Vinyl chloride-butyl acrylate copolymer resin with ultralow polymerization degree and preparation method thereof

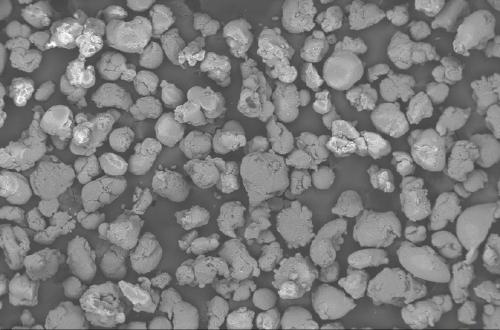

The technology of butyl acrylate copolymer resin and butyl acrylate is applied in the field of ultra-low polymerization degree vinyl chloride-butyl acrylate copolymer resin and its preparation, and can solve the problems of irregular particle shape, poor resin fluidity, low apparent density and the like , to achieve the effect of regular particle shape, short plasticization time and good resin fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The ultra-low polymerization degree vinyl chloride-butyl acrylate copolymer resin, raw materials include desalted water, vinyl chloride monomer, composite dispersant, composite initiator, chain transfer agent mercaptoethanol, butyl acrylate, wherein, desalted water The weight ratio of compound dispersant to vinyl chloride monomer is 1.1 to 1.4:1, the weight ratio of composite dispersant to vinyl chloride monomer is 7 to 9:10000, and the weight ratio of compound initiator to vinyl chloride monomer is 6 to 10000. 10:10000, the weight ratio of chain transfer agent mercaptoethanol to vinyl chloride monomer is 6 to 10:10000, and the weight ratio of butyl acrylate to vinyl chloride monomer is 1 to 10:100.

Embodiment 2

[0022] Embodiment 2: The ultra-low degree of polymerization vinyl chloride-butyl acrylate copolymer resin, raw materials include desalted water, vinyl chloride monomer, composite dispersant, composite initiator, chain transfer agent mercaptoethanol mercaptoethanol and butyl acrylate, wherein, The weight ratio of desalted water to vinyl chloride monomer is 1.1 or 1.4:1, the weight ratio of composite dispersant to vinyl chloride monomer is 7 or 9:10000, and the weight ratio of composite initiator to vinyl chloride monomer is 6 or 10:10000, the weight ratio of chain transfer agent mercaptoethanol to vinyl chloride monomer is 6 or 10:10000, and the weight ratio of butyl acrylate to vinyl chloride monomer is 1 or 10:100.

Embodiment 3

[0023] Example 3: As an optimization of the above example, the composite dispersant is polyvinyl alcohol, and the composite initiator includes di(3,5,5-trimethylhexanoyl peroxide) and tert-butyl peroxyneodecanoate.

[0024] The composite dispersant can be polyvinyl alcohol of common commercially available models B72, A80, GH20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com