Composite fire retardant used for asphalt mixture and preparation method thereof

A technology of composite flame retardant and asphalt mixture, which is applied in the direction of building insulation materials, building components, buildings, etc., and can solve problems such as unfavorable construction, segregation, and influence of flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

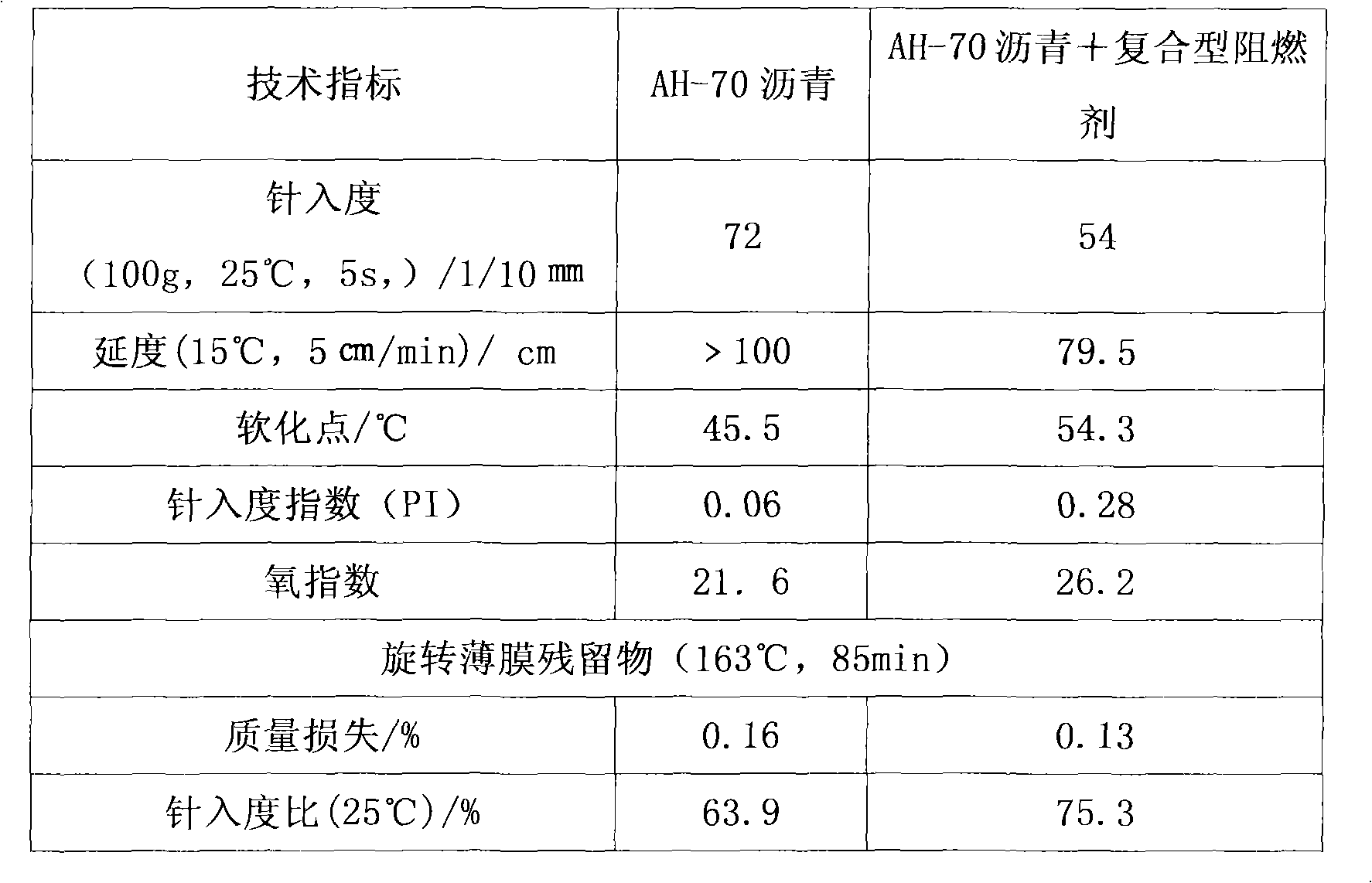

[0017] Composite flame retardant, its composition and content are: (Table 1)

[0018] Table 1 Composition and content of composite flame retardant

[0019] component name

Specification

content(%)

place of origin

Decabromodiphenylethane

45

Shandong company

Particle size<2.5μm

15

Hunan Company

Organic Montmorillonite

Wafer thickness<30nm

10

Zhejiang company

lake asphalt

25

commercially available

Polyethylene (LDPE)

1F7B

5

commercially available

total

100

[0020] The above-mentioned components are added into the mixer in proportion and mixed evenly, and then kneaded, extruded, cut or pulverized by a twin-screw extruder to form a composite flame retardant.

[0021] When in use, mix the composite flame retardant in an amount of 20% (weight ratio) of the asphalt weight with heated sand, mineral powder, asphalt (or modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com