Inner hexagonal fine punching die

A technology of fine punching and punching die, applied in the field of inner hexagonal fine punching die, can solve the problems such as the temperature of the punch can not be dissipated in time, the hexagonal position is not full, the performance of the punch is degraded, etc., so as to improve the surface quality of the product and the full hexagonal position. , The effect of reducing work resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

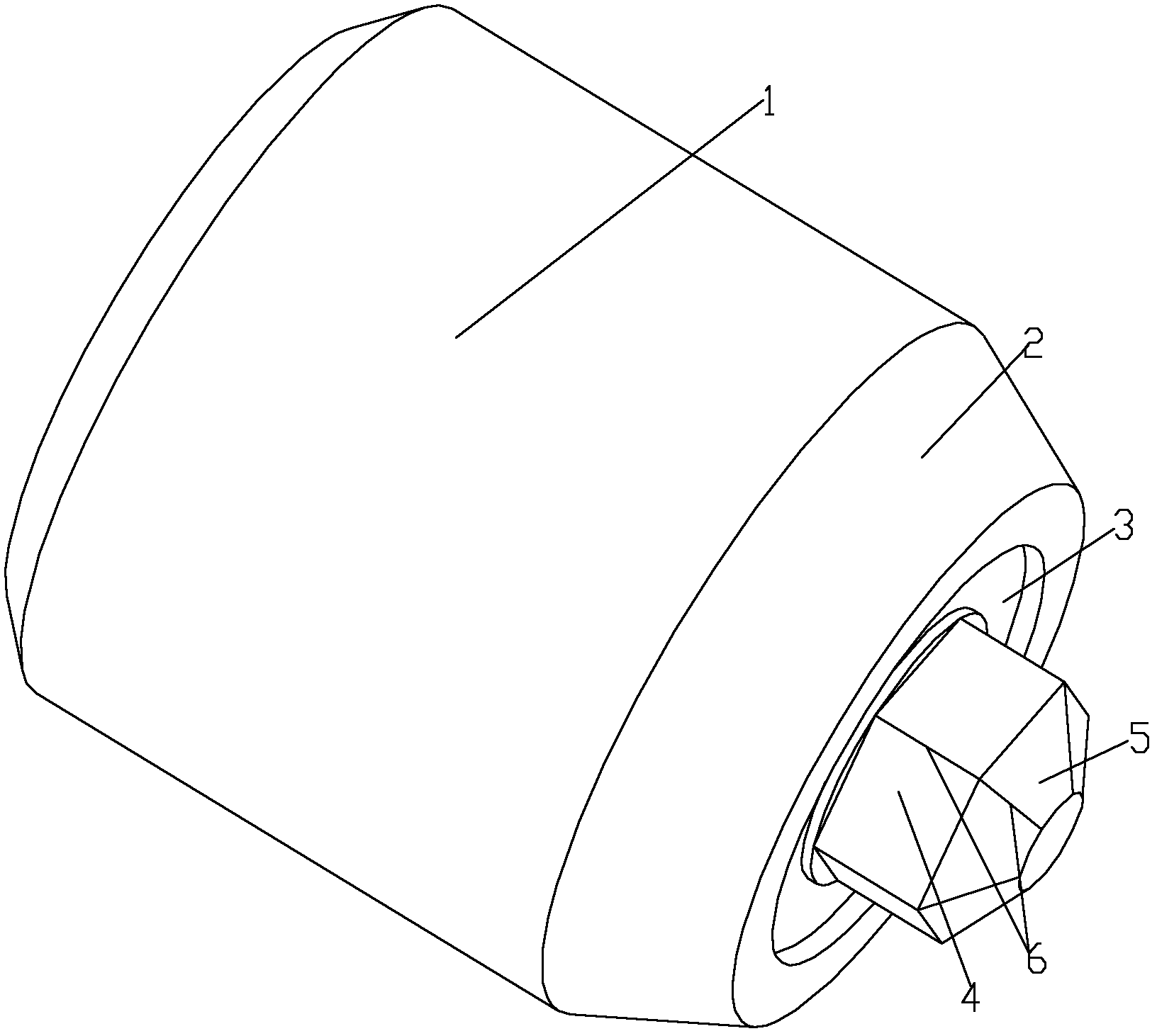

