Patents

Literature

54results about "Separation machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

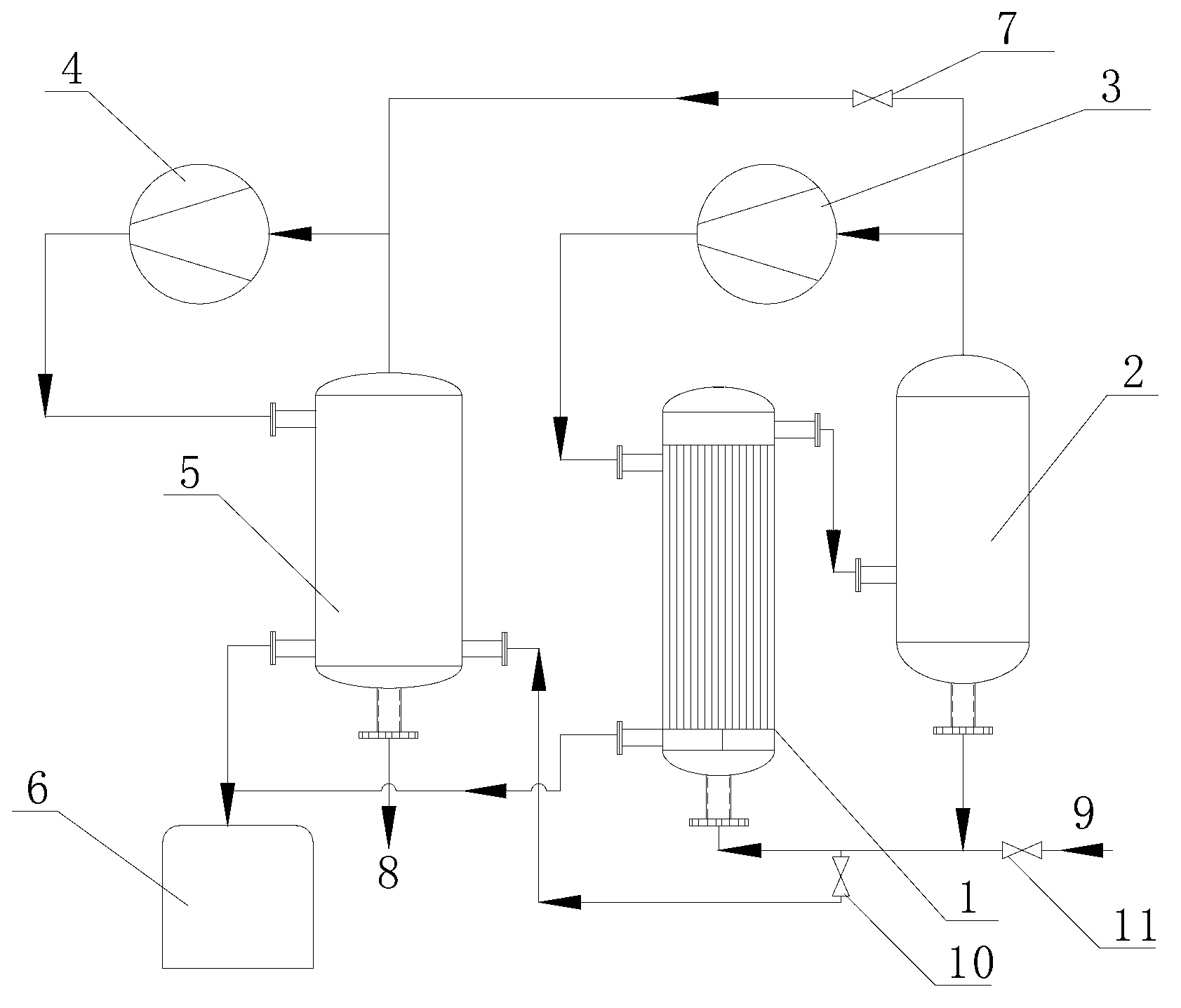

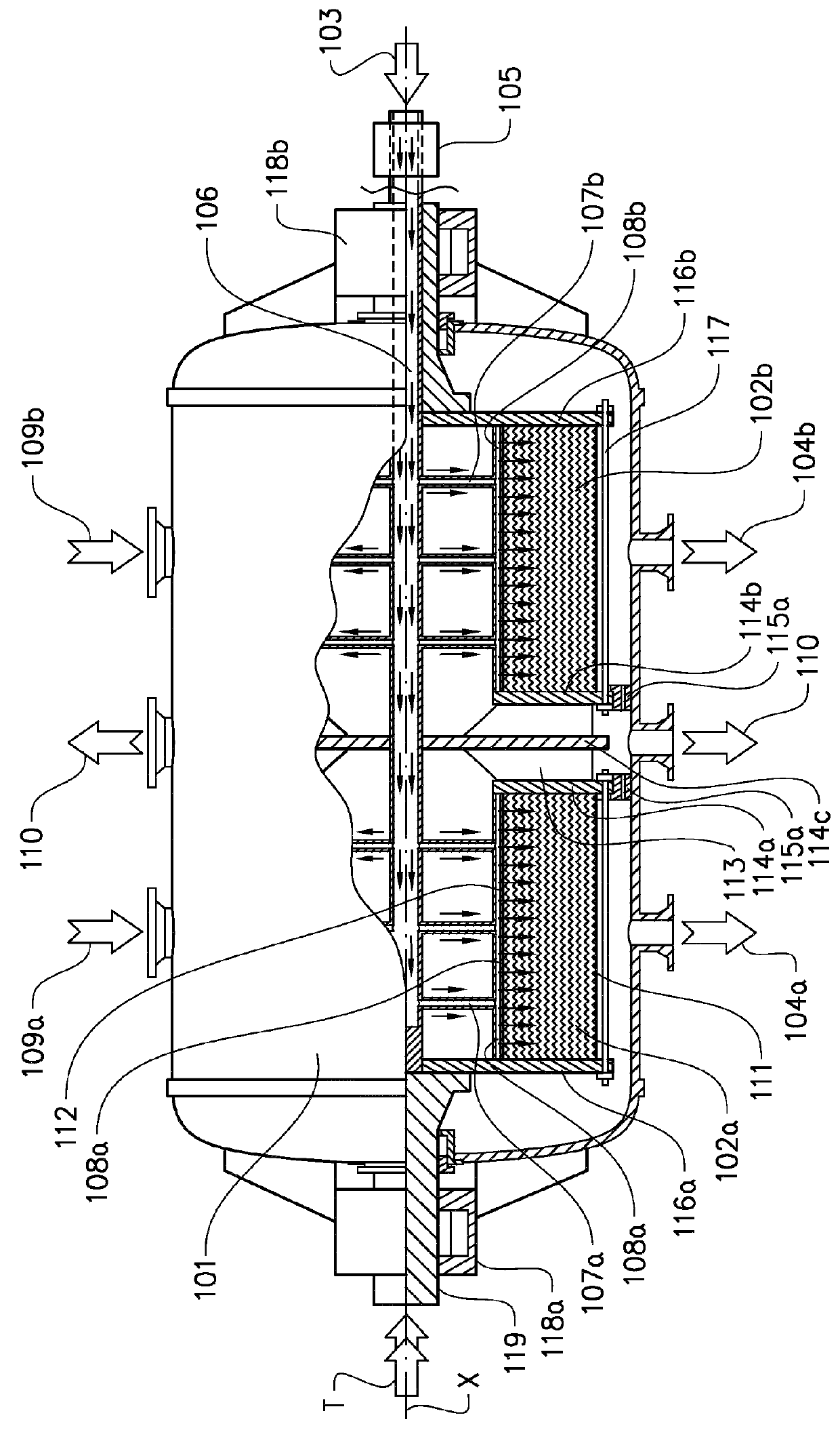

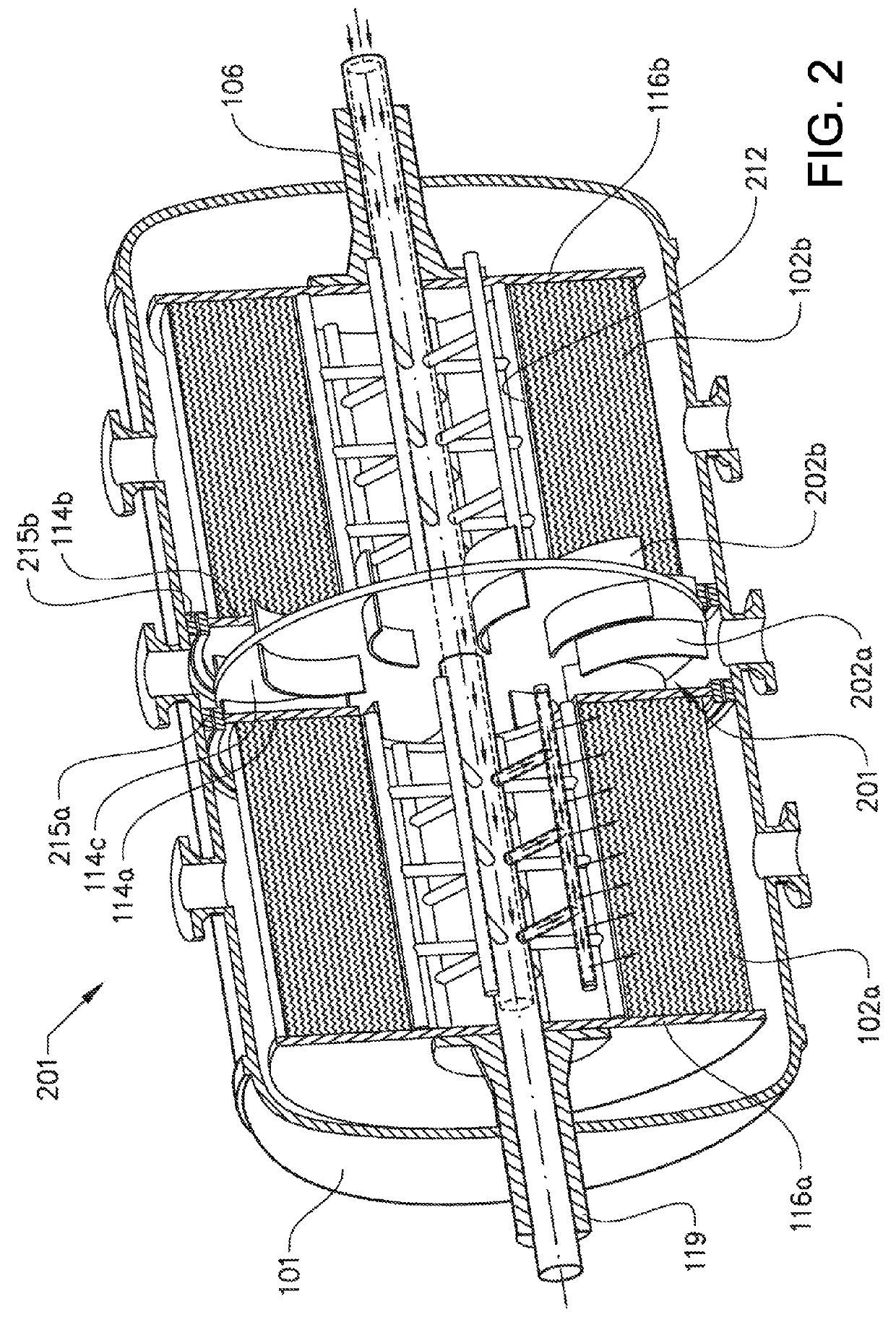

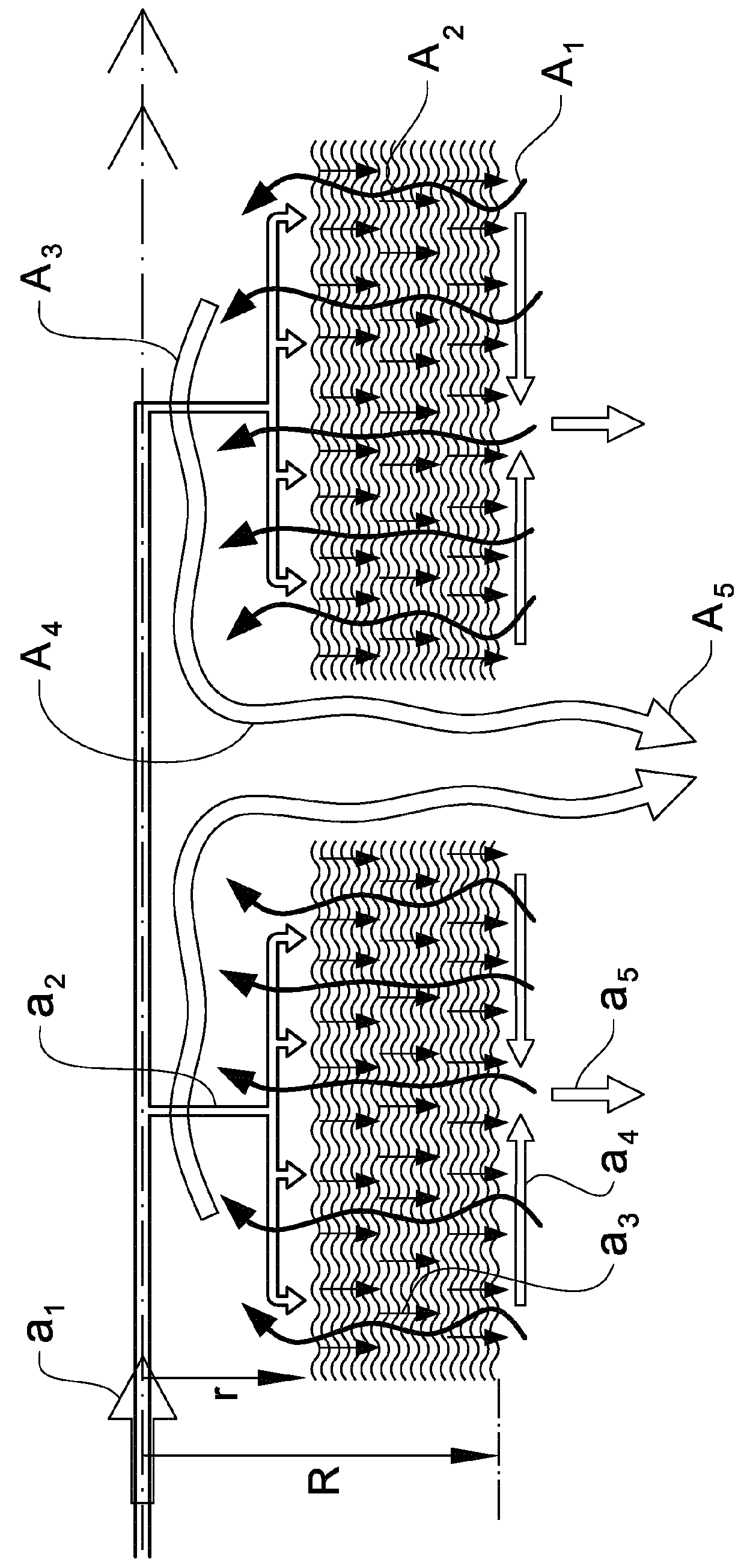

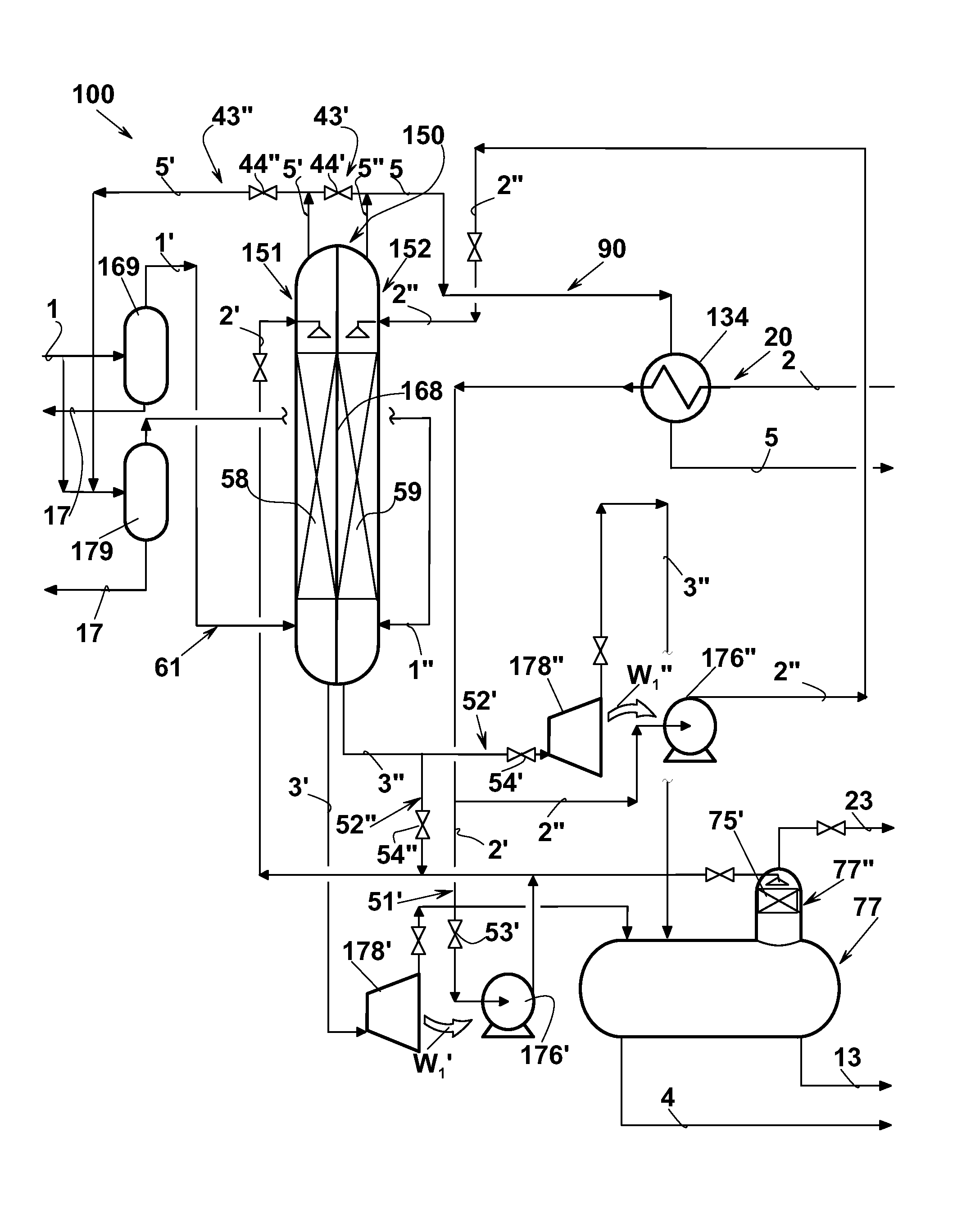

Mechanical steam recompression continuous evaporative crystallization system and mechanical steam recompression continuous evaporative crystallization method

ActiveCN103007553ASmall footprintSave spaceEvaporator accessoriesSolution crystallizationGas compressorEvaporation

The invention relates to a mechanical steam recompression continuous evaporative crystallization system and a mechanical steam recompression continuous evaporative crystallization method. The system comprises an evaporation unit and a crystallization unit, wherein the evaporation unit and the crystallization unit are both provided with water steam compressors; material liquid enters the evaporation unit to be evaporated and subsequently is subjected to gas-liquid separation; the separated secondary steam enters a steam compressor to be compressed, and subsequently enters the crystallization unit to be used as heat source heating material liquid; the material liquid which is evaporated and compressed in an evaporator enters the crystallization unit to be crystallized; the secondary steam generated by crystallization enters the steam compressor to be compressed, subsequently enters the crystallization unit and is used as a heat source for heating the materials in the crystallization unit so as to crystallize the materials; and the crystallized materials are discharged. The system is compact in equipment, small in occupied area and small in desired space, and a cooling system can be omitted; and the secondary steam in the evaporation and crystallization process is sufficiently utilized, the latent heat is recycled, and the heat efficiency is improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

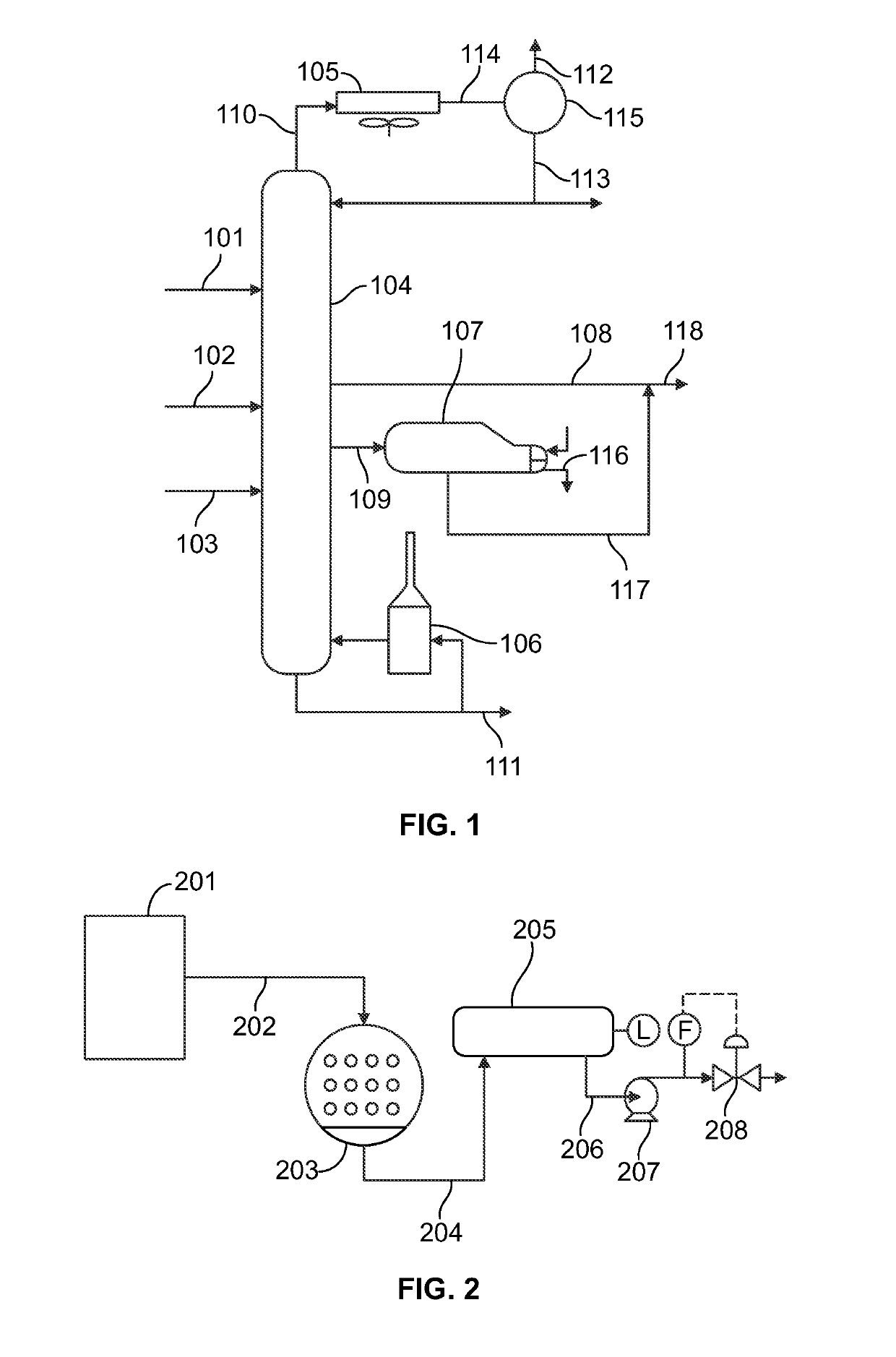

Process to remove product alcohol from a fermentation by vaporization under vacuum

A fermentation liquid feed including water and a product alcohol and optionally CO2 is at least partially vaporized such that a vapor stream is produced. The vapor stream is contacted with an absorption liquid under suitable conditions wherein an amount of the product alcohol is absorbed. The portion of the vapor stream that is absorbed can include an amount of each of the water, the product alcohol and optionally the CO2. The temperature at the onset of the absorption of the vapor stream into the absorption liquid can be greater than the temperature at the onset of condensation of the vapor stream in the absence of the absorption liquid. The product alcohol can be separated from the absorption liquid whereby the absorption liquid is regenerated. The absorption liquid can include a water soluble organic molecule such as an amine.

