Normal-pressure continuous seawater desalting system based on hydrate method and use method of desalting system

A technology for the generation of hydrates and hydrates, applied in chemical instruments and methods, seawater treatment, water/sewage treatment, etc. It can solve the problems of seawater desalination technology efficiency and yield limitation, discontinuous freshwater production, etc., and achieve debugging and use methods. Simple, well-structured, and easy to reuse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described below in conjunction with accompanying drawing and specific embodiment:

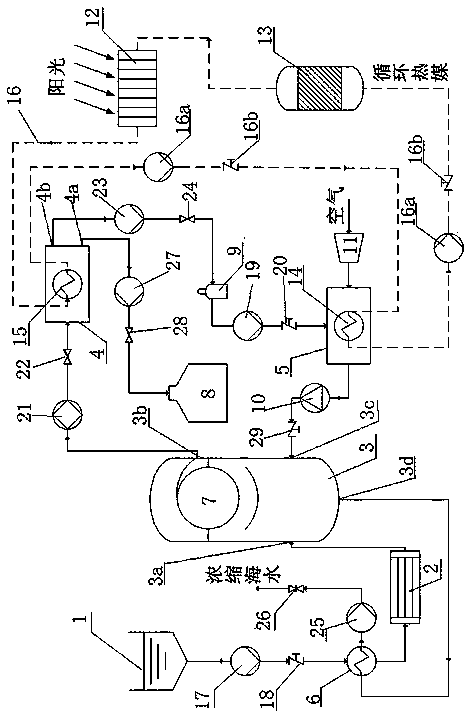

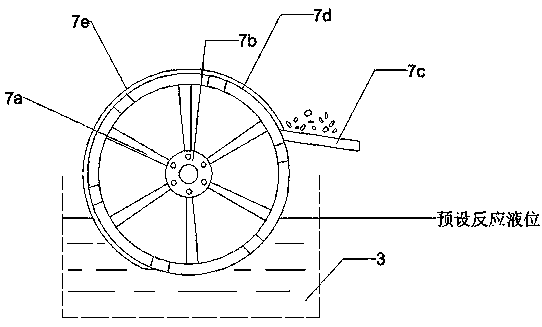

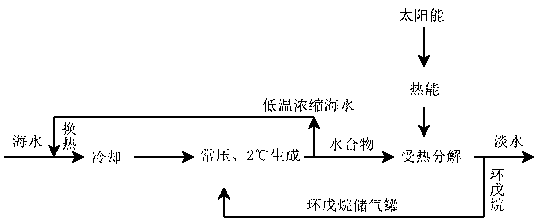

[0024] figure 1 It is a structural schematic diagram of an atmospheric continuous seawater desalination system based on the hydrate method. An atmospheric continuous seawater desalination system based on the hydrate method, comprising a seawater pool 1, a cooler 2, a hydrate generation chamber 3, a heat exchange decomposer 4 and a steam generator 5, a seawater pool 1, a cooler 2, a hydration The substance generation chamber 3 and the heat exchange decomposer 4 are connected sequentially through connecting pipelines; a heat exchanger 6 is connected between the input end of the seawater pool 1 and the cooler 2; the hydrate generation chamber 3 is a hollow cavity structure, and the hydrate The side wall of the generation chamber 3 is provided with a cooling seawater input port 3a, a hydrate output port 3b and a gasified cyclopentane input port 3c, and the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com