Clamping fixture for molten steel casting system long nozzle

A technology for fixing devices and casting systems, applied in casting equipment, casting melt containers, metal processing equipment, etc., can solve the problems of useful signal loss, interference, steel leakage at joints, etc., to reduce loss and attenuation, and stabilize vibration signals , Eliminate the effect of signal mutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

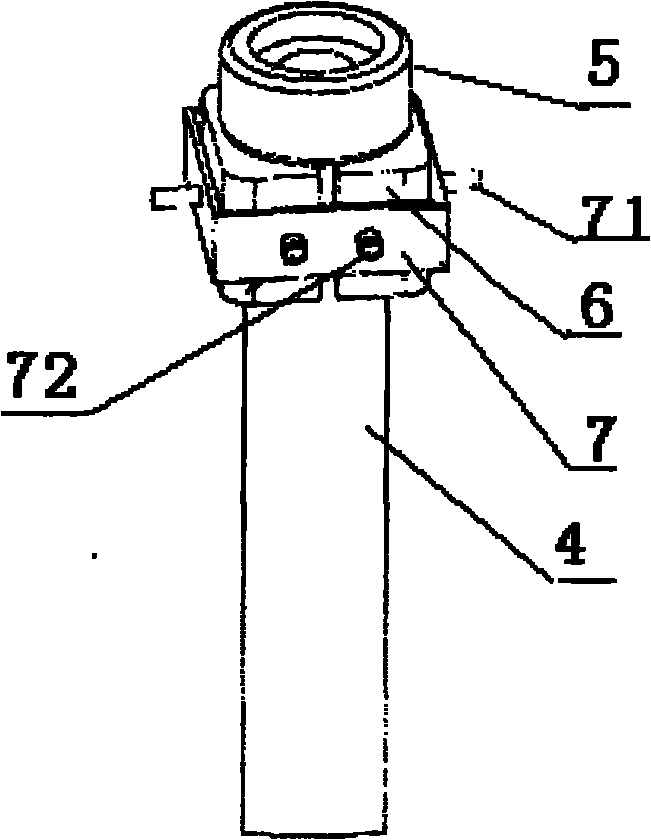

[0027] image 3 It shows a structural schematic view of the shroud clamping and fixing device according to the first embodiment of the present invention (in the clamping state). Such as image 3 As shown, the clamping and fixing device of the nozzle is located under the outer hoop 5 of the shroud, which is composed of a clamping block 6 and a fixing bracket 7. There are two clamping blocks 6, which are respectively arranged on both sides of the shroud 4, and the shroud 4 clamping and fixed in the clamping surface. The fixing bracket 7 is a square metal bracket surrounding the clamping block 6 , and the clamping block 6 is movably hinged on the fixing bracket 7 through a pin shaft 72 . There is a certain gap between the clamping block 6 and the fixed bracket 7, and the clamping block 6 can freely adjust the opening and closing degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com