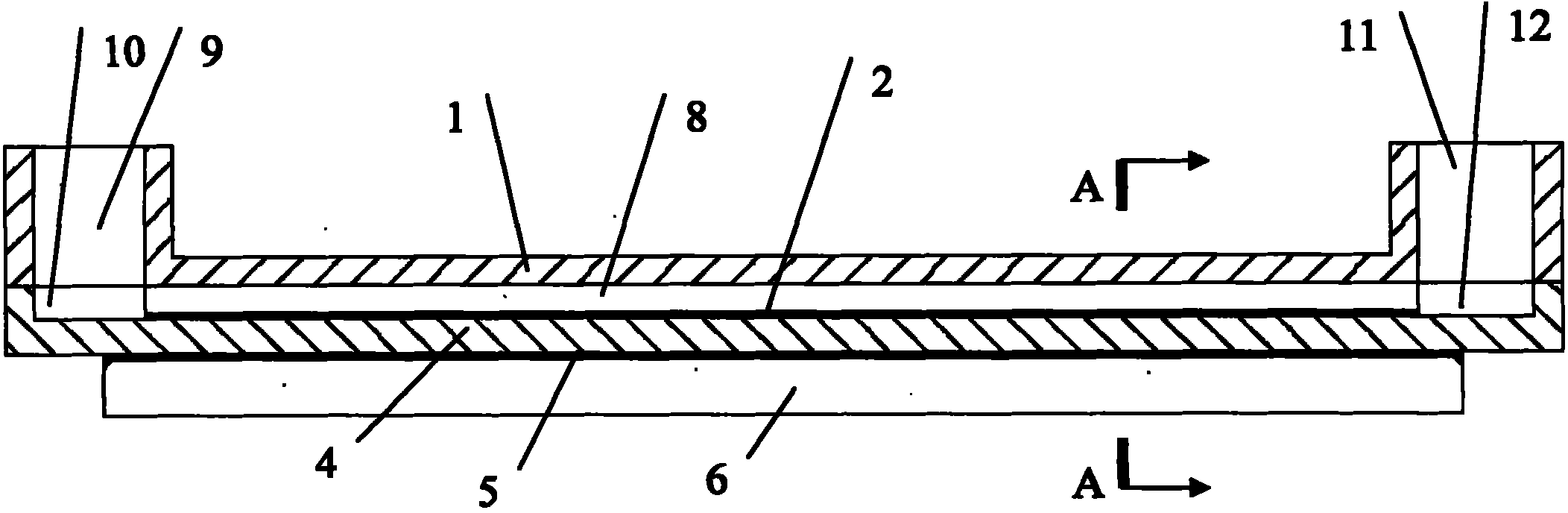

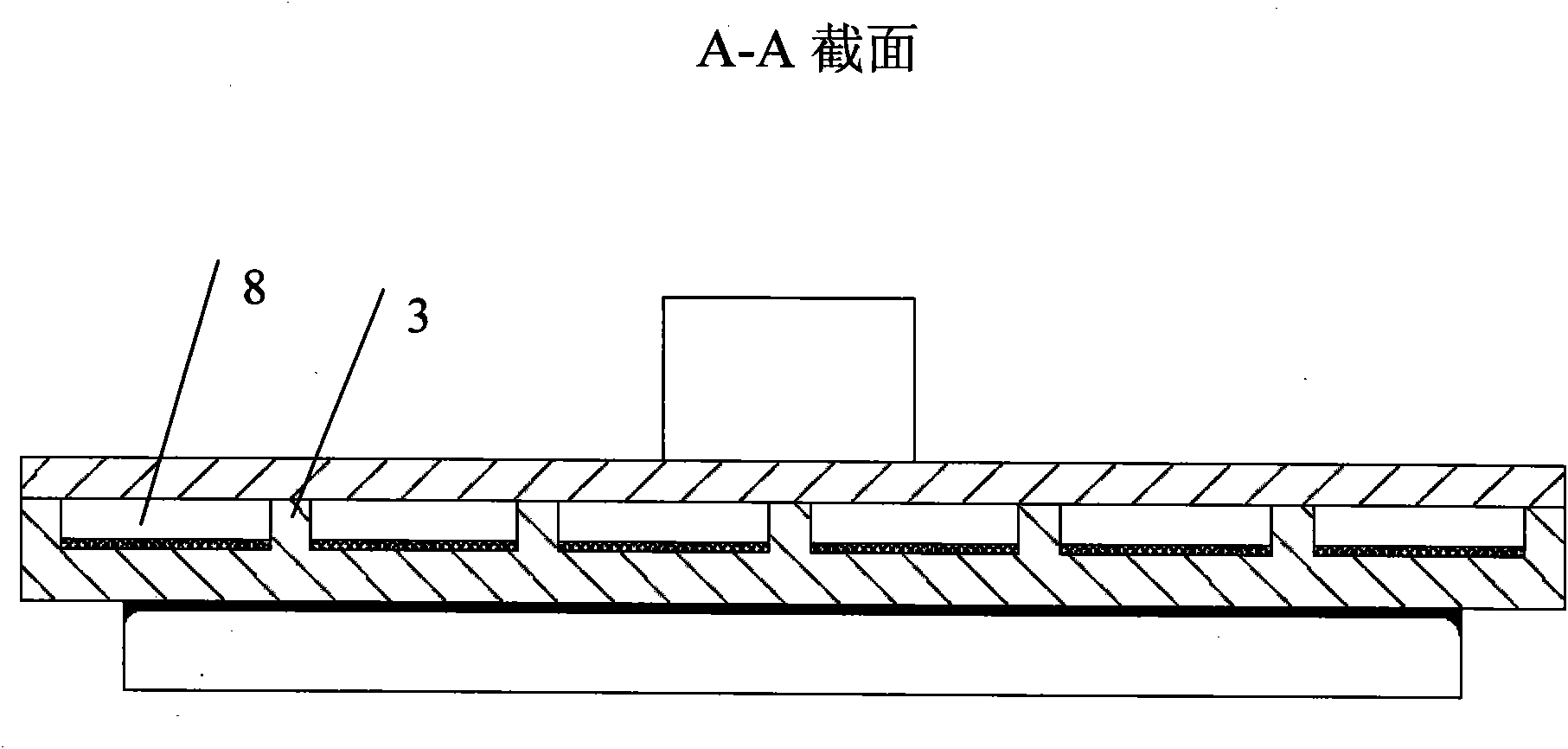

[0037] see figure 1 and Figure 2-1, Figure 2-2. The chip cooling evaporator of the present invention is a rectangular body, the main body includes an upper cover plate 1 and a lower bottom plate 4, the lower bottom surface of the lower bottom plate is a rectangular heat-conducting silicone grease connection layer 5, which is bonded with the electronic chip packaging layer 6, and the evaporator There are evaporator inlets 9 and evaporator outlets 10 at both ends of the cover plate, which are respectively used as coolant inlets and coolant outlets. There is a cavity at both ends of the evaporator, and the cavity on the side of the coolant inlet is a liquid buffer zone 10. It is used to divert the cooling liquid to each liquid chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com