High efficiency flame retardant plastic-wood composite sheet and its preparation method

A technology for wood-plastic composite materials and boards, which is applied in the field of high-efficiency flame-retardant wood-plastic composite materials and its preparation, can solve problems such as inability to meet the needs of use, and achieve the effects of convenient production and manufacturing, low production costs, and reduced product raw material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

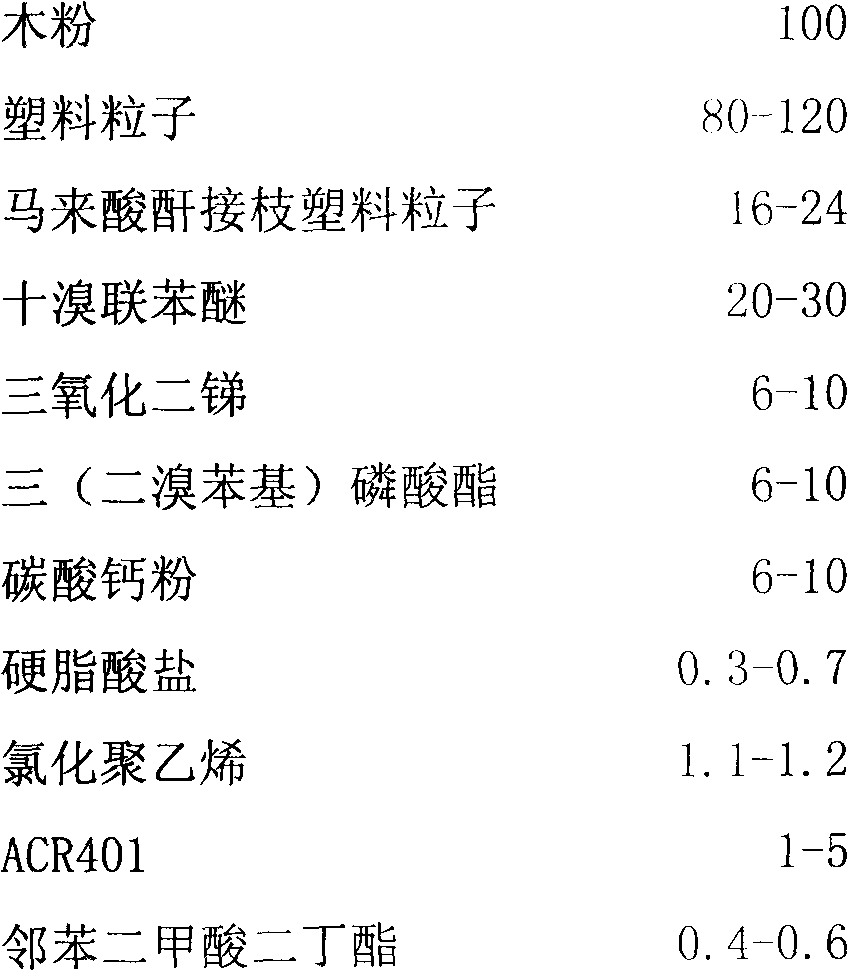

Embodiment 1

[0028]

[0029] (1), take each raw material by formula quantity;

[0030] (2), three (dibromophenyl) phosphate and acetone are mixed uniformly by weight ratio 1: 75, and wherein acetone is solvent;

[0031] (3), immerse the wood powder in it, ultrasonically treat it for 15 minutes at a frequency of 30kHz, take out the wood powder, and dry to obtain the modified wood powder;

[0032] (4), plastic particles, maleic anhydride grafted plastic particles, decabromodiphenyl ether, antimony trioxide and stearate are placed in a mechanical stirring tank and stirred for 3 minutes, extruded to granulate, extruder The cylinder temperature is 180°C, and the die head temperature is 190°C to obtain modified plastic particles;

[0033] (5), the above-mentioned modified plastic particles, modified wood powder, calcium carbonate powder, chlorinated polyethylene, ACR401, dibutyl phthalate are placed in the mechanical stirring tank and mechanically stirred again for 4 minutes;

[0034] (6) A...

