Low temperature multiple-effect distillation seawater desalination system and process flow thereof

A technology of multi-effect distillation and process flow is applied in the process field of preheating feed seawater, which can solve problems such as low desalination efficiency, and achieve the effect of saving cost and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

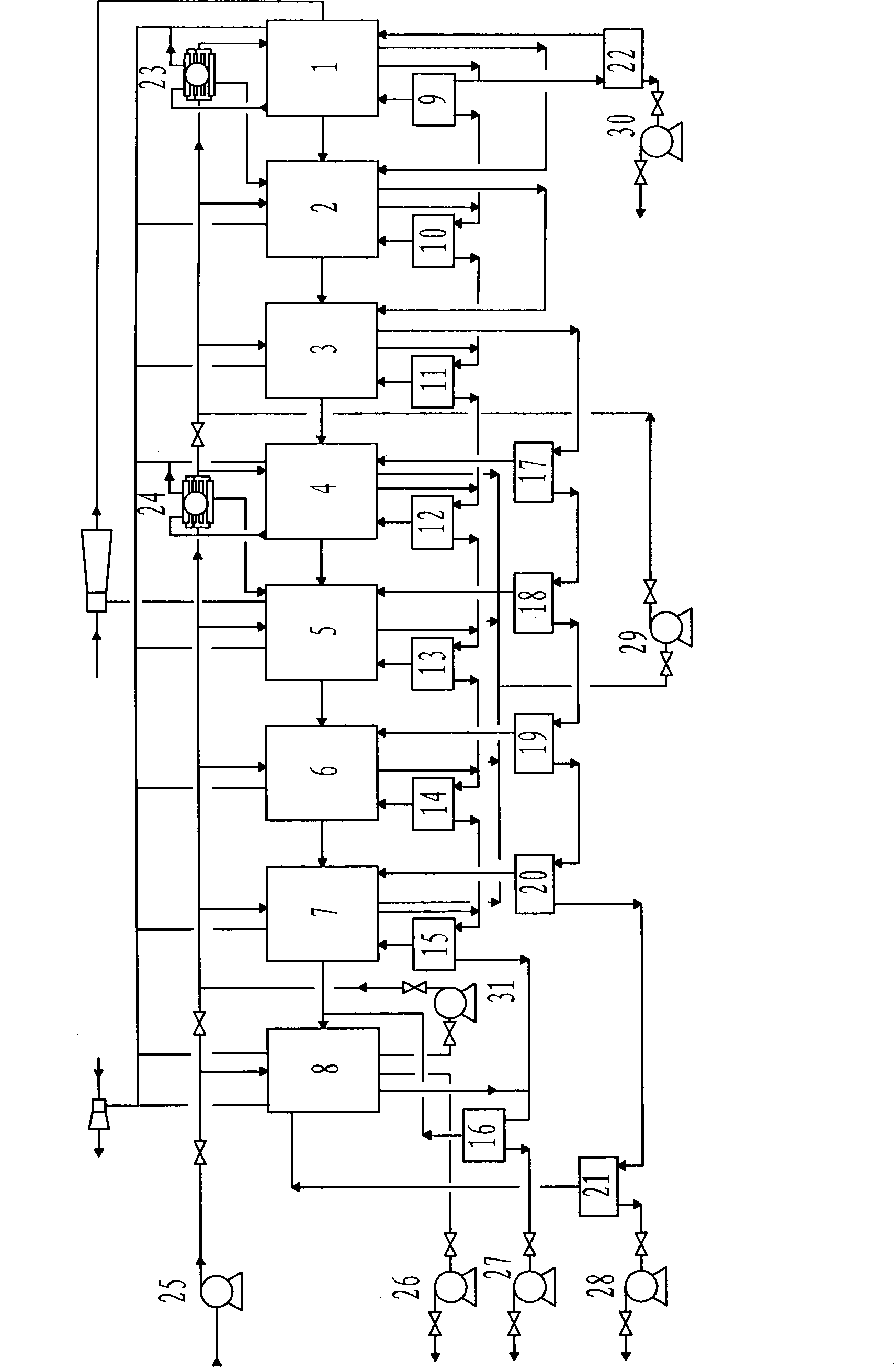

[0030] An embodiment shown in the accompanying drawing is a 7-effect group preheating feed process. In the accompanying drawing, the evaporator is divided into two evaporation groups. The first to third effect evaporators are the first evaporation group, and the fourth to third effect evaporators are the first evaporation group. The 7th effect evaporator is the second evaporation group. Take this embodiment as an example to further describe its technological process below:

[0031] First, raw seawater enters the condenser 8, part of it is discharged through the cooling water pump 26 after preheating, and the remaining part enters the second evaporation group through the feed pump 31 as feed seawater. In the second evaporation group, the seawater enters the 4th to 7th effects in parallel. Before feeding the 4th effect, the seawater is preheated by the heater 24 first. The 24 heater uses the secondary steam of the 4th effect to preheat the raw water. The preheated seawater ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com