A kind of pretreatment method of artificial graphite material and obtained product and application

An artificial graphite and pretreatment technology, which is applied in the direction of graphite, electrical components, battery electrodes, etc., can solve the problems of low compaction density and imperfect surface correction of particles, and achieve stable material properties, simple and feasible production process, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

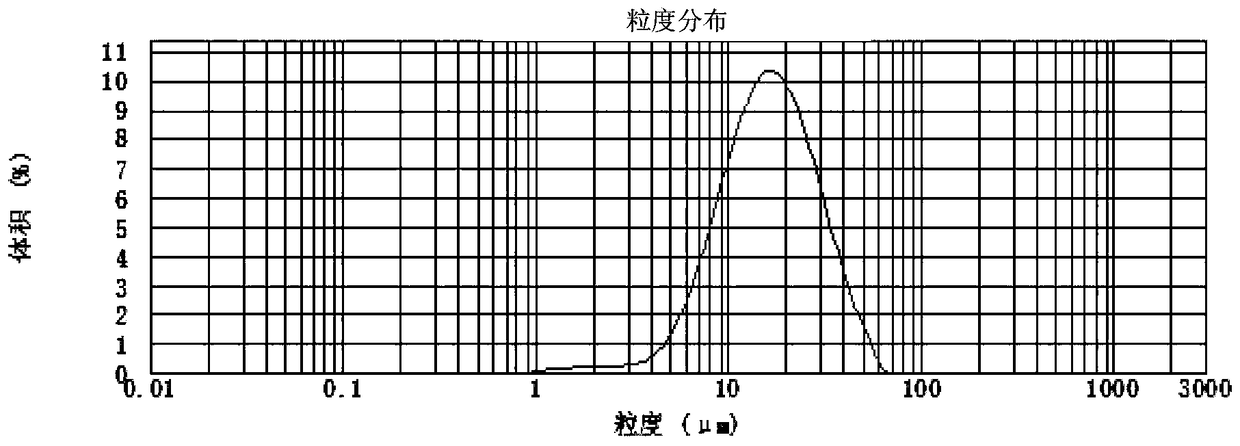

[0027] Artificial graphite material (referred to as raw material A), the D50 marked on the product is about 16 μm, the raw material is 2kg in total, the volume average particle diameter D50 of the sample before processing is 16.4 μm, and the true density is 2.24g / cm 3 , compacted density 1.49g / cm 3 .

[0028] (1) Put the artificial graphite material in a drying oven and dry it at 150°C for 1.5 hours until the moisture in it accounts for ≤2% of the total mass of the material;

[0029] (2) Check whether the equipment of the fusion machine is running normally, clean the fusion machine to ensure that there are no impurities; put 2kg of artificial graphite material with a D50 of 16.4μm into the high-speed modified fusion machine for mixing, the time is 3 minutes, and the speed is 1700r / m; after that, the material can be sieved, and the sieve mesh number is 250 mesh.

[0030] After testing, the particle size of the treated artificial graphite material is 16.0μm, and the true dens...

Embodiment 2

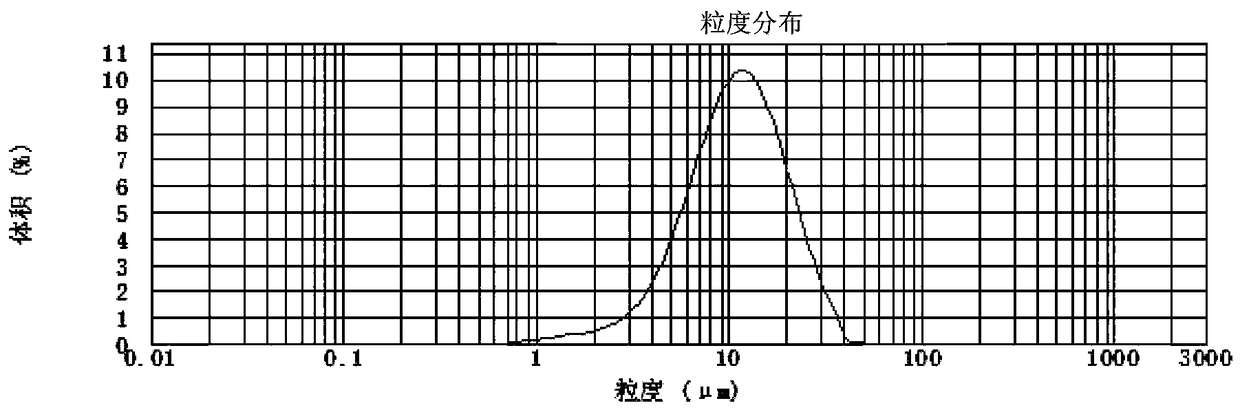

[0032] Artificial graphite material (denoted as raw material B), the D50 marked on the product is about 18 μm, the raw material is 2kg in total, the volume average particle diameter D50 of the sample before processing is 18.2 μm, and the true density is 2.25g / cm 3 , compacted density 1.47g / cm 3 .

[0033] (1) Put the artificial graphite material in a drying oven and dry it at 150°C for 1.5 hours until the moisture in it accounts for ≤2% of the total mass of the material;

[0034] (2) Check whether the equipment of the fusion machine is running normally, clean the fusion machine to ensure that there are no impurities; put 2.5kg of artificial graphite materials with a D50 of 18.2 μm into the high-speed modified fusion machine for mixing, the time is 5 minutes, and the speed is 1700r / m; after that, the material can be sieved, and the sieve mesh number is 250 mesh.

[0035] After testing, the particle size of the treated artificial graphite material is 17.5μm, and the true dens...

Embodiment 3

[0037] Artificial graphite material (denoted as raw material A), the D50 marked on the product is about 16 μm, the total raw material is 2.5kg, the volume average particle diameter D50 of the sample before processing is 16.4 μm, and the true density is 2.24g / cm 3 , compacted density 1.49g / cm 3 .

[0038] (1) Put the artificial graphite material in a drying oven and dry it at 150°C for 2.0 hours, until the moisture in it accounts for ≤2% of the total mass of the material;

[0039] (2) Check whether the equipment of the fusion machine is running normally, clean the fusion machine to ensure that there are no impurities; put 2kg of artificial graphite materials with a D50 of 16.4μm into the high-speed modified fusion machine for 10 minutes, and the speed is 1800r / m; after that, the material can be sieved, and the number of sieved meshes is 250 meshes.

[0040] After testing, the particle size of the treated artificial graphite material is 15.4μm, and the true density is 2.24g / c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com