Heat conductive silicone grease composition

A technology of thermal conductive silicone grease and composition, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of difficult thermal conductivity, little research and improvement of powder fillers, etc., and achieve high bonding strength and good thermal conductivity. conduction and flow properties, enhance the effect of wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

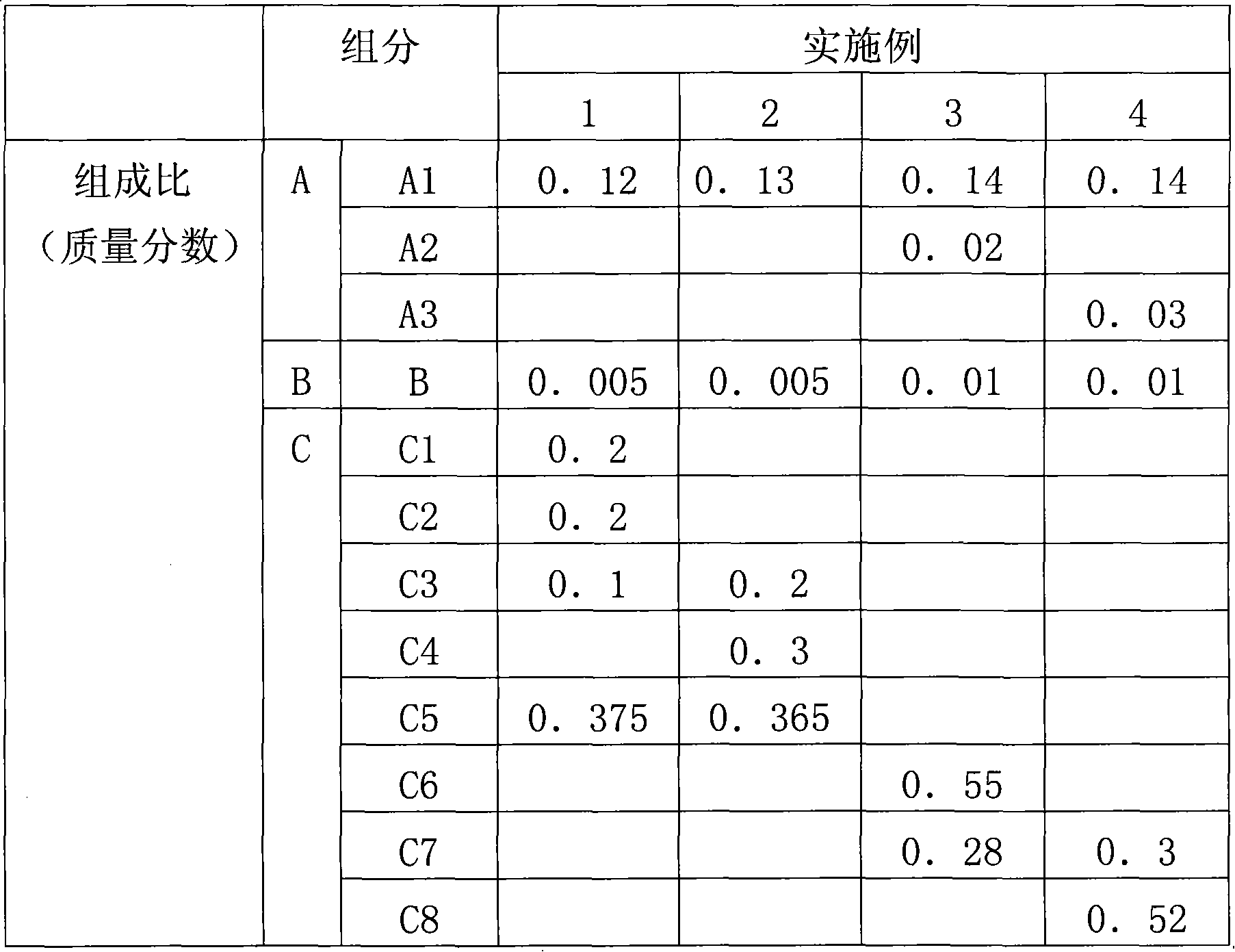

[0039] The preparation of embodiment 1~4 heat-conducting silicone grease composition

[0040] (1) At first prepare or buy following various components on the market:

[0041] (A) Silicone oil

[0042] A1: Dimethyl silicone oil, A2: Hydrogen silicone oil, A3: Benzyl silicone oil;

[0043] (B) Siloxane coupling agent KH570

[0044] (C) Thermally conductive filler

[0045] C1: Aluminum powder (average particle size 15μm)

[0046] C2: Aluminum powder (average particle size 5μm)

[0047] C3: Aluminum powder (average particle size 1μm)

[0048] C4: copper powder (average particle size 3μm)

[0049] C5: Zinc oxide powder (average particle size 0.5μm)

[0050] C6: Silicon nitride powder (average particle size 10μm)

[0051] C7: Boron nitride powder (average particle size 1μm)

[0052] C8: aluminum nitride powder (average particle size 5μm)

[0053]Put the above-mentioned aluminum powder, copper powder, etc. in the reaction kettle, and thermally oxidize it in an air atmospher...

