Method for treating riboflavin fermentation waste water

A technology for fermented wastewater and treatment methods, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve the problem of sludge treatment capacity decline, odorous gas polluting the environment, and affecting sewage treatment and other problems, to achieve the effect of solving B/C value, saving water resources, and easy biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Raw wastewater quality index: PH value: 6.4, COD: 26970mg / L, BOD 5 : 21830mg / L, NH 3 -N: 3520mg / L, SS (suspended matter): 2787 mg / L.

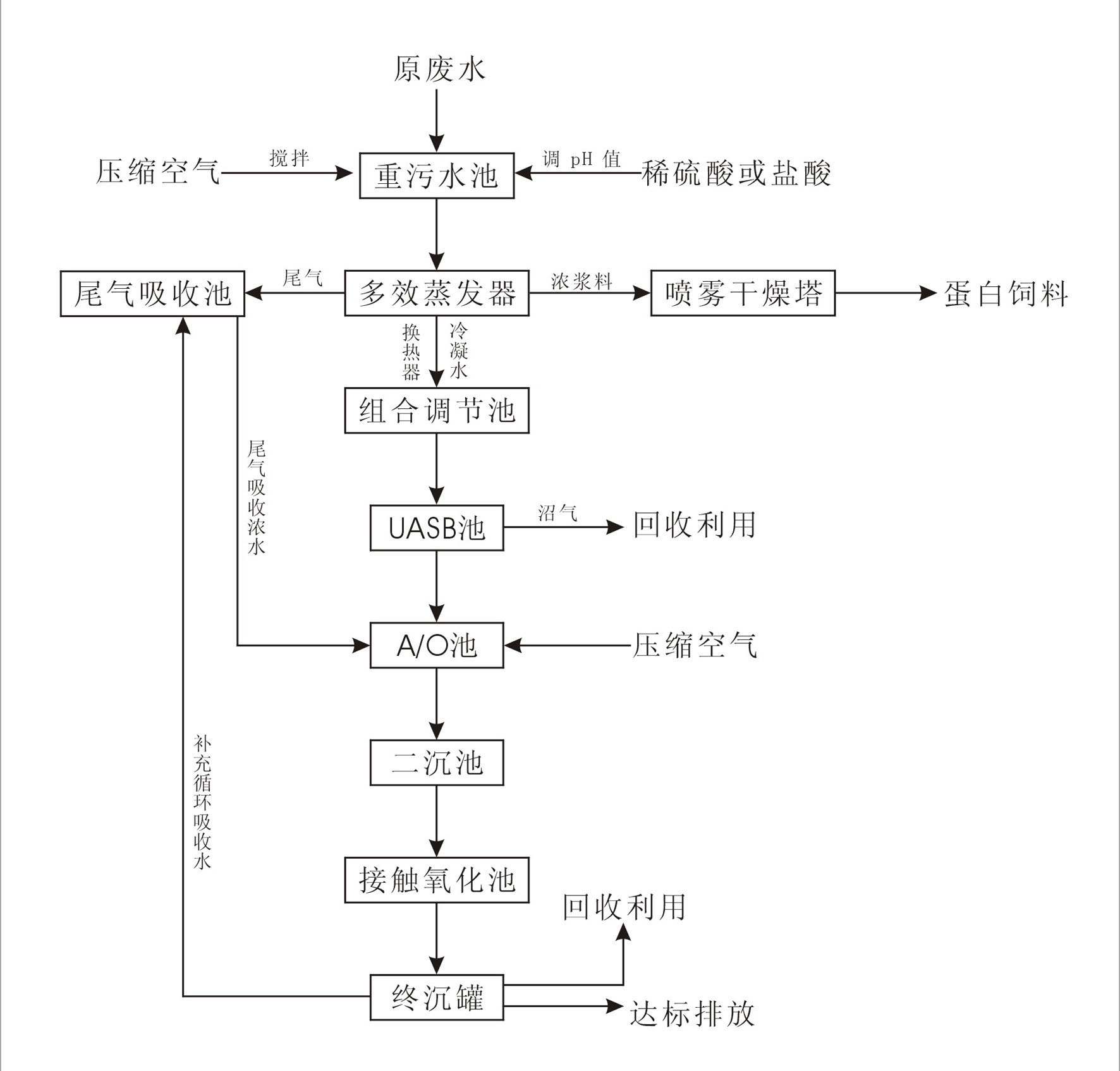

[0017] Pour the original wastewater into a heavy sewage tank, add a certain amount of dilute sulfuric acid or hydrochloric acid under compressed air stirring, adjust the pH between 4.5 and 6.0, and send it to a multi-effect evaporator for concentration and drying after the water quality is uniform. The concentrated slurry is sent to the spray drying tower to be dried into protein feed particles (or into a drum dryer to be dried and crushed into protein feed powder). The condensed water condensed in the multi-effect evaporator enters the combined adjustment tank, adjusts and mixes with domestic sewage or other clean sewage, heats it at medium temperature (35-40°C), and enters the UASB pool. After treatment, the supernatant overflows The flow enters the A / O pond, and the generated biogas is recycled. The tail gas produced in the multi-effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com