Hydrogen Energy Systems

a technology of energy systems and hydrogen fuel, applied in the direction of electrolysis components, aluminium compounds, electrolysis processes, etc., can solve the problems of no system that efficiently, safely and easily generates hydrogen, no system exists that provides safe and simple modification of gasoline or diesel internal combustion engines to run partially on hydrogen fuel, no system exists that efficiently, safely and easily provides heated water, etc., to achieve the effect of preventing overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

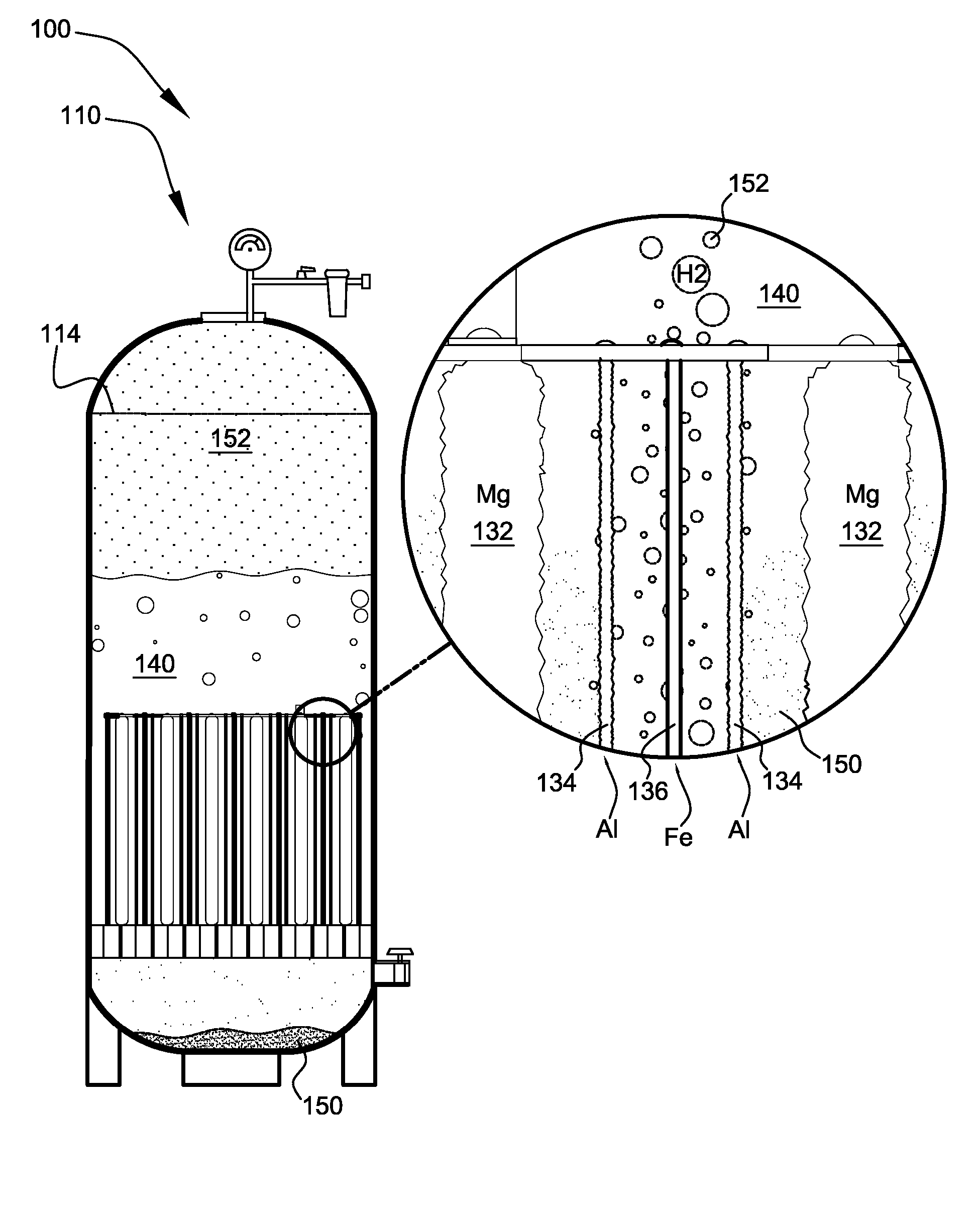

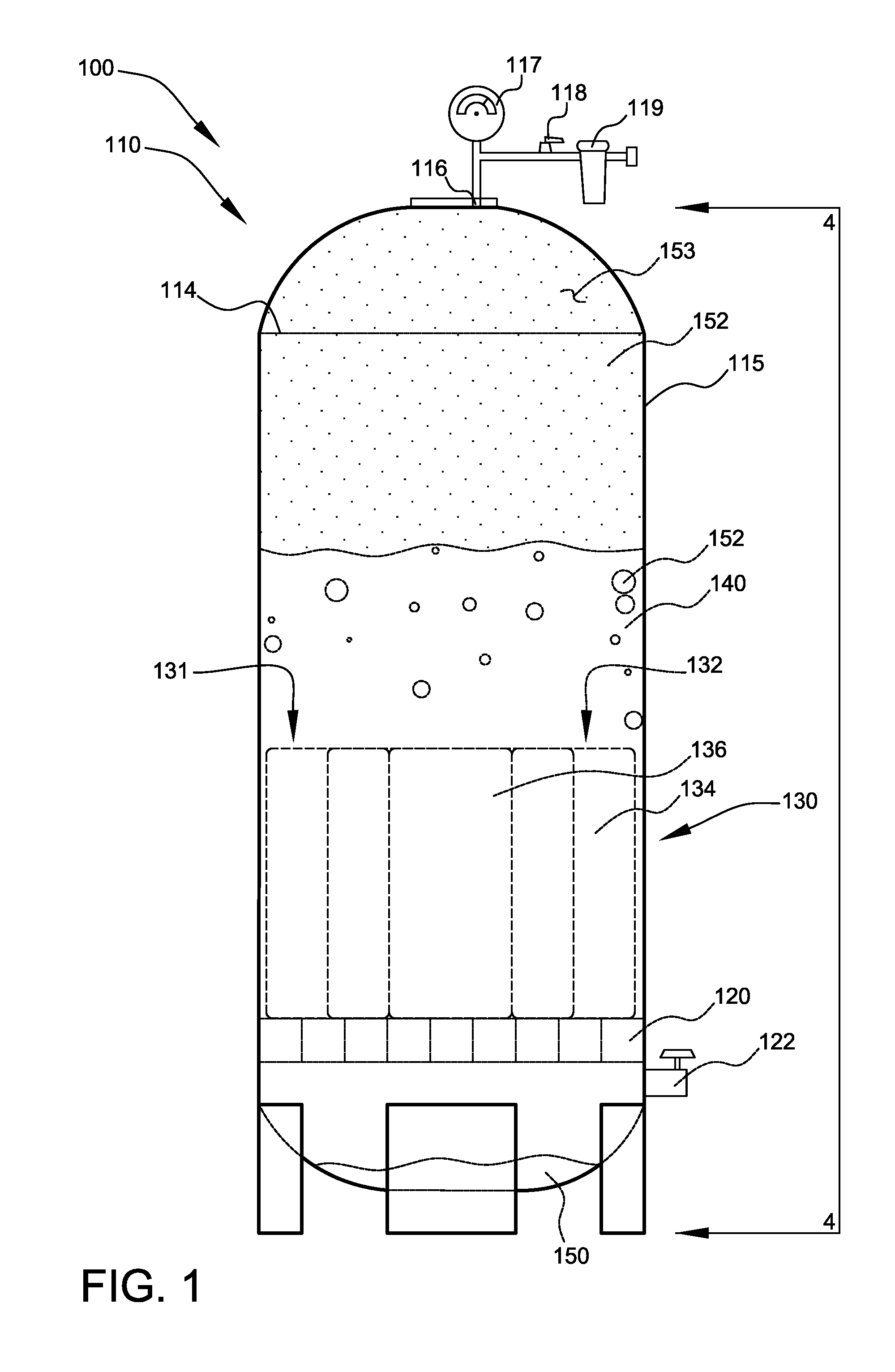

[0085]FIG. 1 shows a side view illustrating large galvanic hydrogen generator 110 according to a preferred embodiment of the present invention. Preferably, hydrogen energy system 100 comprises large galvanic hydrogen generator 110, as shown. Preferably, large galvanic hydrogen generator 110 comprises a container, preferably tank 115, and galvanic cell 130, as shown.

[0086] Preferably, tank 115 comprises a gas-tight tank, preferably a stainless steel tank, preferably a 99-gallon gas tank (preferably a propane tank that has been temporarily opened to receive galvanic cell 130 and then has been sealed shut again along construction seam 114), as shown. Preferably, tank 115 comprises gas outlet 116, pressure gauge 117, valve 118, filter 119, and support 120, as shown. Preferably, tank 115 further comprises water outlet 122, as shown. Preferably, filter 119 removes water vapor from hydrogen gas 152. Upon reading the teachings of this specification, those with ordinary skill in the art wil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com