Method for production of ethylene oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

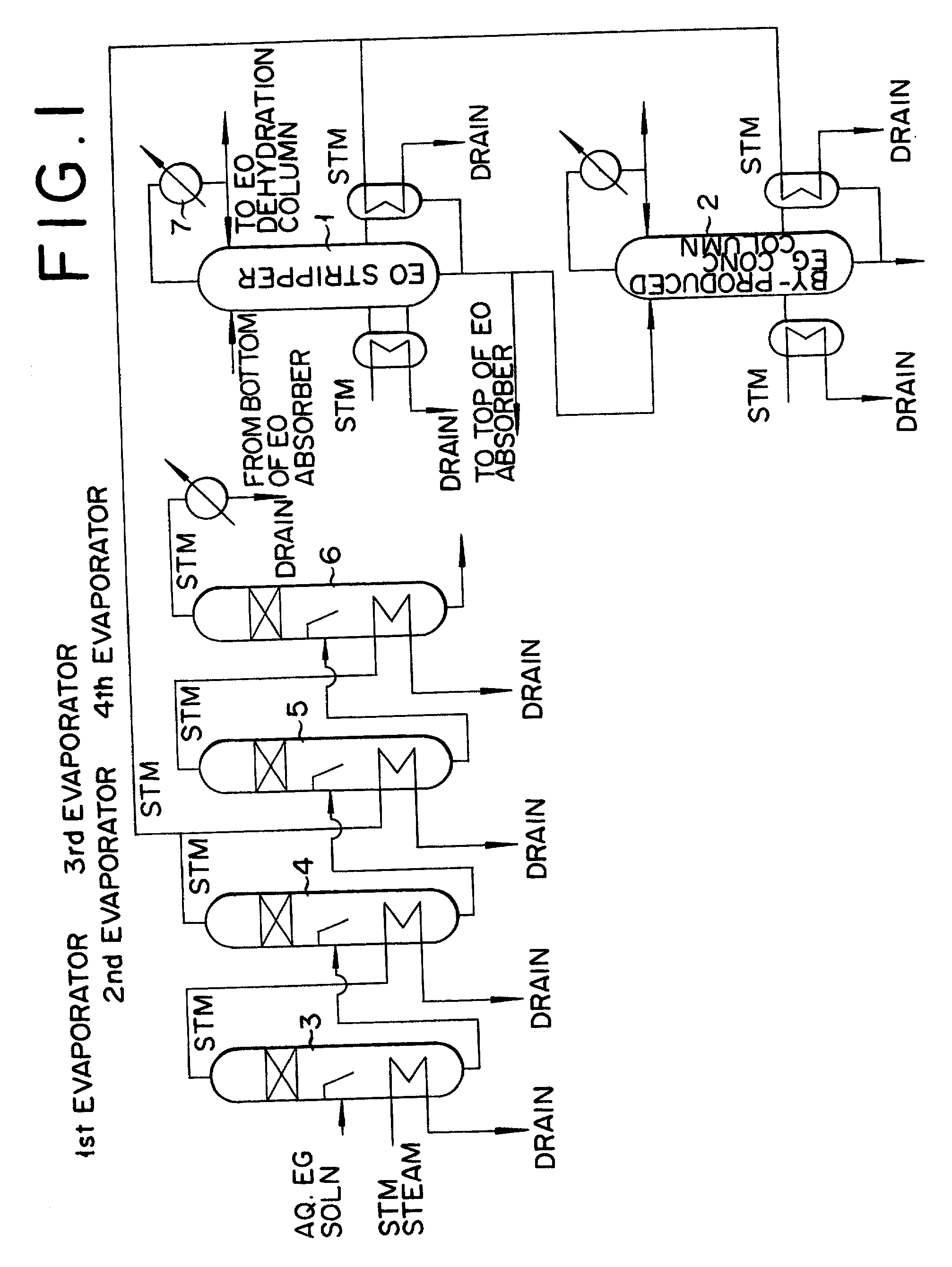

[0024] Now, this invention will be specifically explained below with reference to preferred mode of embodying this invention below.

[0025] The reaction of ethylene oxide with water is carried out under the following conditions. A molar ratio of ethylene oxide and water, namely ethylene oxide:water, is in the range of 1:7-1:50, preferably 1:5-1:30. A reaction pressure is in the range of 0.5-3.0 MPa (Gauge), preferably 1.5-2.5 MPa (Gauge), a reaction temperature is in the range of 120.degree.-250.degree. C., preferably 130.degree.-180.degree. C., and a concentration of the formed ethylene glycol was in the range of 5-40 mass %. The reaction is carried out in the batch-wise, the semibatch-wise, or the continuously, which ever fits the occasion best. The ethylene glycol thus obtained is supplied to the multi-effect evaporator and concentrated and dehydrated till a concentration of 40-95 mass % or over.

[0026] The number of multi-effect evaporators is described in detail at pages 428-431 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com