Material for anti-seepage rubber layer of inner tube of air conditioning hose and method for preparing same

A technology of anti-seepage glue and layer material, which is applied in the field of anti-seepage glue layer material and its preparation in the inner tube of air-conditioning hose, which can solve the problems of high cost and poor oil resistance, and achieve low manufacturing cost, simple process and good adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 100kg of epichlorohydrin rubber, 50kg of PVC2500, 10kg of zinc stearate, 5kg of antioxidant RD, 4kg of phenolic resin 204, 30kg of carbon black N770, 5kg of superfine talcum powder, 4kg of calcium hydroxide, 1kg of crosslinking agent HVA-2, Mixture EA 4kg, vulcanizing agent hexamethylene dicarbamate 1kg.

[0025] Put PVC and components other than crosslinking agent and adhesive in an internal mixer, and masticate for 8 minutes at 150°C;

[0026] Put the above materials in an open mill, and under the condition that the roller temperature is ≤60°C, add a crosslinking agent and an adhesive, pass it thinly for 4 times, put on the triangular bag for 6 times, and then remove the sheet.

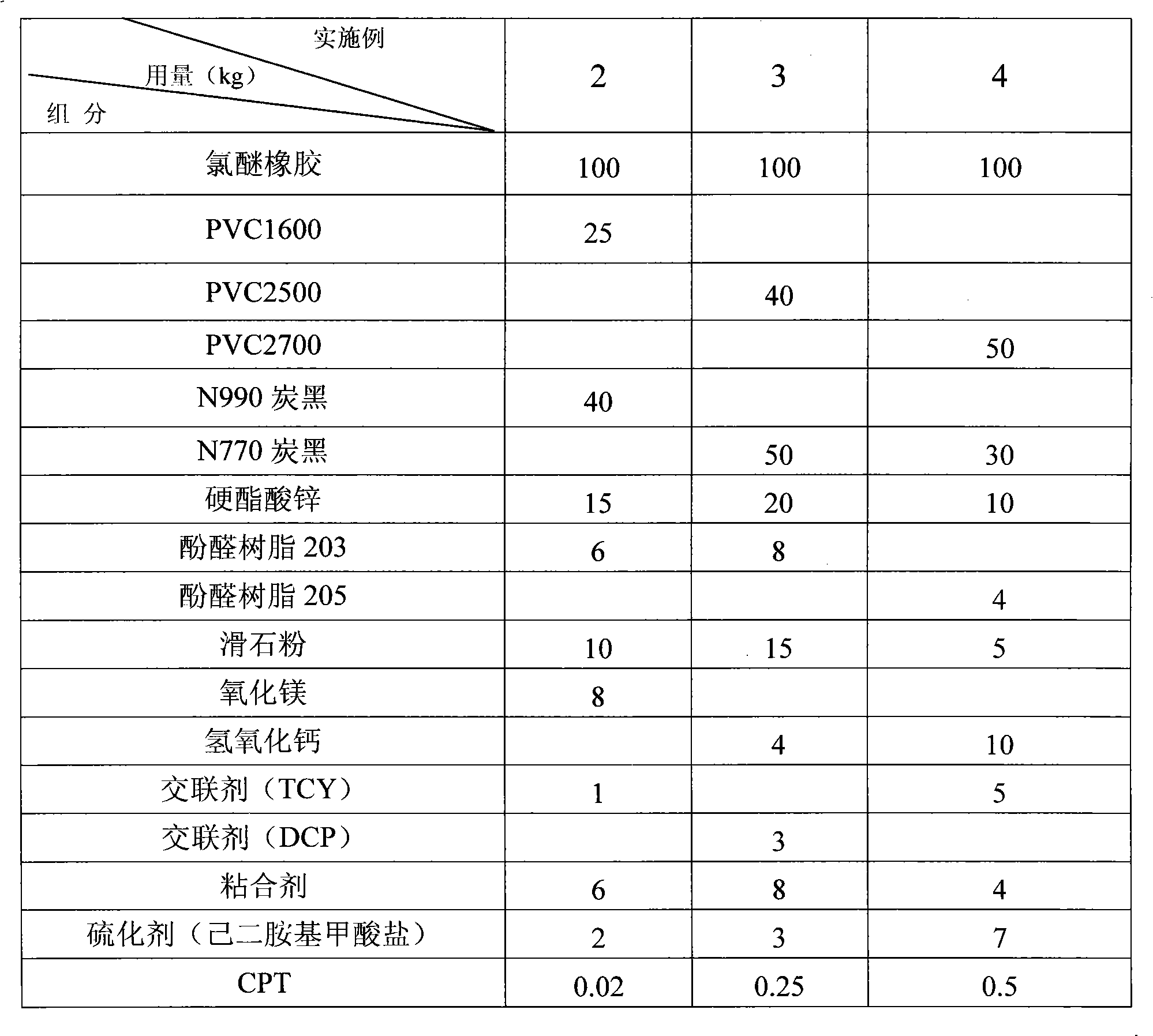

[0027] Embodiment 2~4 preparation method embodiment 1 is the same. The formula dosage is shown in Table 1

[0028] Table 1

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com