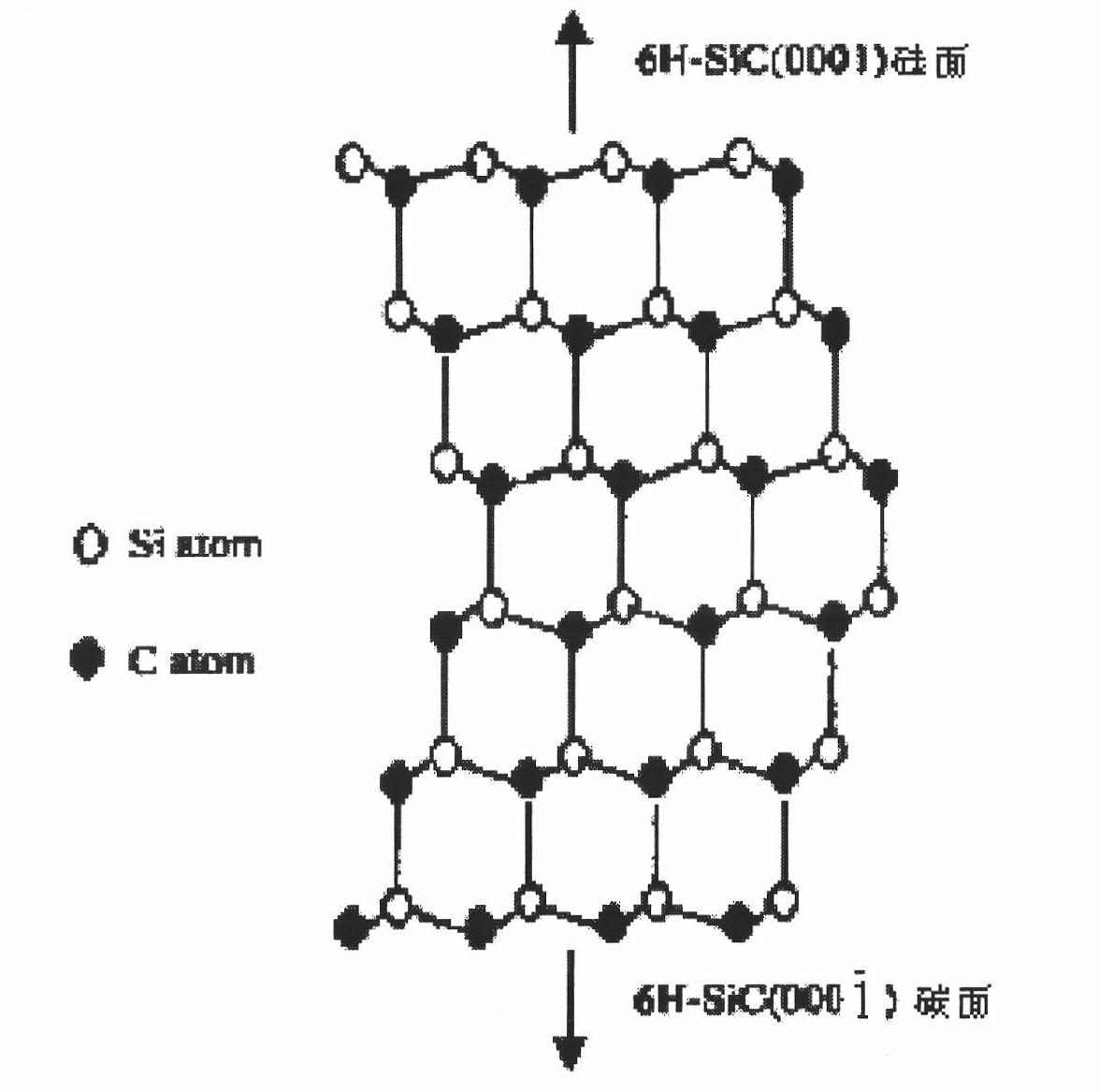

Method for growing graphene on large-diameter 6H-SiC carbon surface

A graphene and 6h-sic technology, applied in the field of microelectronic materials, can solve the problems of difficulty in controlling the number of graphene layers and the difficulty of chemical mechanical polishing, etc., and achieve the effect of fewer layers, low cost and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

