Asphalt pavement in-place hot recycling heating device

A technology for asphalt pavement and heating device, which is applied to roads, roads, road repair and other directions, can solve problems such as insufficient heat energy transfer, increase greenhouse gas emissions, and be unfavorable to environmental protection, achieve huge social and economic benefits, and improve heating depth. and temperature, the effect of improving the utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

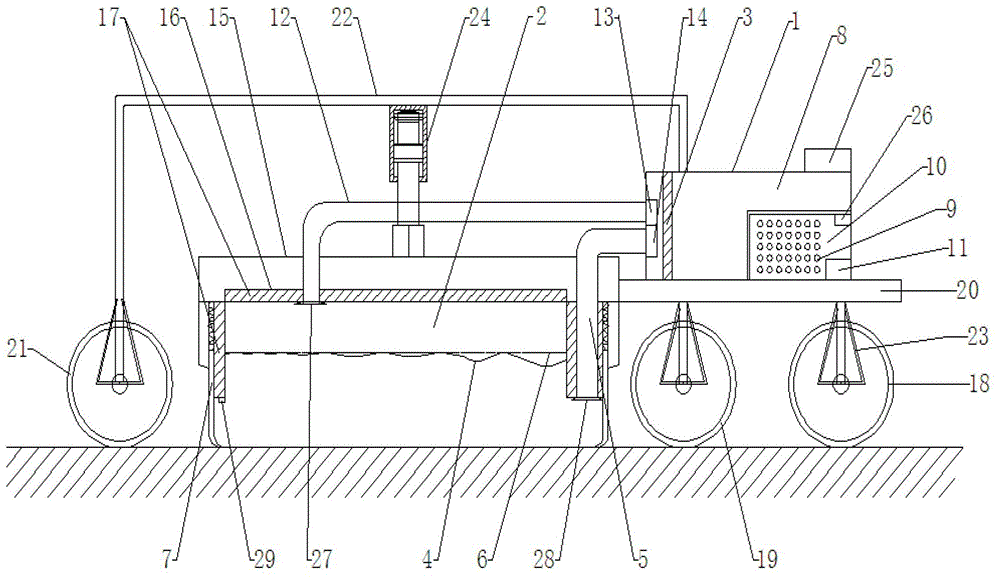

[0019] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure: the in-situ thermal regeneration heating device for asphalt pavement in this embodiment includes a running mechanism and a heating system installed on the running mechanism for heating the asphalt pavement; the heating system It includes a hot wind generating device 1 for generating hot air and a heating chamber 2 for directing the hot air to the asphalt pavement to heat the asphalt pavement; the lower end of the heating chamber 2 is open and the open end is buckled to the asphalt pavement to close; The cavity 2 and the hot air generating device 1 are circulated through the air inlet channel 12 and the return air channel 5, and can be fixed around the heating cavity 2 by elastic rubber plates that can be elastically pressed against the road surface or slide around the heating cavity 2 in the vertical direction The connection setting can be realized by a rigid plate against th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com