Owner:GEVO INC

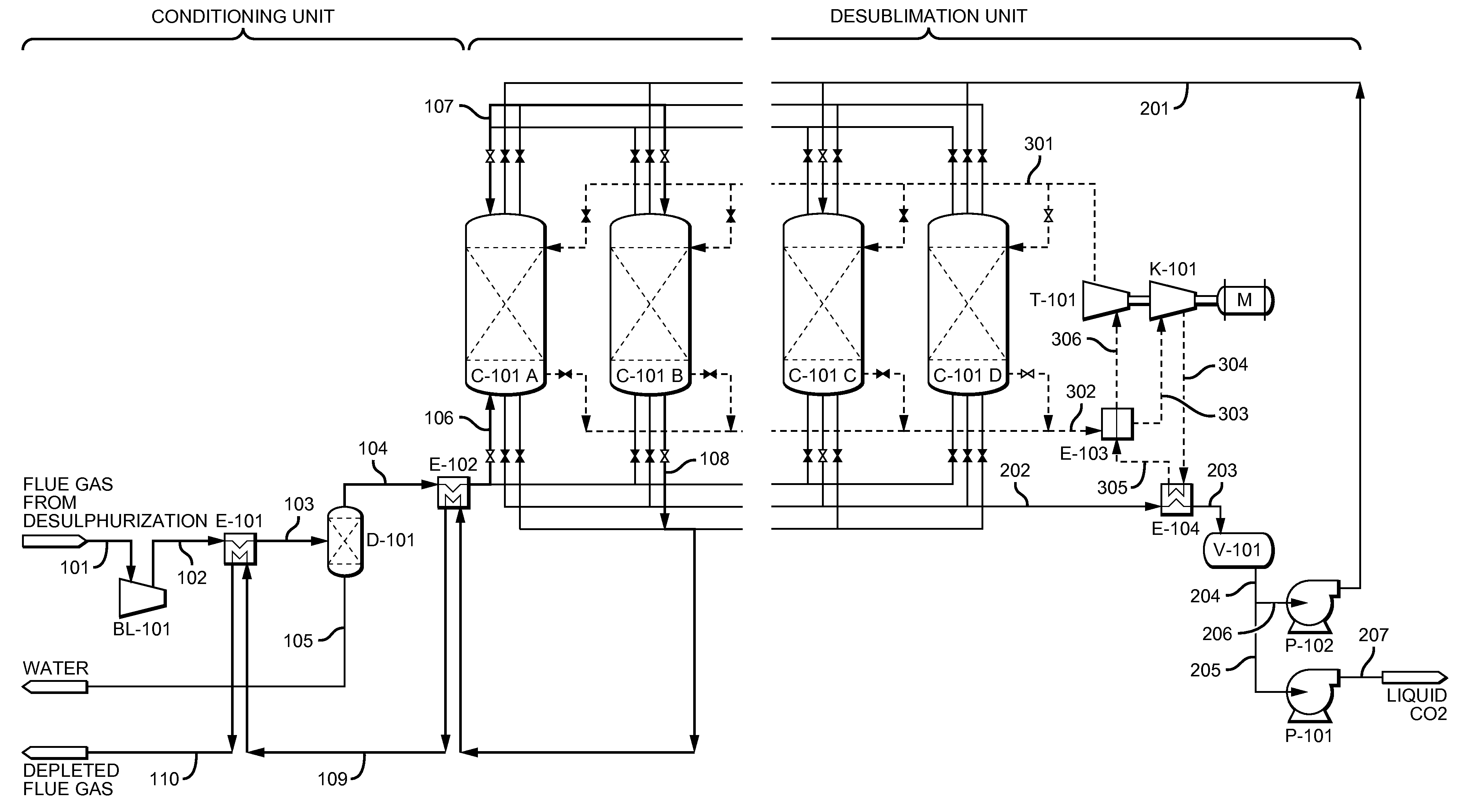

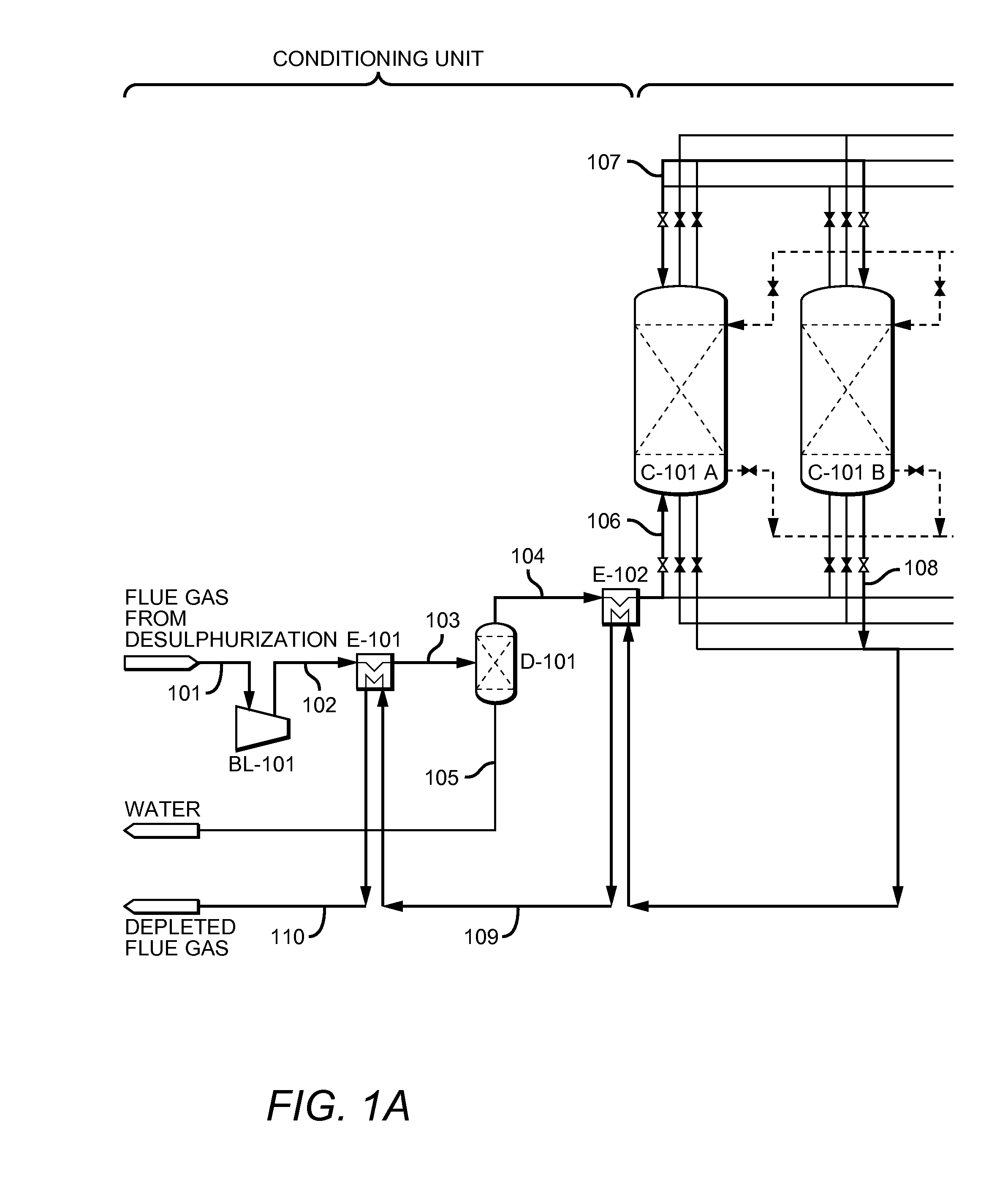

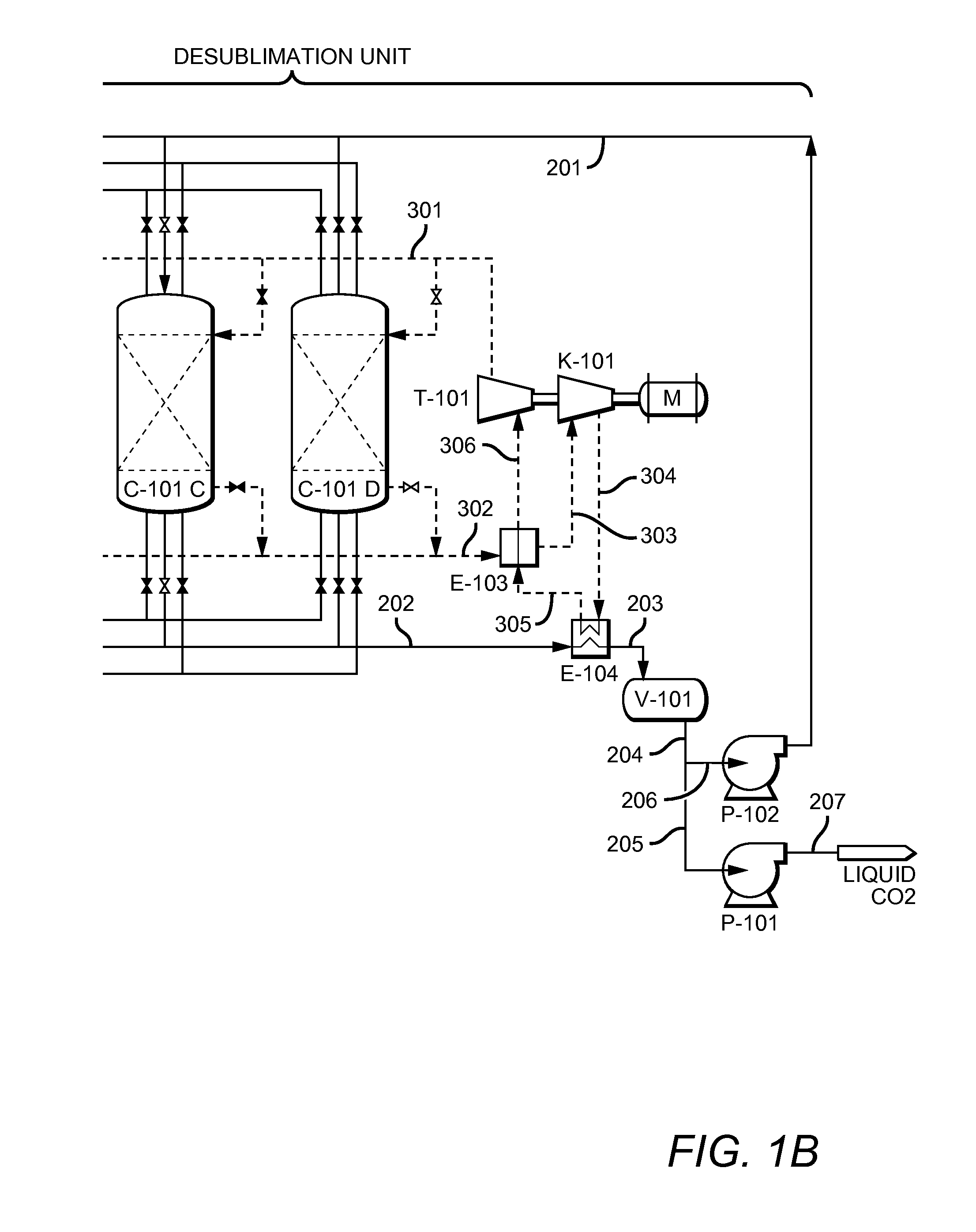

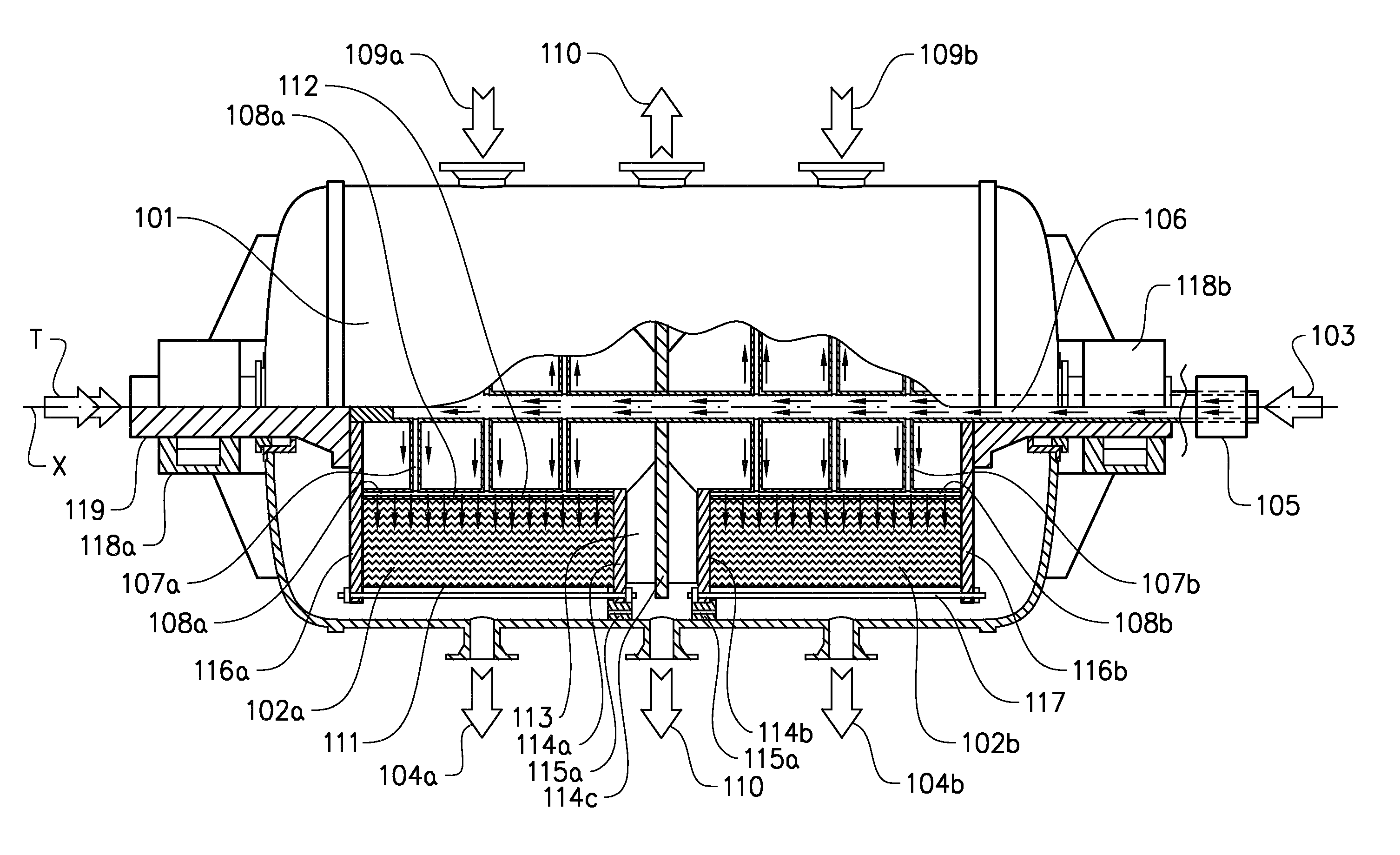

Configurations and methods of Co2 capture from flue gas by cryogenic desublimation

Systems and methods of CO2 desublimation are presented in which refrigeration content is retained within the system. Most preferably, refrigeration content is recycled by providing the refrigeration content of a CO2-lean feed gas to the CO2-containing feed gas and to pre-cooling of a desublimator, and / or by providing refrigeration of effluent of a desublimator in regeneration to a refrigerant in a closed refrigeration cycle for deep-cooling of another desublimator.

Owner:FLUOR TECH CORP

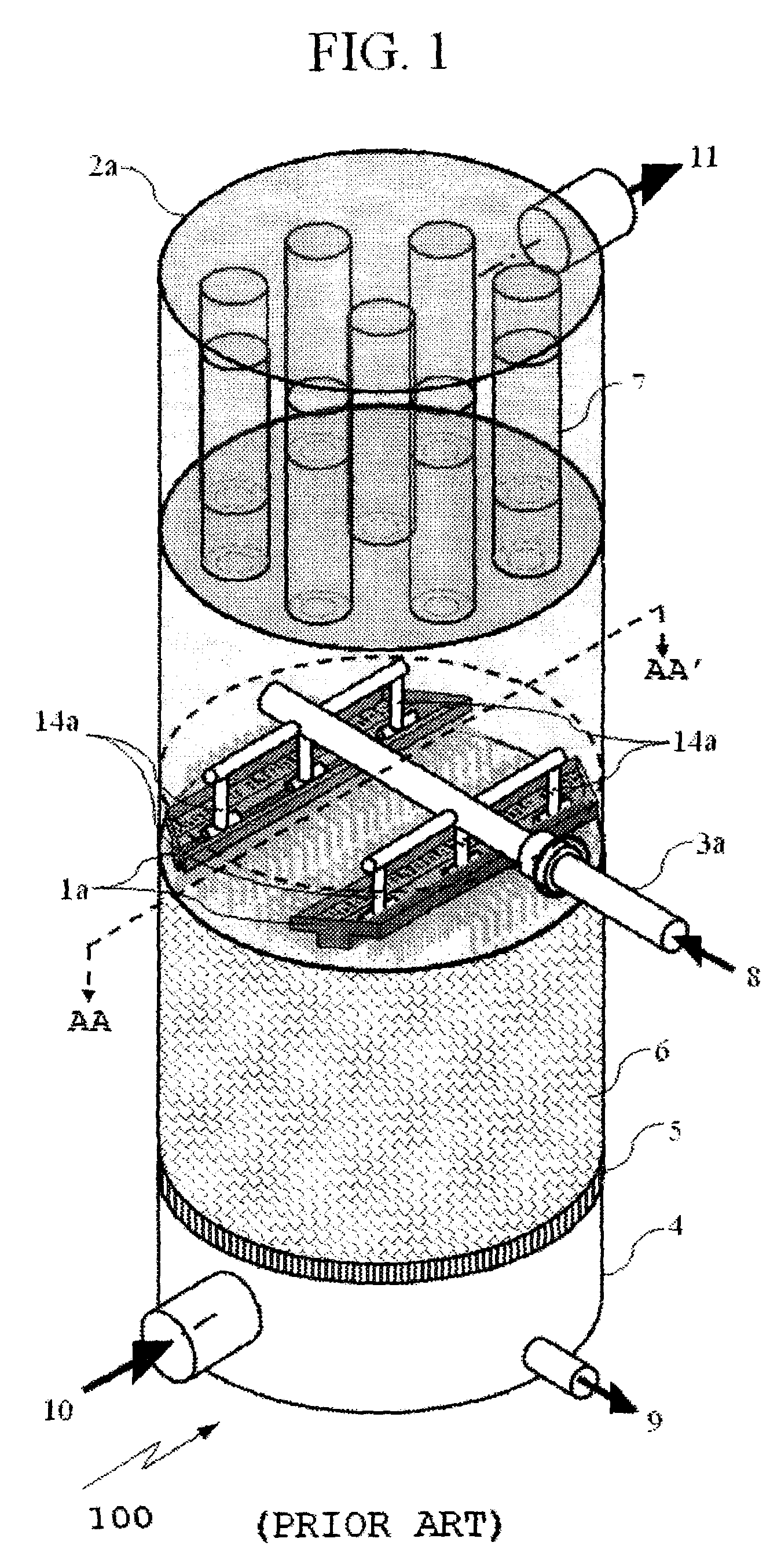

Method and absorber for removal of acid gas from natural gas

ActiveUS20140047979A1Reduce power consumptionGas treatmentUsing liquid separation agentDesorptionPhysical chemistry

The invention relates to a continuous process for removal of acid gas, such as carbon dioxide (CO2) from a fluid stream, such as natural gas comprising mainly hydrocarbons, by means of a absorbent medium in a rotating absorption zone. Subsequently, the acid gas is desorbed in a rotating desorption zone from the absorbent medium to allow the absorbent medium to be recirculated and the acid gas is removed for storage or drying and processing. This process can be carried out continuously, as the absorption medium is re-used.

Owner:DEN NORSKE STATS OLJESELSKAP AS

Liquid distribution trough for use in towers in sulphuric acid and carbon capture plants

ActiveUS9259665B2Easy to optimizeEqually distributedDispersed particle separationLiquid distribution in distillationPreferential flowEngineering

A liquid distribution trough contained within a tower for the purpose of mass or thermal exchange between at least a first liquid and a second fluid; the trough having an upper section and a lower section; the lower section for receiving the first liquid; a horizontal dividing member separating the upper section from the lower section and having at least one dividing member portion defining an aperture to allow for passage of the liquid fluid from the lower section to the upper section; a feed conduit means in communication with the lower section to provide feed first liquid flow to the lower section; the lower section having at least one inlet portion defining a liquid inlet in communication with the feed conduit means; and a first baffle adjacent the inlet portion operably impacted by the first liquid flow and to hinder preferential flow along the walls of the trough and the dividing member. The trough and tower are of particular value in a sulphuric acid plant and a carbon dioxide capture plant.

