A kind of autoclave type preparation method of thermoplastic polyester elastomer foamed particles

A technology of thermoplastic polyester and expanded particles, which is applied in the direction of coating, etc., and can solve the problems of increasing the risk of degradation of polymer resin materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) 100 parts by mass of powdered thermoplastic polyester elastomer (Korean SK G140D, 100 mesh), 18 parts by mass of polyamide 12 powder (Evonik Degussa 1301 (powder)), 2 parts by mass of oxidation Aluminum powder and 3 parts by mass of calcium carbonate powder are fully mixed in a high-speed mixer, the speed of the high-speed mixer is 200 rpm, the mixing time is 8 minutes, and the mixing temperature is controlled below 50°C;

[0025] (2) At room temperature (25°C, the same below), fully disperse 10 parts by mass of mineral oil (Zhonghai Nanlian, Industrial Grade No. 46) in 30 parts by mass of ethanol to obtain a spray liquid,

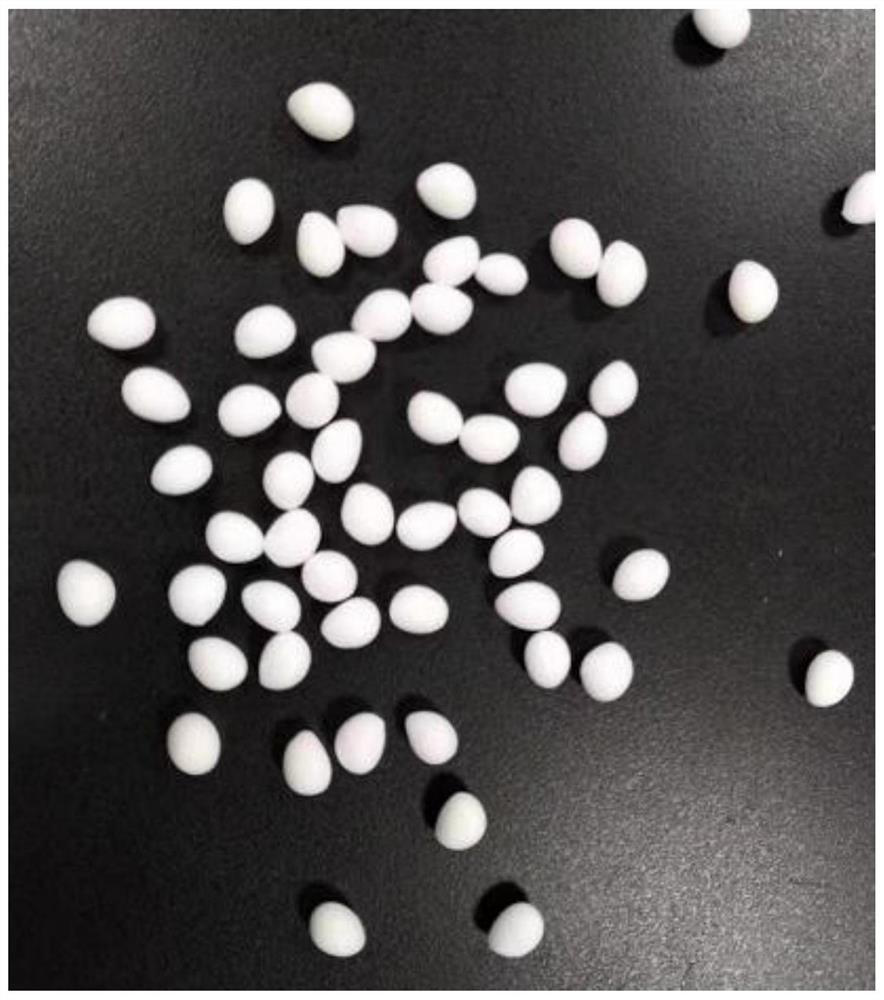

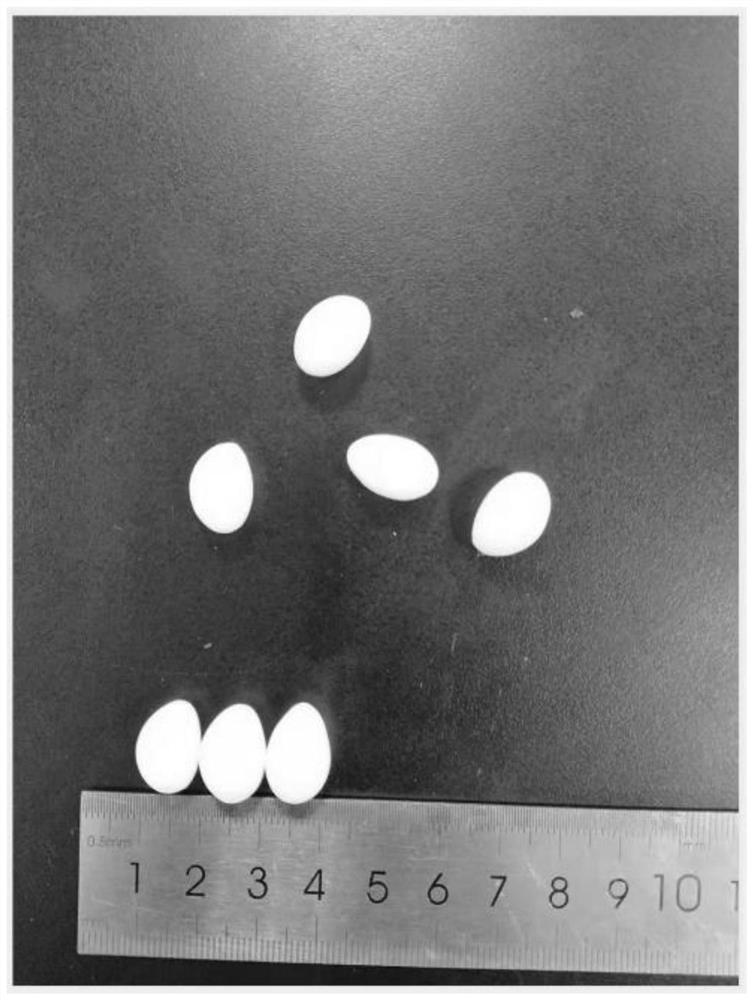

[0026] (3) After the mixture obtained in step (1) is evenly sprayed with the spray liquid obtained in step (2), it is granulated by a disc granulator. Spherical particles with a diameter of 5 mm,

