MVR (Mechanical Vapor Recompression) continuous evaporative crystallization system and continuous evaporative crystallization method

A technology of evaporative crystallization and evaporator, applied in the field of MVR continuous evaporative crystallization system, can solve the problems of no significant advantage of MVR system, increased complexity of MVR system, fine crystal grain size, etc., and achieves small footprint, compact equipment, required small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

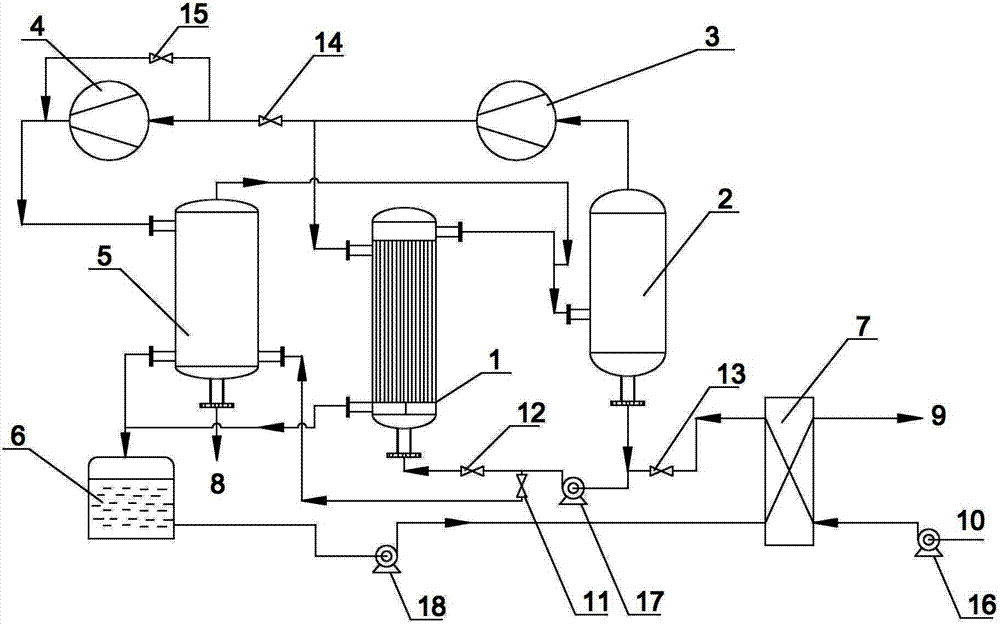

[0046] A MVR continuous evaporation and crystallization system, said system includes an evaporator 1, a vapor-liquid separator 2, a main water vapor compressor 3, an auxiliary water vapor compressor 4 and a crystallizer 5;

[0047] The outlet of the evaporator 1 is connected to the inlet of the vapor-liquid separator 2, and the top outlet of the vapor-liquid separator 2 is connected to the main water vapor compressor 3, and the main water vapor compressor 3 is communicated with the top inlet of the evaporator 1; Described main water vapor compressor 3 is provided with the branch pipeline that is connected into crystallizer 5 on the communicating pipeline of evaporator 1 top entrance, and described branch pipeline is provided with auxiliary water vapor compressor 4; The vapor-liquid separator The outlet at the bottom of 2 is respectively connected to the inlet of evaporator 1 and crystallizer 5; the top of crystallizer 5 is connected to the inlet of vapor-liquid separator 2.

...

Embodiment 2

[0051] Such as figure 1 Shown, a kind of MVR continuous evaporation crystallization system, described system comprises evaporator 1, gas-liquid separator 2, main water vapor compressor 3, auxiliary water vapor compressor 4 and crystallizer 5;

[0052] The outlet of the evaporator 1 is connected to the inlet of the vapor-liquid separator 2, and the top outlet of the vapor-liquid separator 2 is connected to the main water vapor compressor 3, and the main water vapor compressor 3 is communicated with the top inlet of the evaporator 1; Described main water vapor compressor 3 is provided with the branch pipeline that is connected into crystallizer 5 on the communicating pipeline of evaporator 1 top entrance, and described branch pipeline is provided with auxiliary water vapor compressor 4; The vapor-liquid separator The outlet at the bottom of 2 is respectively connected to the inlet of evaporator 1 and crystallizer 5; the top of crystallizer 5 is connected to the inlet of vapor-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com