Process for refining crude salt

A process and salt washing technology, which is applied in the direction of alkali metal chloride, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems that cannot meet the production of high-quality soda ash and industrial ammonium chloride The quality of industrial ammonium chloride, high investment in brine treatment and other issues, achieved the effect of qualified particle size, reduced loss of raw salt, and reduced scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

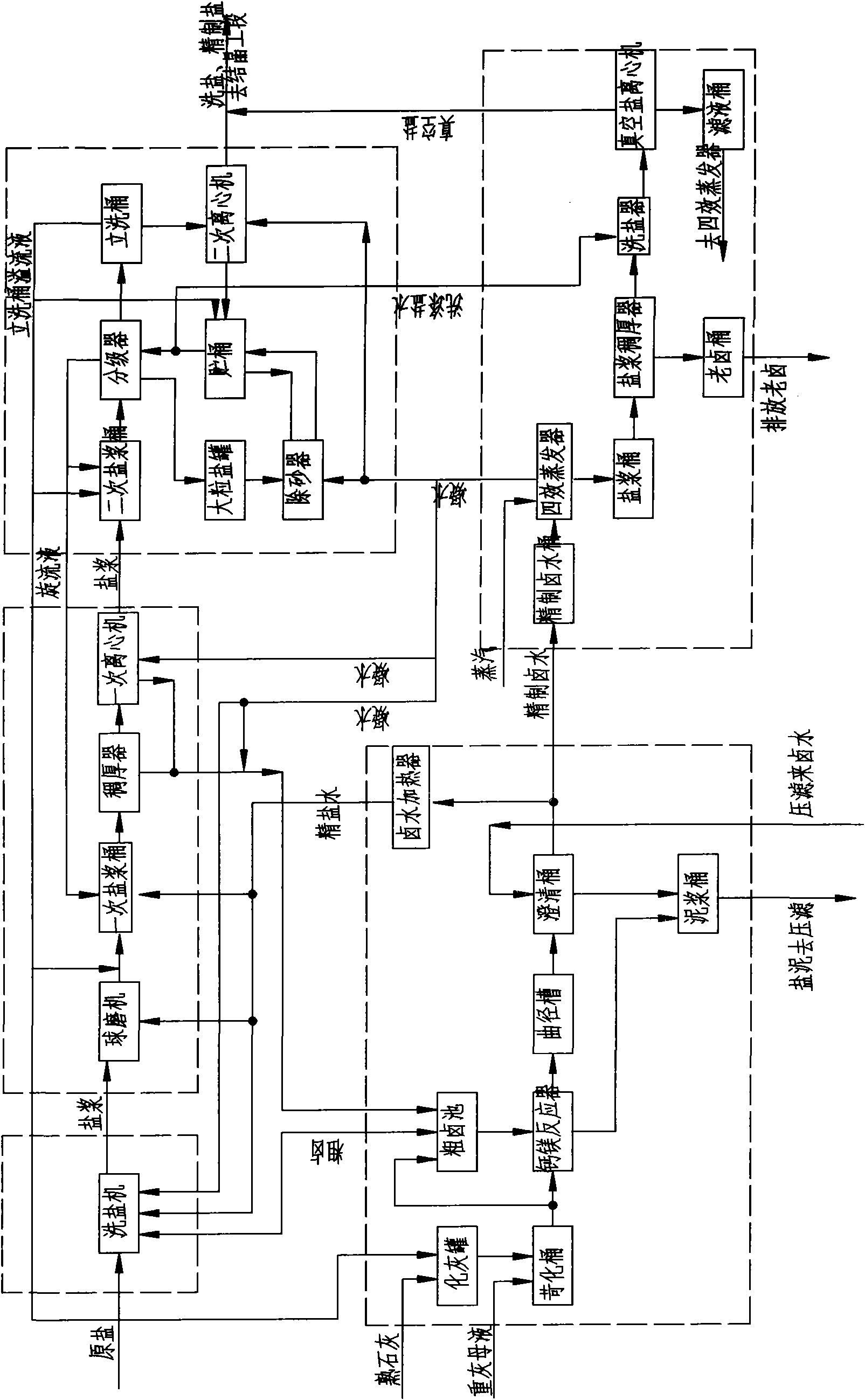

Image

Examples

Embodiment 1

[0054] (1) Salt washing step: (a) Send the raw salt into the salt washing machine, and use SO 4 2- Saturated brine washing solution with a content of not more than 10g / l is countercurrently washed and sent to a ball mill, and the ball mill crushes the raw salt to an average particle size of 0.35 mm and a particle distribution within the particle size range of >70%; (b ) put the pulverized raw salt into the primary salt slurry tank and adjust it to a 30% solid-liquid volume ratio with secondary brine, and then transport the salt slurry to the thickener in turn with a pump. Thick, primary centrifuge adopts condensed water to wash the salt slurry; (C) the salt slurry separated from the primary centrifuge is sent into the secondary salt slurry bucket with SO 4 2- The third-grade brine with a content of not more than 3.76g / l is adjusted so that the solid-liquid ratio is 30%, and then pumped to the classifier for flotation classification, and the qualified salt slurry after classi...

Embodiment 2

[0062] (1) Salt washing step: (a) Send the raw salt into the salt washing machine, and use SO 4 2- Saturated brine washing solution with a content not greater than 10g / l is countercurrently washed and sent to a ball mill, which crushes the raw salt to an average particle size of 0.3 mm and a particle distribution within the particle size range of >70%; (b ) put the pulverized raw salt into the primary salt slurry bucket and adjust it to a 25% solid-liquid volume ratio with a first-grade brine, and then transport the salt slurry to a thickener successively with a pump Thick, primary centrifuge adopts condensed water to wash the salt slurry; (C) the salt slurry separated from the primary centrifuge is sent into the secondary salt slurry bucket with SO 4 2- The third-grade brine with a content of not more than 3.76g / l is adjusted so that the solid-liquid ratio is 25%, and then pumped to the classifier for flotation classification, and the qualified salt slurry after classificat...

Embodiment 3

[0070] (1) Salt washing step: (a) Send the raw salt into the salt washing machine, and use SO4 2- Saturated brine washing solution with a content not greater than 10g / l is countercurrently washed and sent to a ball mill, and the ball mill pulverizes the raw salt to an average particle size of 0.42 mm and a particle distribution within the particle size range of >70%; (b ) put the pulverized raw salt into the primary salt slurry tank and adjust it to a 35% salt slurry depending on the solid-liquid volume ratio with a first-grade brine, and then transport the salt slurry to a thickener successively with a pump Thick, primary centrifuge adopts condensed water to wash the salt slurry; (C) the salt slurry separated from the primary centrifuge is sent into the secondary salt slurry bucket with SO 4 2- The third-grade brine with a content of not more than 3.76g / l is adjusted so that the solid-liquid ratio is 35%, and then pumped to the classifier for flotation classification, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com