Preparation method of TPU (thermo plastic polyurethanes) calendered film

A calendered film and film forming technology, which is applied in the field of TPU calendered film, can solve the problems of high processing cost and low plasticizing efficiency, and achieve the effects of improving plasticizing efficiency, saving costs, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form.

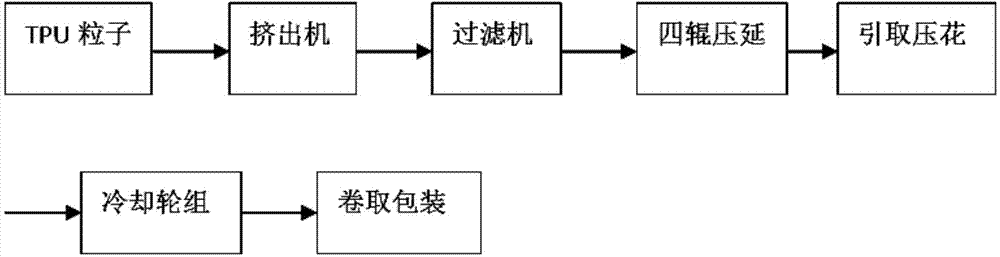

[0024] like figure 1 As shown, the present embodiment provides a method for preparing a TPU calendered film, and the specific steps of the method include:

[0025] Step 1: Use a single-screw extruder to plasticize TPU particles into semi-finished products;

[0026] Step 2: The single-screw extruder is directly connected to the filter of the calendering equipment, and the semi-finished product in step 1 is filtered and plasticized again on the filter of the calendering equipment;

[0027] Step 3: Process the semi-finished product plasticized in step 2 through four-roll forming equipment to form the film;

[0028] Step 4: The film in step 3 is drawn into embossing, cooled by cooling wheel set, and coiled and packaged b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com