Mechanical steam recompression continuous evaporative crystallization system and mechanical steam recompression continuous evaporative crystallization method

A mechanical steam, evaporation and crystallization technology, applied in evaporation, solution crystallization, separation methods, etc., can solve the problems of no significant advantages of the MVR system, increased complexity of the MVR system, poor crystallization effect, etc., and achieves a small footprint and no need for Steam boiler, the effect of compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

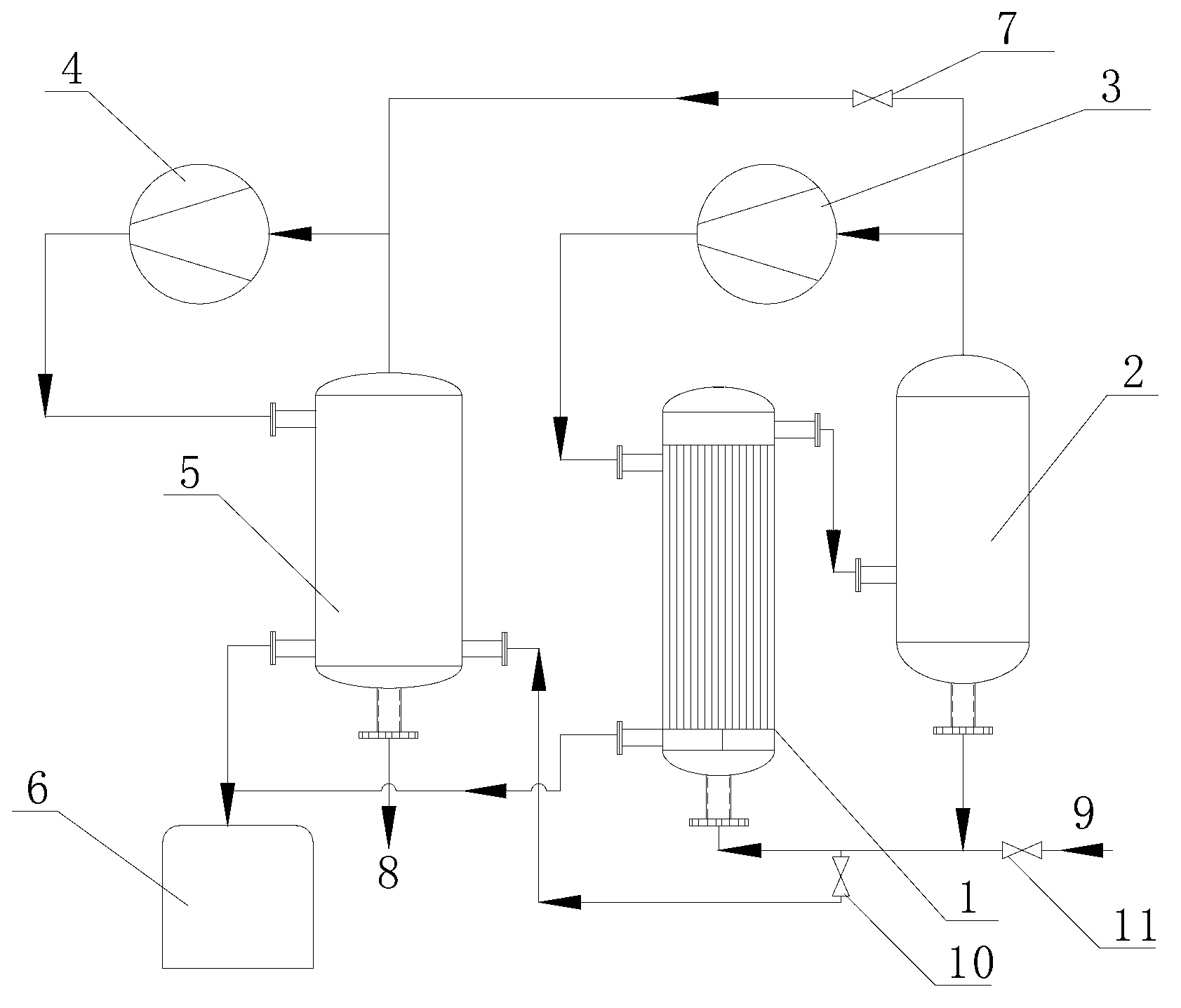

[0043] Such as figure 1 Shown, a kind of mechanical vapor recompression continuous evaporation crystallization system, described system comprises evaporator 1, separator 2, primary water vapor compressor 3, secondary water vapor compressor 4 and crystallizer 5; Said evaporator 1 is connected to the separator 2, and the separator 2 is connected to the primary steam compressor 3, and the primary steam compressor 3 is connected to the evaporator 1; the inlet of the crystallizer 5 is connected to the outlet of the evaporator 1, and the top of the crystallizer is connected to the secondary water The steam compressor 4 and the secondary steam compressor 4 are connected with the crystallizer 5 again.

[0044] The bottom of the separator 2 is connected to the feed pipe 9 of the evaporator 1; the feed pipe 9 is equipped with a tee, and its branch is connected to the discharge throttle valve 10 and then connected to the crystallizer 5 inlet.

[0045] The feed pipe 9 controls feed throu...

Embodiment 2

[0050] The mechanical vapor recompression continuous evaporation crystallization system of the present invention is used for the recovery of inorganic salts such as sodium chloride and sodium sulfate in papermaking wastewater, so that the wastewater can be discharged or reused up to the standard:

[0051] The papermaking wastewater enters the evaporator 1 to evaporate and then enters the separator 2 for vapor-liquid separation. Most of the separated secondary steam enters the first-stage water vapor compressor 3 to be compressed. The heat source heats the incoming wastewater, and the liquid in the lower part of the separator 2 re-enters the evaporator 1 to continue to evaporate; when the concentration of the wastewater reaches the saturated concentration of sodium chloride or sodium sulfate, open the discharge throttle valve 10 and enter the crystallizer 5 for crystallization;

[0052] Part of the secondary steam separated from the separator 2 passes through the bypass valve 7 ...

Embodiment 3

[0055] The mechanical vapor recompression continuous evaporation crystallization system of the present invention is used for seawater desalination:

[0056] The seawater enters the evaporator 1 to evaporate and then enters the separator 2 for vapor-liquid separation. Most of the separated secondary steam enters the first-stage water vapor compressor 3 to be compressed. After increasing the temperature and pressurization, the enthalpy is increased and enters the evaporator 1 as a heat source. Heating the incoming seawater, the liquid in the lower part of the separator 2 re-enters the evaporator 1 to continue evaporating; when the seawater reaches the saturation concentration, open the discharge throttle valve 10 and enter the crystallizer 5 for crystallization;

[0057] Part of the secondary steam separated from the separator 2 passes through the bypass valve 7 and merges with the secondary steam generated during the crystallization process, enters the secondary water vapor comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com