Energy efficient system and process for the continuous production of fuels and energy from syngas

a technology of energy efficiency and system, applied in the direction of combustible gas production, combustible gas purification/modification, chemical production, etc., can solve the problems of low efficiency of systems, high cost, environmental protection, etc., and achieve the effect of maximizing the carbon and energy conversion potential and efficiency of the associated components or subsystems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Production of Syngas and Fuels

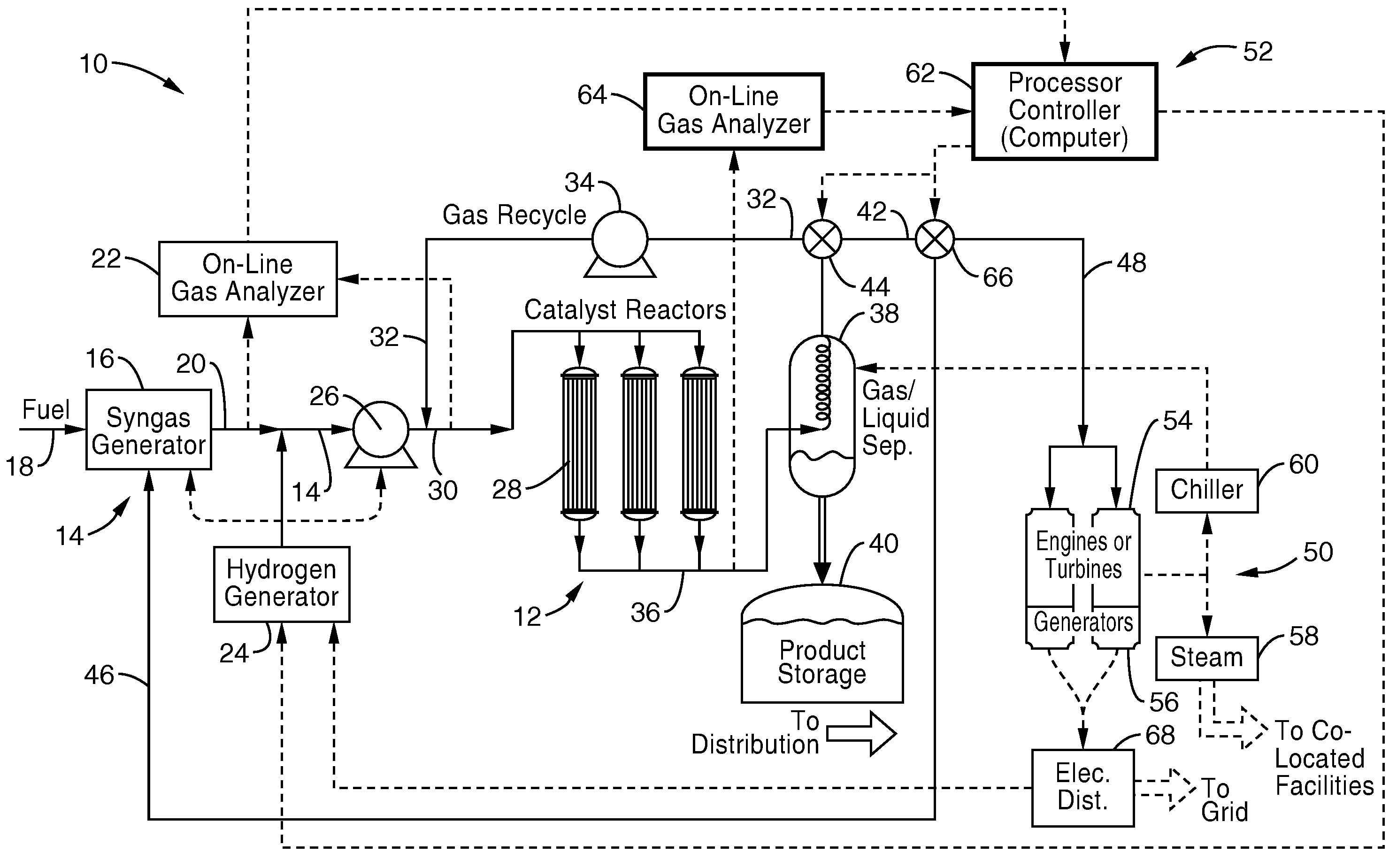

[0093]In Example 1, a pyrolysis / steam reforming system is operated in the absence of oxygen or air to produce syngas with an average molar composition of 35% H2, 28% CO, 18% CO2 and 18% CH4 (Table 1).