Owner:CHEMETICS

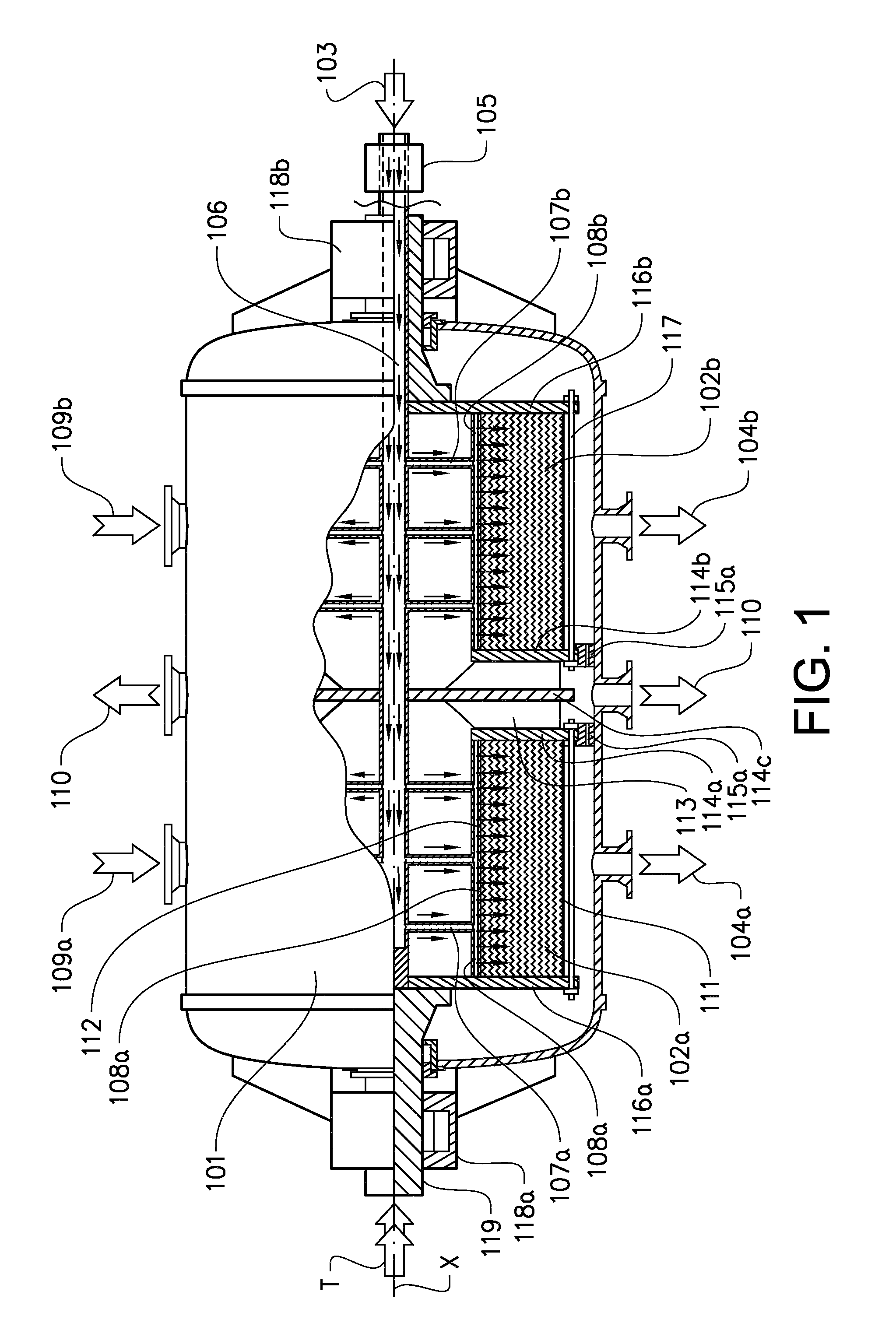

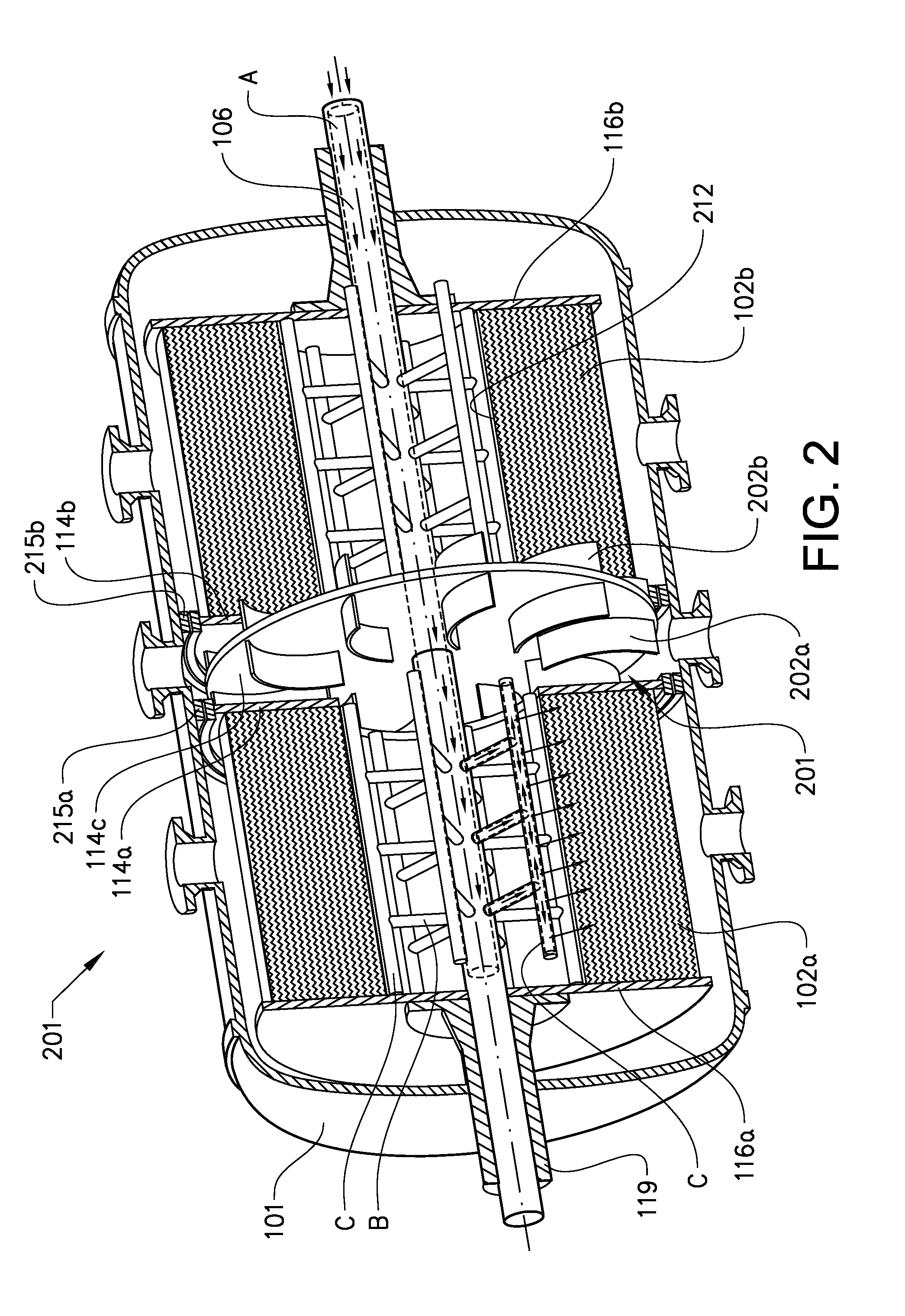

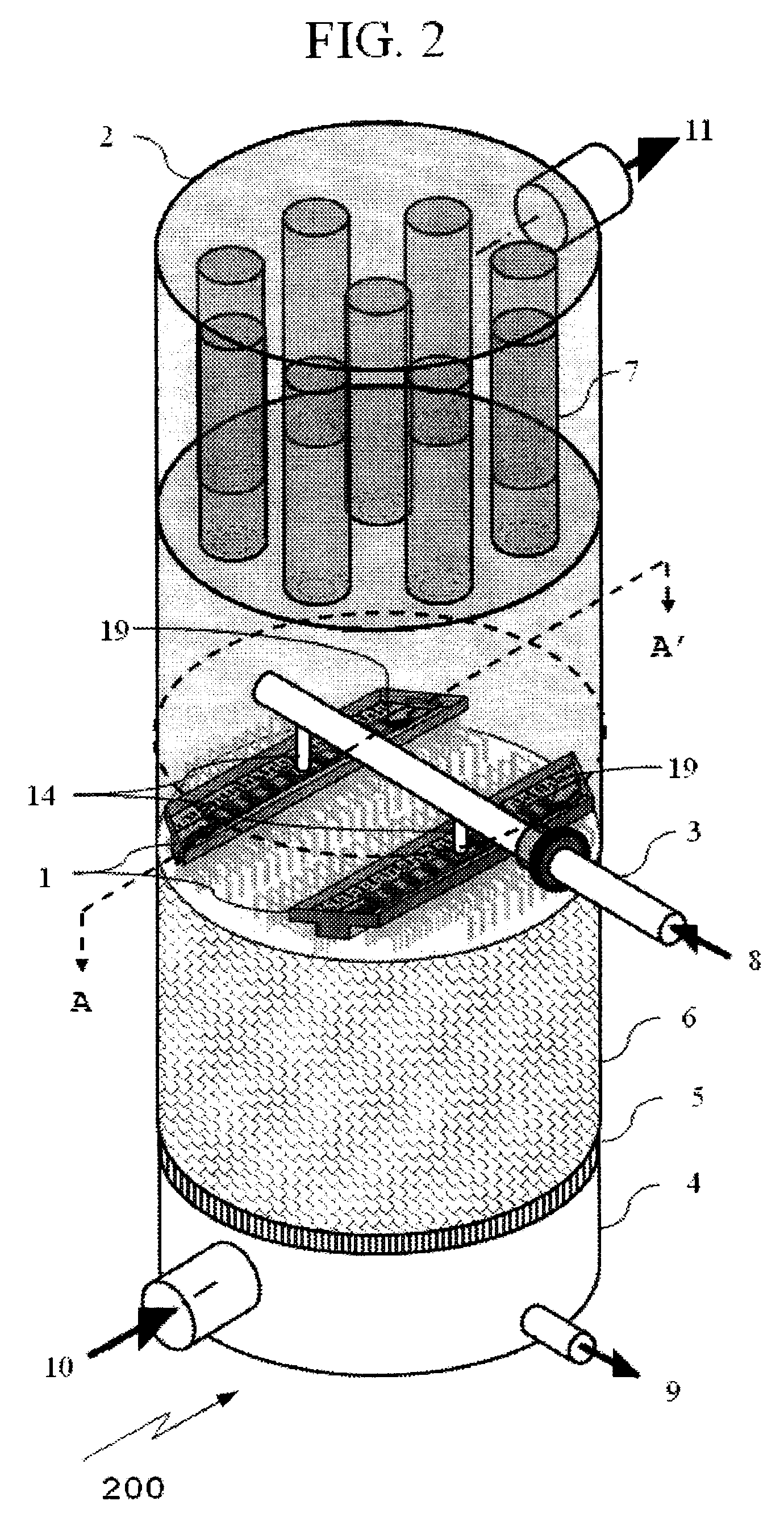

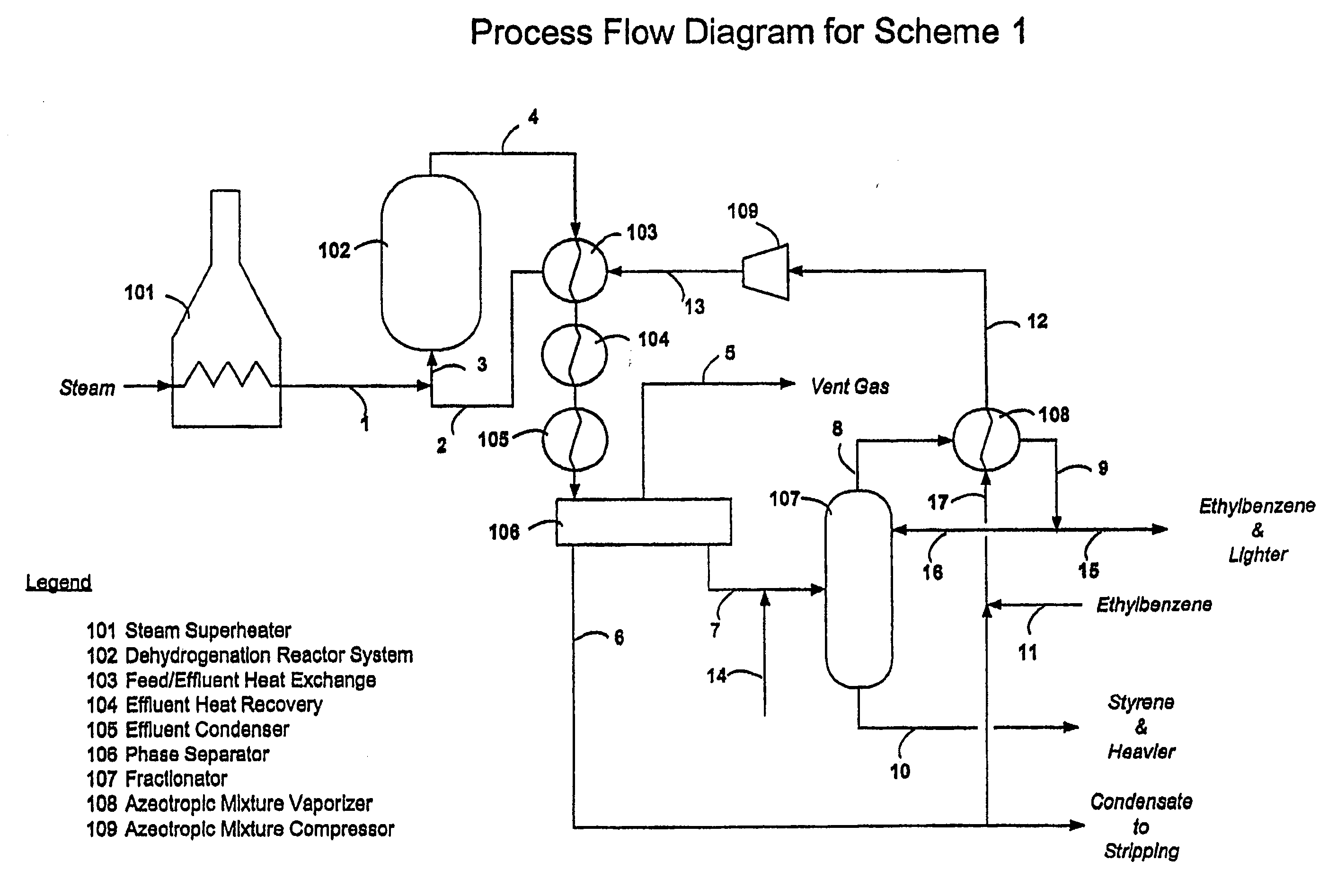

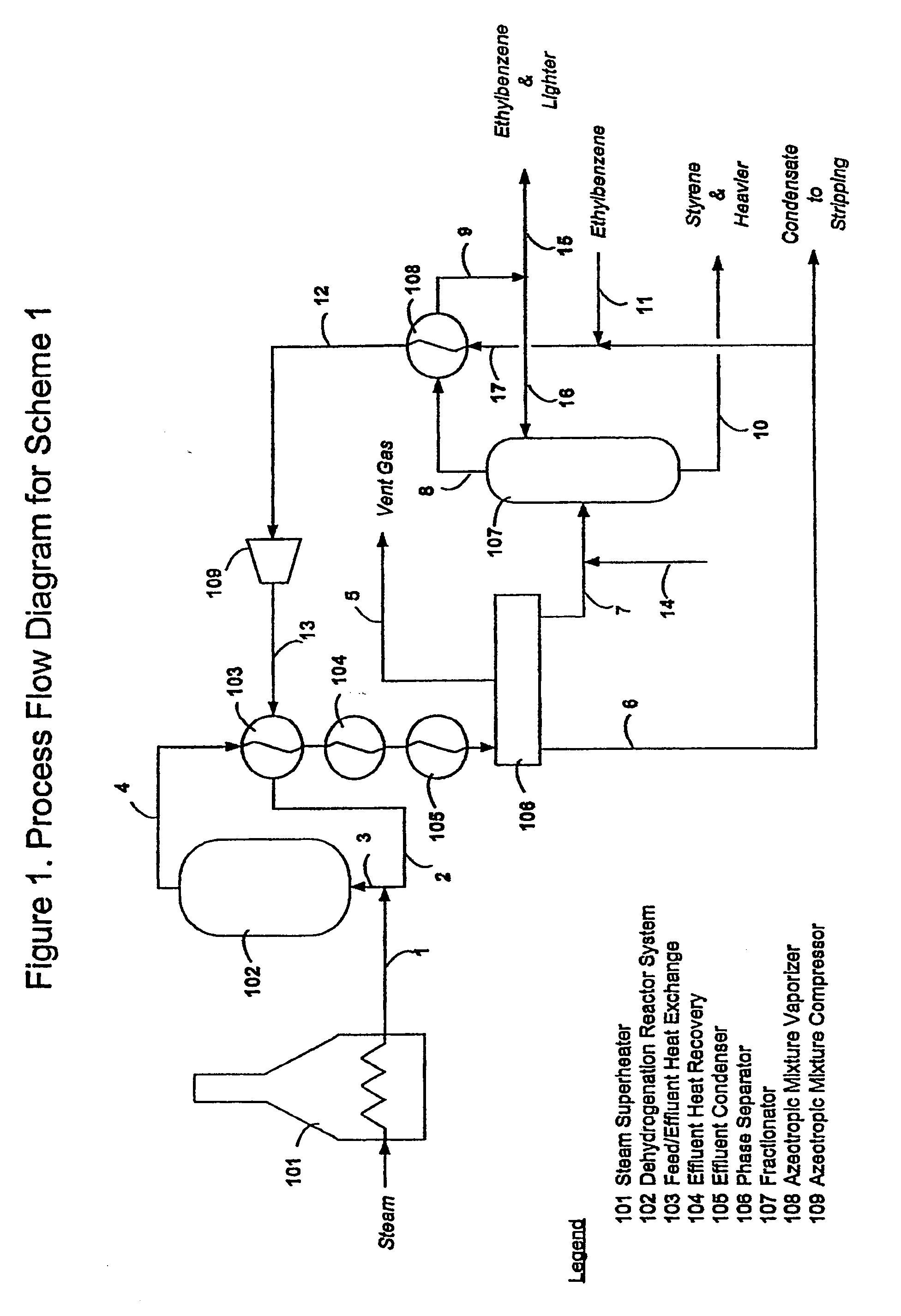

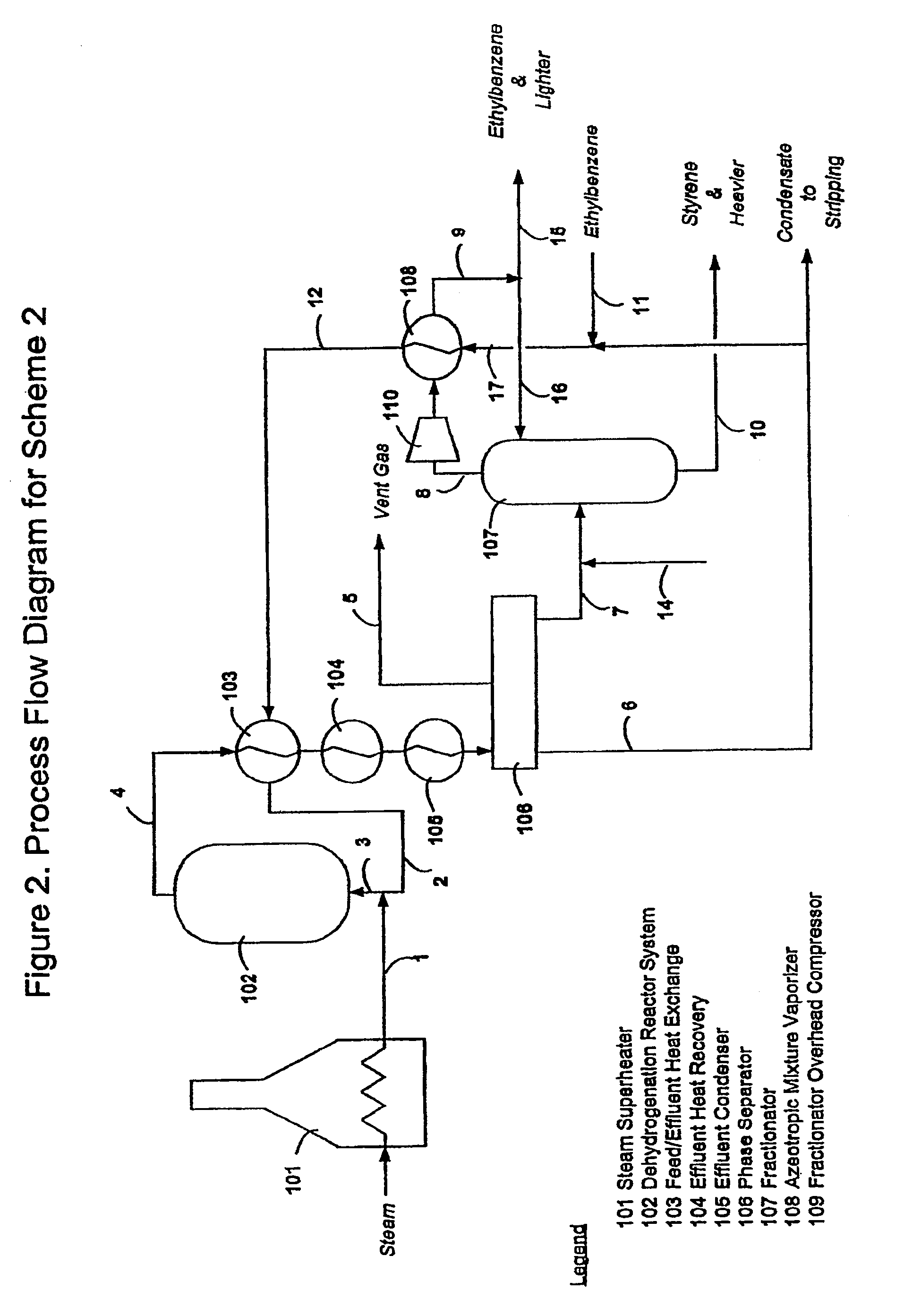

Eb/sm splitter heat recovery

InactiveUS20100111785A1Reduce stressIncrease the differencePhysical/chemical process catalystsEvaporation with vapour compressionDehydrogenationVaporization

Owner:STONE & WEBSTER PROCESS TECH

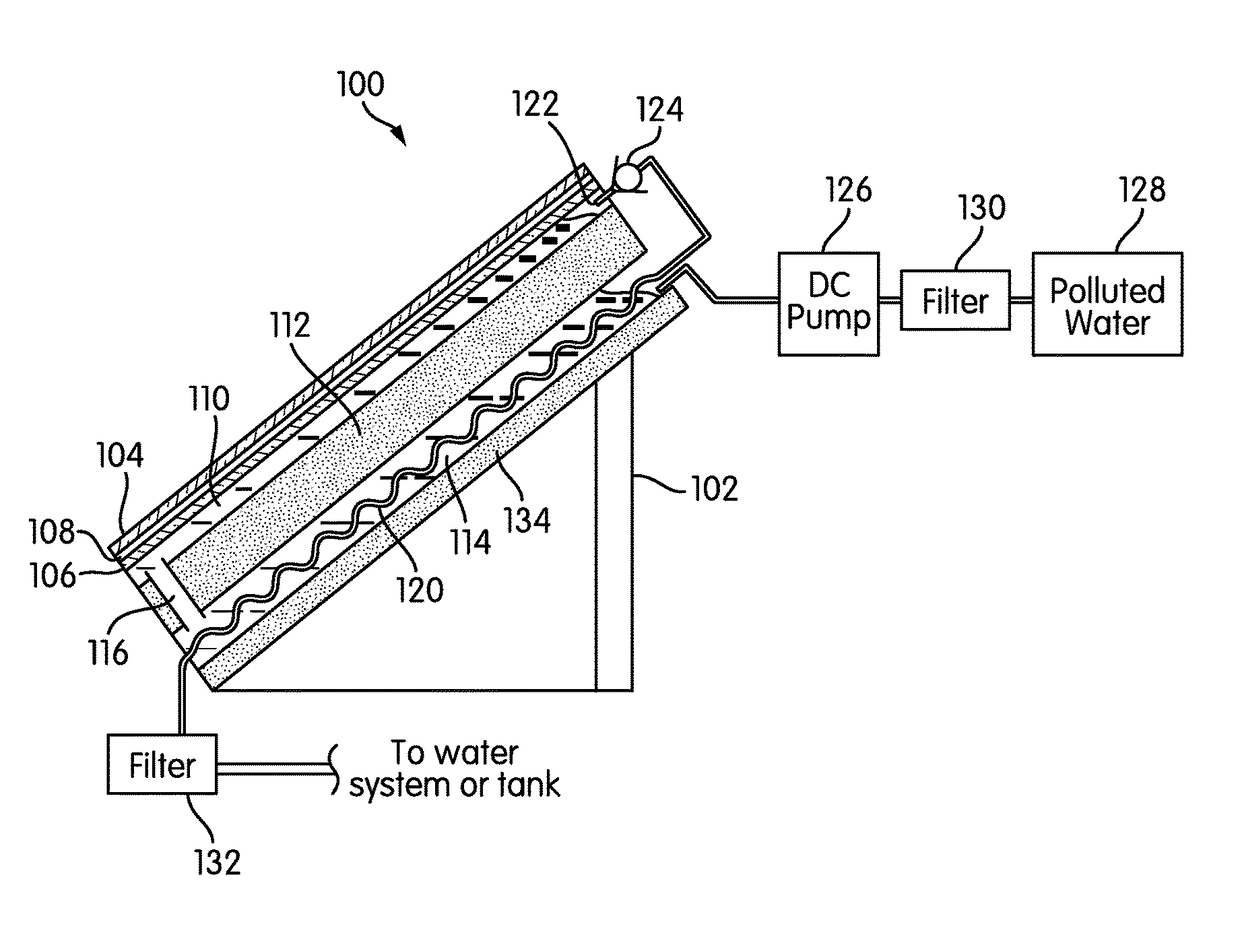

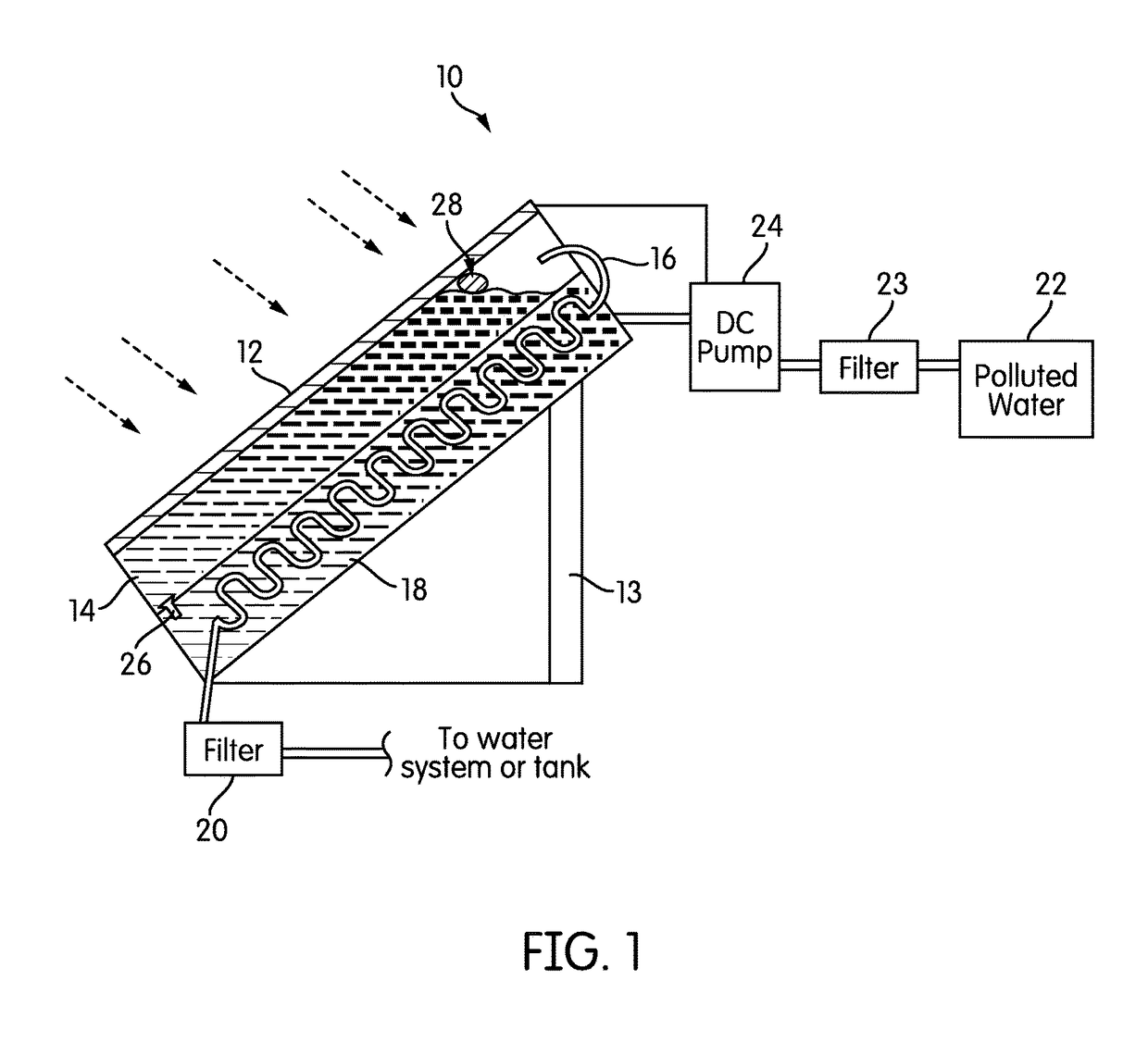

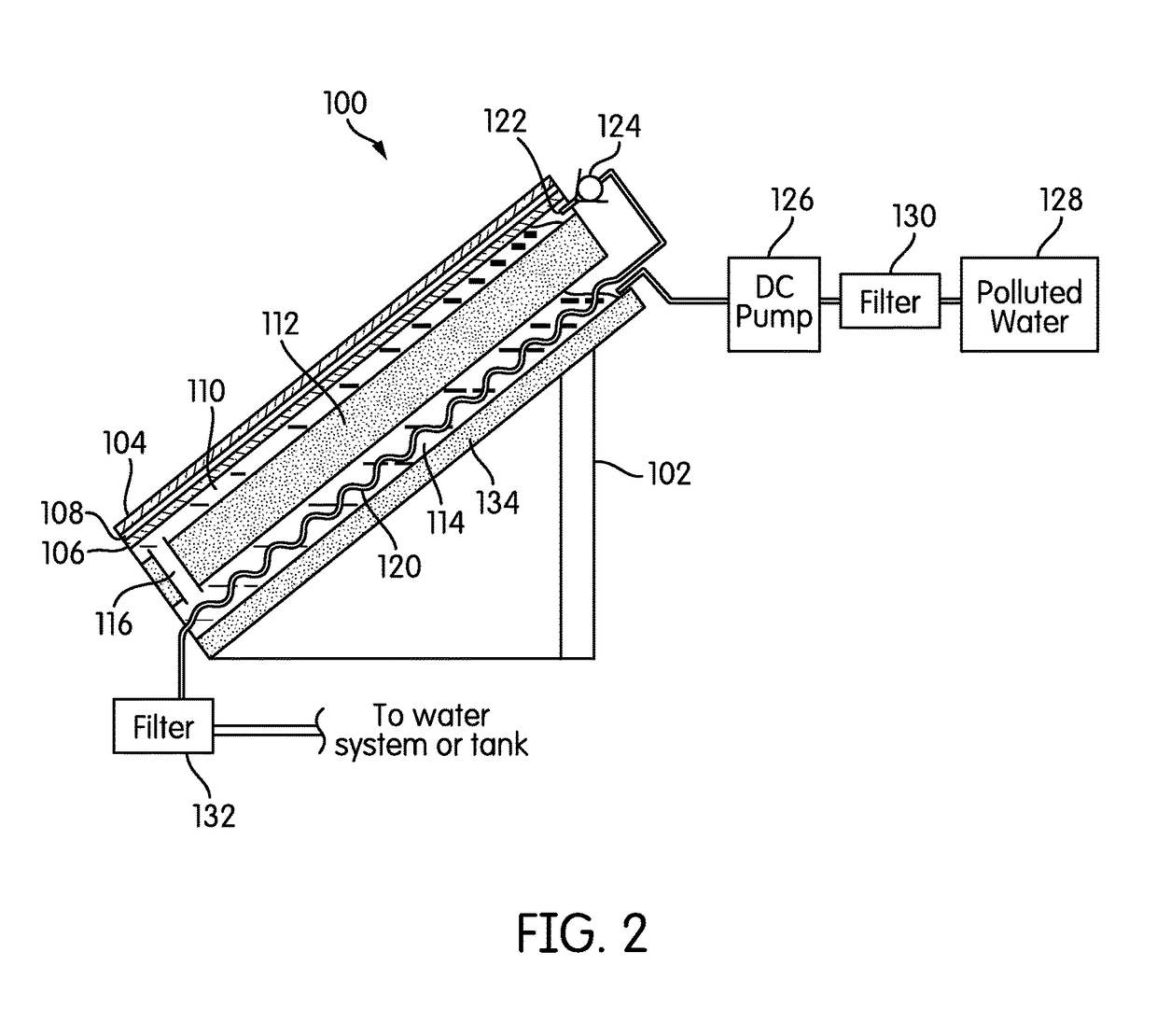

Solar water purifier

ActiveUS9796602B2General water supply conservationSpecific water treatment objectivesSolar waterEnvironmental engineering

A solar water purifier is disclosed. The solar water purifier uses waste heat from a solar panel, or direct heat from the sun, to boil, evaporate, and condense water to create a stream of purified water. In one embodiment, a boiling tank is mounted under and in direct thermal contact with a solar panel to absorb waste heat. In another embodiment, a transparent wall of the boiling tank is directly exposed to solar energy. Unpurified water enters the boiling tank from an inlet tank. Once in the boiling tank, a stream of steam and water vapor leaves the tank and is allowed to condense within a condenser. The condenser is located within the inlet tank, such that the heat recovered during condensation is used to preheat the inlet water to the boiling tank.