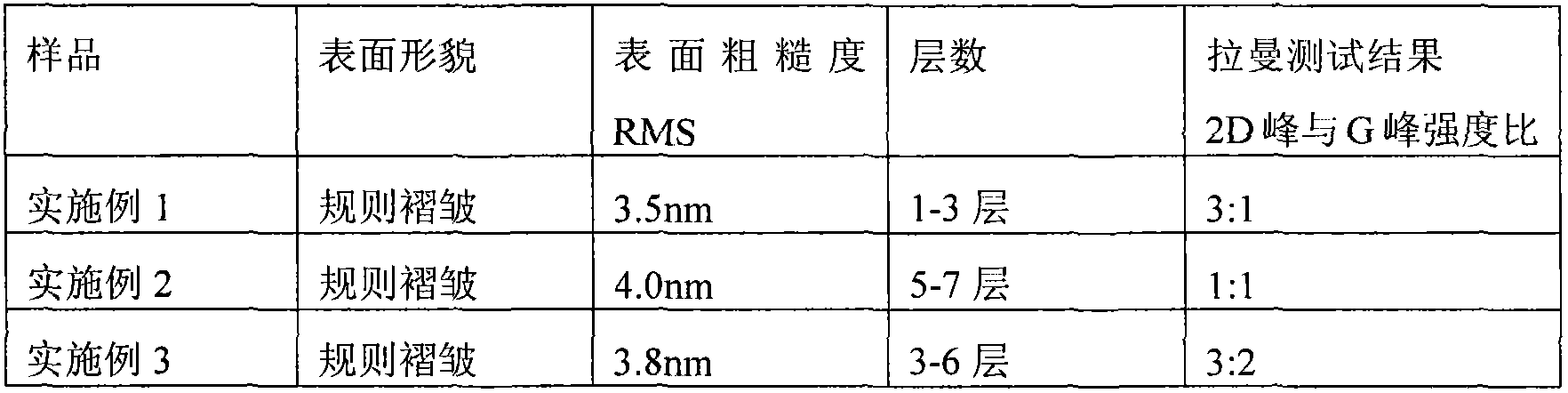

Embodiment 1

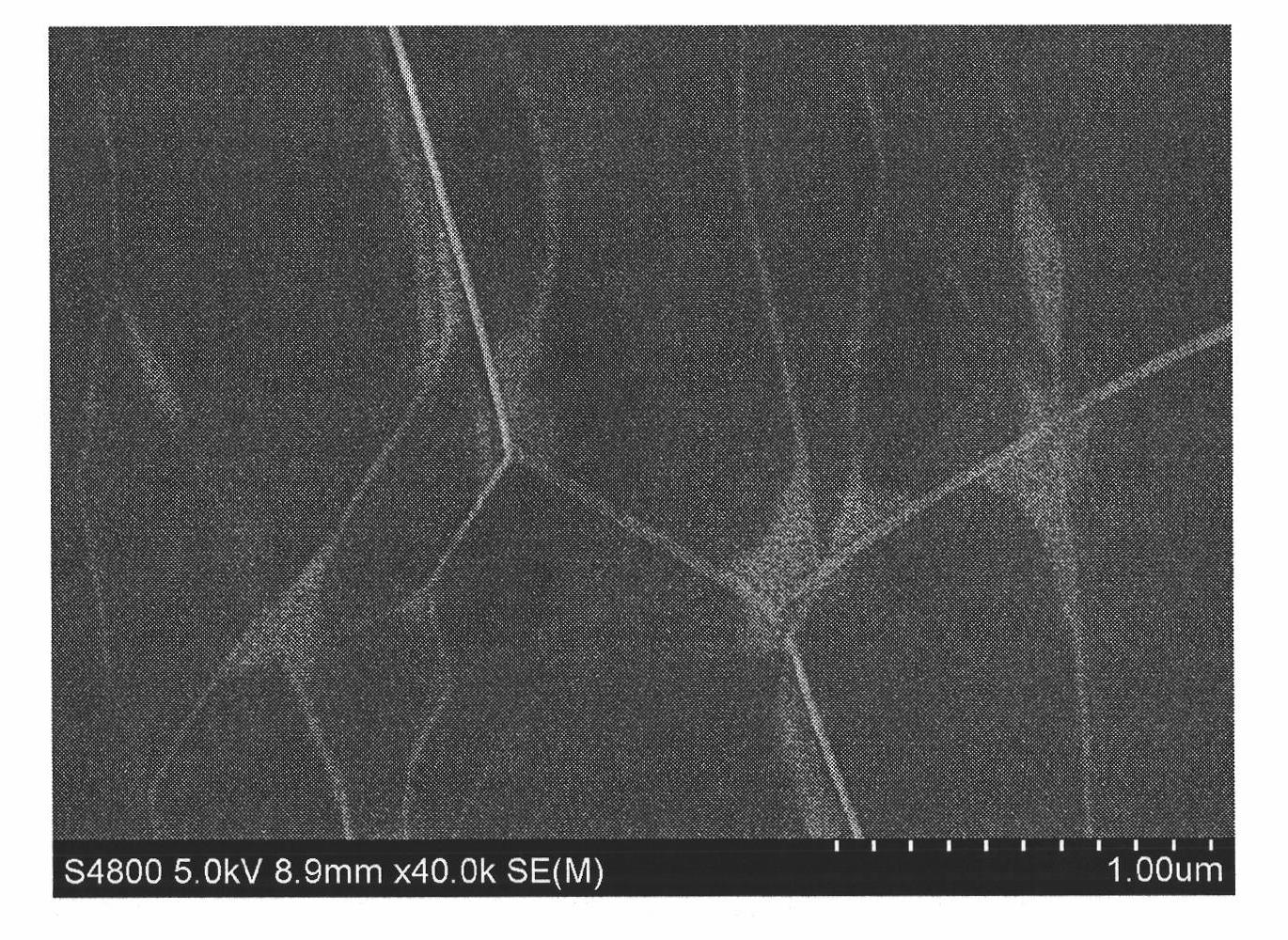

[0038] A method for preparing graphene on a large-diameter 6H-SiC carbon surface, comprising the steps of:

[0039] 1) Polish and clean the carbon surface of a 6H-SiC wafer with a diameter of 3 inches, so that the surface roughness of the carbon surface is less than 0.3nm, and the flatness is less than 5μm, to obtain 6H-SiC with a thickness of 350μm and regular atomic steps on the surface. Among them, the carbon surface polishing of 6H-SiC wafer adopts chemical mechanical polishing method, and the steps are as follows:

[0040] Diamond micropowder (produced by Hengyuan Diamond Micropowder Factory, Zhecheng County, Henan Province) with a particle size of 2 μm, and oxidizing agent sodium hypochlorite and dispersant sodium silicate in a mass ratio of 1:0.1:0.03 are used to prepare a polishing solution with a pH of 5. The liquid has good fluidity, good suspension performance, non-toxicity, and is easy to clean; after the polishing liquid is prepared, it is placed in the polishing ...

Embodiment 2

[0044] A method for preparing graphene on a large-diameter 6H-SiC carbon surface, comprising the steps of:

[0045] 1) The carbon surface of the 6H-SiC wafer is polished and cleaned, as in Example 1.

[0046] 2) Place the processed 6H-SiC sample in the tray of the high temperature growth furnace crucible, with the carbon side facing up, and vacuumize to 1×10 -7 mbar, quickly increase the power to 1750°C, the heating rate is 80°C / min, pass high-purity argon (purity 99.999%), the