Preparation method of monodisperse ferrum-acid-nickel-zinc nano material

A technology of nickel-zinc ferrite and nanomaterials, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., to achieve the effects of low production cost, convenient industrial production, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

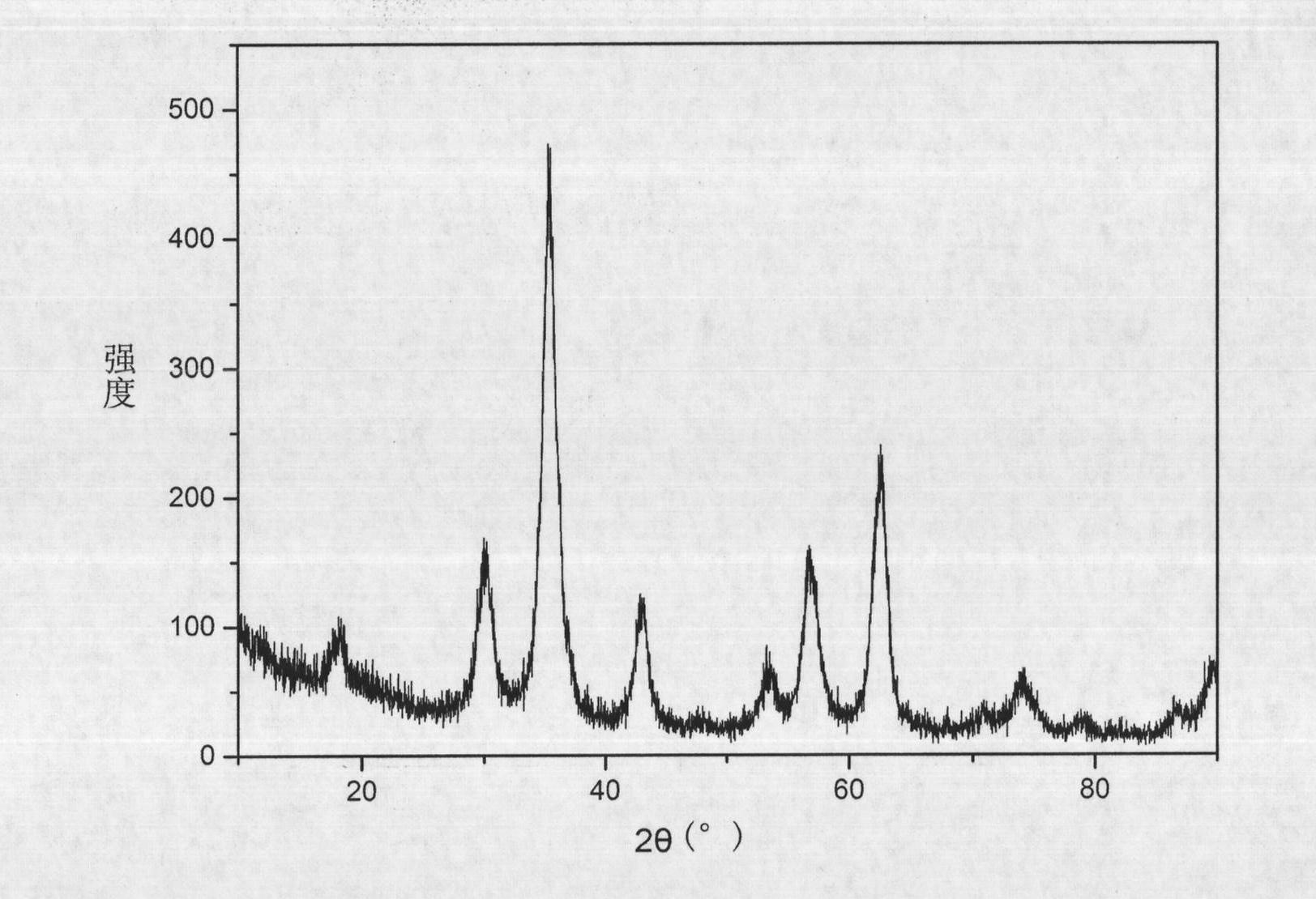

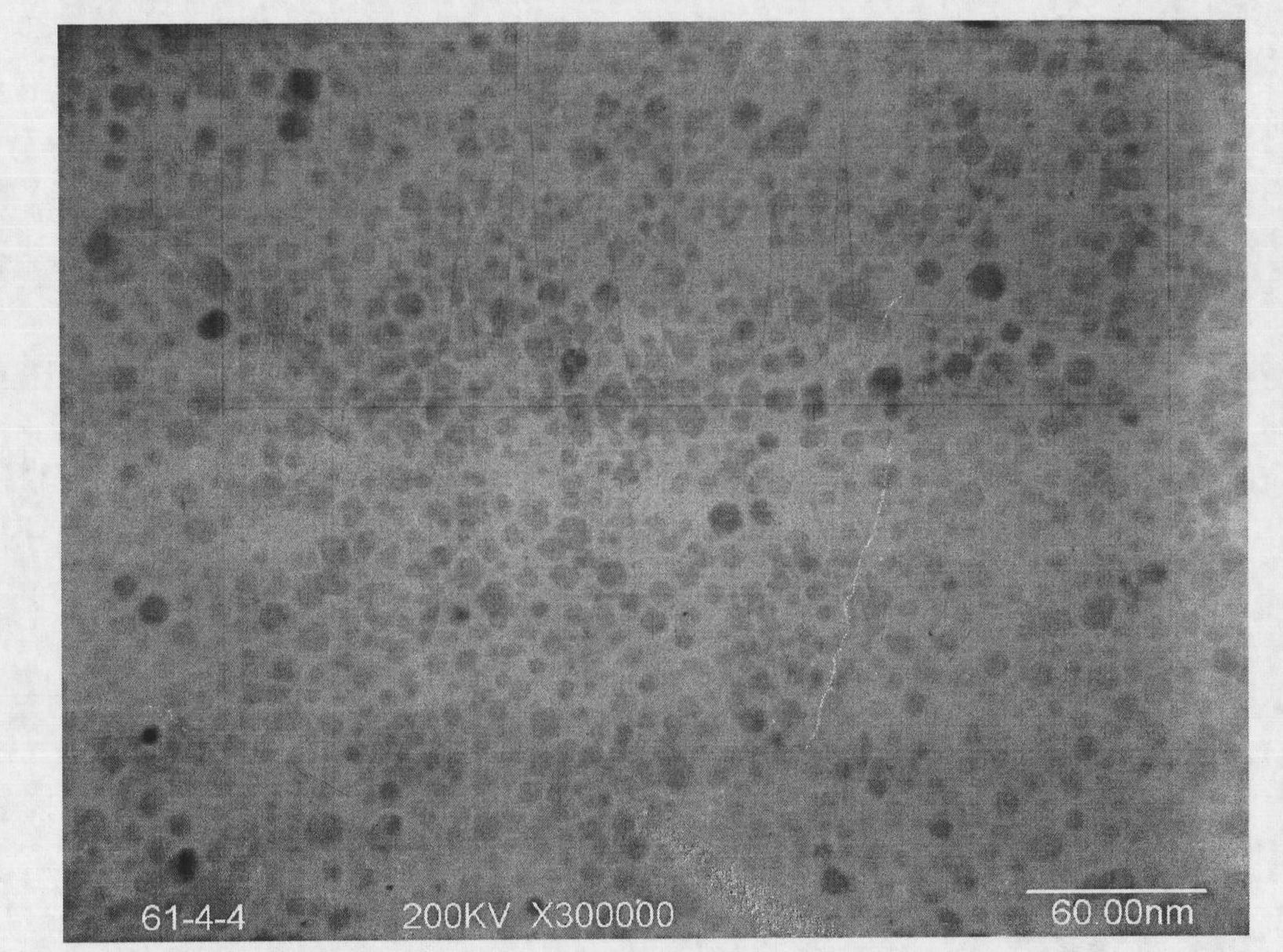

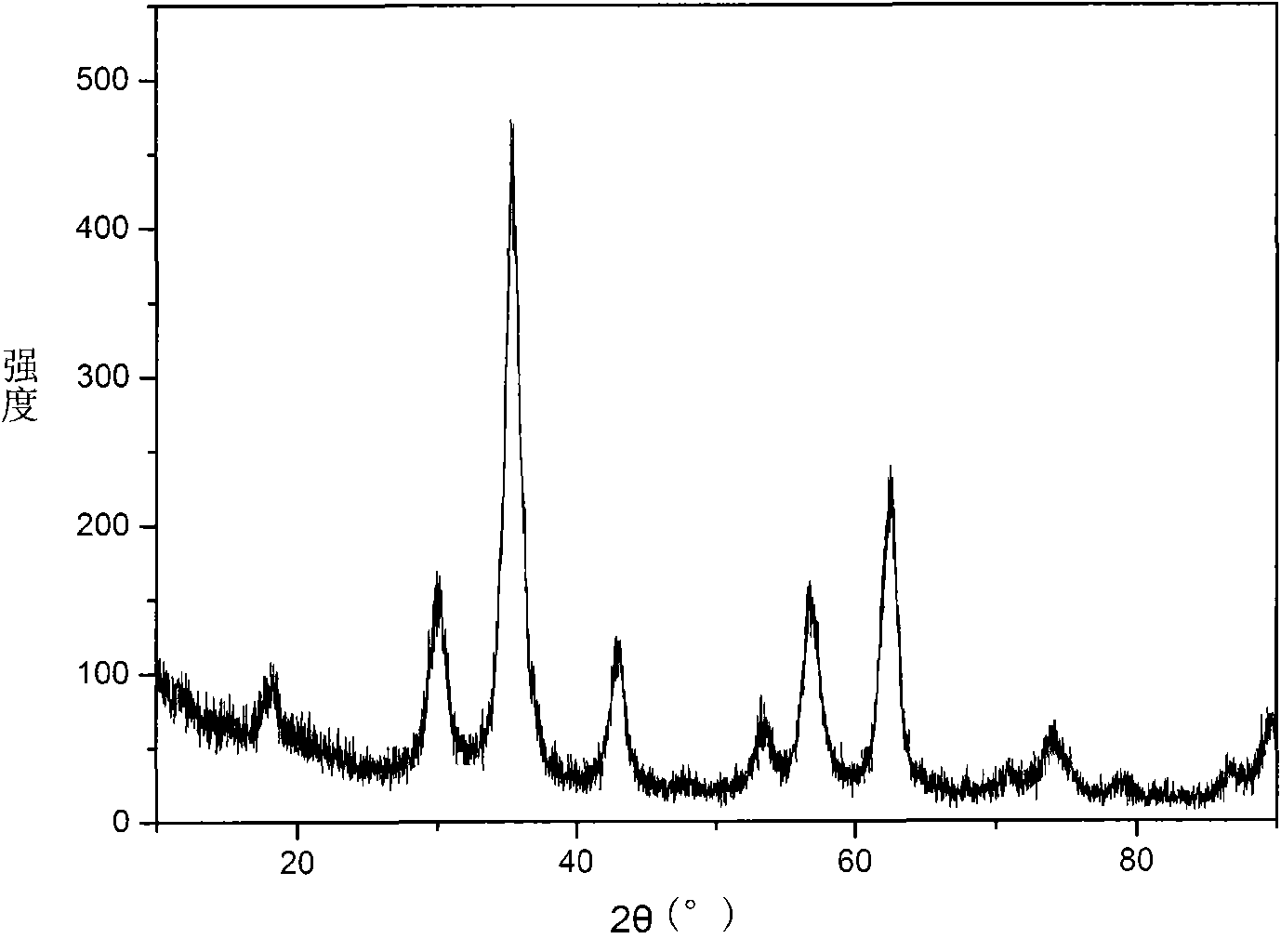

[0020] Weigh 0.5mmol of nickel acetylacetonate, 0.5mmol of zinc acetylacetonate and 2mmol of iron acetylacetonate into a 250ml three-necked flask, then add 30mmol of octadecylamine and 64mmol of diphenyl ether; heat up to 110°C for one hour to remove the drug Then heat up to the boiling point of the solution and react for 8 hours. After the reaction, the solution is cooled