Owner:NF IND

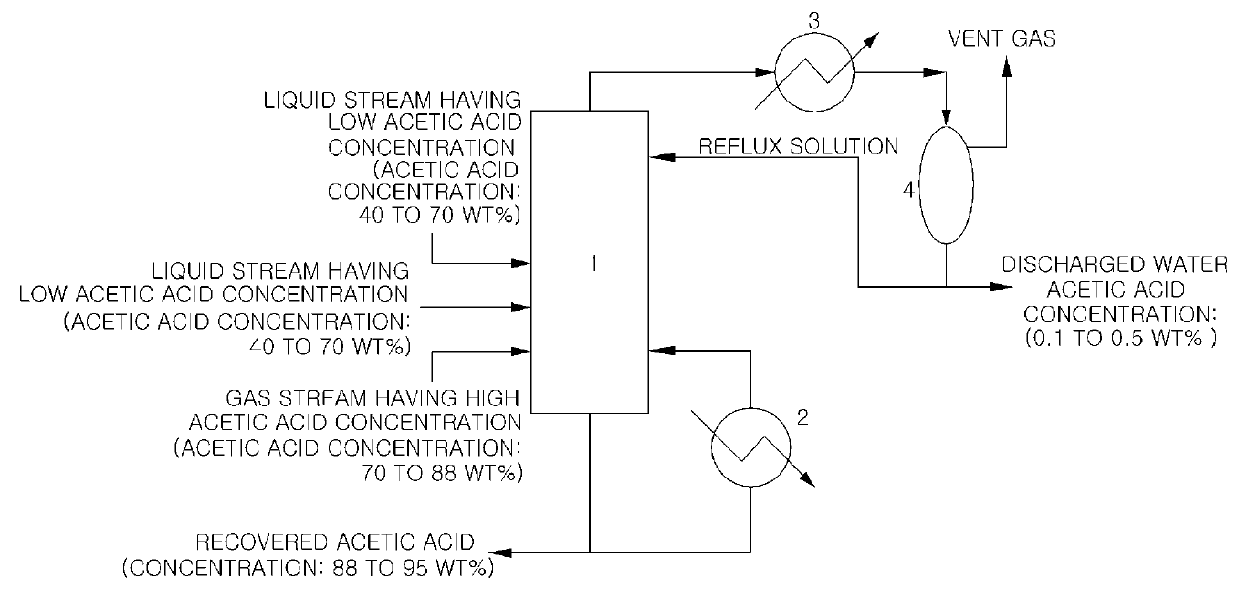

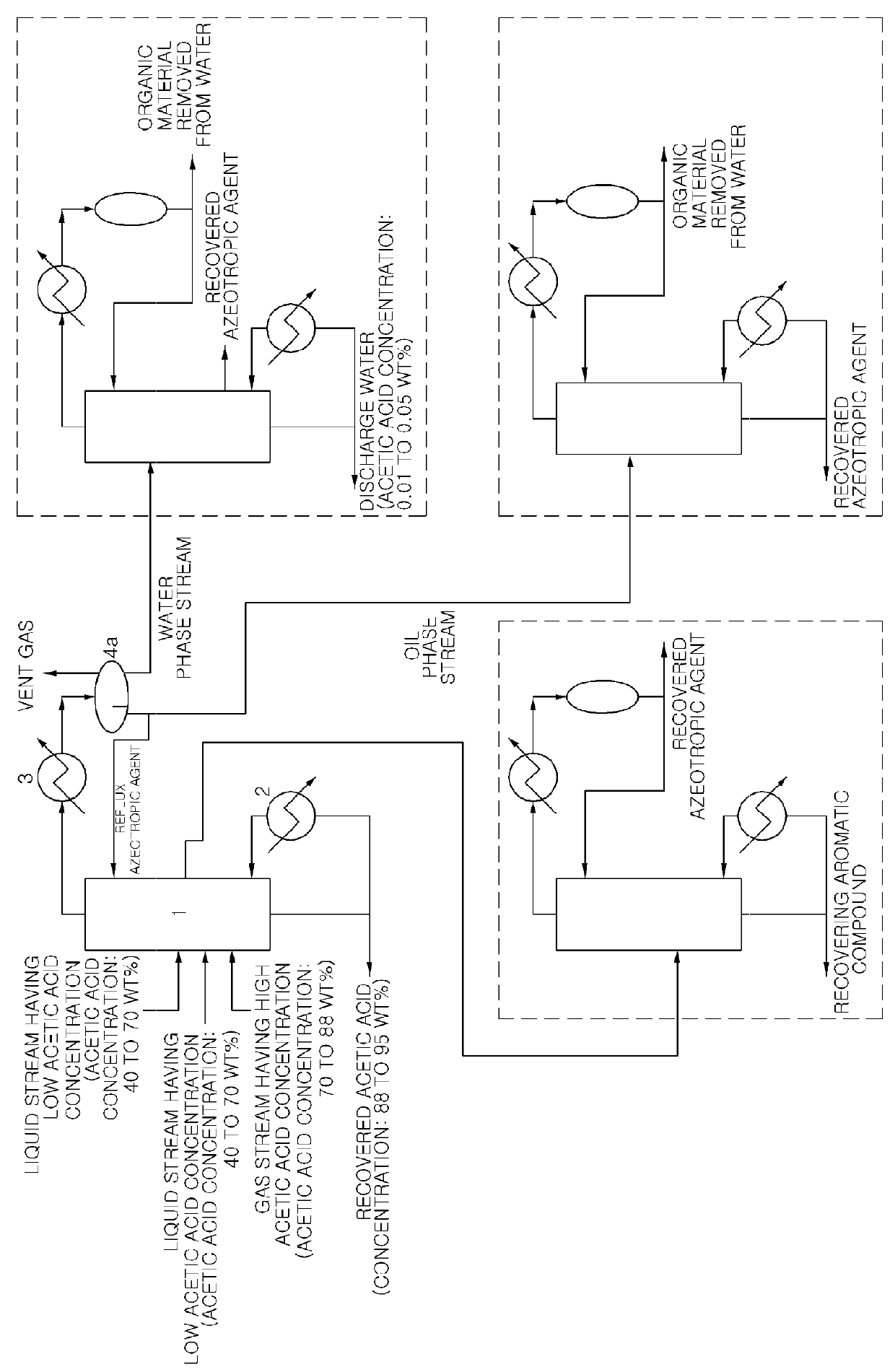

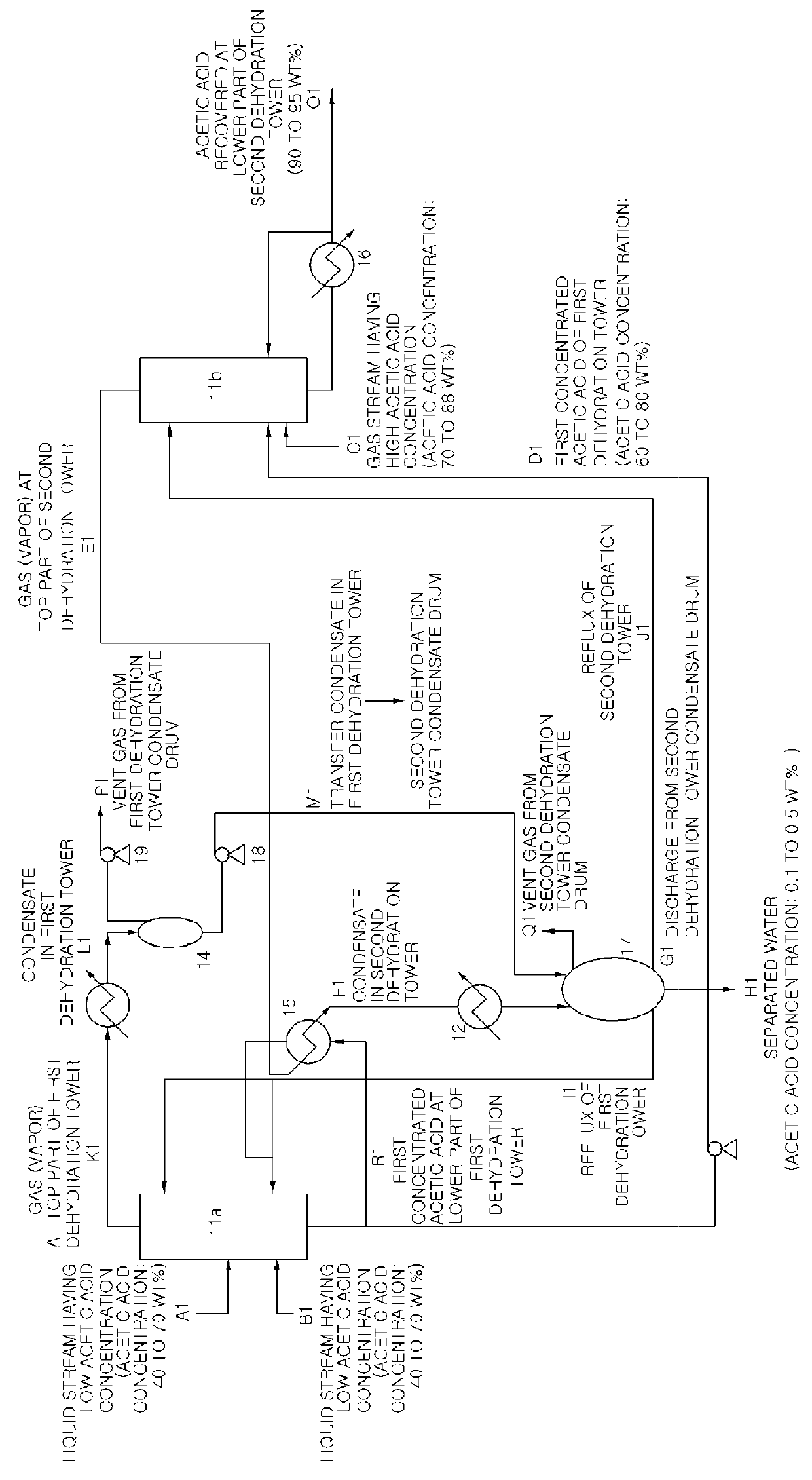

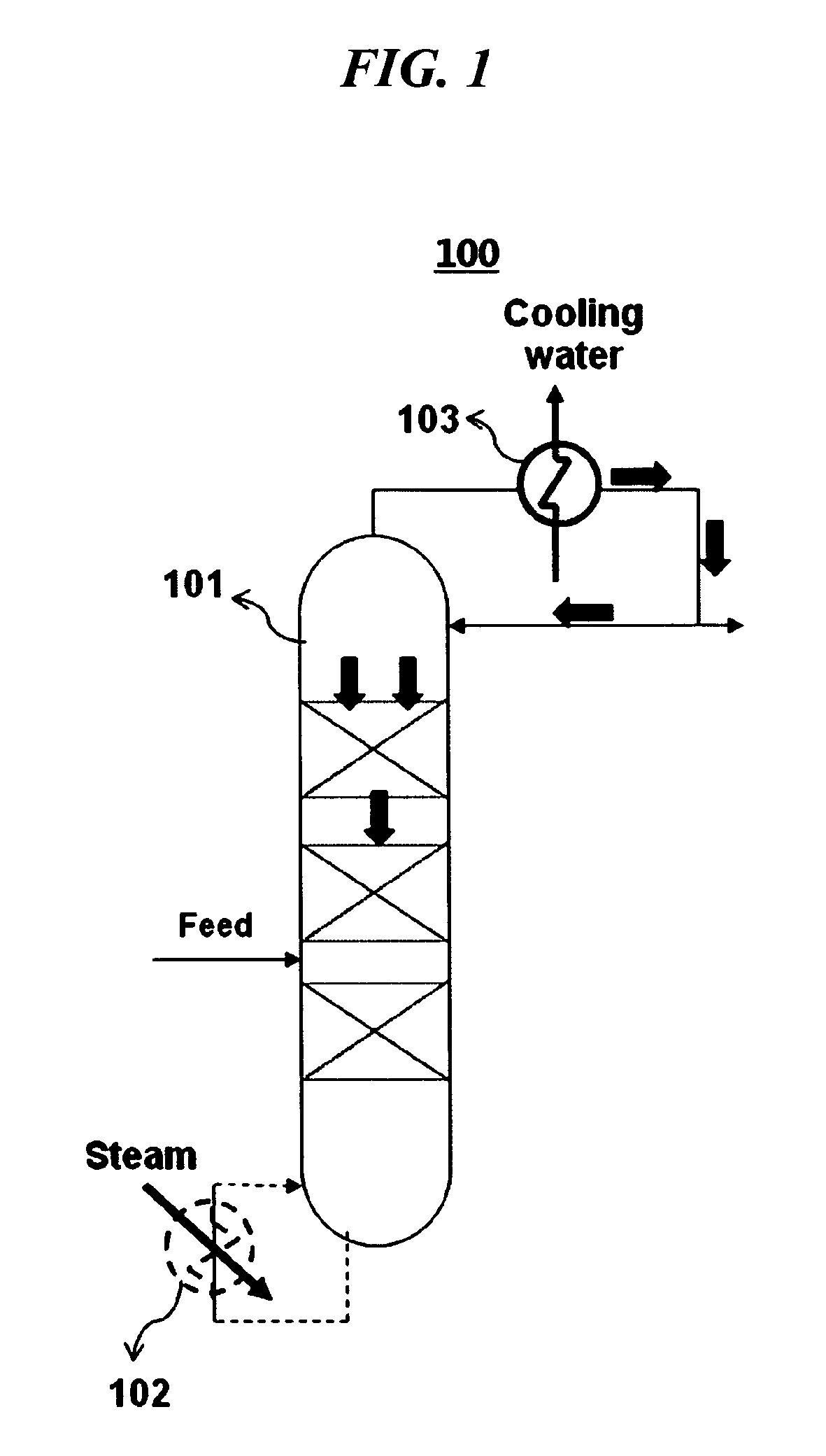

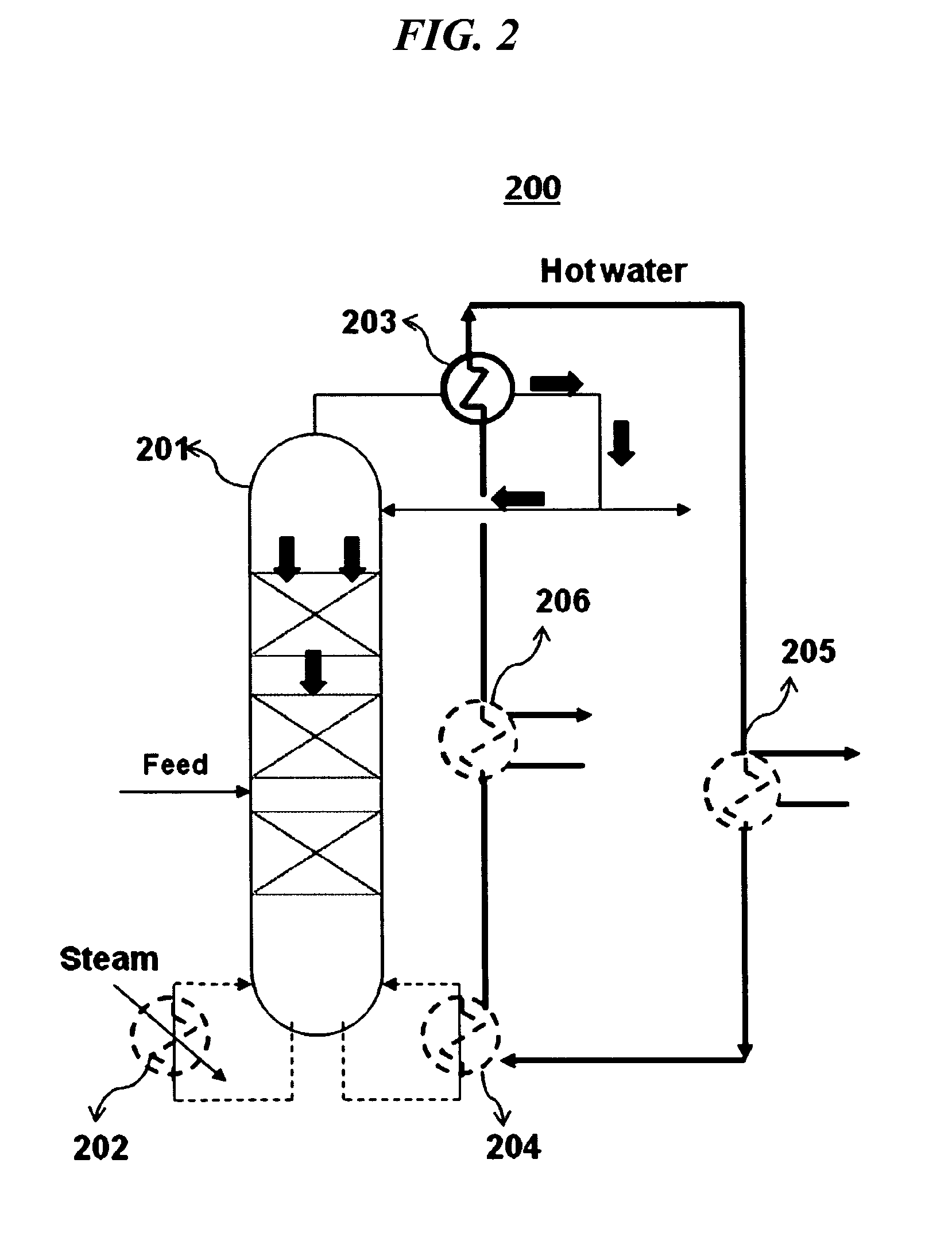

Device and method for separating off water and recovering a carboxylic acid from reactor discharge during an aromatic compound oxidation reaction using energy donating coupled distillation

InactiveUS9334222B2Reduce energy consumptionReduce consumptionOrganic compounds purification/separation/stabilisationOrganic compound preparationReboilerCarboxylic acid

Provided is a method of separating off reaction product water and recovering a carboxylic acid used as a solvent in a reactor from a reactor discharge during oxidation of an aromatic compound, and more particularly, a method of separating off reaction product water and recovering a carboxylic acid used as a solvent in a reactor from a reactor discharge during oxidation of an aromatic compound, wherein during the oxidation of the aromatic compound, the reactor discharge is led into two or more dehydration towers having different operating pressures such that a condenser of one dehydration tower operates as a reboiler of another dehydration tower, thereby remarkably reducing energy consumption.

