Method for producing polyvinyl chloride special for high-impact-resisting building material product

A production method and high impact resistance technology, applied in the field of graft copolymer preparation, can solve the problems that cannot be applied in the field of PVC building materials, and achieve the effects of light sticking, concentrated distribution, and less fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Step 1: Synthesis of Polyacrylate Composite Latex Particles:

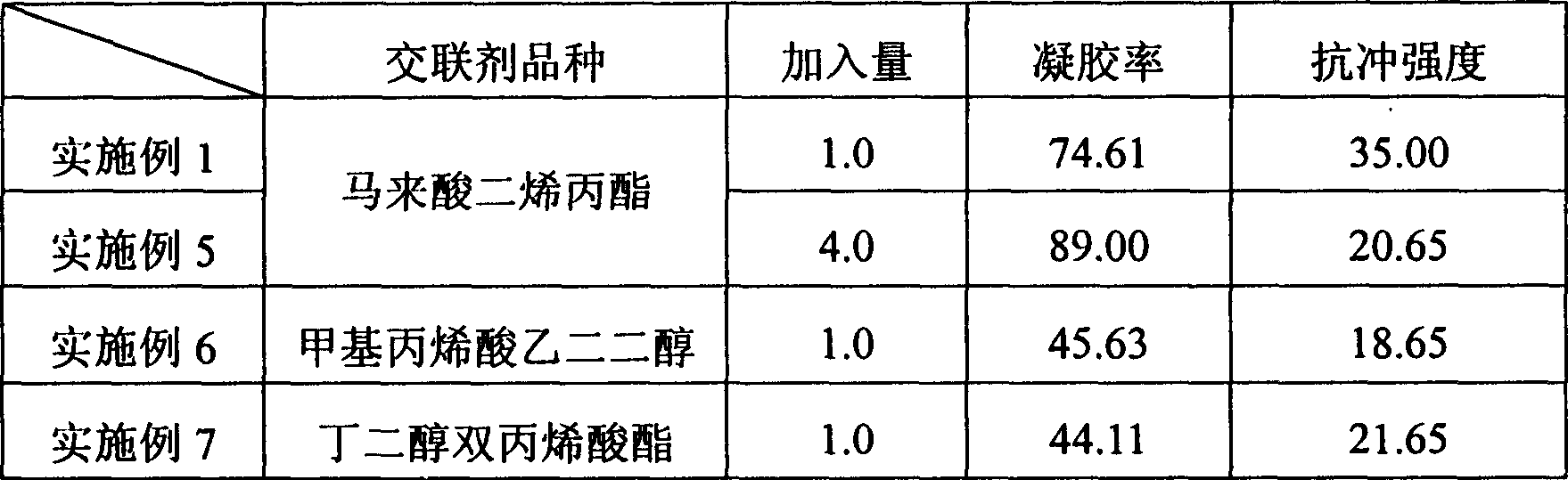

[0064] Introduce high-purity nitrogen into a 1L four-necked flask equipped with electric speed-adjustable stirring, reflux condenser, and electric heating bowl to exhaust oxygen, add 380ml of deionized water and 0.24g of sodium lauryl sulfate under the continuous protection of nitrogen, and start stirring 200rpm to raise the temperature to 85°C; at this temperature, add pre-configured butyl acrylate (BA) / crosslinking agent diallyl maleate (DAM) / sodium lauryl sulfate (SLS)=192g / 1.92g / 0.72g) of the pre-emulsion 40ml, add potassium persulfate 0.50g, temperature control reaction for 1 hour, continuously drop the remaining BA pre-emulsion and KPS solution 1.92g (4% concentration), react for 2-3 hours, the nuclear partial polymerization is completed ;