to 60°C and transferred to a centrifuge tube. Add 30ml of ethanol to settle and centrifuge. The product is washed with ethanol three times, dried at 70°C for 12h, and ground to obtain Ni 0.5 Zn 0.5 Fe 2 o 4 Brown solid powder. figure 1 is its XRD pattern, figure 2 is its TEM image. It can be seen from the figure that the particle size distribution is 6-12nm.

Embodiment 2

[0022] Weigh 0.5mmol of nickel acetylacetonate, 0.5mmol of zinc acetylacetonate and 2mmol of iron acetylacetonate into a 250ml three-necked flask, then add 30mmol of octadecylamine and 128mmol of diphenyl ether; raise the temperature to 100°C for three hours, then raise the temperature React for 12 hours at the boiling point of the solution, transfer the solution to a centrifuge tube when it cools down to 60°C after reaction, add 60ml of ethanol to settle, centrifuge, wash the product with ethanol three times, dry at 70°C for 12h, and grind to obtain brown Ni 0.5 Zn 0.5 Fe 2 o 4 solid powder.

Embodiment 3

[0024]Weigh 0.1mmol of nickel acetylacetonate, 0.9mmol of zinc acetylacetonate and 2mmol of iron acetylacetonate into a 250ml three-necked flask, then add 4mmol of octadecylamine and 160mmol of diphenyl ether; heat up to 110°C for one hour, then heat up to Reaction at the boiling point of the solution for 10 hours. After the reaction, the solution is cooled to 100°C and transferred to a centrifuge tube. Add 50ml of ethanol to settle and centrifuge. The product is washed with ethanol three times, dried at 50°C for 24 hours, and ground to obtain brown Ni. 0.1 Zn 0.9 Fe 2 o 4 solid powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com