Microwave preparing method for nanometer silver or gold

A nano-silver and nano-gold technology, which is applied in the field of microwave preparation of nano-silver or nano-gold, can solve the problems of reported, unseen microwave preparation methods of nano-silver or nano-gold, and achieves controllable reaction process, regular particle shape, The effect of narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the reactor, add 0.01mol / L silver nitrate or chloroauric acid solution and 0.5% sodium carboxymethyl cellulose solution in a ratio of 1:1, add an appropriate amount of secondary distilled water to 200 milliliters of the reaction system; Put it into the microwave reaction chamber and fix it, turn on the magnetic stirrer with a rotating speed of 100 rpm, set the microwave power to 0.3 kilowatts, and react for 7 hours; after the reaction, the solution is air-dried, or vacuum freeze-dried, or spray-dried to obtain nano-silver or Nanogold powder, or nanosilver or nanogold colloid concentrated to the desired concentration by vacuum.

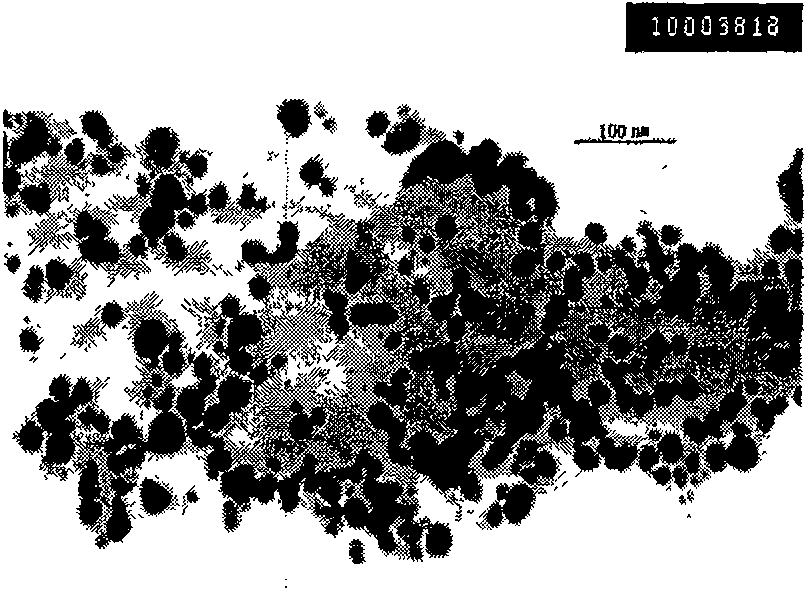

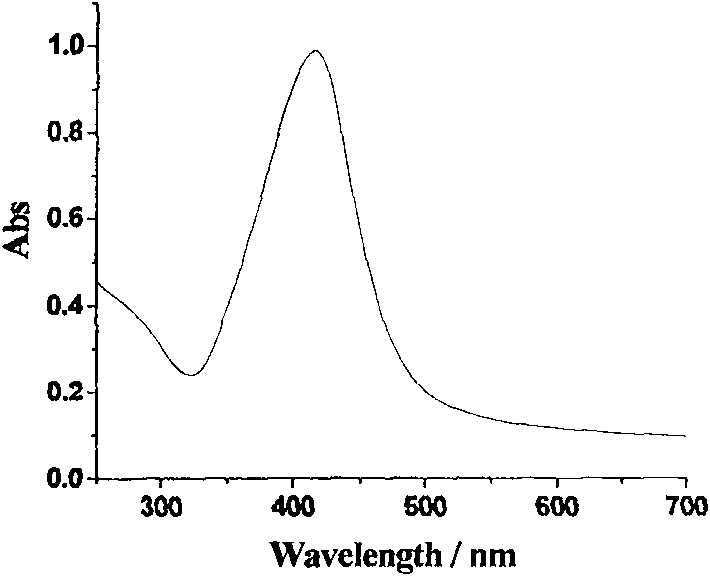

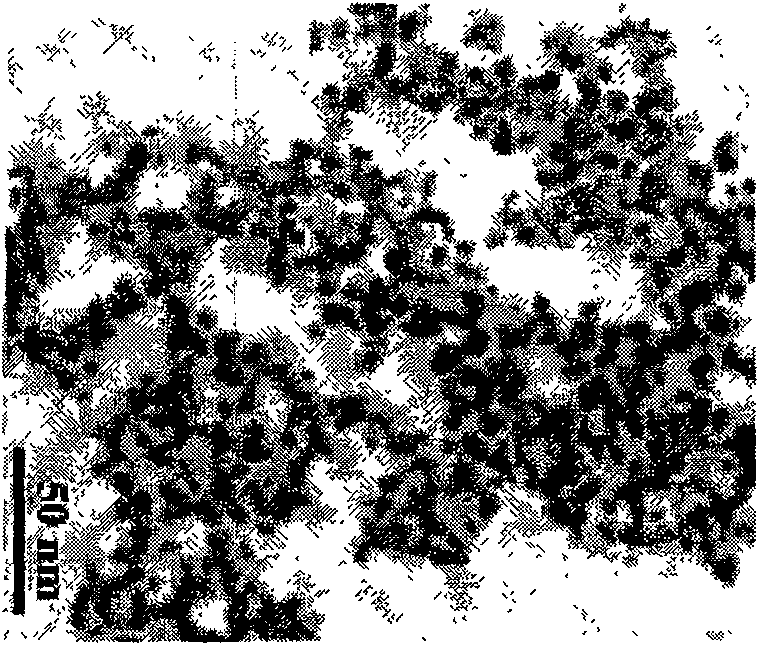

[0024] The electron microscope picture and ultraviolet spectrogram of this nano-silver or nano-gold are as follows: figure 1 , 2 , 3, 4 shown.

Embodiment 2

[0026] In the reactor, add 0.01mol / L silver nitrate or chloroauric acid solution and 1% starch solution in a ratio of 1:1, add an appropriate amount of secondary distilled water to a reaction system of 200 milliliters, add 1 milliliter of 0.01mol / L ammonia water as a catalyst; Put the reactor into the microwave reaction chamber and fix it, turn on the magnetic stirrer with a rotating speed of 100 rpm, set the microwave power to 0.3 kilowatts, and react for 1 hour. After the reaction, adjust the pH of the solution to neutral; after the reaction, the solution is dried by airflow. Or vacuum freeze-drying, or spray drying to prepare nano-silver or nano-gold powder, or vacuum-concentrate to the desired concentration of nano-silver or nano-gold colloid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com