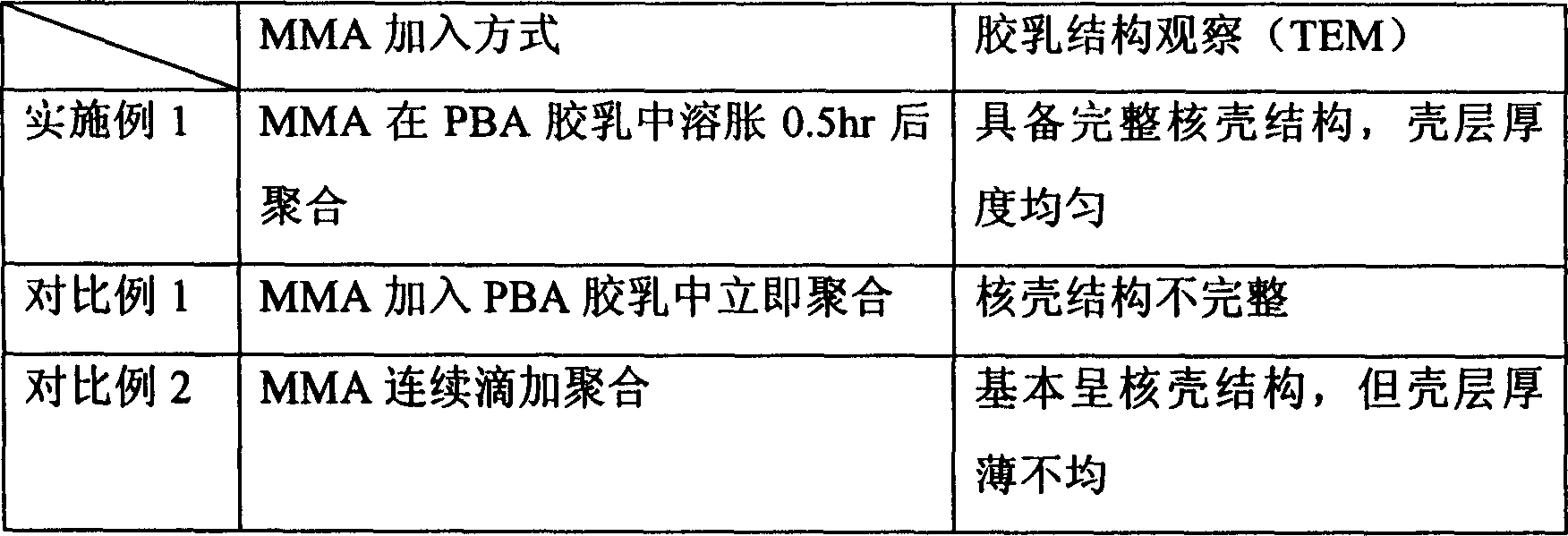

[0065] Cool down and add 48g methyl methacrylate monomer (BA / MMA feeding ratio 80 / 20) to stir and swell for 0.5 hours, add 0.48g (4% concentration) of sodium lau...

Embodiment 2

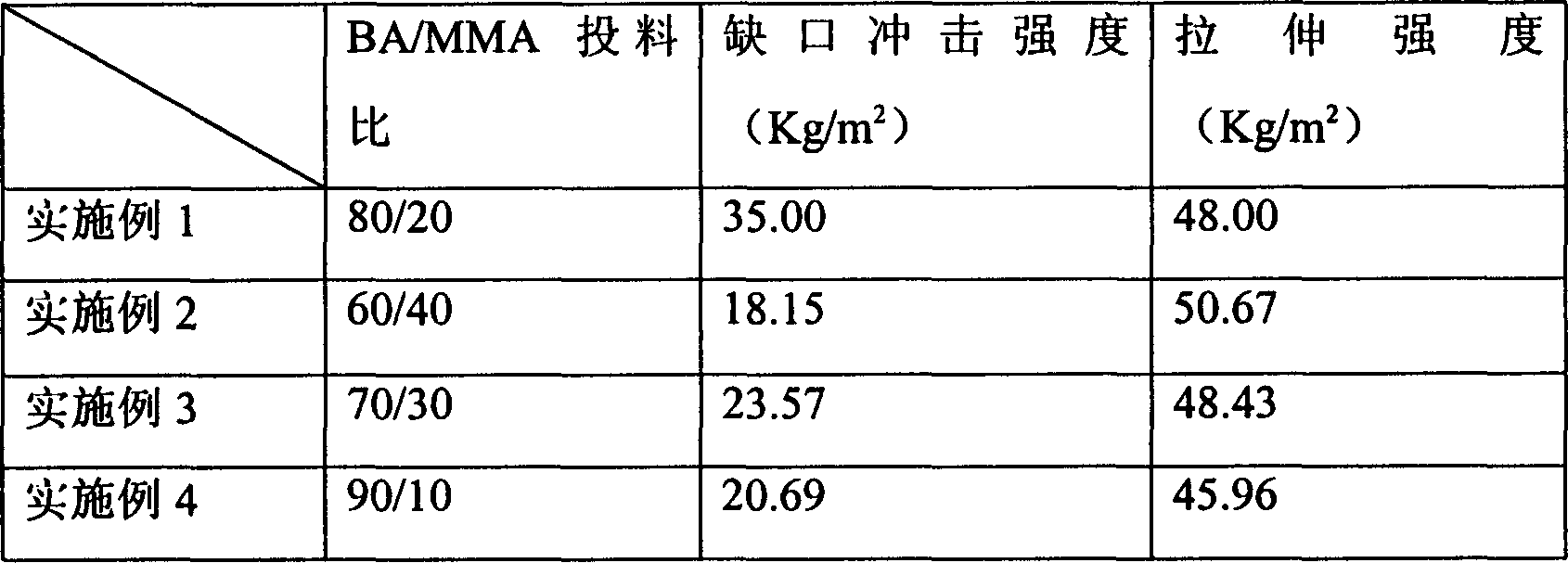

[0072] In the first step, when the polyacrylate composite latex particles are synthesized, 144g of butyl acrylate is fed, 96g of methyl methacrylate is fed, and the ratio of feeding is 60 / 40. Other processes are implemented with 1. (See Table 1 for the results)

Embodiment 3

[0074] In the first step, when polyacrylate composite latex particles are synthesized, 168g of butyl acrylate is fed, 72g of methyl methacrylate is fed, and the ratio of charging is 70 / 30. Other processes are implemented with 1. (See Table 1 for the results)

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com