Improved water desalination system

A desalination and water-salt technology, applied in the field of desalination systems, can solve the problems of increasing the time required for new equipment permits and construction, ecological problems, high costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

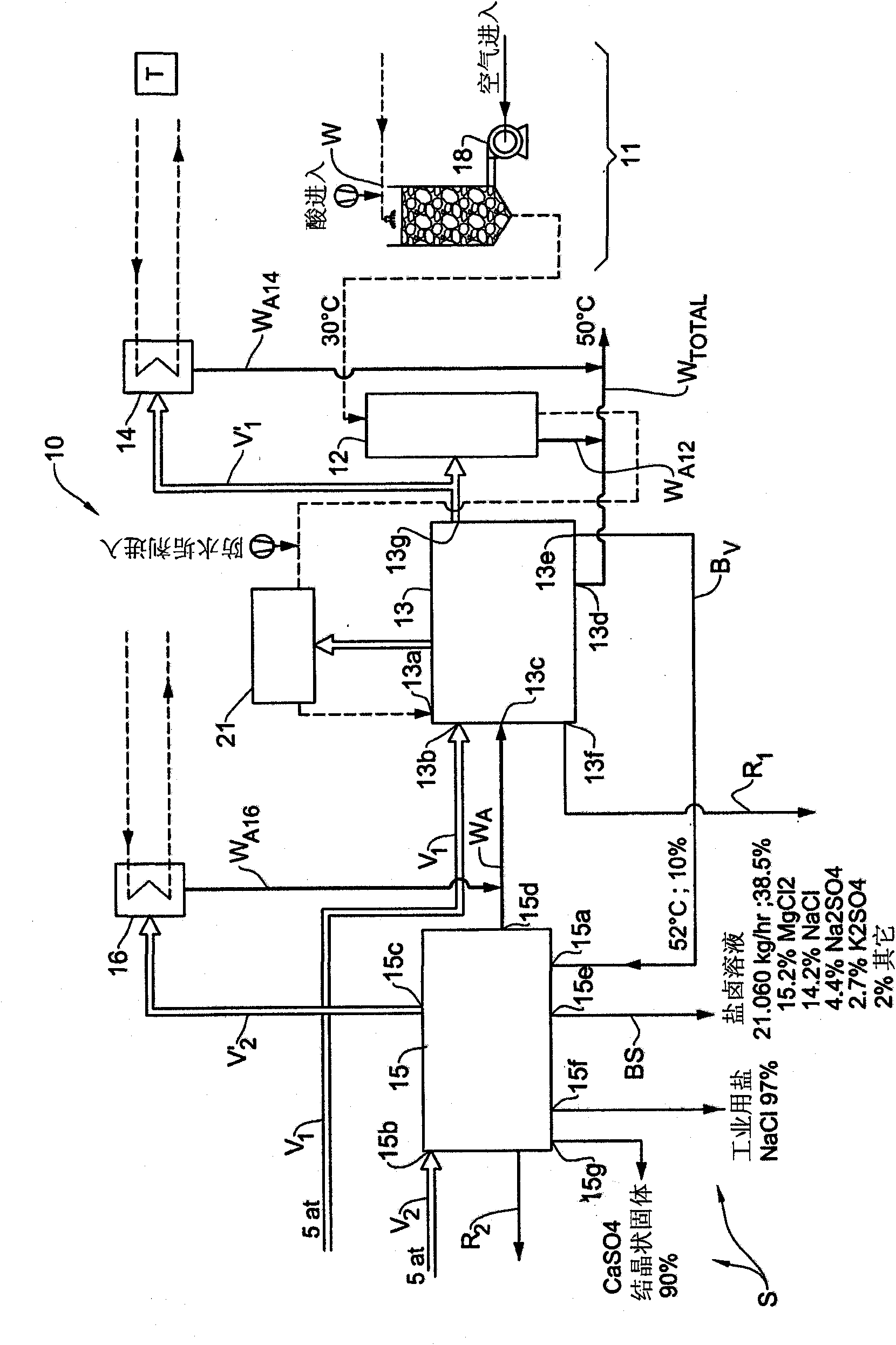

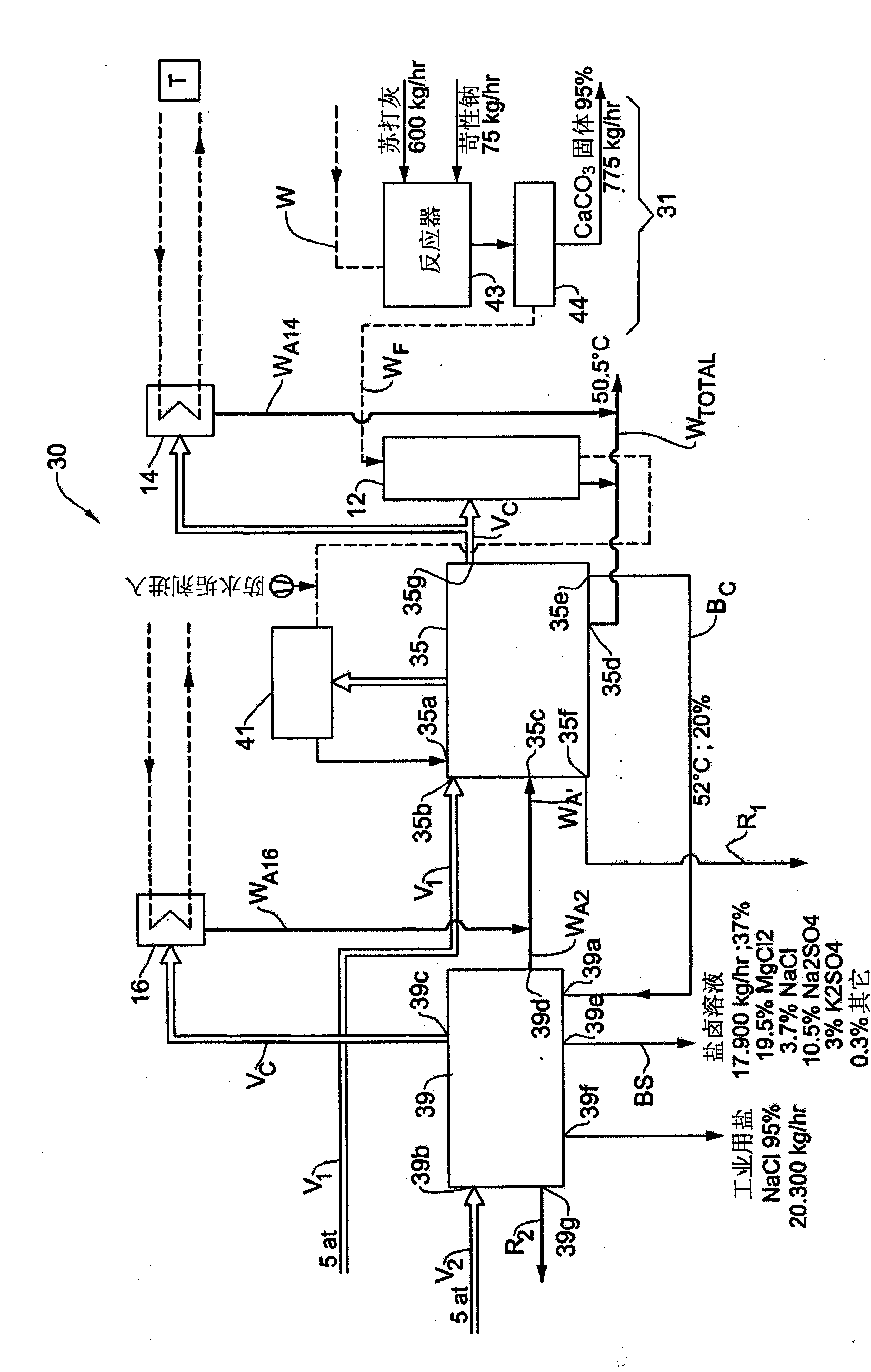

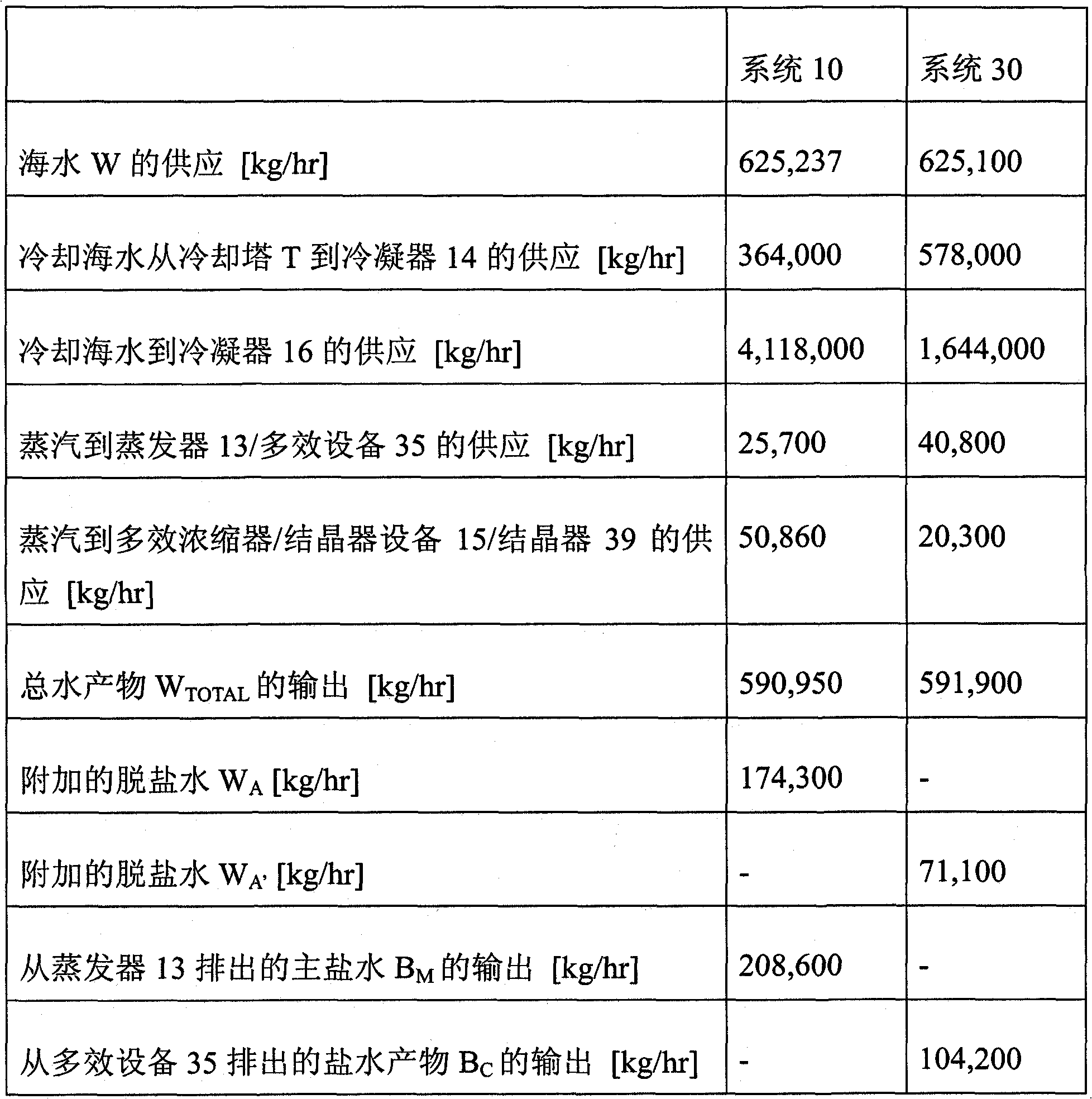

[0036] figure 1 and figure 2 Two examples of systems for seawater desalination according to the invention are schematically shown, designated 10 and 30 respectively.

[0037] The system 10 includes: a pretreatment subsystem 11; a multiple effect evaporator 13, with its associated feedwater heater 21; a concentrator 17 (not shown), combined with a crystallizer 19 (not shown) in a common multiple effect concentrator In the crystallizer / crystallizer apparatus 15, said apparatus 15 has a series of corresponding primary concentration (PC) effects and primary crystallization (PCR) effects. Concentrator 17 and crystallizer 19 may further be two different separate pieces of equipment.

[0038] Similarly, the system 30 includes: a pretreatment subsystem 31; a multiple effect evaporator 33 having associated therewith a feed water heater 41; an evaporator 33 (not shown) combined with a concentrator 37 (not shown) in a common In the multi-effect device 35, there is a series of corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com