Owner:AMTPACIFIC +1

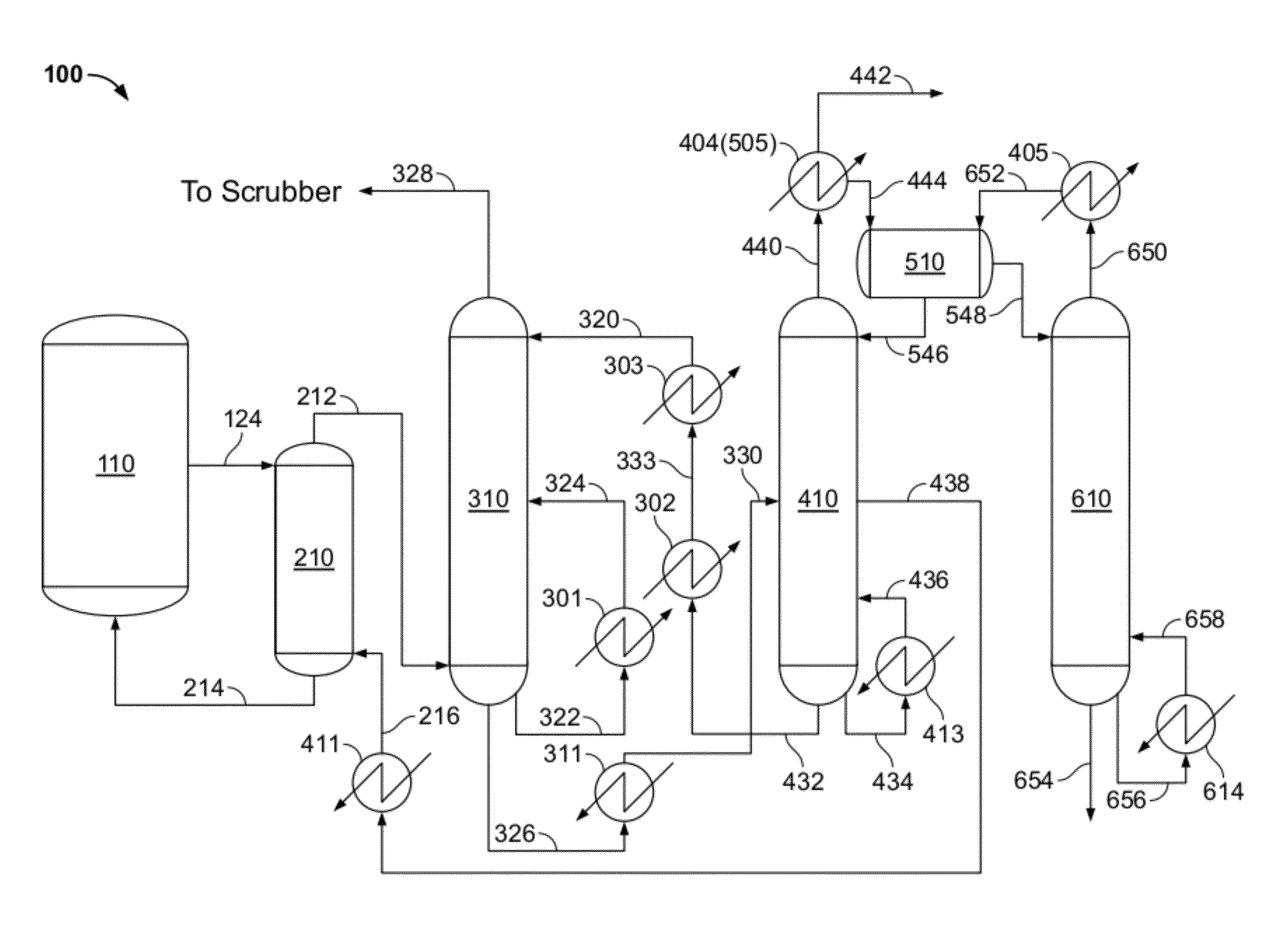

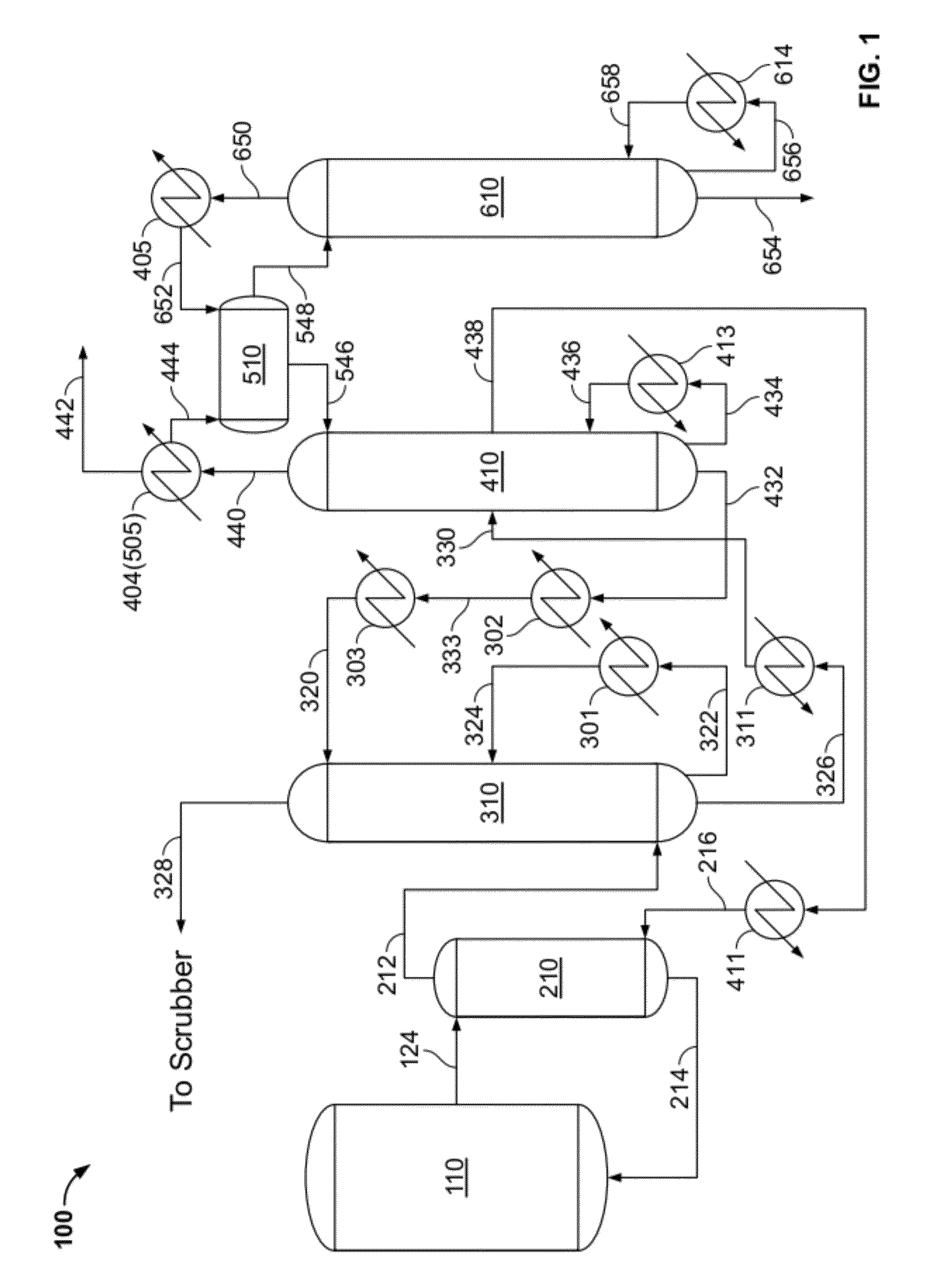

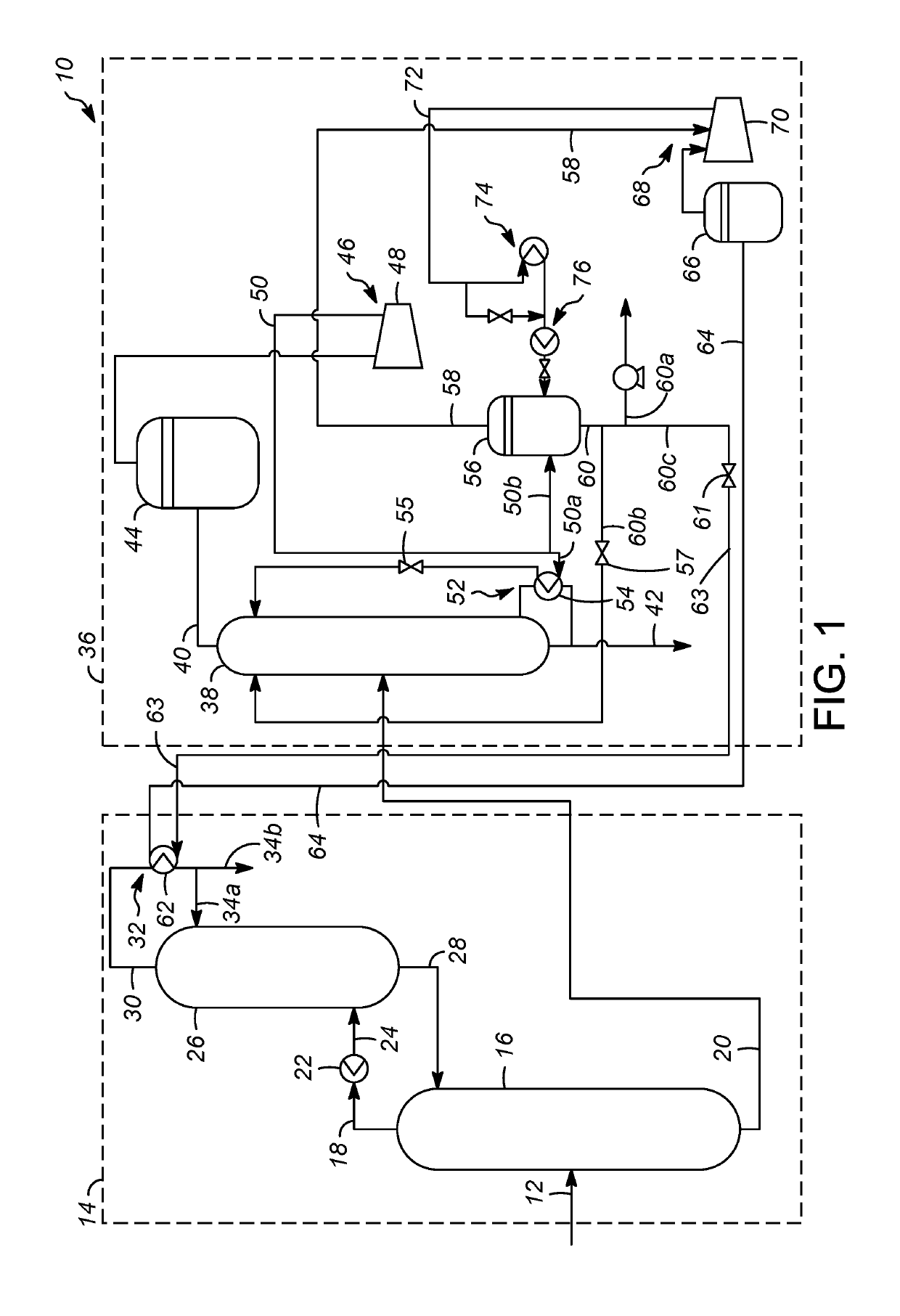

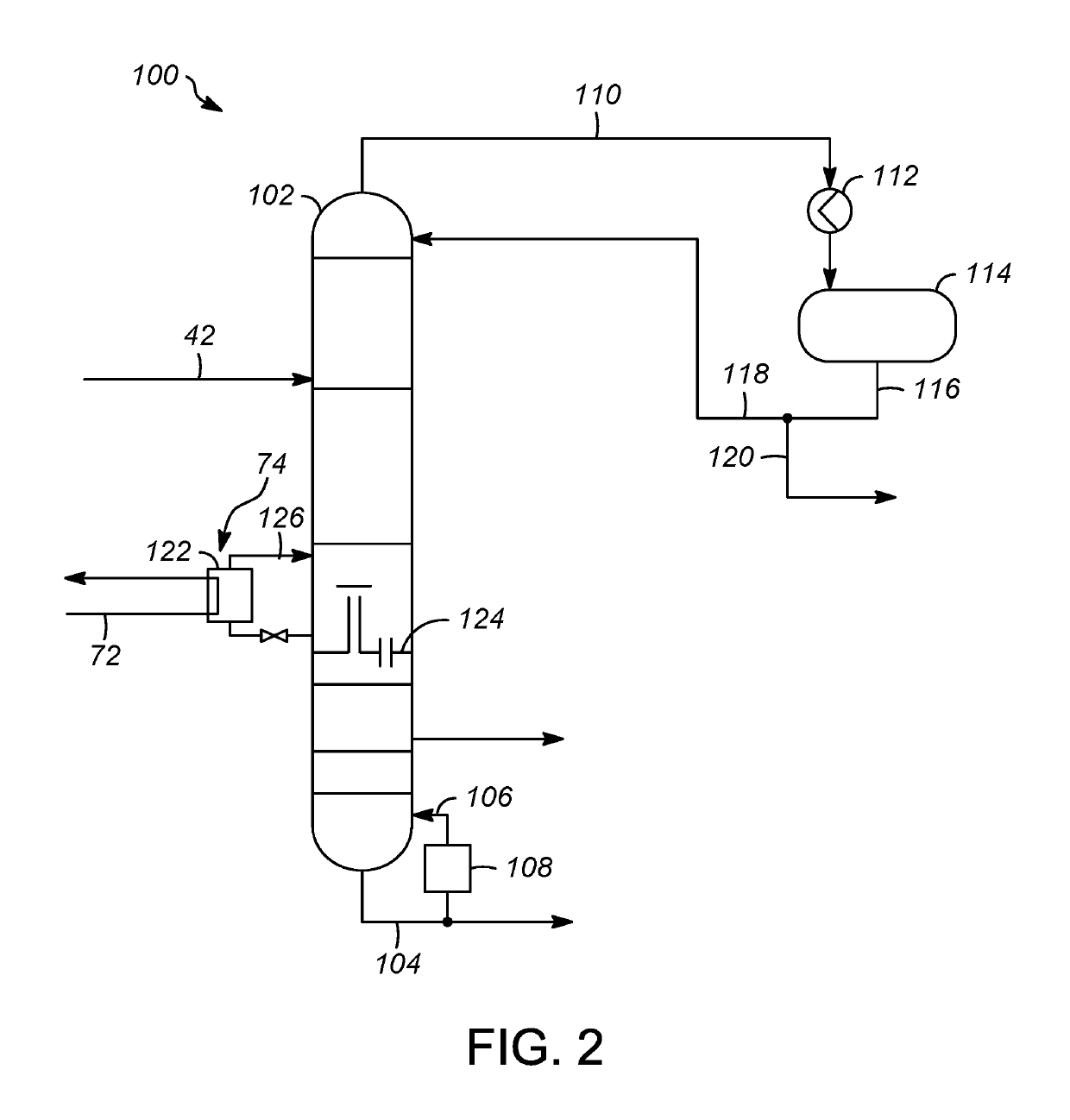

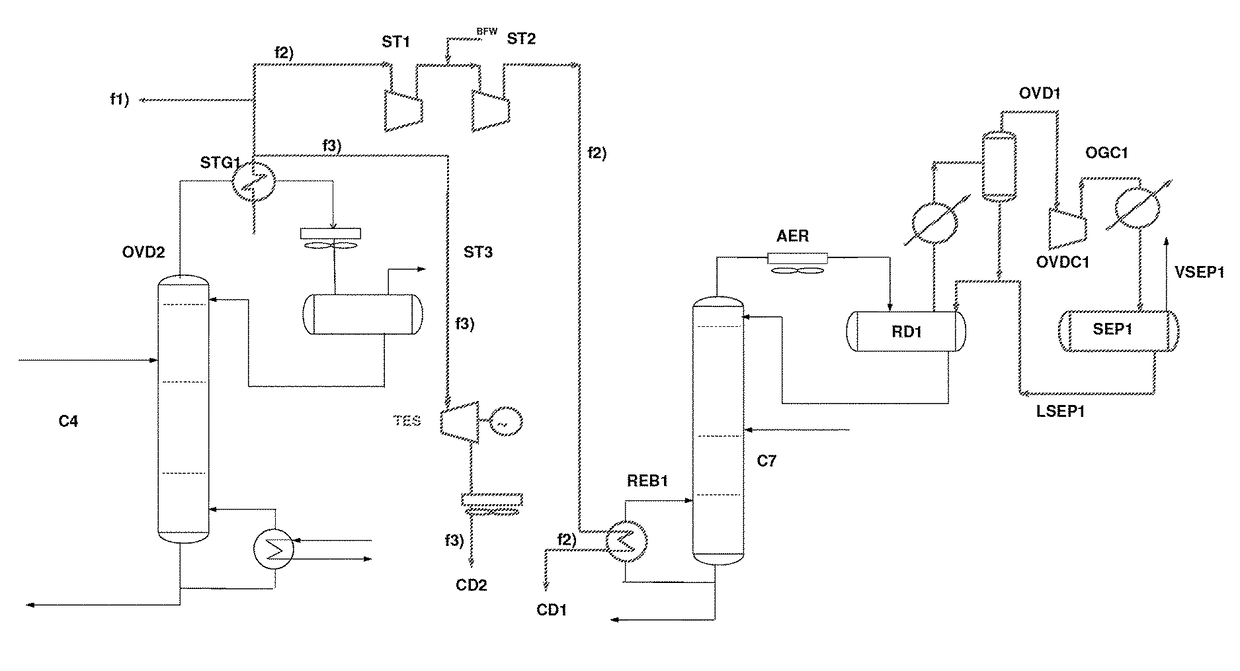

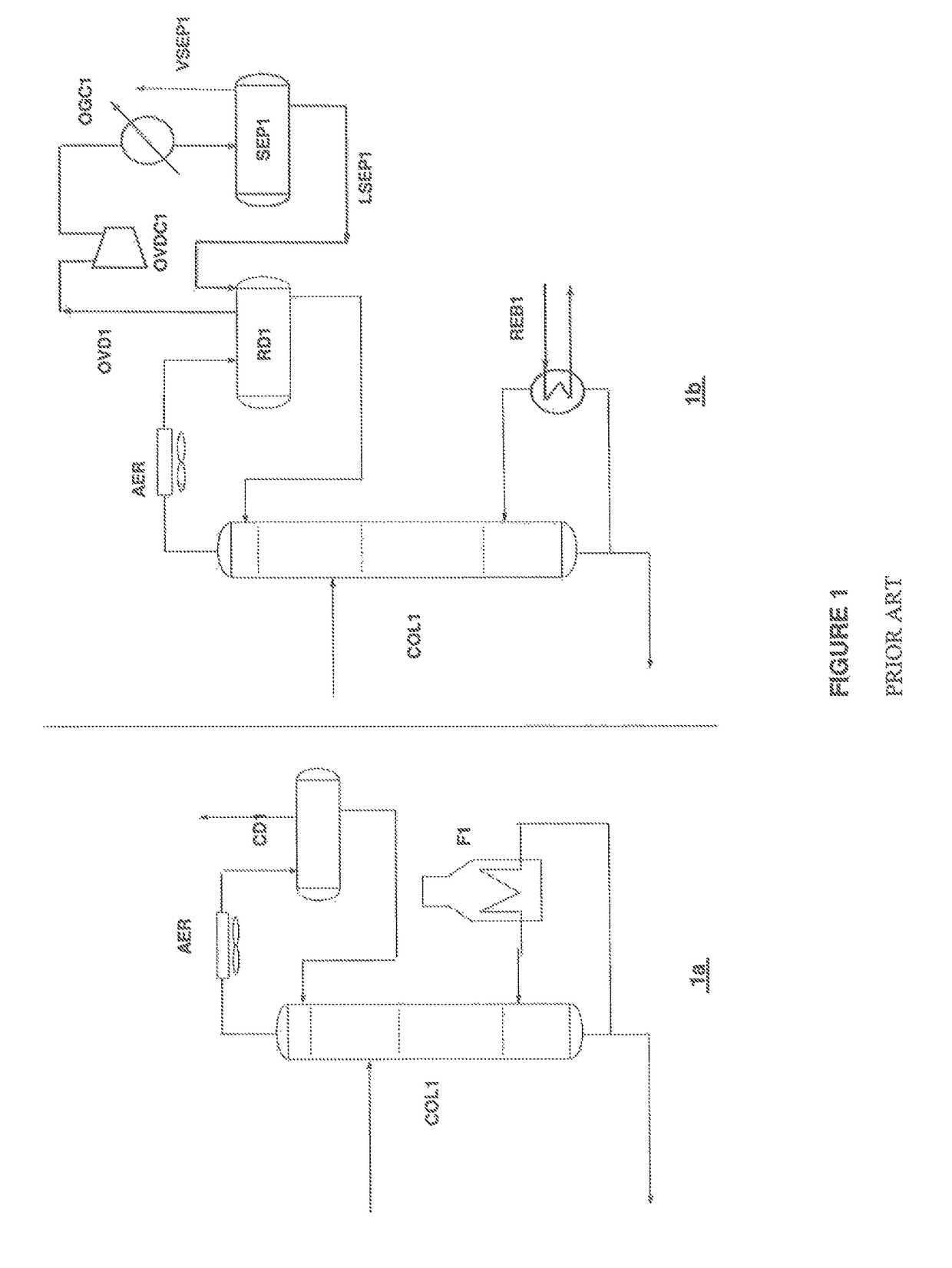

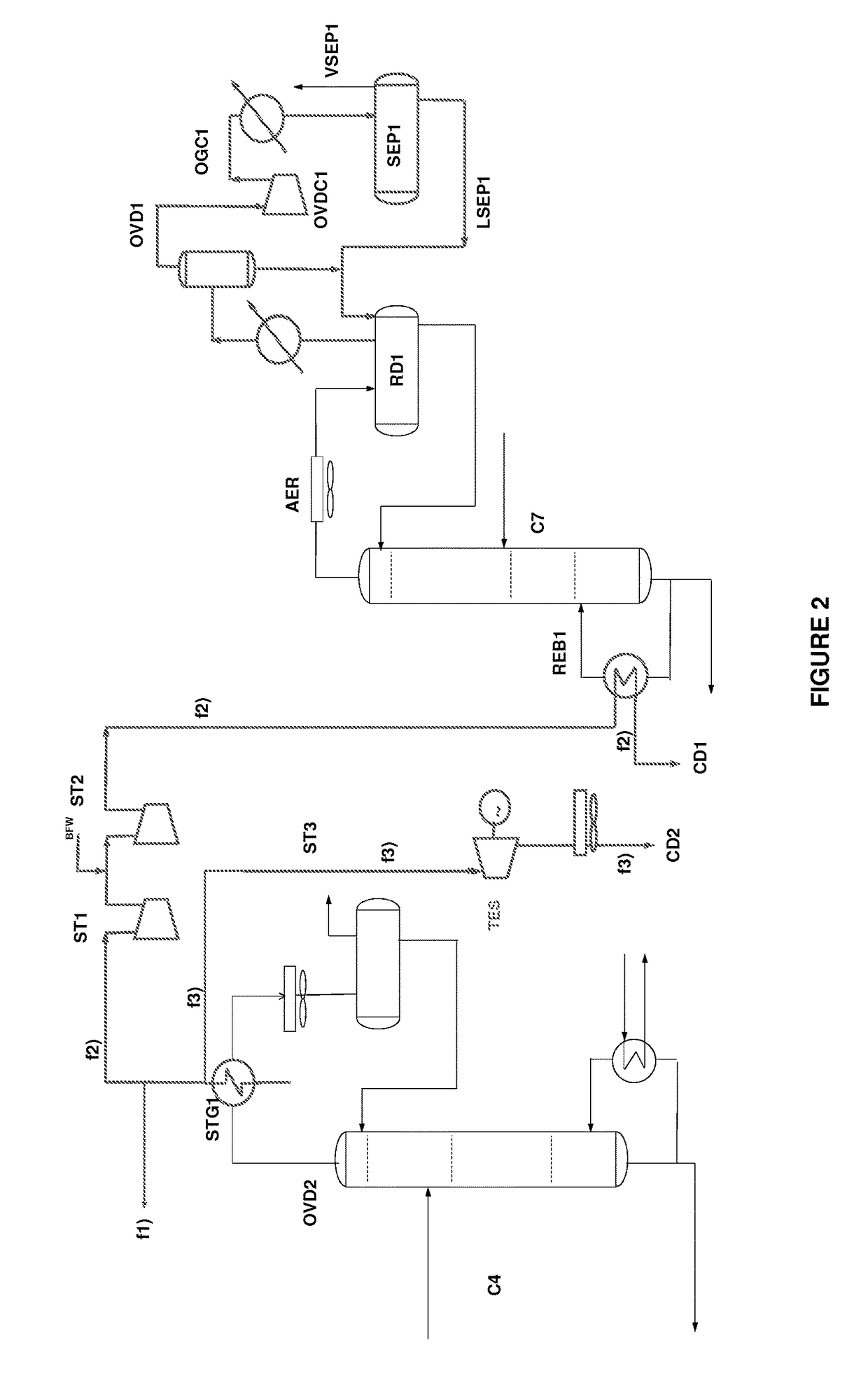

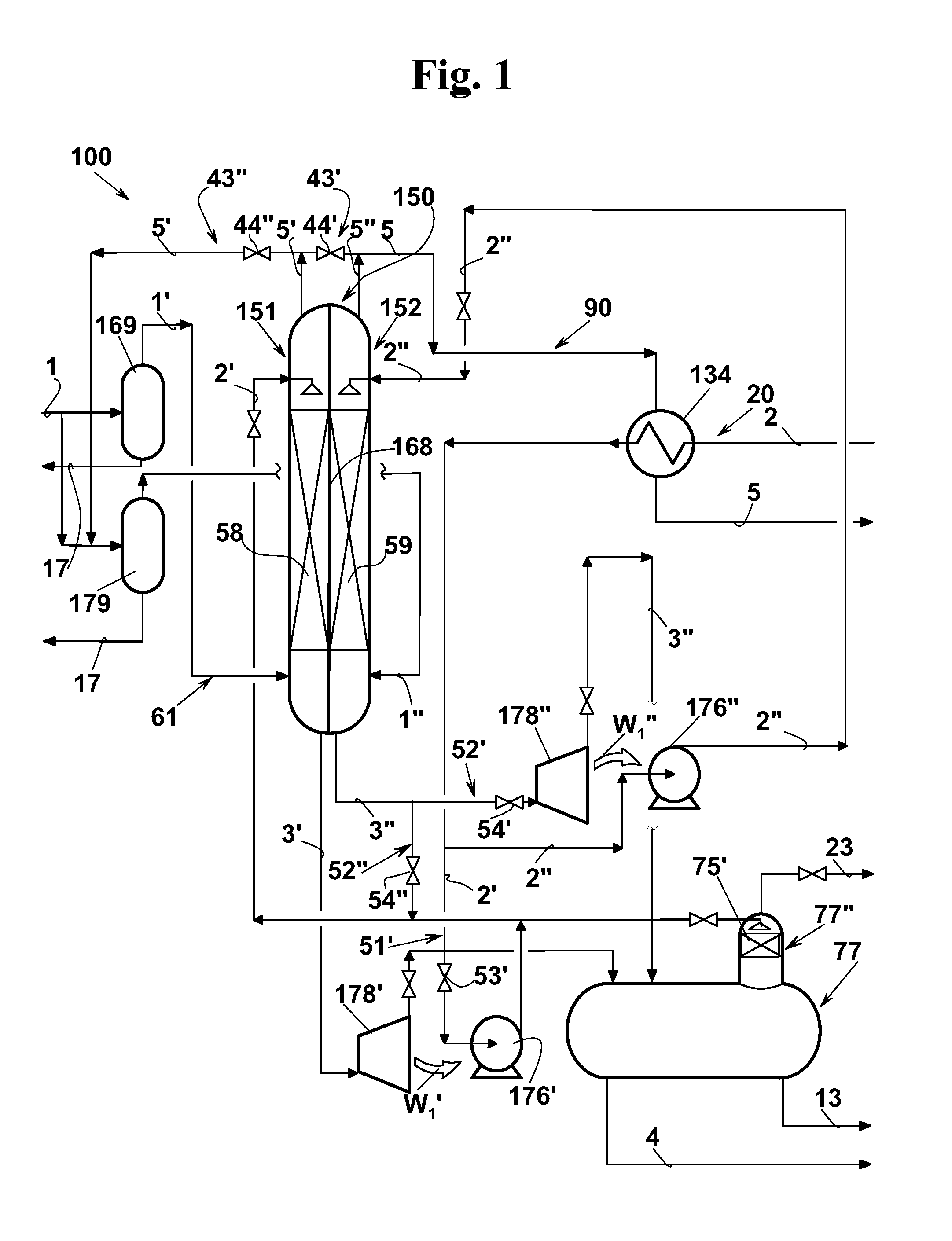

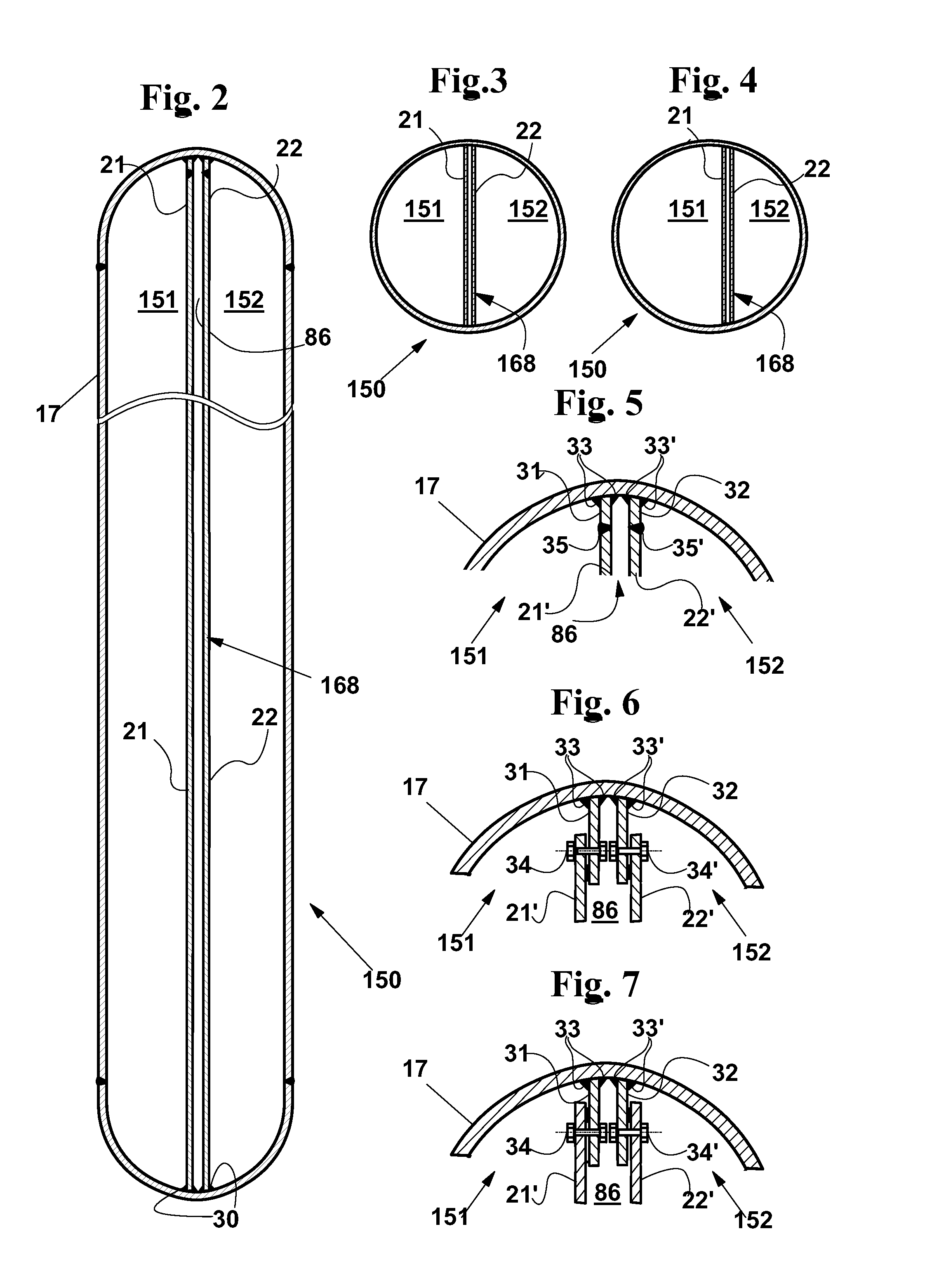

Process for recovering heat from a hydrocarbon separation

ActiveUS10315971B2Extended stayGood chanceDistillation regulation/controlEvaporation with vapour compressionReboilerFractionation

Systems and processes for heat recovery associated with the separation of hydrocarbon components. Two compressors are used to compress a portion of an overhead vapor stream from a fractionation column. A pressure of the liquid portion of the compressed overhead is reduced and used to recover heat from an overhead of another separation zone having a fractionation column. Once the heat has been recovered the stream is recompressed. The recovered heat may be removed from the recompressed stream in a reboiler of another fractionation column. The fractionation columns may comprise a deethanizer stripper, propane-propylene splitter, and a depropanizer column.

