Semi-dry nano silver synthesis method

A synthesis method and nano-silver technology, applied in the direction of nano-technology, can solve the problems of limiting the use range of nano-silver, the biological toxicity of reducing agents, and the high energy consumption of nano-silver, and achieve regular particle shape, good dispersion, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Embodiment 1: First, silver nitrate and agar are fully mixed according to the mass ratio of 3:1, and deionized water with 6 times the mass of the agar is then fully ground; continue to add sodium carbonate to adjust the pH value to 8.5, and grind to a paste; then control the temperature React at 75° C. for 3 h; finally vacuum freeze-dry to prepare agar-protected nano-silver powder.

Embodiment 2

[0010] Embodiment 2: First silver nitrate and agar are fully mixed according to the mass ratio of 1:1, then fully ground with deionized water with 5 times the mass of the agar; continue to add sodium carbonate to adjust the pH value to 8, and grind to a paste; then control the temperature React at 65°C for 6 hours; finally vacuum freeze-dry to obtain agar-protected nano-silver powder.

Embodiment 3

[0011] Embodiment 3: first silver nitrate and agar are fully mixed according to mass ratio 5:1, add the deionized water of 8 times of agar quality and grind fully again; Continue to add sodium carbonate to adjust pH value to be 8-9, grind to paste; Then The temperature was controlled at 90° C. for 0.5 h; finally, vacuum freeze-drying was performed to obtain agar-protected nano-silver powder.

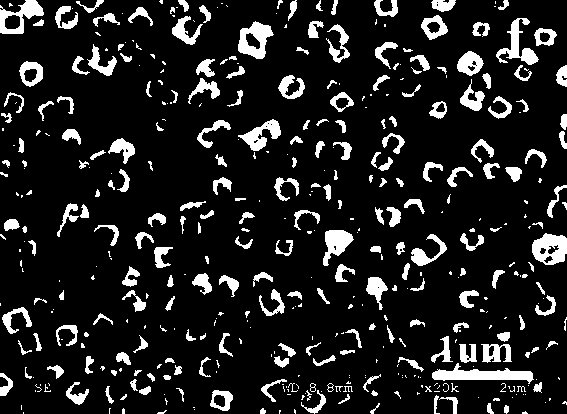

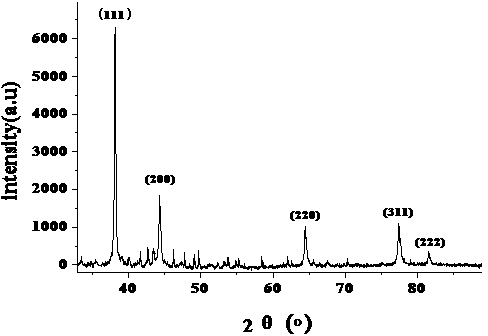

[0012] The electron microscope figure of embodiment 1-3 gained nano-silver is as figure 1 Shown; The XRD figure of embodiment 1-3 gained nano silver figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com