Heat conductive silicone grease composition and cured product thereof

A technology of thermally conductive silicone grease and composition, which can be used in lubricating compositions, semiconductor/solid-state device parts, electrical solid-state devices, etc. The effect of thermal conductivity and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

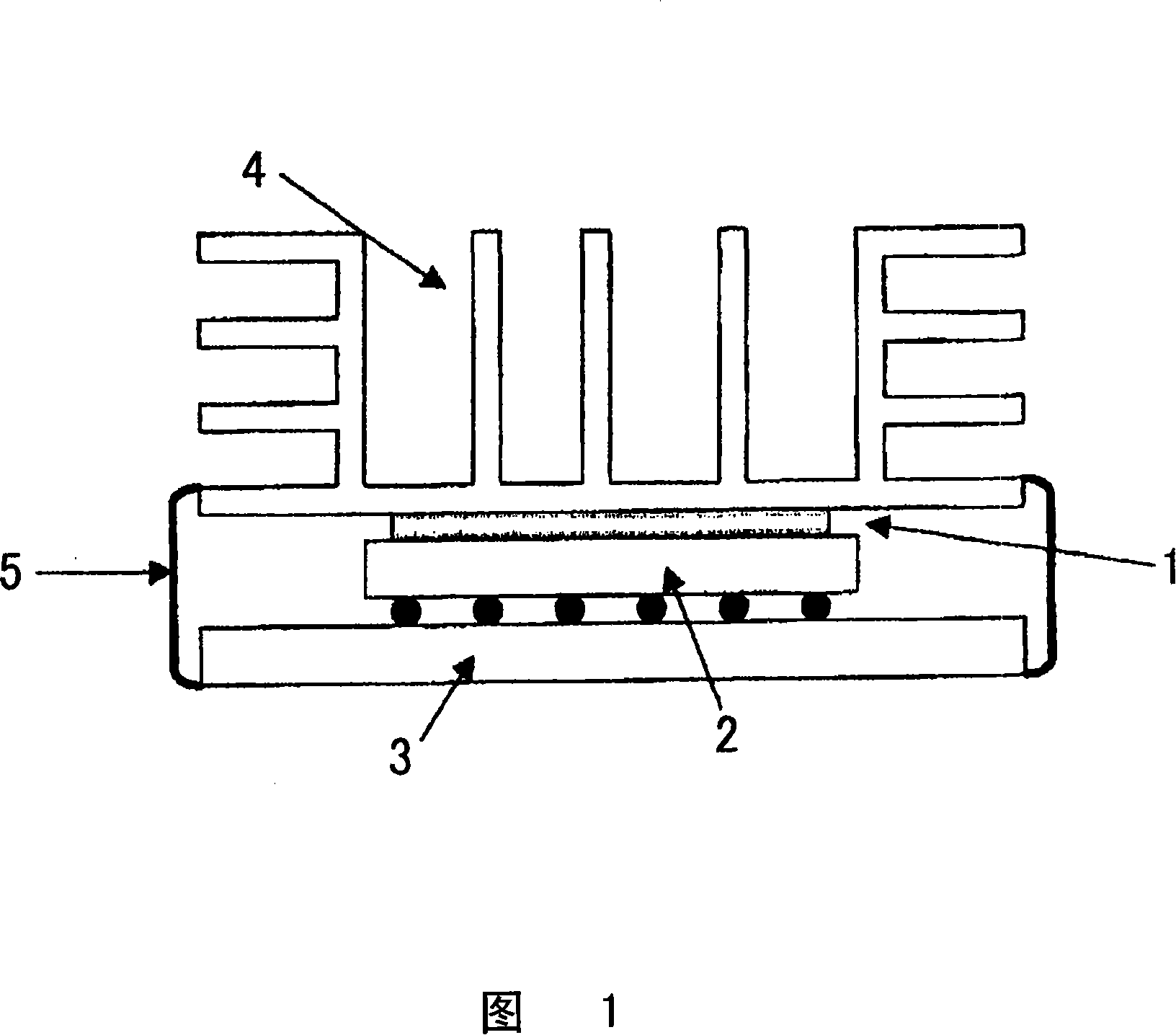

Image

Examples

preparation example Construction

[0141] [Preparation of the composition of the present invention]

[0142] The thermally conductive silicone grease composition of the present invention can be obtained by a preparation method comprising the following steps:

[0143] (a) group (A), component (B)), component (C), component (E) and component (H) (if used) preferably at 40-120 ° C, more preferably 50-100 kneaded together at a temperature of °C, thereby preparing a homogeneous mixture, and

[0144] (b) Add component (D), component (F), component (G) and any other optional components (if used) to the homogeneous mixture, then preferably at 10-60°C, even more preferably Kneading is carried out at a temperature of 20-50° C. to prepare a homogeneous mixture.

[0145] In the above steps, kneading may be performed using a mixing-kneading device such as a conditioning mixer or a planetary mixer, which is equipped with a heating device and may further include a cooling device as necessary.

[0146] Step (b) is preferabl...

Embodiment

[0169] The present invention is described in more detail below using a series of examples and comparative examples, although the present invention is not limited by these examples in any way.

[0170] First, the following components required to form the composition of the present invention are prepared.

[0171]

[0172] -(A-1) Dimethylpolysiloxane having both ends of the molecular chain terminated by dimethylvinylsiloxy groups having a thickness of 600 mm at 25° C. 2 / s kinematic viscosity.

[0173] -(A-2) Dimethylpolysiloxane whose molecular chain both ends are terminated by dimethylvinylsiloxy groups, which has a thickness of 30,000mm at 25°C 2 / s kinematic viscosity.

[0174]

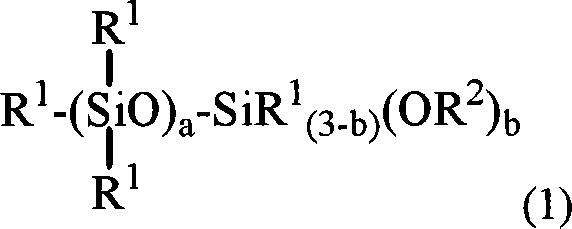

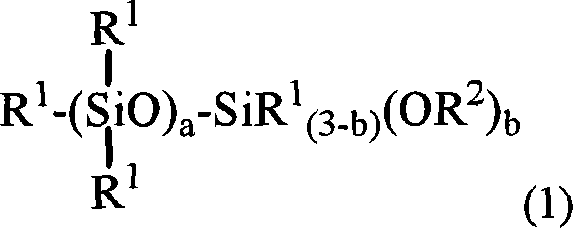

[0175] -(B-1) The organopolysiloxane represented by the structural formula shown below (having a thickness of 35mm at 25°C) 2 / s kinematic viscosity).

[0176]

[0177]

[0178] -(C-1) An alkoxysilane represented by the following formula.

[0179] C 10 h 21 Si(OCH 3 ) 3

[0180] -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com