Process for preparing rubber cable sheath material

A sheath material, rubber cable technology, applied in the direction of insulated cables, cables, circuits, etc., to achieve the effect of improving flame retardant performance, simple preparation process, and improving low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

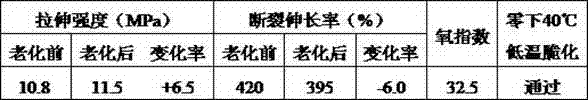

[0014] Example: A preparation process for a rubber cable sheath material. In the rubber cable sheath material, chlorinated polyethylene and EPDM rubber are blended to improve the low-temperature performance of the material. At the same time, by adding a flame retardant Diantimony and chlorinated paraffin act synergistically to improve the flame retardancy of rubber sheathing materials, specifically, antimony trichloride (Sb 2 x 3 ), antimony trichloride can be used as a free radical capture agent in the gas phase combustion zone, which can effectively capture free radicals generated by polymer combustion, play a flame retardant role, and achieve flame retardancy. The oxygen index of the sheath material is greater than 32% , also, improve the physical and mechanical properties of the rubber sheath material by adding reinforcing agent carbon black and precipitated silica, so that the tensile strength of the sheath material is greater than 10MPa, and the elongation at break is gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com