Owner:UOP LLC

Method for heat recovery in vinyl chloride monomer structures or in the structure composite dichloroethane/vinyl chloride, and device suitable for same

ActiveUS9334209B2Energy efficiencyInexpensive wayChlorine/hydrogen-chloride purificationPreparation by hydrogen halide split-offBoiling pointProcess engineering

Energy savings in an integrated DCE / VCM plant, optionally also containing a PVC plant, is accomplished by using at least part of the vapor from a DEC quenching column to supply heat to an HCl column. The DCE plant has a high boiler column operating at superatmospheric pressure, and heat is removed from an overhead stream and used to supply heat to other portions of the process.

Owner:THYSSENKRUPP IND SOLUTIONS AG +1

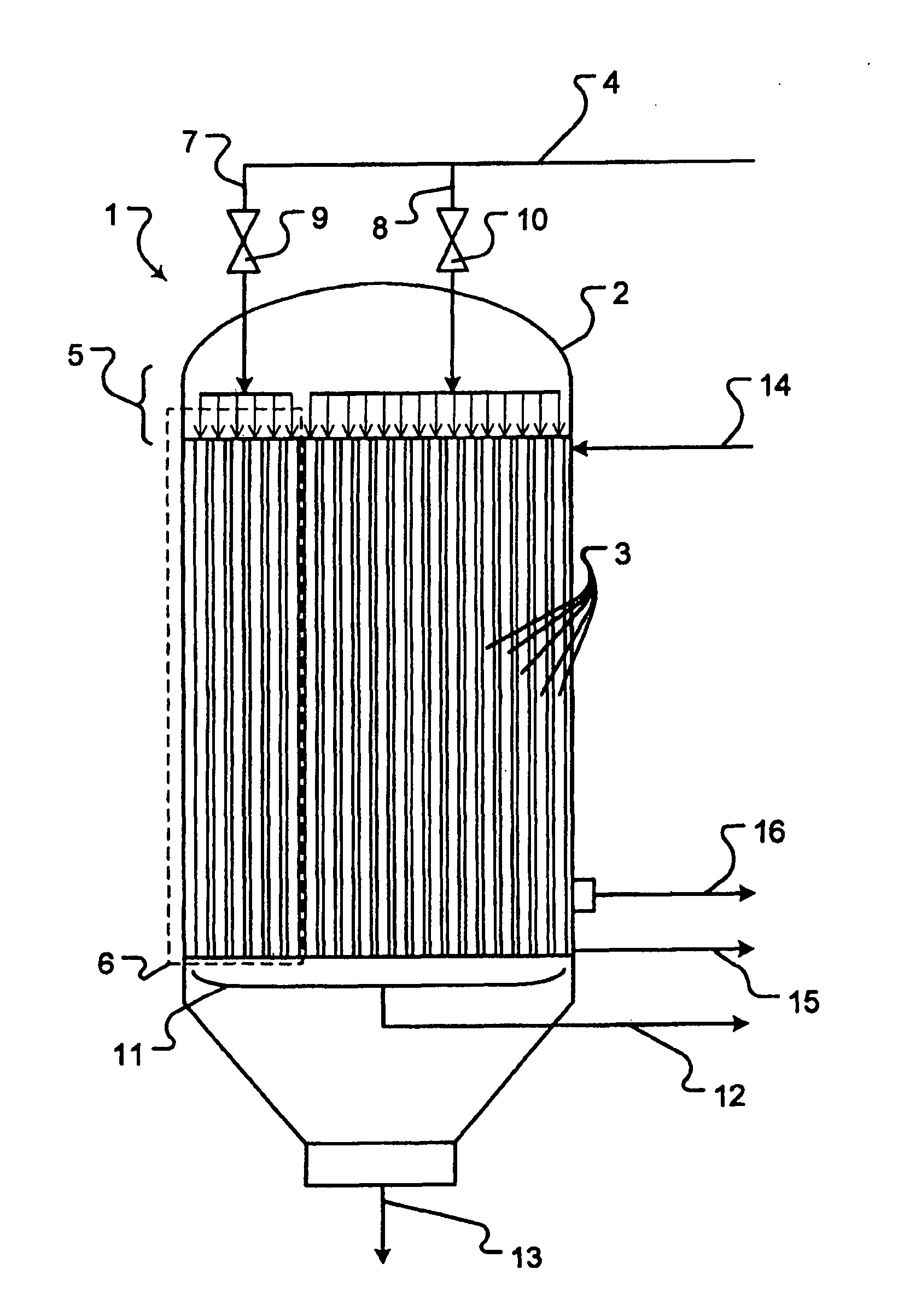

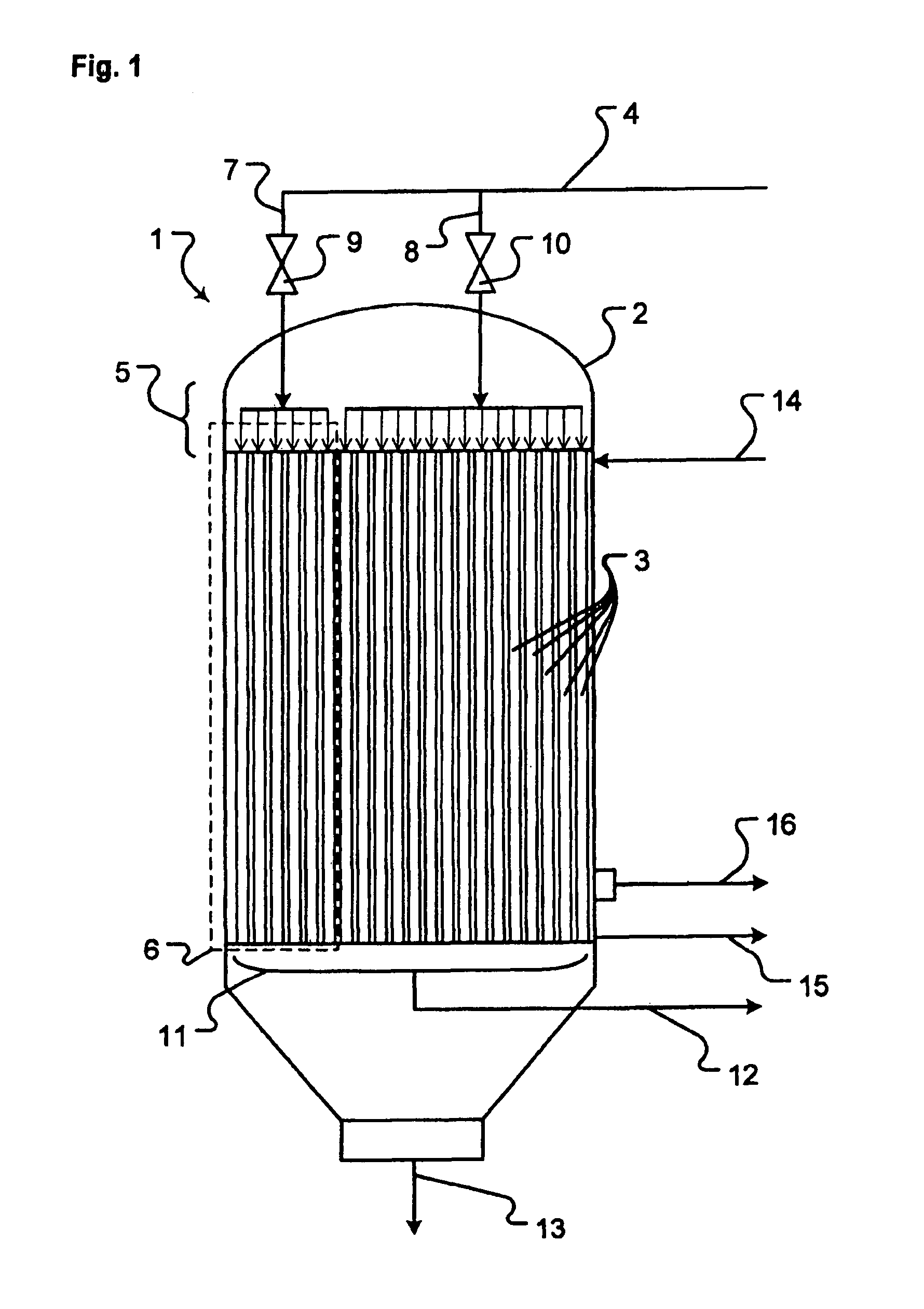

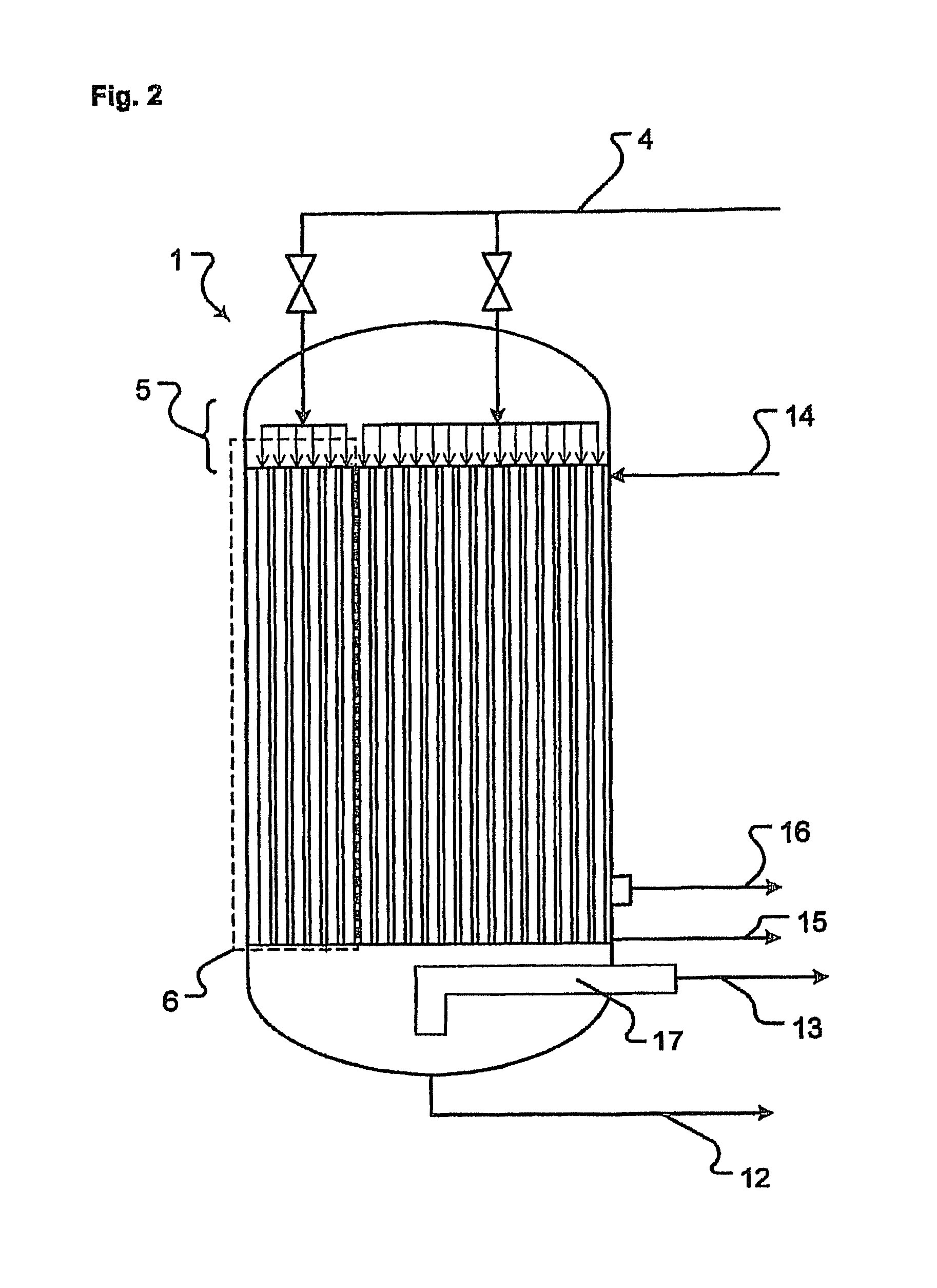

Partial load enabled falling film evaporator and method for operating a partial load

InactiveUS7959768B2Charging-discharging device combinationsDistillation regulation/controlDistributor1,2-Dichloroethane

Owner:UHDE GMBH

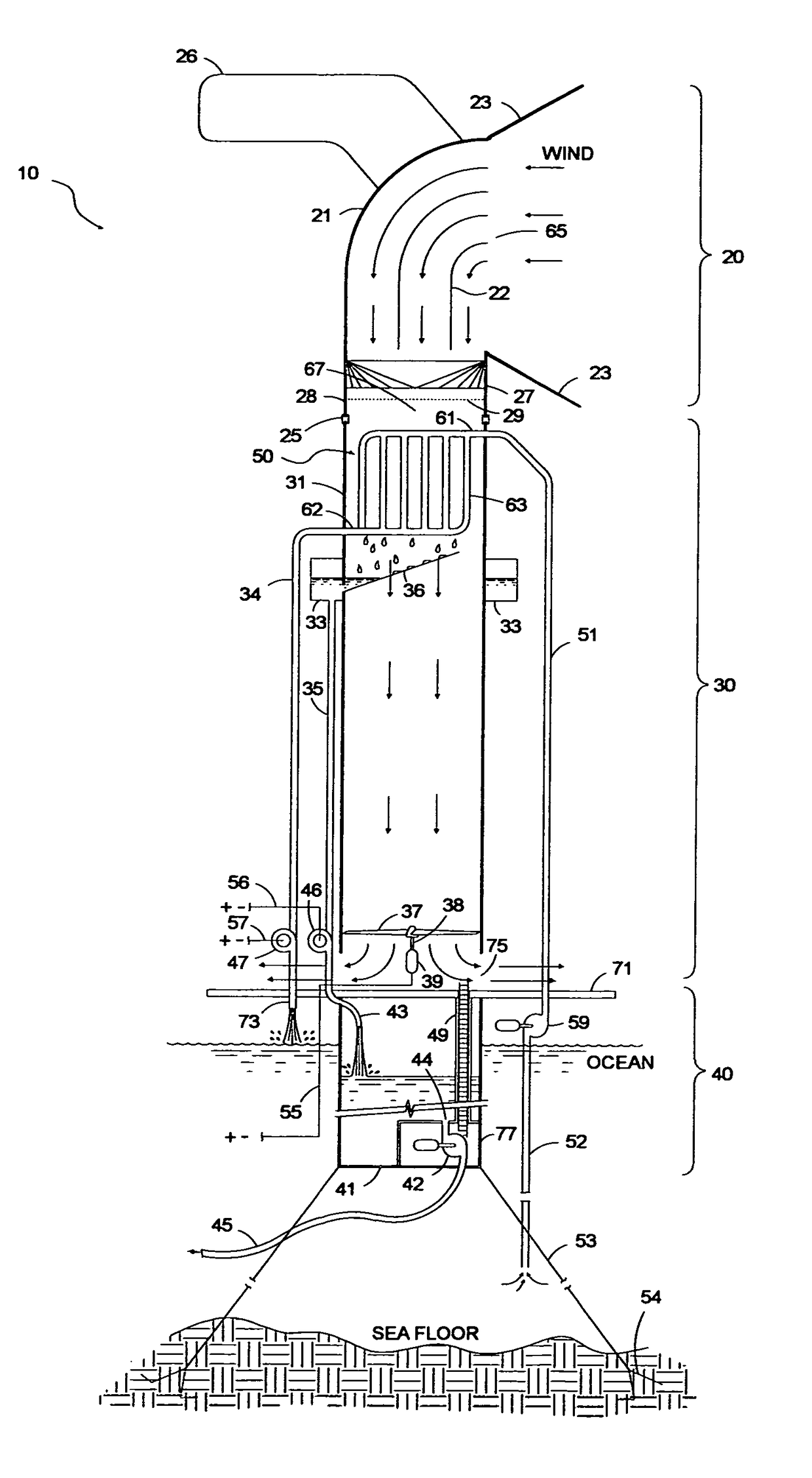

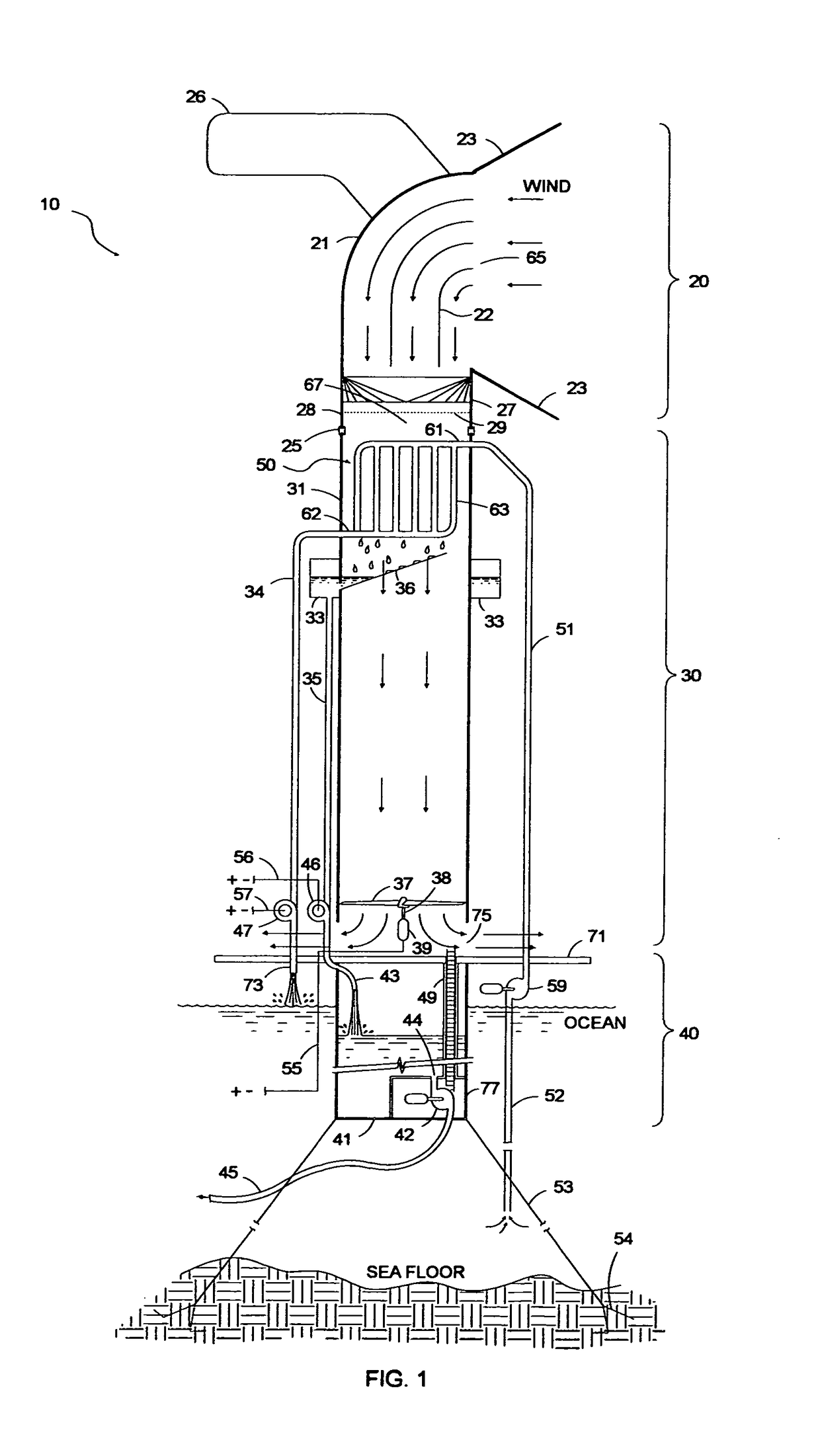

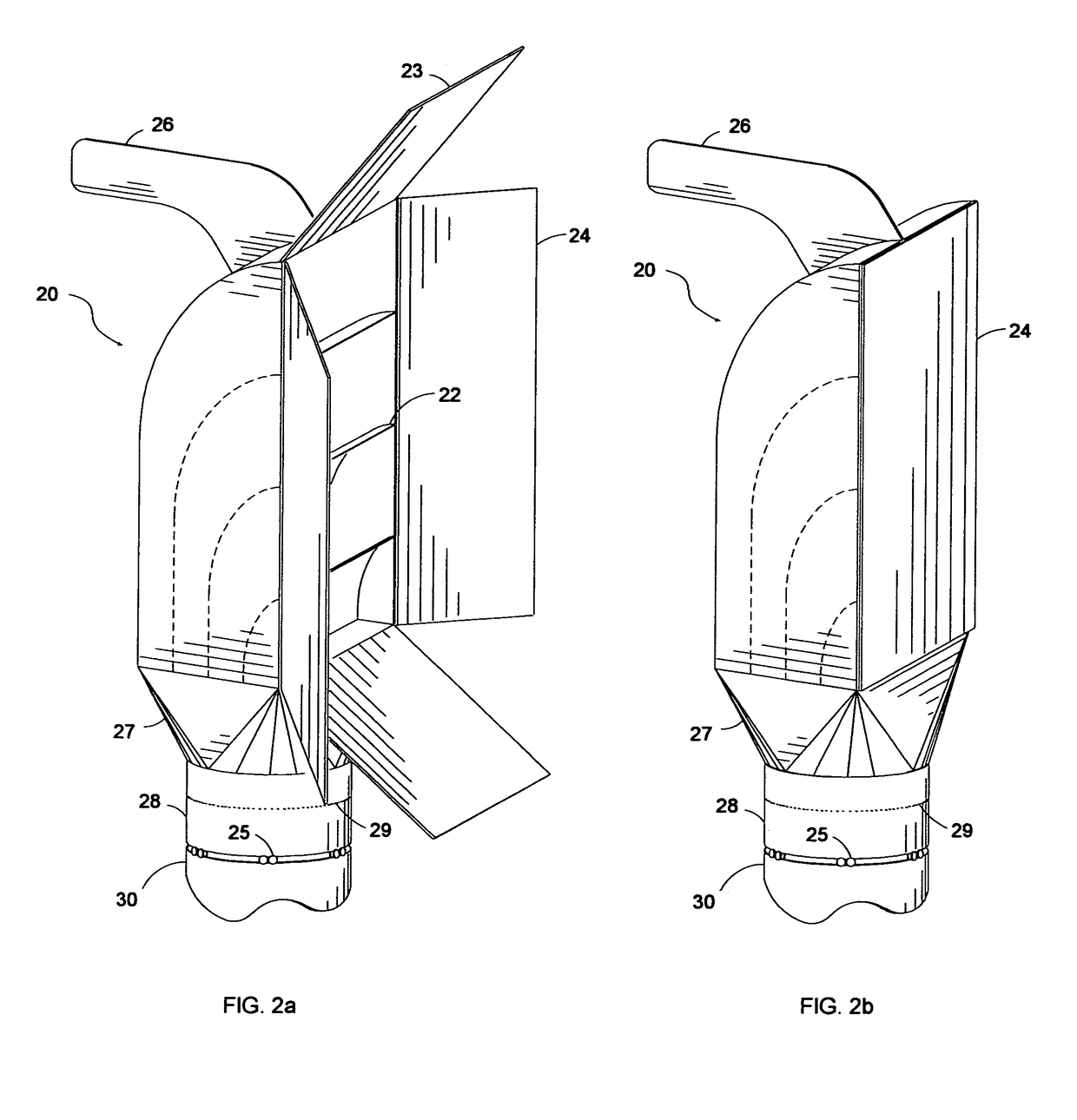

System for producing fresh water and electricity using cold ocean water in combination with wind power

A system for producing potable water and electrical power utilizing the difference in temperature between ambient air and deep, cold ocean water is disclosed. Cold water from depths of 2000 feet (610 meters) or more is pumped to a liquid / gas heat exchanger in the upper portion of a hollow cylinder. Ambient air currents are concentrated and diverted into the exchanger, becoming cooler and denser. Moisture condensing from the ambient air onto the cool surface of the heat exchanger is collected and channeled to storage or piped to shore. The air gains velocity before reaching a wind turbine near the bottom of the cylinder. This turbine is connected to a generator to extract the wind energy. This extracted energy is converted to electricity by the generator and sent to shore.