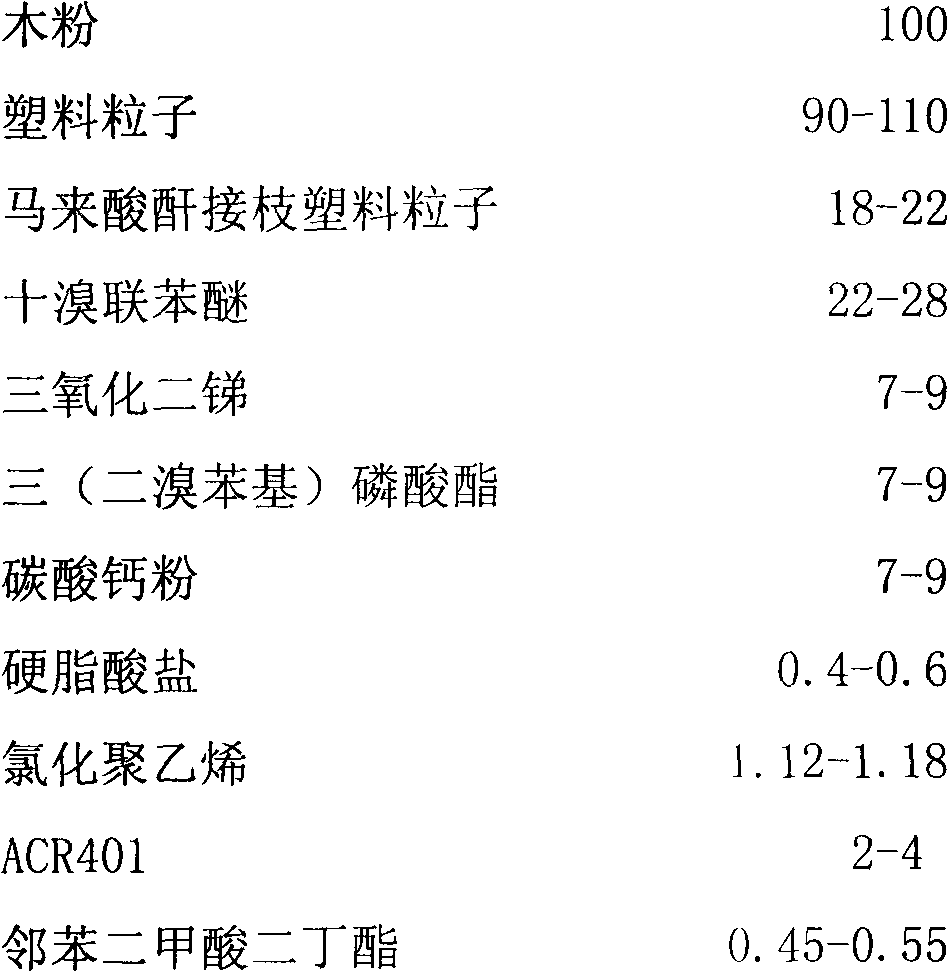

Embodiment 2

[0037]

[0038] (1), take each raw material by formula quantity;

[0039] (2), three (dibromophenyl) phosphate and acetone are mixed uniformly by weight 1: 50, and wherein acetone is solvent;

[0040] (3), immerse the wood powder wherein, ultrasonic treatment 10 minutes under the frequency of 20kHz, take out the wood powder, dry to obtain the modified wood powder;

[0041] (4), plastic particles, maleic anhydride grafted plastic particles, decabromodiphenyl ether, antimony trioxide and stearate are placed in a mechanical stirring tank and stirred for 1 minute, extruded to granulate, extruder The barrel temperature is 160°C, and the die head temperature is 170°C to obtain modified plastic particles;

[0042] (5), the above-mentioned modified plastic particles, modified wood powder, calcium carbonate powder, chlorinated polyethylene, ACR401, dibutyl phthalate are placed in the mechanical stirring tank and mechanically stirred again for 3 minutes;

[0043] (6) After mixing, ...

