Technology for producing stone-plastic floor, and die head for producing floor substrate

A technology of stone-plastic flooring and production technology, which is applied in the direction of layered products, synthetic resin layered products, glass/slag layered products, etc., and can solve problems such as unfavorable cleaning, uneven thickness of substrate, and short cleaning cycle of flow channels, etc. , to save later repair and maintenance costs, good sound absorption and foot feel, and prolong the cleaning cycle of the flow channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

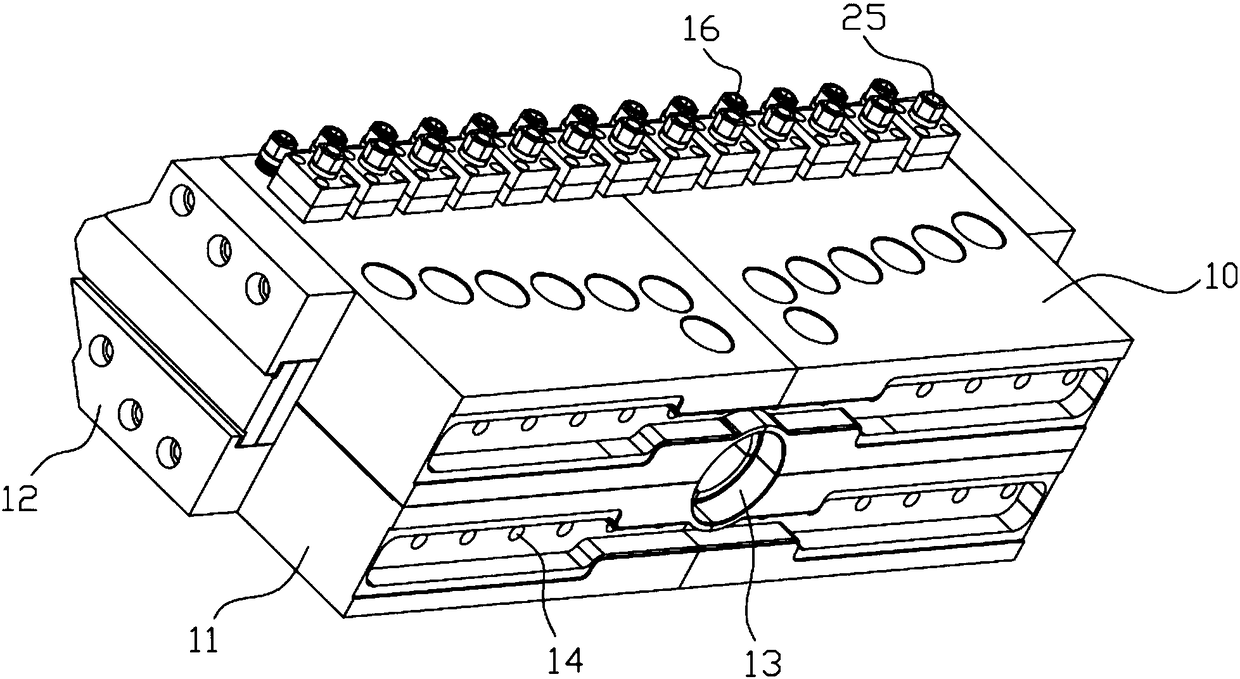

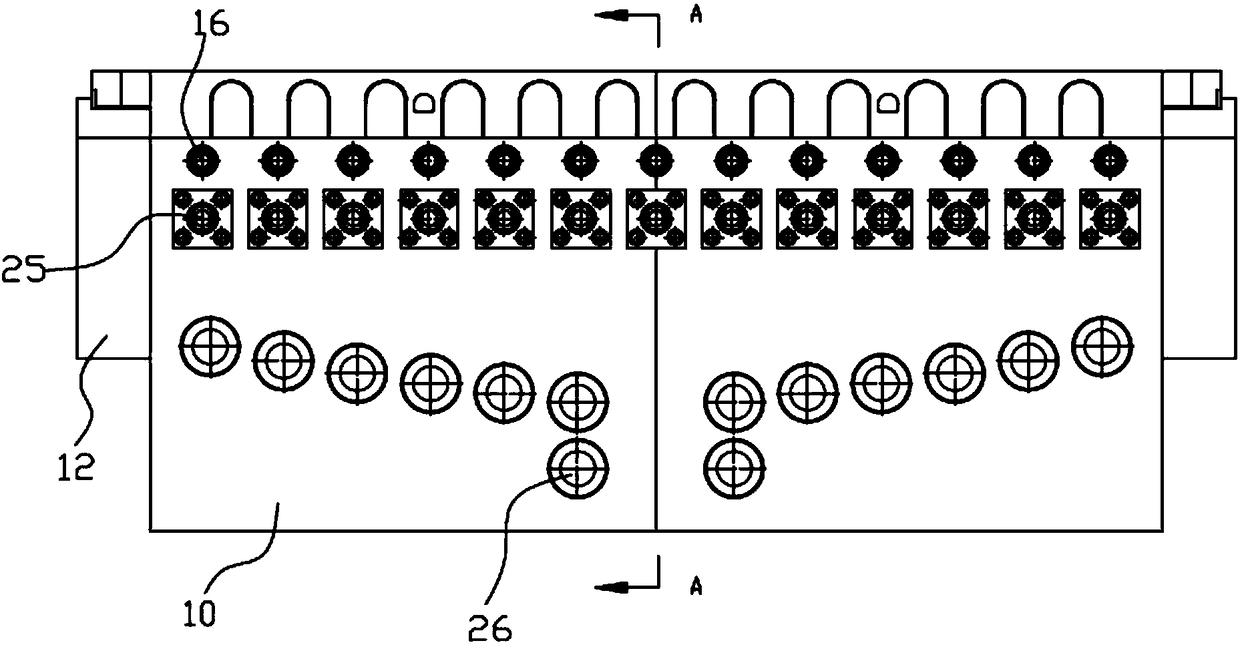

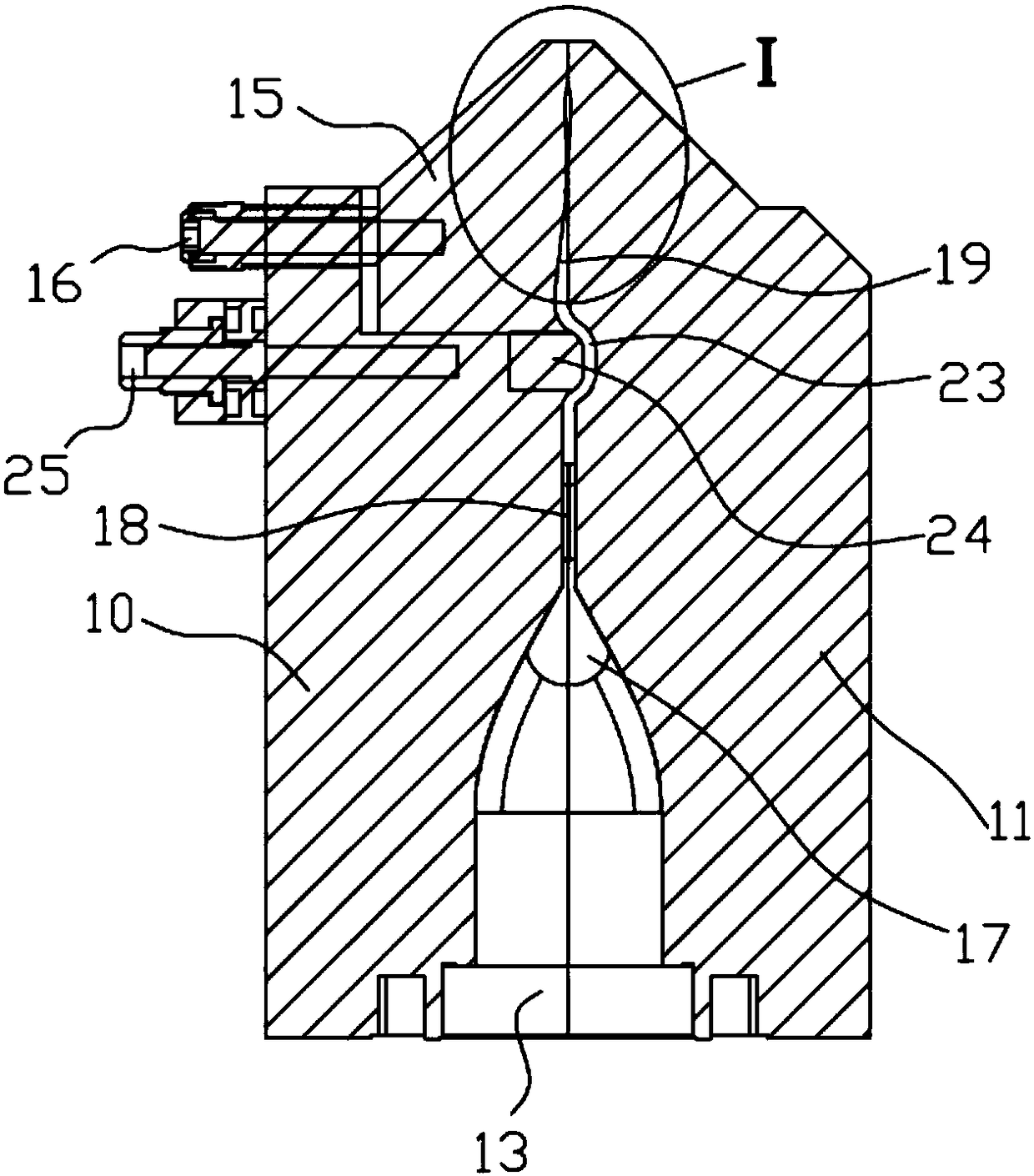

[0031] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —7: A stone-plastic floor, wherein the stone-plastic floor includes a wear-resistant layer, a glass fiber layer and a base material, and by weight, the wear-resistant layer is composed of the following components: 95 parts of PVC, 2.2 parts of calcium zinc Stabilizer, 23 parts of dioctyl ester, dioctyl ester is a plasticizer with good mixing performance, high plasticizing efficiency, low volatility, good low temperature softness, water extraction resistance, high electrical performance, heat resistance and Good weather resistance, 1.6 parts of epoxy soybean oil can greatly improve the weather resistance, heat resistance and transparency of PVC, 0.4 parts of acrylate copolymer can speed up the plasticization process of PVC, improve the rheological properties of thermoplastic melt, improve Melt mechanical properties under the thermoelastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com