Owner:HENDRIX GLEN TRUETT

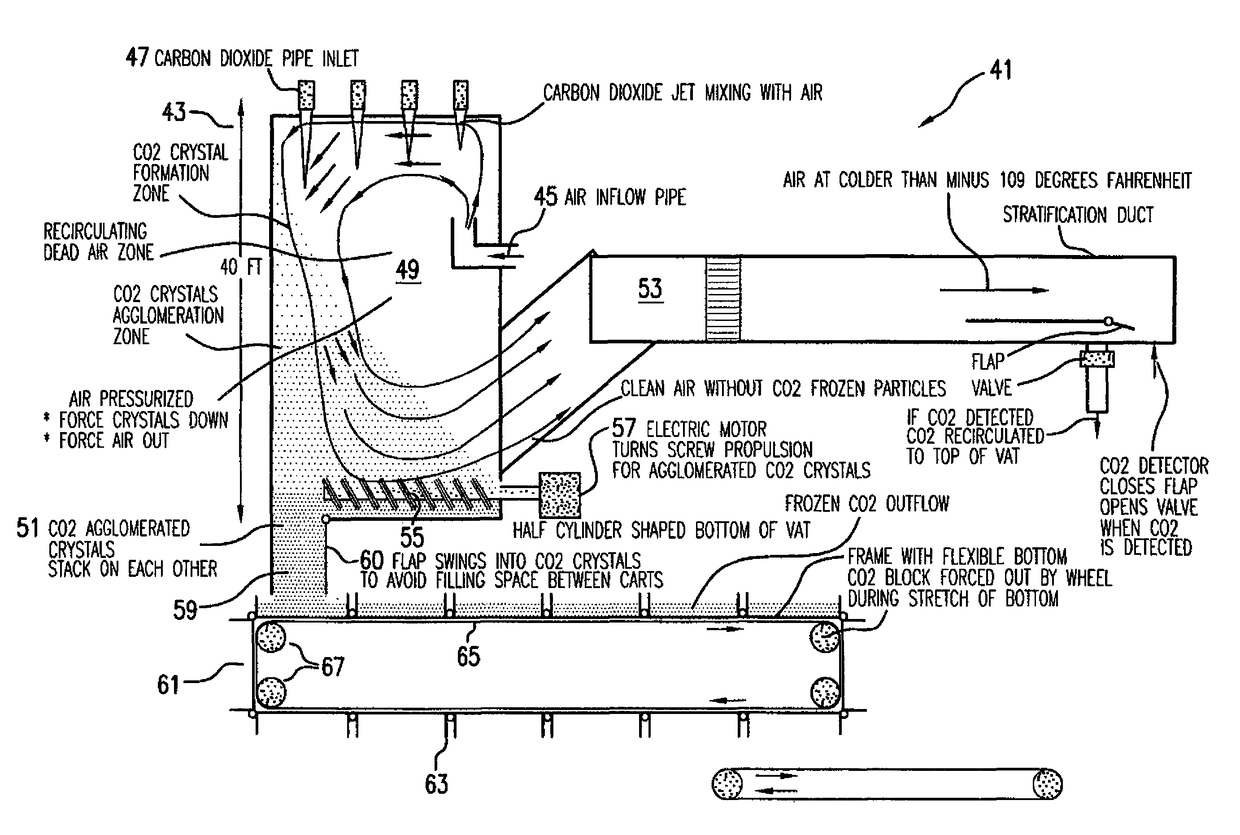

Method and apparatus for using frozen carbon dioxide blocks or cylinders to recover oil from abandoned oil wells

A method and apparatus for enhanced oil recovery comprising separating CO2 gas from coal or flue emissions of a power plant, and flash freezing the CO2 gas with super chilled air, to form frozen CO2 ice blocks or cylinders, wherein the CO2 blocks or cylinders can then be inserted into an abandoned oil well, and the CO2 can be allowed to warm up and change phase to a gas, which enables the CO2 gas to mix with the oil, and helps reduce the viscosity of the oil and allows it to flow more freely, so that it can be pumped out using conventional equipment. A first application comprises having top and bottom valves and the CO2 blocks or cylinders being allowed to change phase to a gas while inside the injection pipe, to increase the pressure therein, such that, by opening the bottom valve, pressurized jets of CO2 gas can be released into the oil, causing the oil to mix vigorously with the carbon dioxide gas, and reduce the viscosity thereof. A second application comprises allowing the CO2 cylinders or blocks to drop into the oil itself, wherein the relatively warm oil causes the frozen CO2 to change phase to a gas, which causes violent gas bubbles to form that vigorously mix with the oil, which helps reduce the viscosity of the oil so it flows more freely through the reservoir.

Owner:ENIS BEN M +1

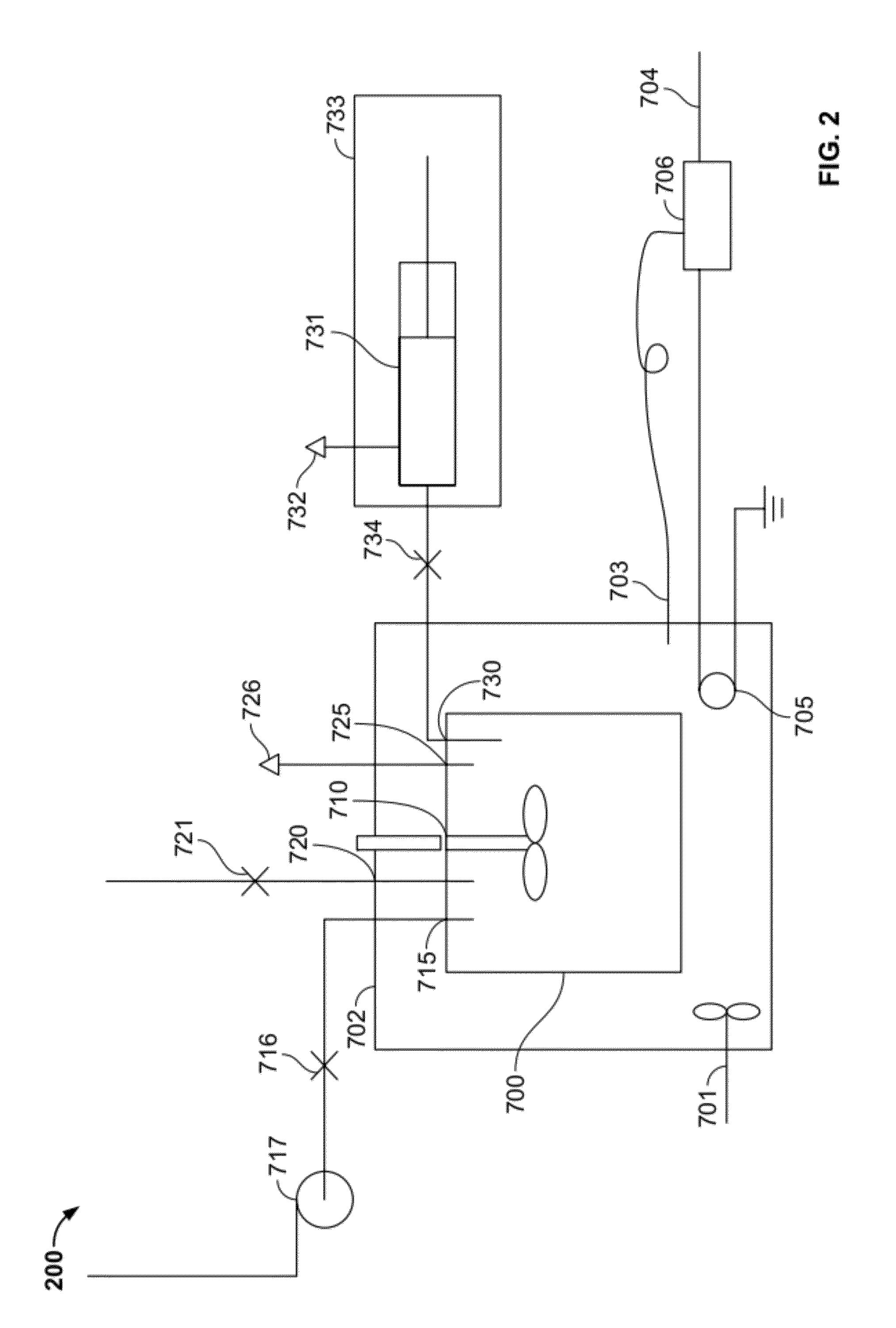

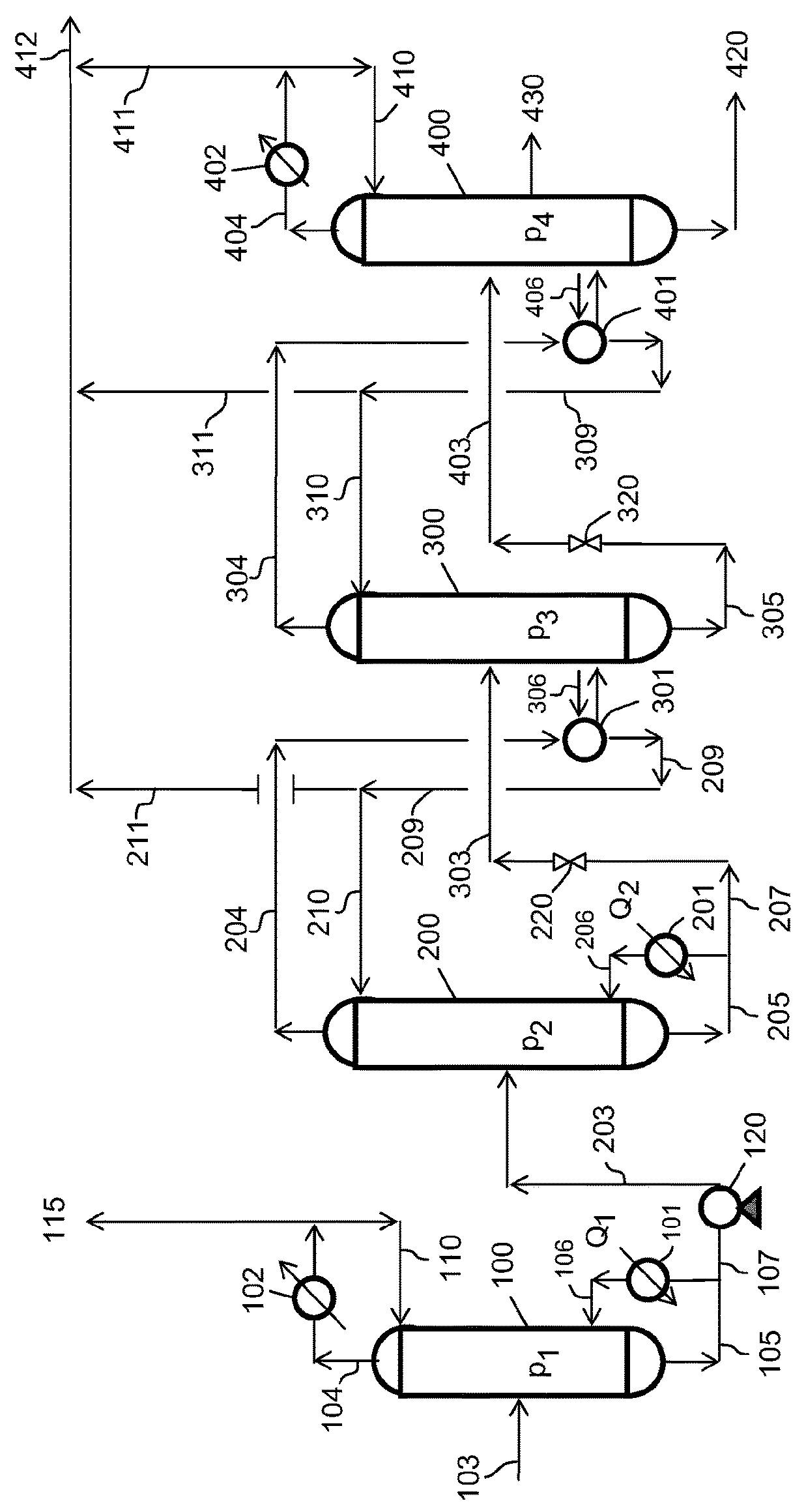

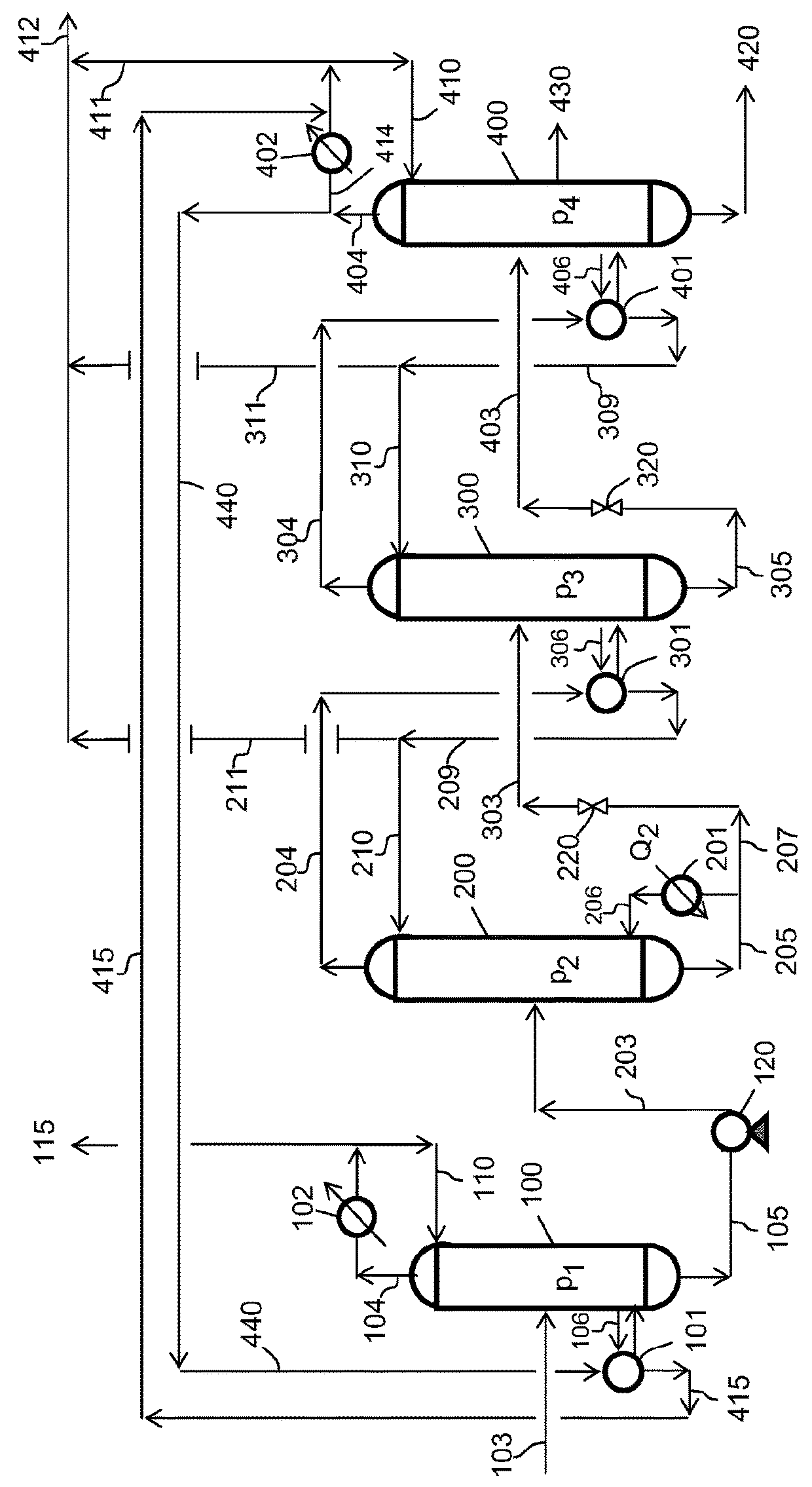

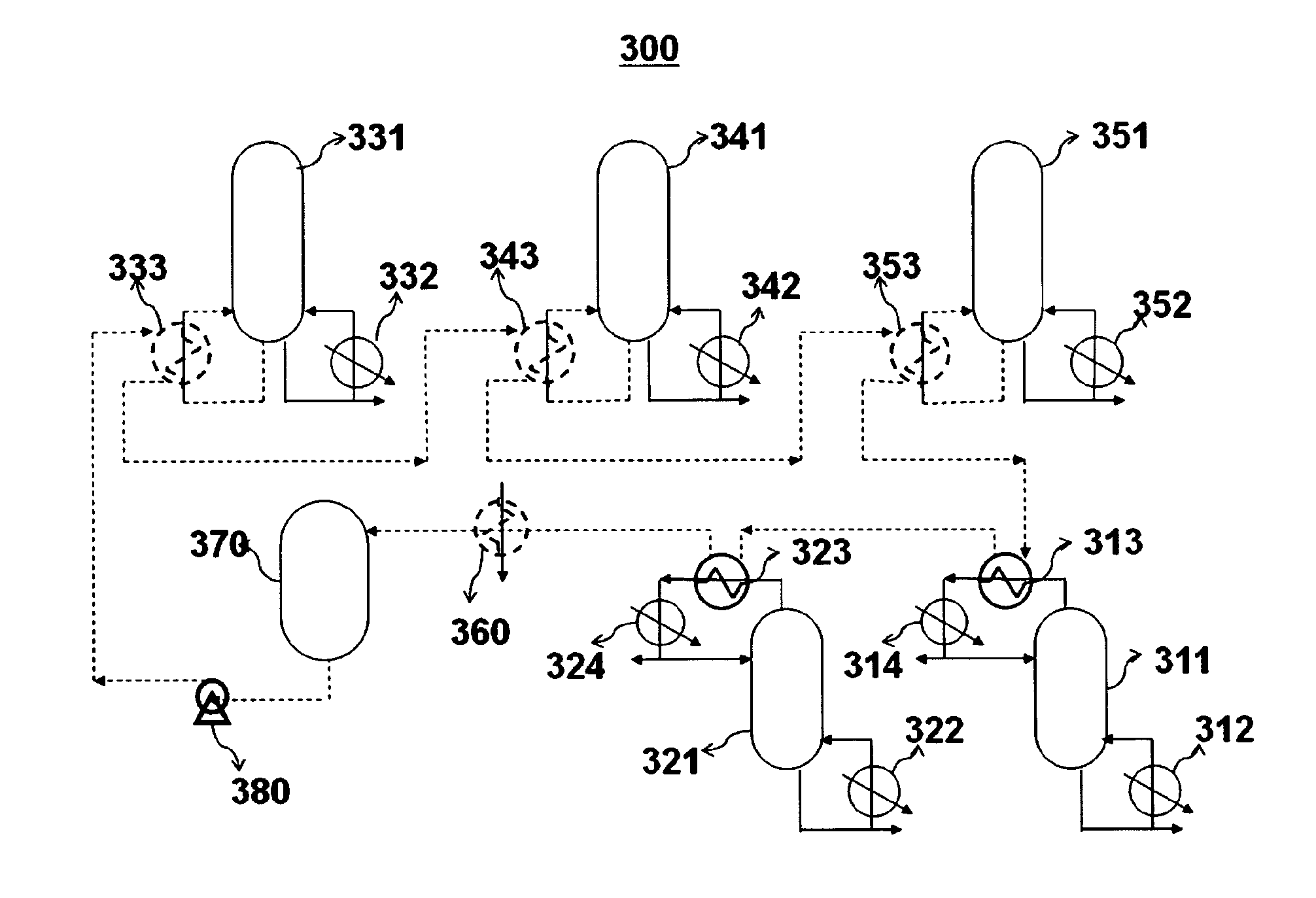

Process and plant for distillation of methanol with heat recuperation

ActiveUS10040738B2Reduce consumptionIncrease heightFermented solutions distillation/rectificationOrganic compound preparationDistillationMethanol

Process and plant for refining crude methanol, comprising at least three distillation stages operating in cascade at decreasing pressures, wherein a first stage (200) operates at a maximum distillation pressure (p2), a second stage (300) operates at a medium distillation pressure (p3), and a final distillation stage (400) operates at a minimum distillation pressure (p4), wherein the first stage and the distillation stage each produce a respective gaseous stream (204, 304) of distilled methanol, and a respective solution containing methanol that is fed to the next distillation stage, and wherein at least one first gaseous stream of distilled methanol (204), produced in the first distillation stage, and a second gaseous stream of distilled methanol (304), produced in the second distillation stage, are used as heat sources to heat the second distillation stage and the final distillation stage, respectively.

Owner:CASALE SA

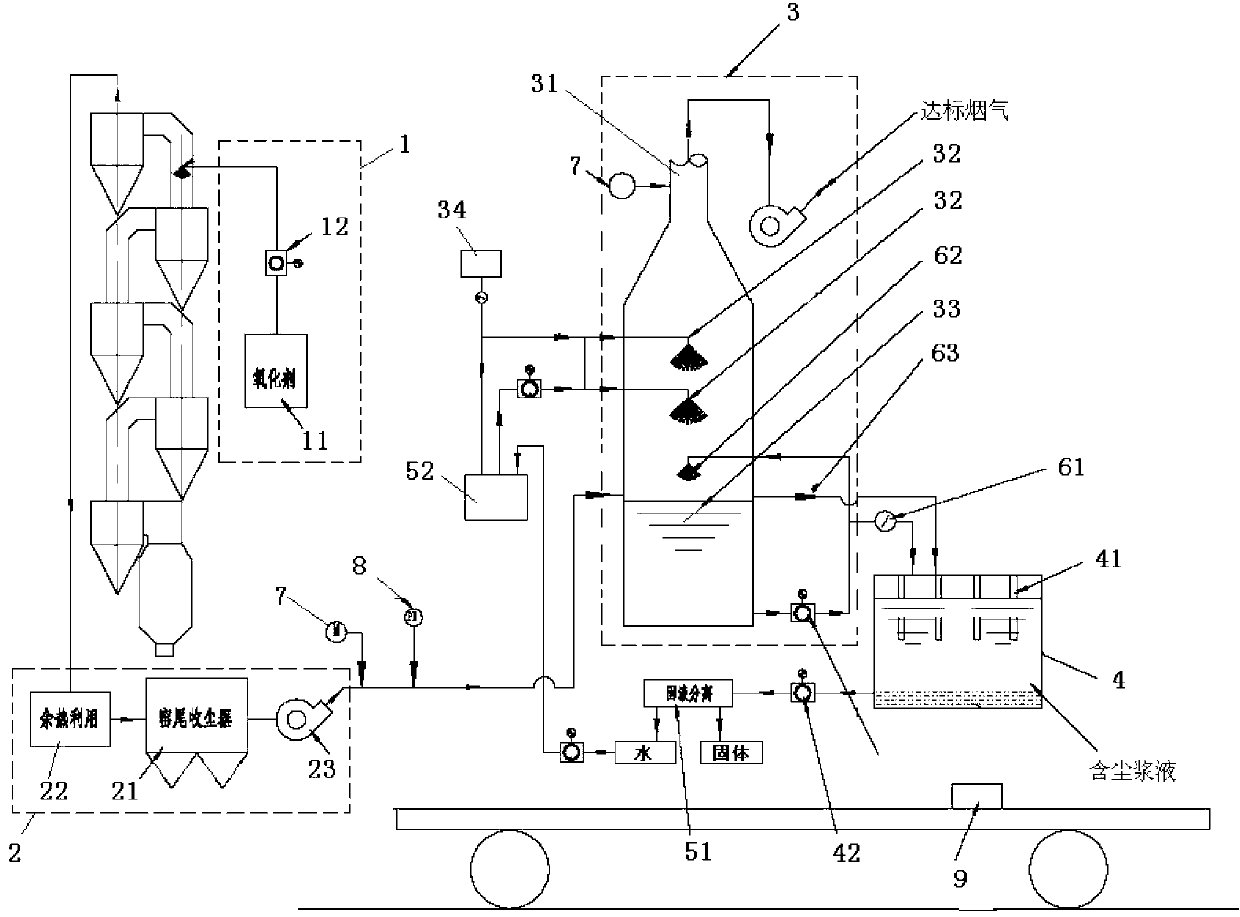

Smoke purification method and smoke purification device

InactiveCN102989280AImprove purification efficiencyFull filterUsing liquid separation agentSeparation machinesPurification methodsHazardous substance

The invention relates to a smoke purification method and a smoke purification device. The method comprises the steps of: (1) smoke pretreatment step: adding an oxidant into low-temperature smoke of a preheater to convert NOx and SO2 in the smoke into water-soluble high-valence compounds; (2) smoke spraying and waste liquid collecting step: mixing the high-valence compounds with water to form high-valence compound waste liquid; and (3) biological denitration step: adding bacteria into the waste liquid to react with the high-valence compounds in the waste liquid to obtain bacterial derivatives. According to the method and the device, the NOx and the SO2 in the smoke are converted into the bacterial derivatives by the oxidation and biochemical treatment so as to obviate emission of greenhouse gas and the catalyst escape in the whole process, thereby obviating the secondary pollution. The high-valence compounds are extremely easy to dissolve in the water to produce acidic waste liquid, so that harmful substances in the smoke can be removed effectively, so that the relatively high smoke purification efficiency can be obtained.

Owner:高玉宗 +2

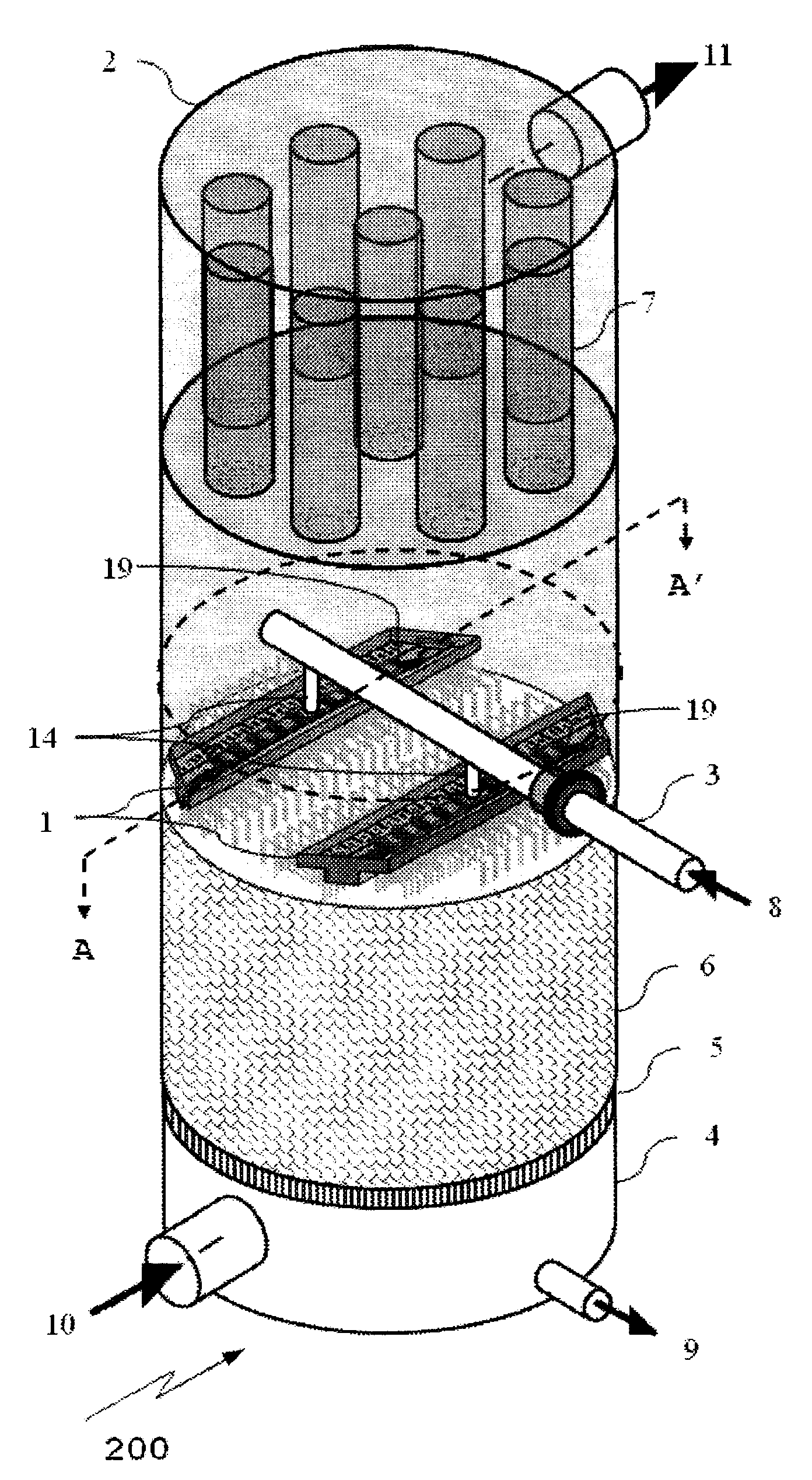

Method and absorber for removal of acid gas from natural gas

ActiveUS9381463B2Reduce power consumptionGas treatmentDispersed particle separationDesorptionPhysical chemistry

The invention relates to a continuous process for removal of acid gas, such as carbon dioxide (CO2) from a fluid stream, such as natural gas comprising mainly hydrocarbons, by means of a absorbent medium in a rotating absorption zone. Subsequently, the acid gas is desorbed in a rotating desorption zone from the absorbent medium to allow the absorbent medium to be recirculated and the acid gas is removed for storage or drying and processing. This process can be carried out continuously, as the absorption medium is re-used.