[0094]Continuous Gas Analyzers (22 and 64) in FIG. 1 and FIG. 2, specifically mass spectrometers in this example, are used to obtain real-time measurements by monitoring the molecular peaks of the gas-phase species listed in Table 1 before (BC) and after the catalyst reactors (AC). The syngas generator for this example utilizes pyrolysis / steam reforming thermochemical process in the absence of oxygen or air. Since nitrogen has the same nominal mass as carbon monoxide (m / e: 28) and oxygen has the same nominal mass as methanol (m / e: 32), the presence of nitrogen and oxygen could cause an error in the quantitative measurement of carbon monoxide and methanol. Therefore, the initial concentrations of the gas-phase species, listed under FPS Operation (Initial Con...

example 2

Production of Methanol

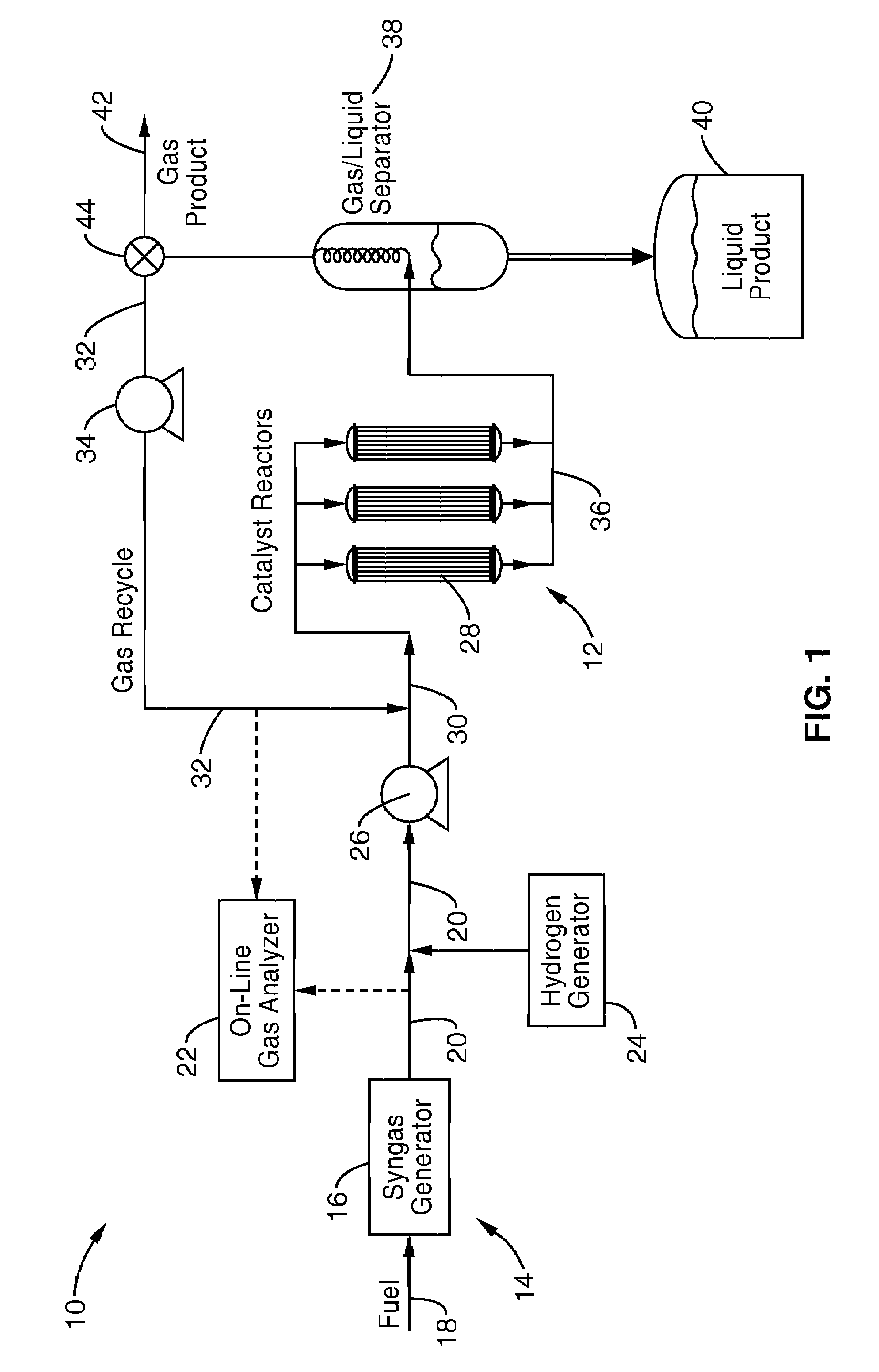

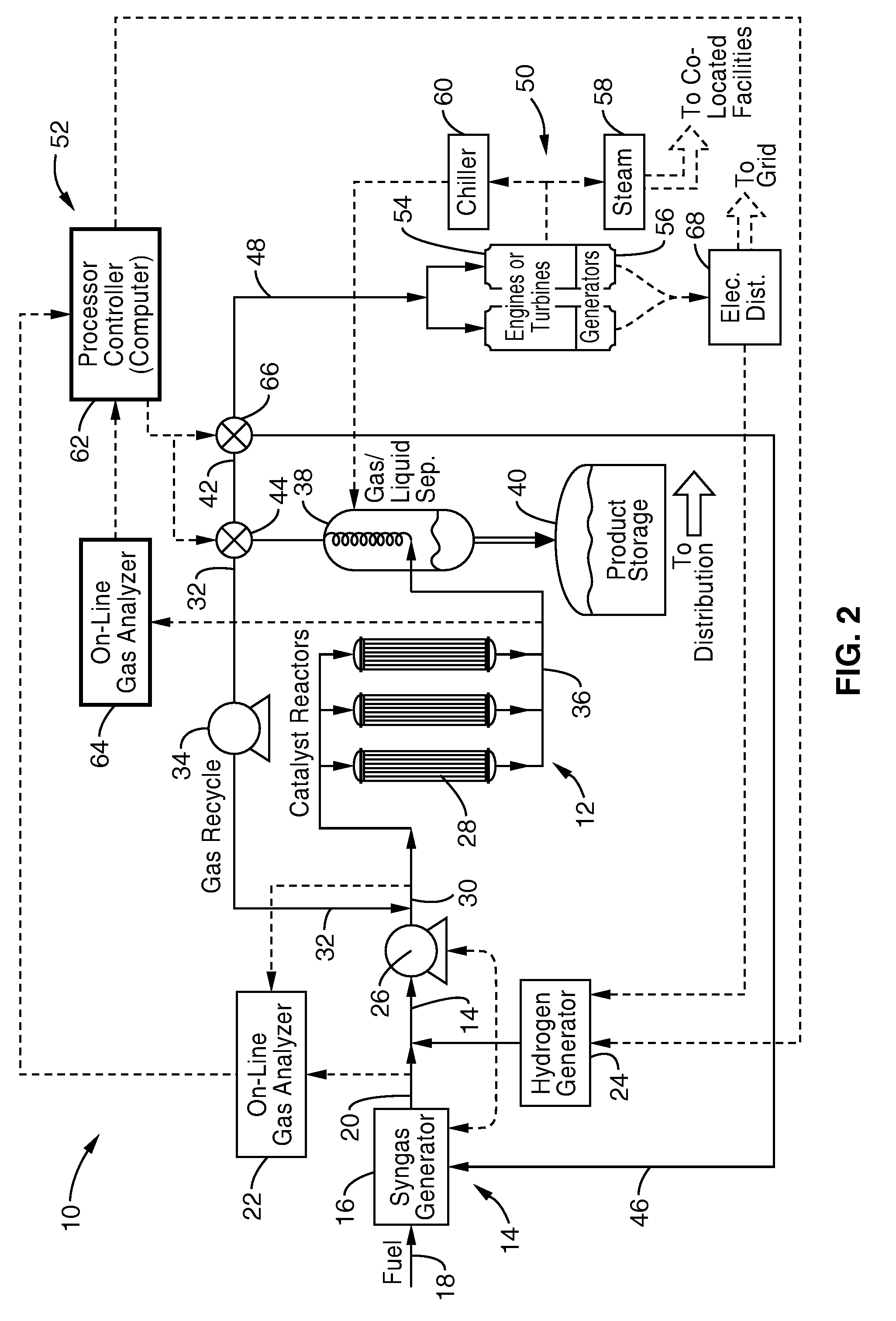

[0101]In order to demonstrate the production of one liquid product and electricity with the system shown schematically in FIG. 2, the catalyst of the reactor 28 was selected to produce methanol. The catalyst used in the synthesis reactor 28 was a Cu—Zn based catalyst used for methanol synthesis. Table 3 shows the operating conditions for this system including catalyst pressure, reactor temperature, CO conversion, and selectivity. In addition, Table 3 summarizes the resulting outputs and efficiencies for this system with a syngas input of 500,000 SCF per hour. The productivity of the plant is shown for three different recycle rates (0%, 75%, and 90%) to demonstrate the range of operating conditions and product mixes.

[0102]It can be seen that the synthesis of liquid fuels alone gives lower (9%-37%) thermal conversion efficiencies that are particularly pronounced at lower recycle rates. The combined production of fuel and electricity also provides a higher thermal...

example 3

Production of Mixed Alcohols

80% Ethanol, 15% Methanol, 5% C3+Alcohols

[0103]This example uses a multi-layered catalyst combination based on a promoted Cu—Zn and a promoted Group VIII metal catalyst to produce a mixture of alcohols containing primary ethanol.

[0104]Table 4 shows the operating conditions for this system including catalyst pressure, reactor temperature, CO conversion, and selectivity. In addition, this table summarizes the resulting outputs and efficiencies for this system with a syngas input of 500,000 SCF per hour. The productivity of the plant is shown for three different recycle rates (0%, 75%, and 90%) to demonstrate the range of operating conditions and product mixes.

[0105]The productivity and efficiency for the production of ethanol and electricity seen in Example 3 is similar to that shown Example 2 for a product stream with a higher energy density. This product stream of ethanol may be more suitable for fuel applications or more desirable for economic reasons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com