High-concentration organic waste water evaporating and concentration processing method

An organic wastewater, evaporation and concentration technology, applied in the direction of heating water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of low separation efficiency and high COD of wastewater, and achieve high organic content and concentration The effect of high multiple and reduction of incineration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

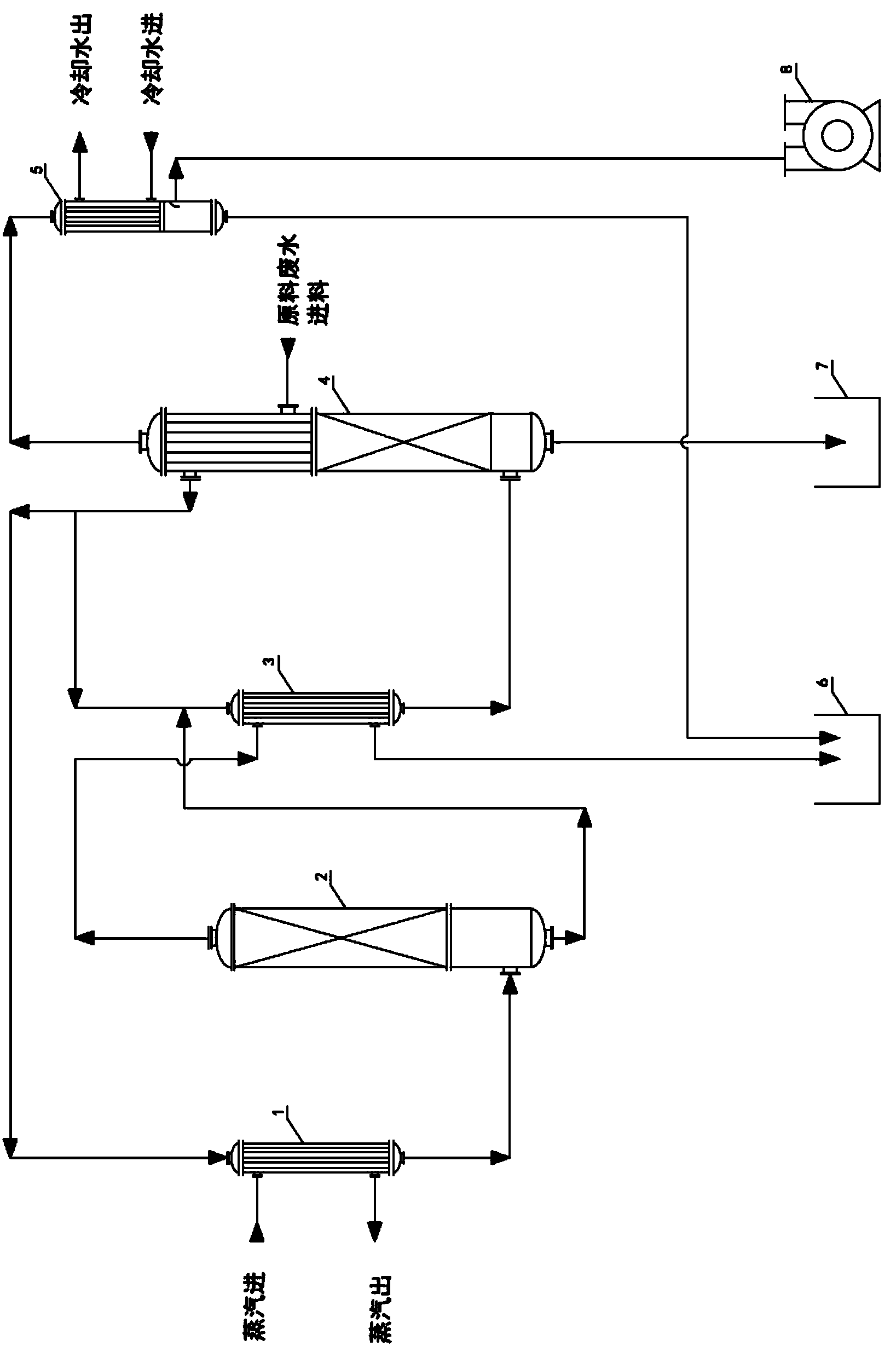

Method used

Image

Examples

Embodiment 1

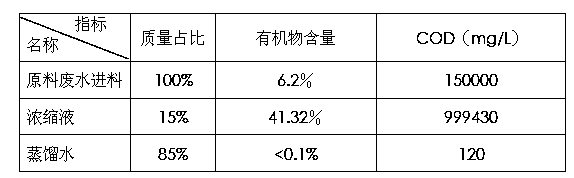

[0026] Implementation example 1: A kind of equipment cleaning wastewater in the organic solvent industry, with COD as high as 150,000mg / L, containing 6.2% organic matter (such as toluene, xylene, ethyl acetate and other organic matter).

[0027] After the above wastewater is treated by the method of the present invention, 15 parts of concentrated liquid can be obtained from 100 parts of organic wastewater, and the remaining 85 parts are distilled water, and the organic matter content is less than 0.1% (COD: 120mg / L). During subsequent treatment, the concentrated liquid that needs to be incinerated at high temperature is reduced by 85%; the COD of distilled water is very low, and the oxidative degradation is also very fast and easy, so it has a good economic prospect. The specific waste water inflow and outflow are as follows:

[0028]

Embodiment 2

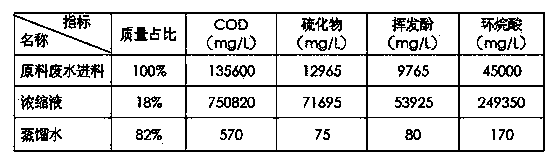

[0029] Implementation example 2: Treatment of alkali slag wastewater in oil refineries In the process of petroleum refining and processing, an alkali washing process is usually used to remove sulfides in oil products. Various alkali slag wastewater of organic matter. In this example, the source of sewage is catalytic diesel alkali residue wastewater from an oil refinery, in which COD is 135600mg / L, sulfide is 12965mg / L, volatile phenol is 9765mg / L, and naphthenic acid is 4.5%.

[0030] After the above-mentioned alkali slag waste water is through settling and filtering, after being processed by the method of the present invention, the result is as follows

[0031] surface:

[0032]

[0033] After the treatment, the volume of the concentrated liquid to be incinerated is reduced by 82%, and the COD of the distilled water is reduced to 570mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com