flow rate is 10L / min, the pressure is controlled at 850mbar, and then slowly increase the power to heat up to 1950°C , the heating rate is 10° C. / min, and the growth of graphene is completed after 1 min of heat preservation. The number of graphene layers is 5-7 layers, and the graphene covers the entire surface of the substrate.

[0047] 3) Turn off the argon gas, pass the hydrogen gas at a large flow rate, the hydrogen gas flow rate is 5L / min, the pressure is controlled at 850mbar, and the temperatur...

Embodiment 3

[0049] A method for preparing graphene on a large-diameter 6H-SiC carbon surface, comprising the steps of:

[0050] 1) The carbon surface of the 6H-SiC wafer is polished and cleaned, as in Example 1.

[0051] 2) Put the processed 6H-SiC sample in the tray of the crucible of the high temperature growth furnace, and evacuate to 1×10 -7 mbar, quickly increase the power to heat up to 1730°C, the heating rate is 50°C / min, pass high-purity argon (purity is 99.999%), the flow rate is 8L / min, the pressure is controlled at 880mbar, and then slowly increase the power to heat up to 1900°C , the heating rate is 5° C. / min, and after 5 minutes of heat preservation, the growth of graphene is completed. The number of graphene layers is 3-6 layers, and the graphene covers the entire surface of the substrate.

[0052] 3) Turn off the argon gas, pass the hydrogen gas at a large flow rate, the hydrogen gas flow rate is 8L / min, the pressure is controlled at 880mbar, and the temperature is rapidl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com