[0027] (4) The granule that step (3) obtains, the water of 160 mass parts, the surfactant sodium dodecylbenzene sulfonate of 2.5 mass parts join in ...

Embodiment 2

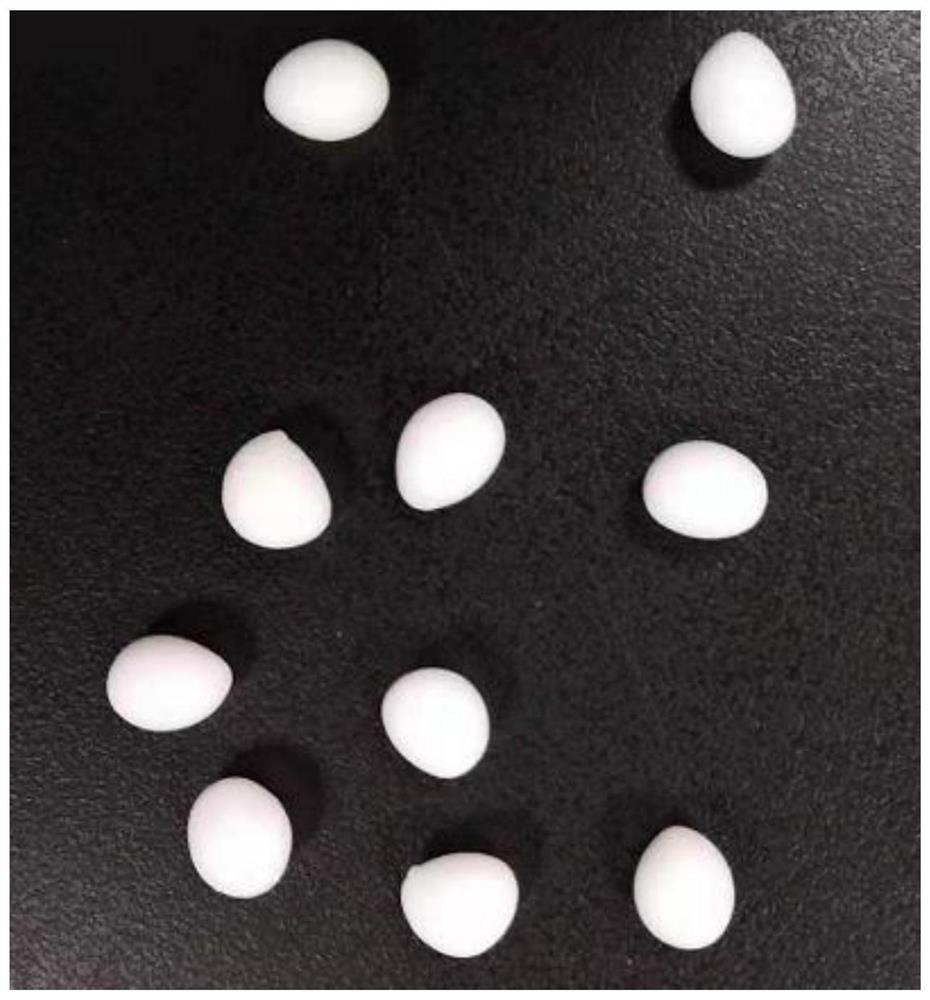

[0033] "10 mass parts of mineral oil" in step (2) is revised to "6 mass parts of mineral oil", "30 mass parts of ethanol" is revised to "18 mass parts of ethanol", and all the other operations are the same as in the embodiment 1. After heating and foaming in the reactor, the resin remains in granular form.

[0034] After testing, the foaming density of the foamed particles obtained in Example 2 is 0.42g / cm 3 , the foamed particles are processed and formed by steam forming equipment to obtain a TPEE foamed sheet with a thickness of 2cm (the mold is a concave-convex plate with a depth of 2cm, the molding pressure is 0.25MPa, the molding time is 5 minutes, and the mold peak is 20mm), demoulding After placing it at room temperature for 24 hours, test it with reference to the national standard GB / T6670-2008: the rebound rate of the falling ball reaches 65%.

Embodiment 3

[0036] "10 mass parts of mineral oil" in step (2) is revised to "3 mass parts of mineral oil", "30 mass parts of ethanol" is revised to "9 mass parts of ethanol", and all the other operations are the same as in the embodiment 1. After heating and foaming in the reactor, the resin remains in granular form.

[0037] After testing, the expanded density of the expanded particles obtained in Example 3 is 0.68g / cm 3 , the foamed particles are processed and formed by steam forming equipment to obtain a TPEE foamed sheet with a thickness of 2cm (the mold is a concave-convex plate with a depth of 2cm, the molding pressure is 0.25MPa, the molding time is 5 minutes, and the mold peak is 20mm), demoulding After placing it at room temperature for 24 hours, test it with reference to the national standard GB / T6670-2008: the rebound rate of the falling ball reaches 41%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com