Efficient silicone defoaming agent

A silicone defoamer, high-efficiency technology, applied in the direction of foam dispersion/prevention, can solve problems such as complex production process and difficult production realization, and achieve excellent performance and excellent dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

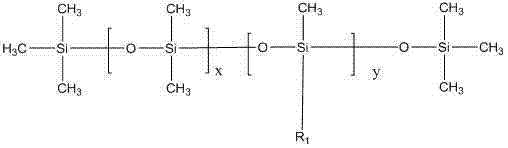

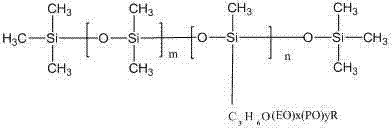

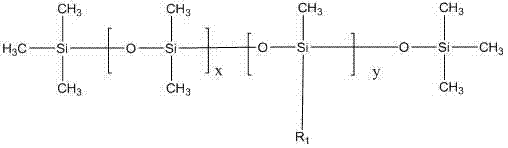

[0033] Example 1, a high-efficiency silicone defoamer is composed of 9 kilograms of hydrophobic white carbon black, 60 kilograms of 500 cst of simethicone oil, and 20 kilograms of 100,000 cst of simethicone oil. Heating the temperature to 150 ° C, the system always maintains a negative Pressed state to remove low molecular weight, stirred and heated at 160°C for 5 hours, cooled naturally to room temperature to obtain a silicone grease mixture, take 40 kg of the above silicone grease mixture, 12 kg of hydrophilic polyether silicone oil, 8 kg of lipophilic polyether Silicone oil, 2 kg of synergist lauryl dimethyl amine oxide, 2 kg of co-emulsifier AEO-3 are added to the reaction kettle, the temperature of the system is raised to 60 °C, and the components are stirred evenly, and then the stirring is increased. At the same time, slowly add hot water at 70°C into the reaction kettle. After the phase transition is completed, stop heating the water, and adjust the stirring to a modera...

Embodiment 2

[0034]Example 2, a high-efficiency silicone defoamer is 12 kg of hydrophobic silica, 45 kg of 700cst simethicone oil, 45 kg of 50000cst simethicone oil, heated to 130 ° C, and the system always maintains negative pressure state, to remove low molecular weight, stir and heat at 140°C for 3 hours, and cool naturally to room temperature to obtain a silicone grease mixture. Take 40 kg of the above silicone grease mixture, 10 kg of hydrophilic polyether silicone oil, and 6 kg of lipophilic polyether silicone oil , 3 kg of synergist dodecyl dimethyl amine oxide was added to the reaction kettle, 2 kg of AEO-3, the system was heated up to 60 ° C, stirred to make the components evenly mixed, and then increased stirring intensity, while 70 ° C hot water Slowly add to the reaction kettle, when the phase transition is completed, stop heating the water, and adjust the stirring force to a moderate level, add normal temperature water containing 1 kg of thickener to the emulsification kettle, ...

Embodiment 3

[0035] Example 3, a high-efficiency silicone defoamer is 12 kg of hydrophobic silica, 60 kg of 600cst simethicone oil, 40 kg of 80000cst simethicone oil, heated to 140 ° C, and the system always maintains negative pressure state, to remove low molecular weight, stir and heat at 160°C for 3 hours, and naturally cool to room temperature to obtain a silicone grease mixture. Take 40 kg of the above silicone grease mixture, 9 kg of hydrophilic polyether silicone oil, and 7 kg of lipophilic polyether silicone oil. , 2 kg of synergist tetradecyl dimethyl amine oxide was added to the reaction kettle, 1 kg of AEO-5, the system was heated up to 60 ° C, stirred to make the components evenly mixed, and then increased stirring intensity, while 70 ° C hot water Slowly add to the reaction kettle, when the phase transition is completed, stop heating the water, and adjust the stirring force to a moderate level, add normal temperature water containing 1 kg of thickener to the emulsification kett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com