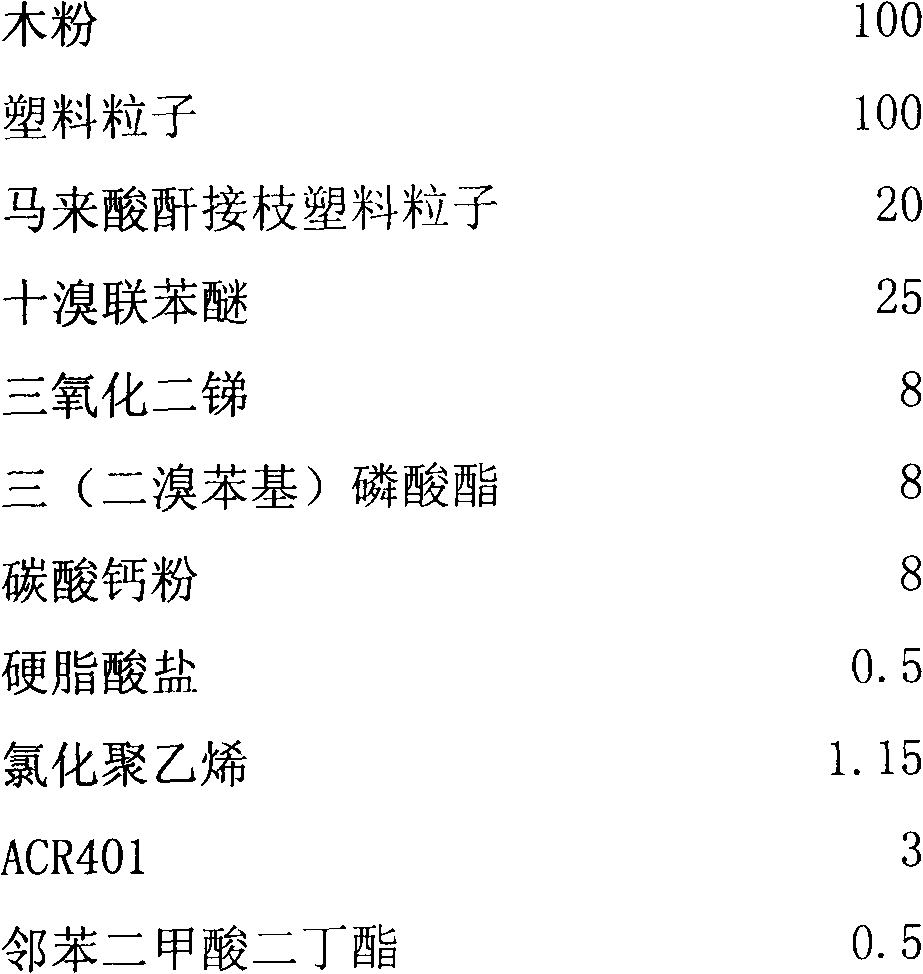

Embodiment 3

[0046]

[0047]

[0048] (1), take each raw material by formula quantity;

[0049] (2), three (dibromophenyl) phosphate and acetone are mixed uniformly by weight ratio 1: 100, and wherein acetone is solvent;

[0050] (3), wood powder is immersed wherein, under 40kHz frequency ultrasonic processing 20 minutes, take out wood powder, dry to obtain modified wood powder;

[0051] (4), plastic particles, maleic anhydride grafted plastic particles, decabromodiphenyl ether, antimony trioxide and stearate are placed in a mechanical stirring tank and stirred for 5 minutes, extruded to granulate, extruder The barrel temperature is 200°C, and the die head temperature is 210°C to obtain modified plastic particles;

[0052] (5), the above-mentioned modified plastic particles, modified wood flour, calcium carbonate powder, chlorinated polyethylene, ACR401, dibutyl phthalate are placed in a mechanically stirred tank and mechanically stirred again for 5 minutes;

[0053] (6) After mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static bending strength | aaaaa | aaaaa |

| Static modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com