experiment Embodiment 1

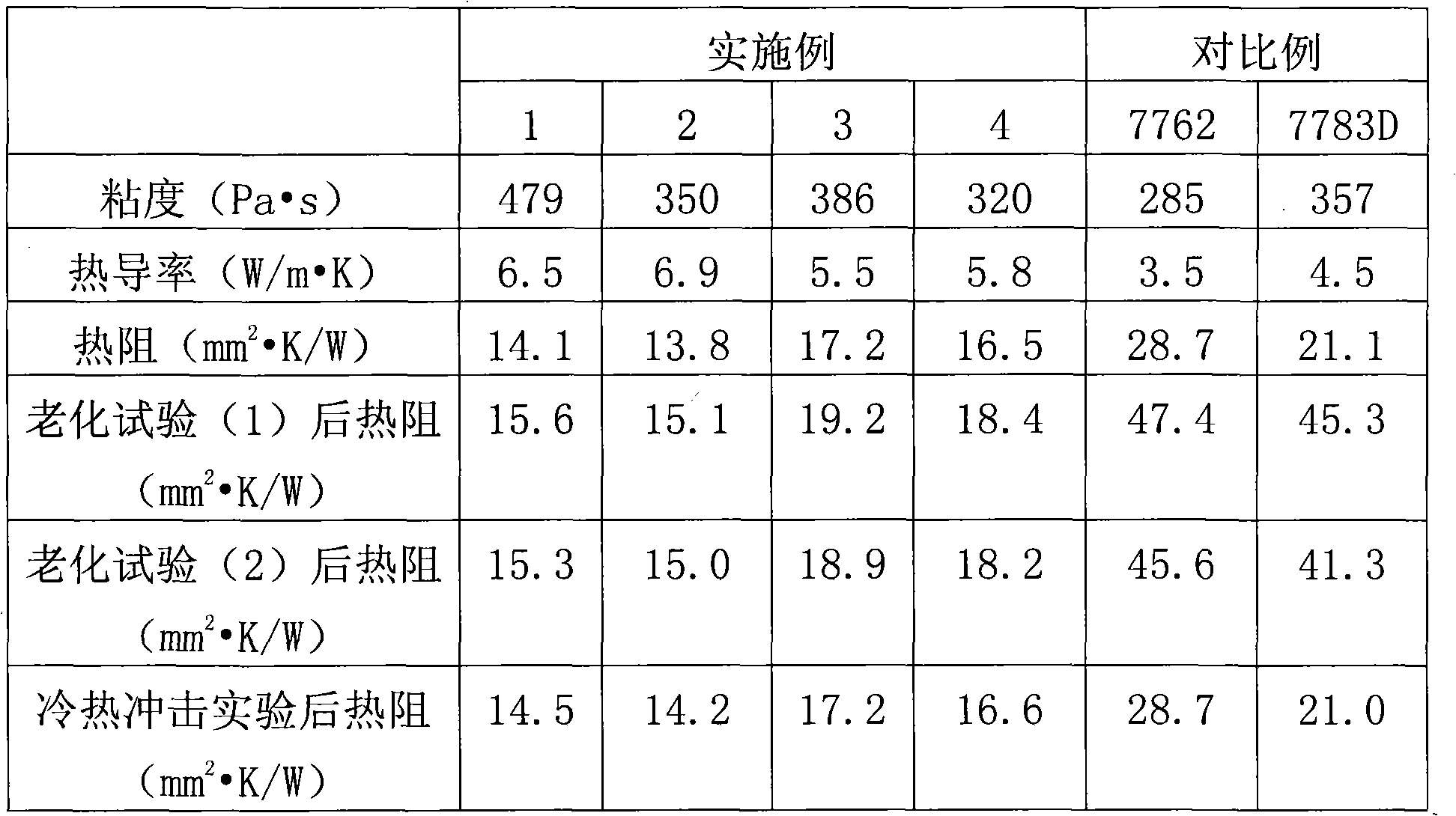

[0058] Experimental Example 1 Viscosity Test of Thermally Conductive Silicone Grease Composition

[0059] The thermally conductive silicone grease compositions prepared in Preparation Examples 1-4 were used to measure the viscosity at a rotational speed of 10 rpm with a rotational viscometer (NDJ-1B, Shanghai Changji Geological Instrument Co., Ltd.). The results (see Table 2) show that the viscosity of the present invention is slightly higher, but does not affect the operability of the coating process, and can help the bonding between the interfaces.

experiment Embodiment 2

[0060] Experimental Example 2 Thermal Conductivity Test of Thermally Conductive Silicone Grease Composition

[0061] Apply the thermally conductive silicone grease composition prepared in Preparation Examples 1 to 4 to the test bench of a BN-TC120 thermal conductivity tester (manufactured by Foxconn) with screen printing, and the thickness is controlled to be 0.075mm, and the thermal conductivity of the composition is measured. rate value. The result (see table 2) shows that on the same test platform, the thermal conductivity of the present invention is significantly better than that of the comparative example, wherein the thermal conductive silicone grease composition not only has the same properties as that of the insulating powder used in embodiments 3 and 4 Commercially available thermal grease has comparable thermal conductivity and can be used in occasions with high insulation requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com