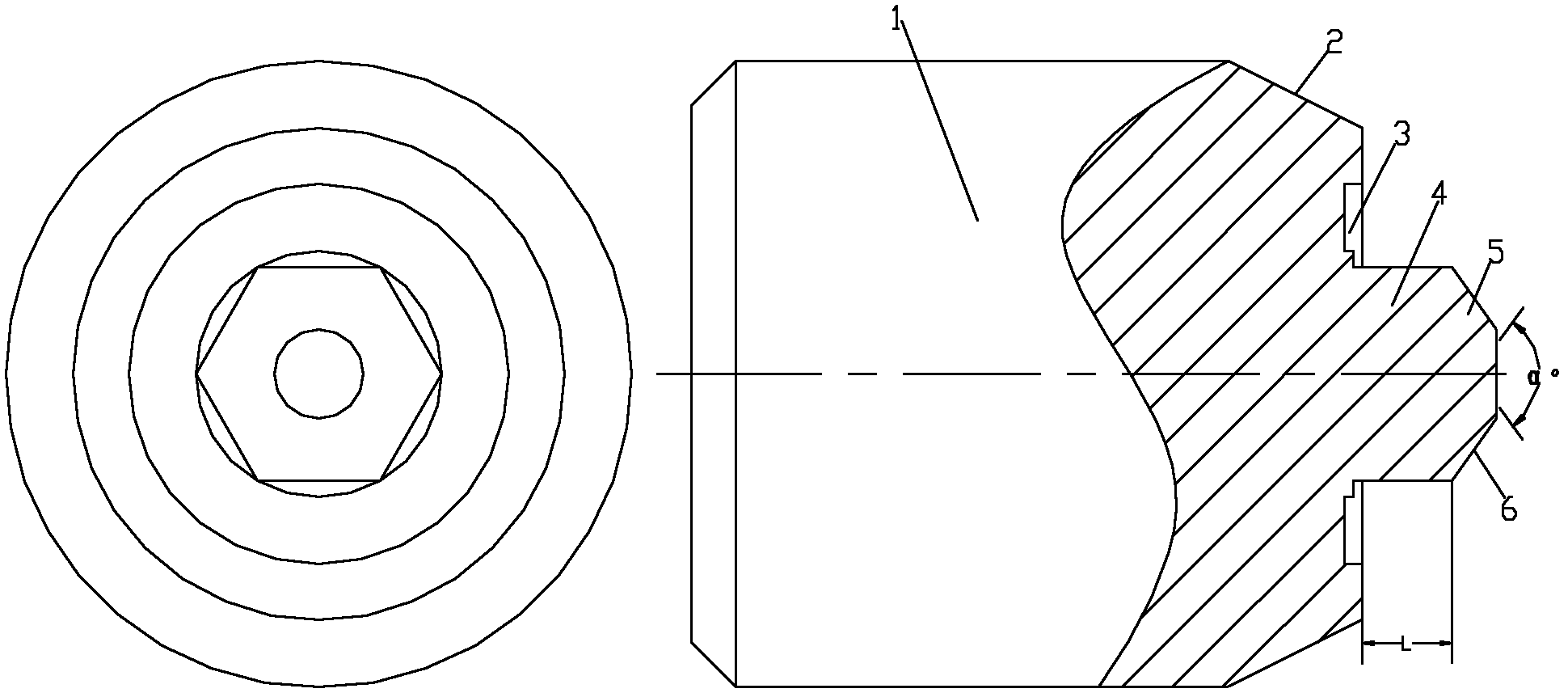

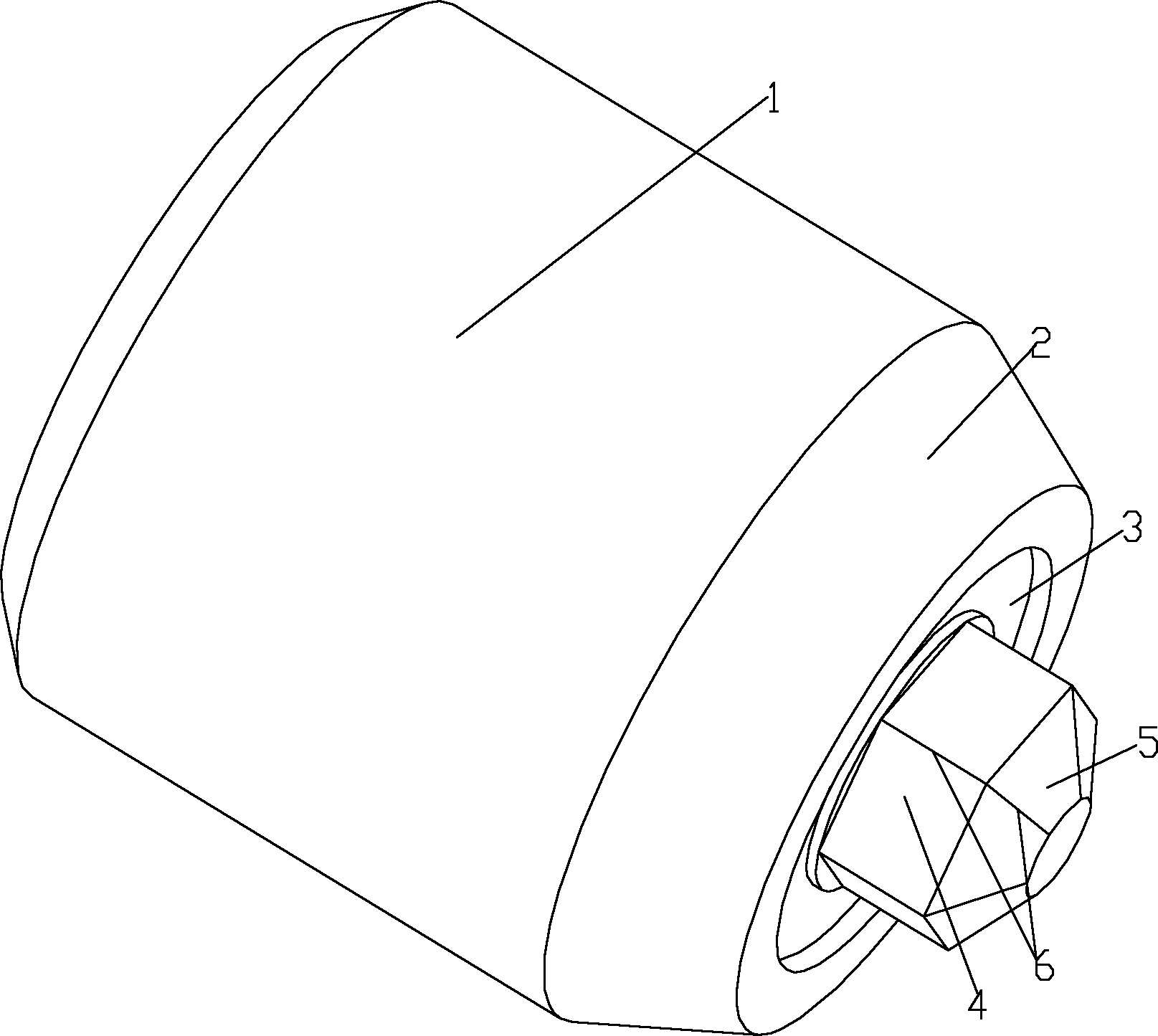

[0014] attached figure 1 , 2 It is a kind of inner hexagon fine punching die according to the present invention, including a die body 1, the die body is made of 7Cr7M02v2si material, one end of the die body 1 is set as a conical end 2; the end surface of the conical end 2 is provided with a groove 3; a punching needle is provided in the groove 3; the punching needle is composed of a hexagonal prism 4 and a head end 5; the head end 5 is a frustum-shaped structure with hexagonal edges; the head end 5 and the hexagon of the hexagonal prism 6 are provided with cutting edge 6; the effective length L of cutting edge 6 on the hexagonal prism 6 is 2.1mm; .

[0015] The above-mentioned embodiments are only to illustrate the technical conception and characteristics of the present invention. Substantial equivalent changes or modifications shall fall within the protection scope of the present i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com