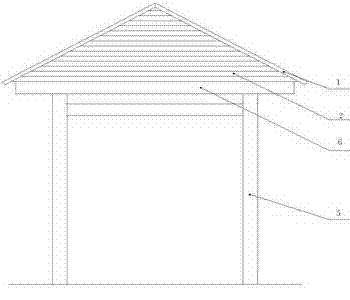

Method for building pavilion by plastic wood profiles instead of wooden materials

A technology for wooden buildings and profiles, applied in small buildings and other directions, can solve problems such as easy corrosion, poor fire resistance, and easy cracking of integral columns, and achieve the effects of high fire resistance, simple construction and installation, and later maintenance and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

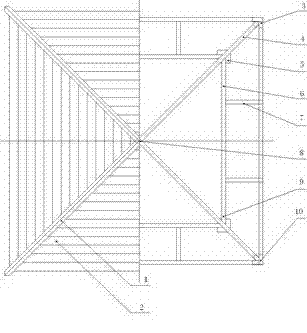

[0027] 30 kg of PE (recycled material fat-melting less than 1.0, 25 fibers), 60 kg of wood powder (or bran powder or bamboo powder) of 60-80 mesh, 10 kg of talcum powder, grafted with maleic anhydride (the grafting rate of PE is not less than 08 ) 2 kg, PA-02 coupling agent (for extrusion, Kunshan Yayang Composite Material Technology Co., Ltd.) 3 kg, PE wax (Nanjing Tianxin Chemical Co., Ltd.) 0.65 kg, anti-aging agent (Nanjing Jingtianwei Chemical Co., Ltd.) Company) 2 kg, halogen-free flame retardant (Guangzhou Denghua Chemical Co., Ltd.) 2 kg were put into a high-speed mixer, mixed evenly at a high temperature of 190 ° C, passed through a screw automatic feeder, and put into the hopper of the extruder, and extruded The extruder is preset at 175°C and kept warm, and the slurry is melted and plasticized by the extruder; through the mold of the prefabricated components of the pavilion (such as: ridge 1, tile 2, wrapping beam 3, oblique beam 4, column 5, beam 6 , Small inclined...

Embodiment 2

[0029] 40 kg of PE granules, 50 kg of 60-80 mesh wood powder (or bran powder or bamboo powder), 10 kg of light calcium carbonate, 2 kg of maleic anhydride grafting (PE grafting rate not less than 08), PA-02 Joint agent (Kunshan Yayang Composite Material Technology Co., Ltd. for extrusion) 2 kg, PE wax (Nanjing Tianxin Chemical Co., Ltd.) 0.75 kg, anti-aging agent (Nanjing Jingtianwei Chemical Co., Ltd.) 2.5 kg, halogen-free resist Put 2 kg of fuel (Guangzhou Denghua Chemical Co., Ltd.) into the high-speed mixer, mix evenly at a high temperature of 190°C, pass through the screw automatic feeder, and put it into the hopper of the extruder. At the same time, the extruder is preset at 175°C and Insulation, melted and plasticized by the extruder slurry; extruded through the mold of the pavilion prefabricated components (such as: ridge 1, tile 2, wrapping beam 3, inclined beam 4, column 5, beam 6, small inclined beam 7) Enter the vacuum sizing device, cool and form the pavilion pref...

Embodiment 3

[0031] 35 kg of PE (recycled material), 55 kg of 60-80 mesh bamboo powder, 10 kg of talc powder, 2 kg of maleic anhydride grafting (PE grafting rate not less than 08), PA-02 coupling agent (extrusion-specific) Put 2.5 kg of PE wax, 0.7 kg of PE wax, 2.5 kg of anti-aging agent, and 2 kg of halogen-free flame retardant into a high-speed mixer, mix evenly at a high temperature of 190°C, pass through a screw automatic feeder, and put it into the hopper of the extruder, and at the same time extrude The extruder is preset at 175°C and kept warm, and the slurry is melted and plasticized by the extruder; through the mold of the prefabricated components of the pavilion (such as: ridge 1, tile 2, wrapping beam 3, oblique beam 4, column 5, beam 6 , Small inclined beam 7) Extrude into the vacuum sizing device, cool and form the pavilion prefabricated profiles corresponding to various structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com