Process and device for drying adsorption type compressed gas regenerated by using compression heat

A technology of compressed gas and drying process, which is applied in gas treatment, membrane technology, and separation of dispersed particles, etc., to achieve significant energy saving and consumption reduction, thorough regeneration, and drift avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

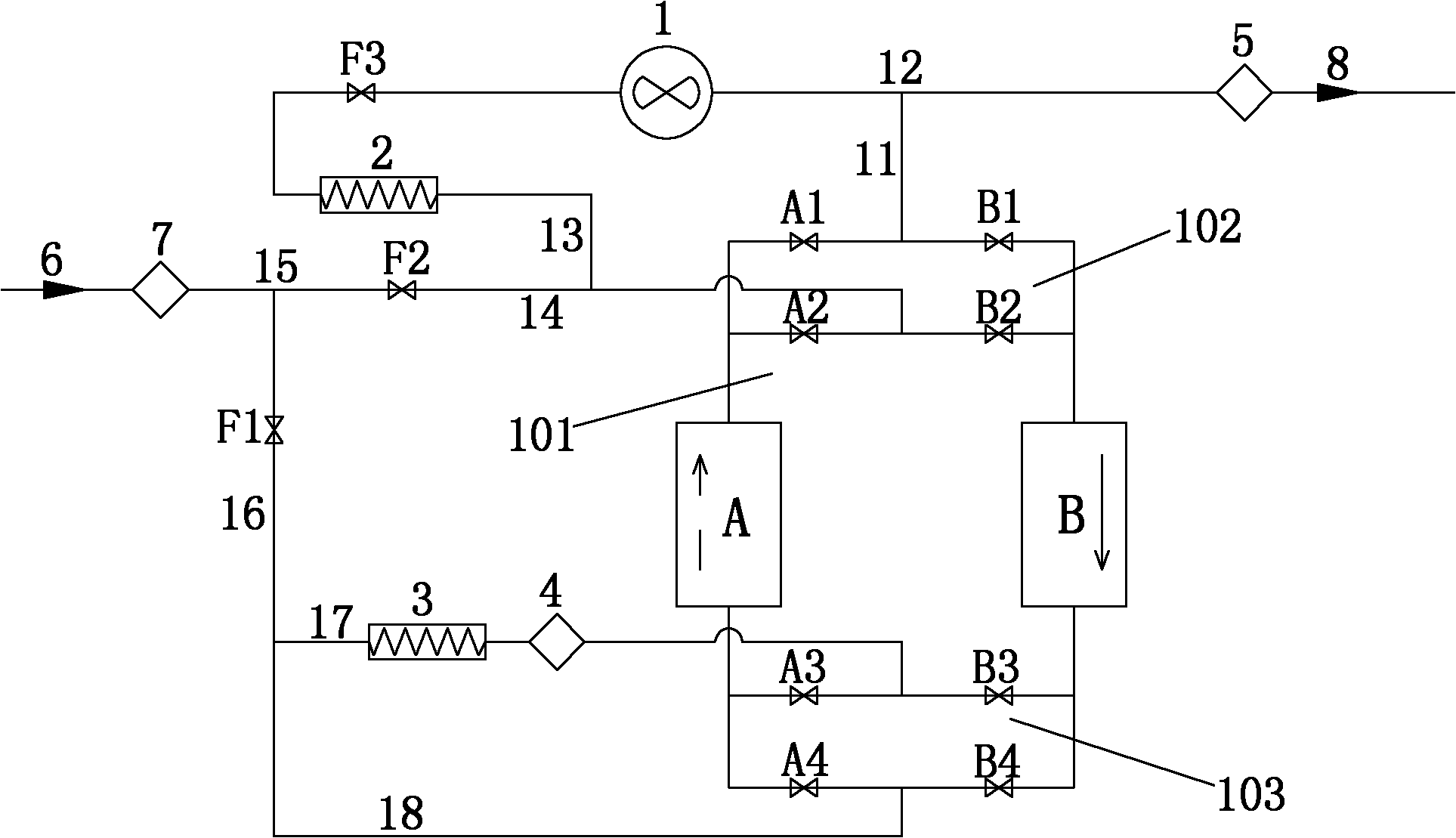

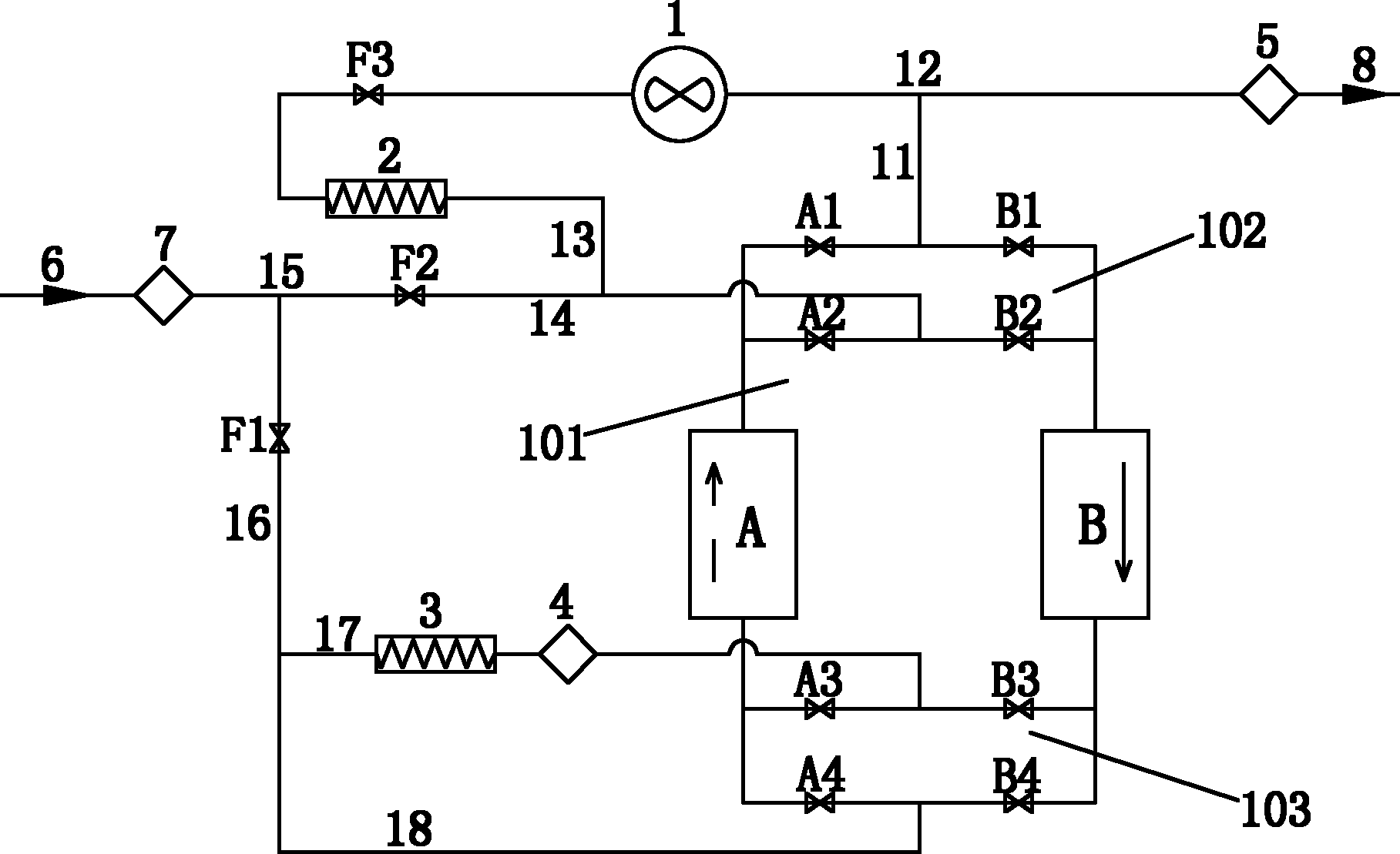

[0037] The adsorption drying method utilizing compression heat regeneration mainly includes the following steps:

[0038] 1] The raw material gas first flows through the regenerated adsorbent at full flow, uses the waste heat of the raw gas to heat the regenerated adsorbent, and then flows through the adsorbed adsorbent, and the above gas is dried by the adsorbent to absorb moisture and become Product gas discharge;

[0039] 2] After cooling and separating the raw material gas, it flows through the adsorbent for adsorption in step 1. After the moisture in the adsorbed raw material gas is dried, it becomes product gas, part of the product gas is discharged, and part of the product gas enters step 3 for processing; enter step 3 or Part of the gas processed in step 4 is 4 to 10% of the total finished product in step 2, preferably 5 to 7%, and the ratio can be adjusted according to specific conditions in actual production;

[0040] 3] Part of the product gas generated in step 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com