Owner:DEN NORSKE STATS OLJESELSKAP AS

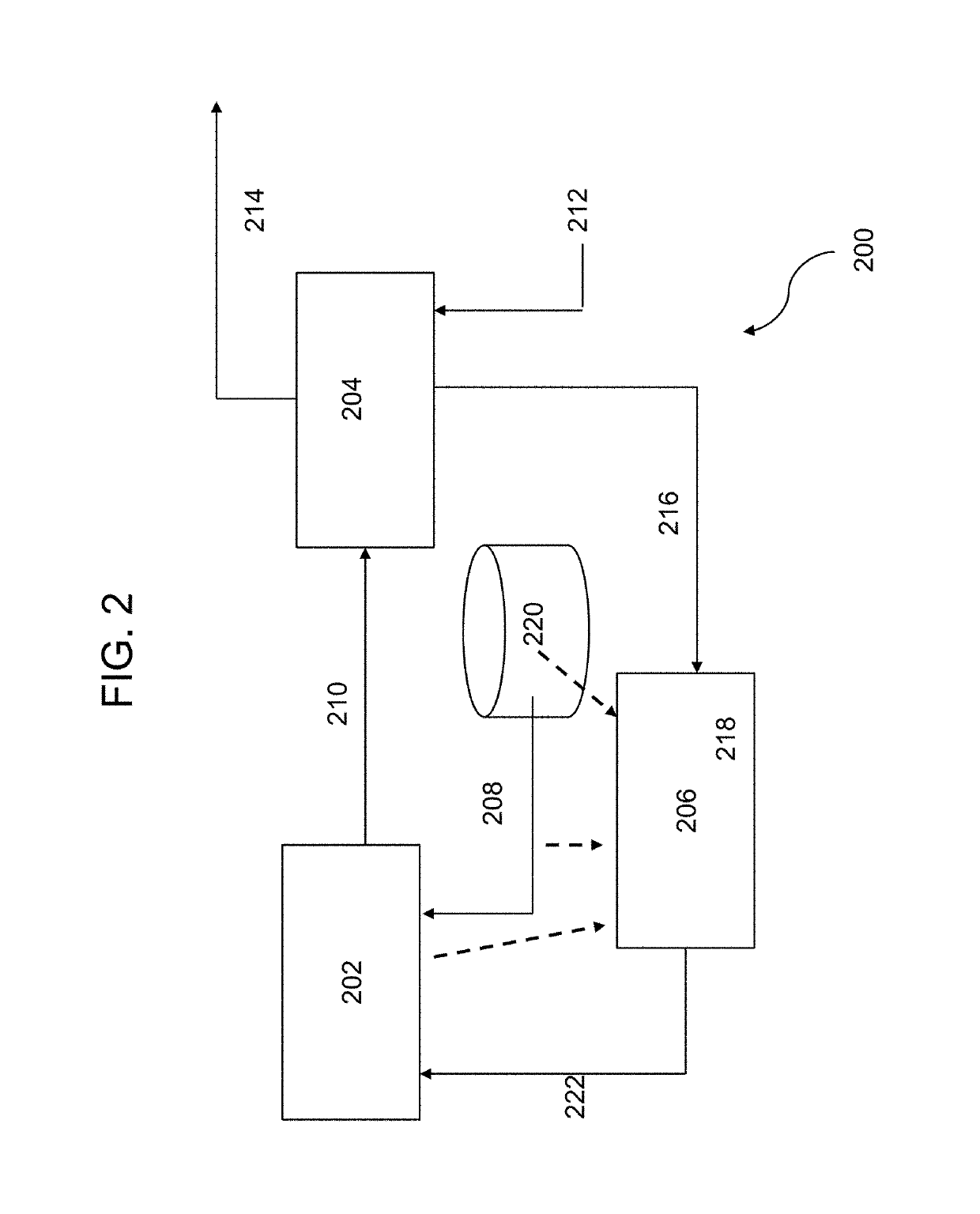

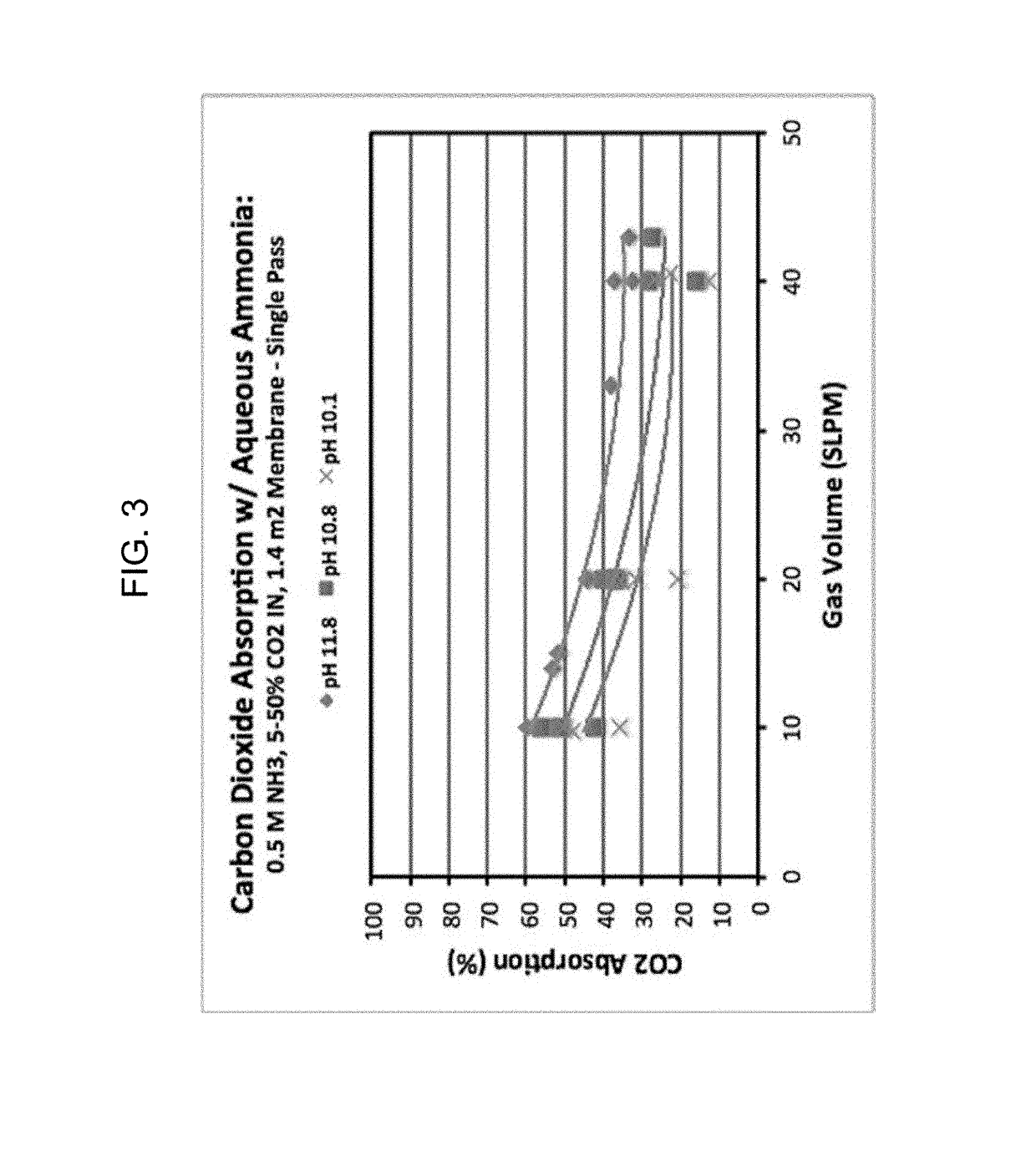

Ammonia mediated carbon dioxide (CO2) sequestration methods and systems

Methods of sequestering carbon dioxide (CO2) are provided. Aspects of the methods include contacting an aqueous capture ammonia with a gaseous source of CO2 under conditions sufficient to produce an aqueous ammonium carbonate. The aqueous ammonium carbonate is then combined with a cation source under conditions sufficient to produce a solid CO2 sequestering carbonate and an aqueous ammonium salt. The aqueous capture ammonia is then regenerated from the from the aqueous ammonium salt. Also provided are systems configured for carrying out the methods.

Owner:BLUE PLANET SYST CORP

Enhanced heat recovery in paraxylene plant

Processes and apparatuses for enhanced heat recover} / in a paraxylene manufacturing plant use a side condenser to recover high quality heat. By placing the side condenser below the location of a feed stream comprising low molecular weight gases, the heat recovered is free of such non-condensable gases. Such gases are undesirable when using the condensed vapor in other applications.

Owner:INEOS US CHEM CO

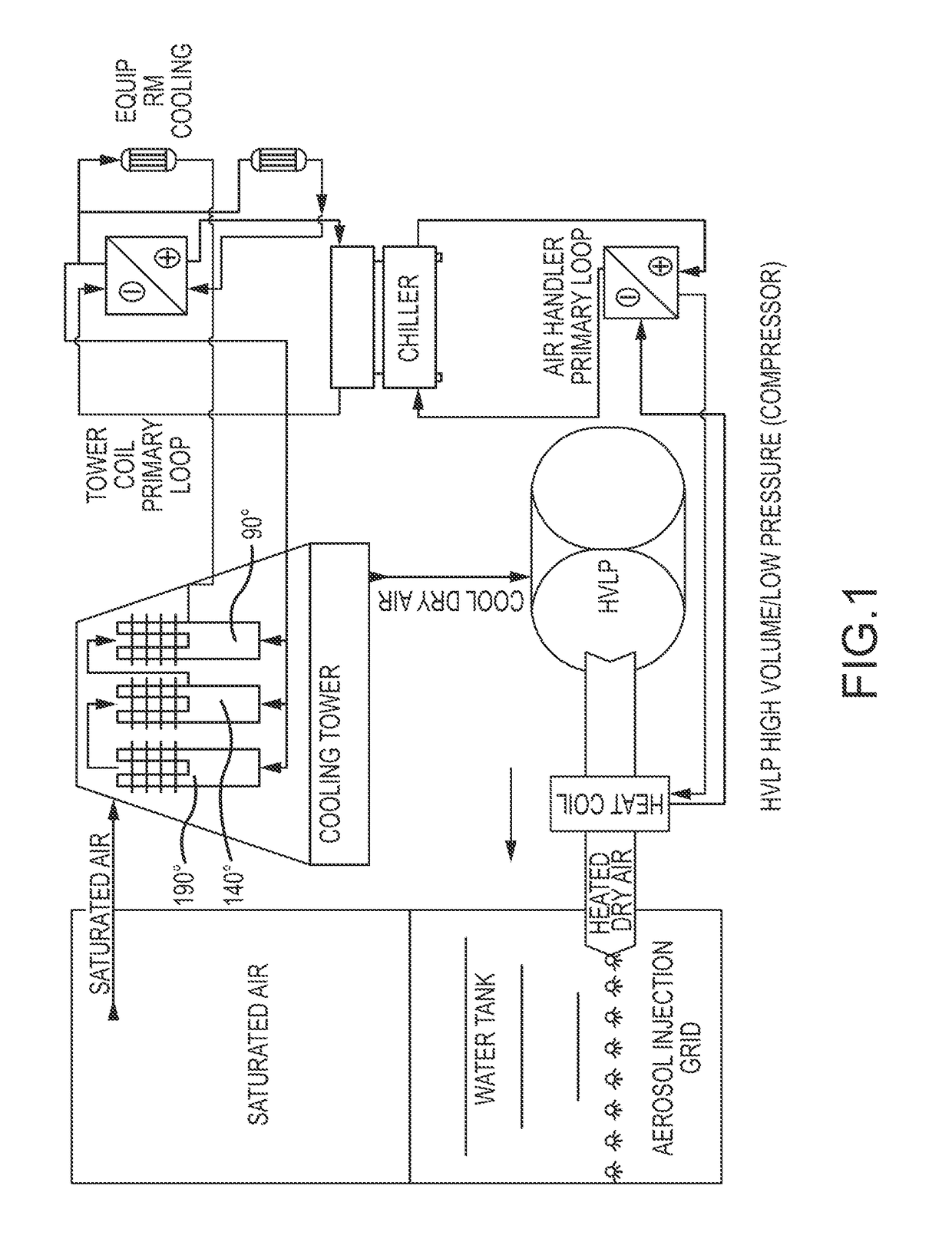

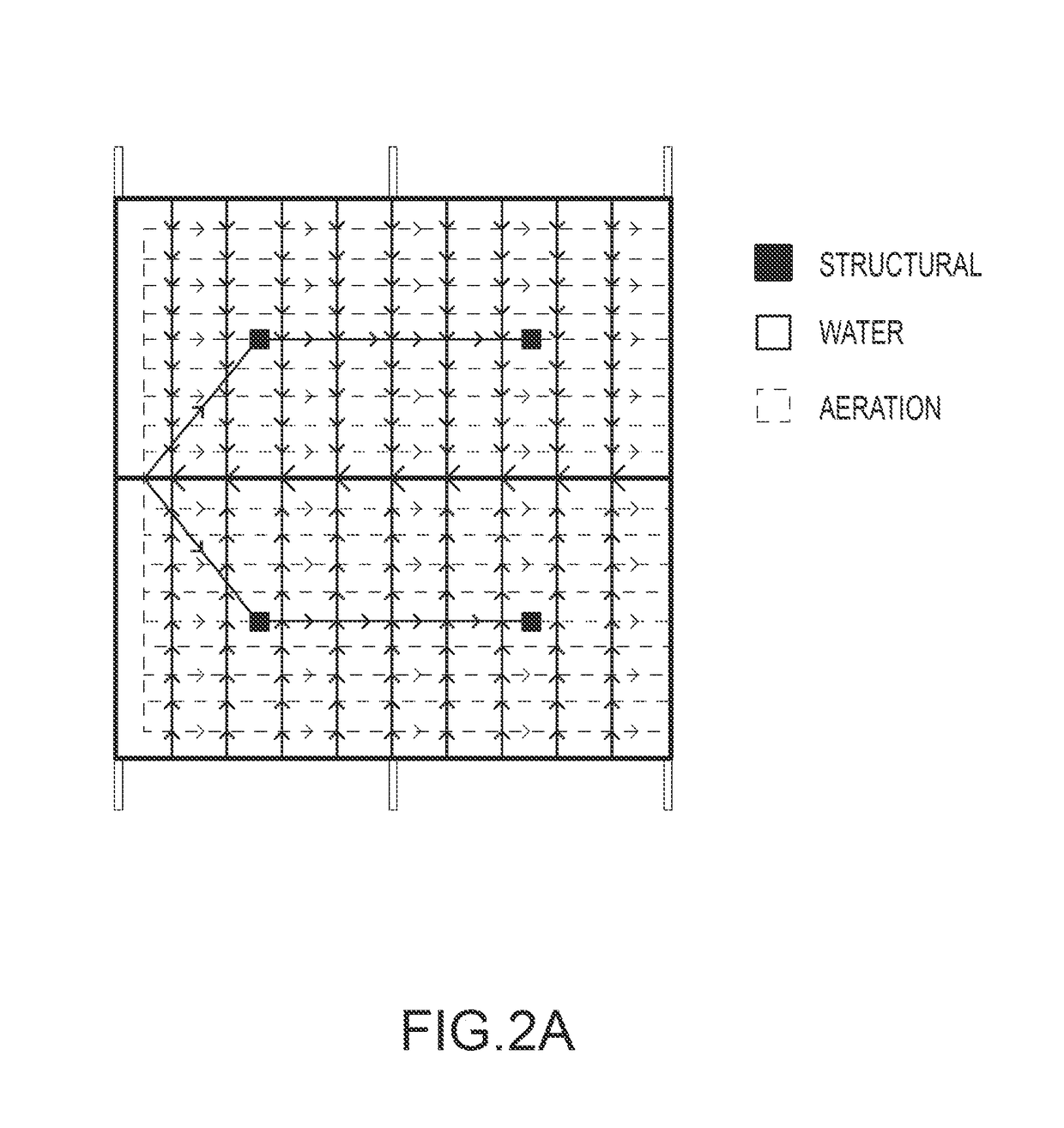

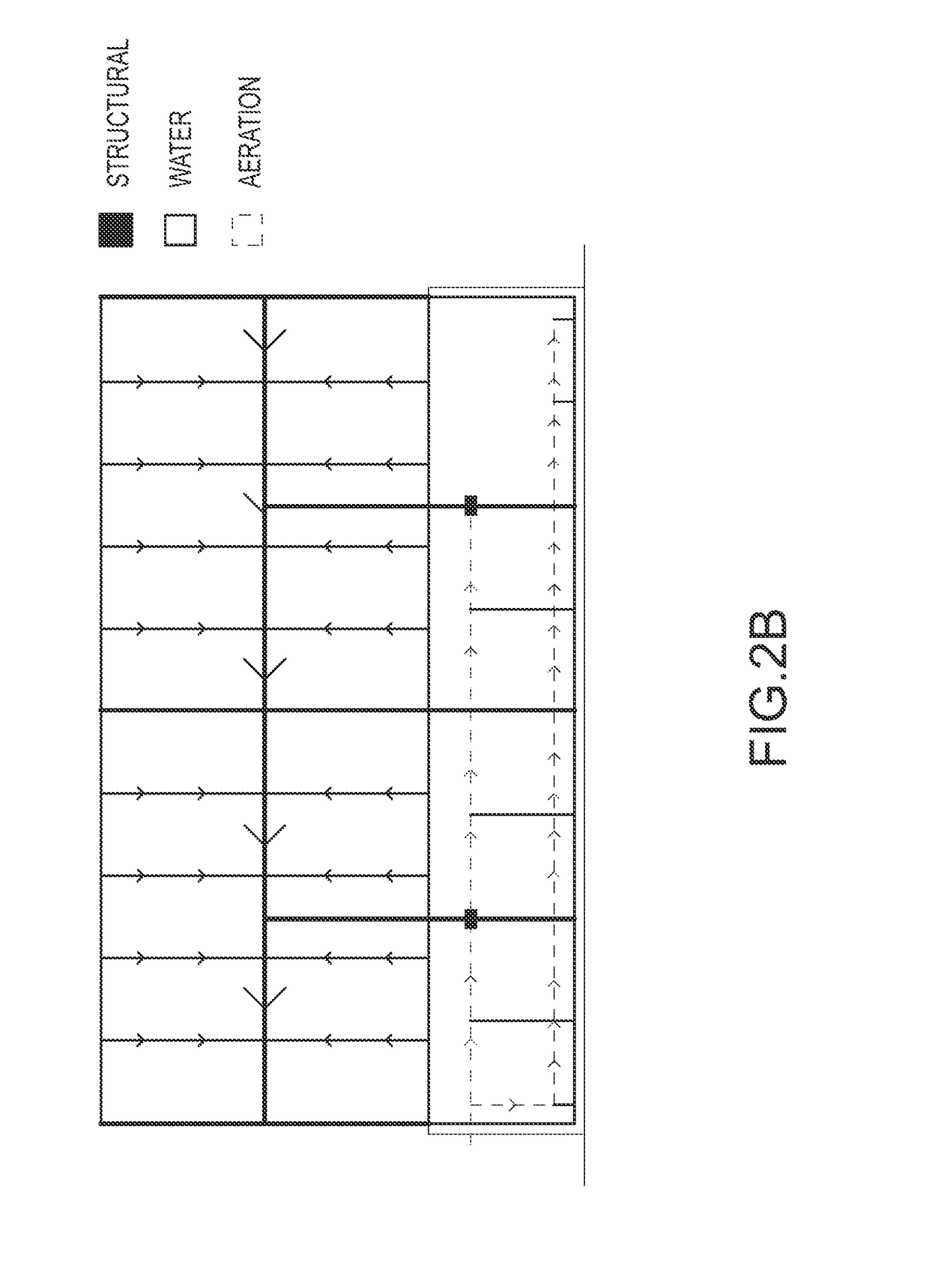

Systems and methods for distillation of water from seawater, brackish water, waste waters, and effluent waters

ActiveUS10144655B2Reduce heat lossGeneral water supply conservationSeawater treatmentSaline waterCooling tower

The present invention relates to water purification using solar energy. More specifically, systems and methods according to the present invention collect solar energy to heat non-potable water in a super-insulated structure. Compressed heated air is injected to evaporate water vapor out of brackish water, saltwater, or dirty water, thereby creating saturated air. The saturated air is drawn through a cooling tower and distilled water is precipitated. The systems and methods employ heat recovery and recycling processes to maximize energy efficiency.

Owner:GLOBAL WATER FARMS CORP

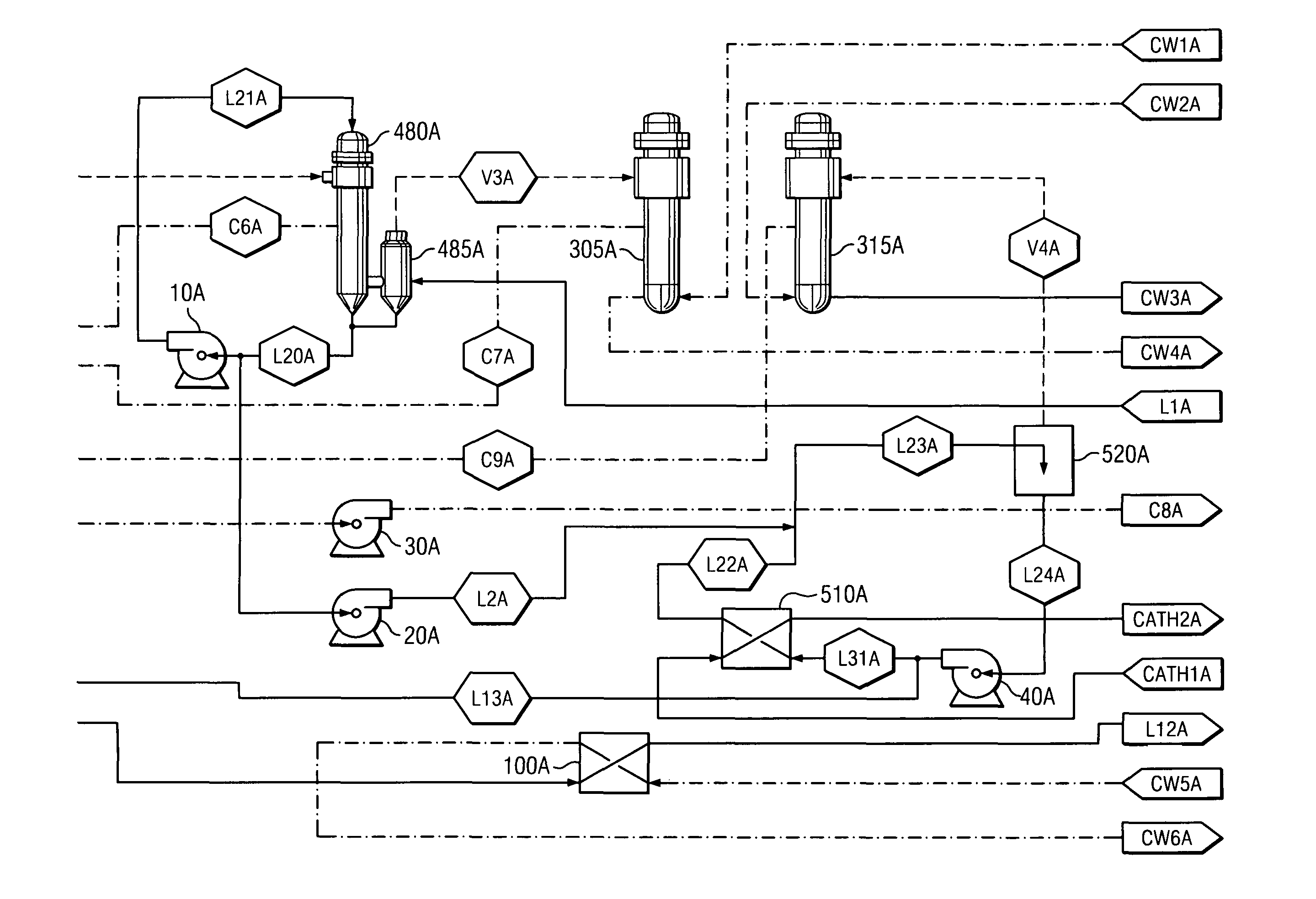

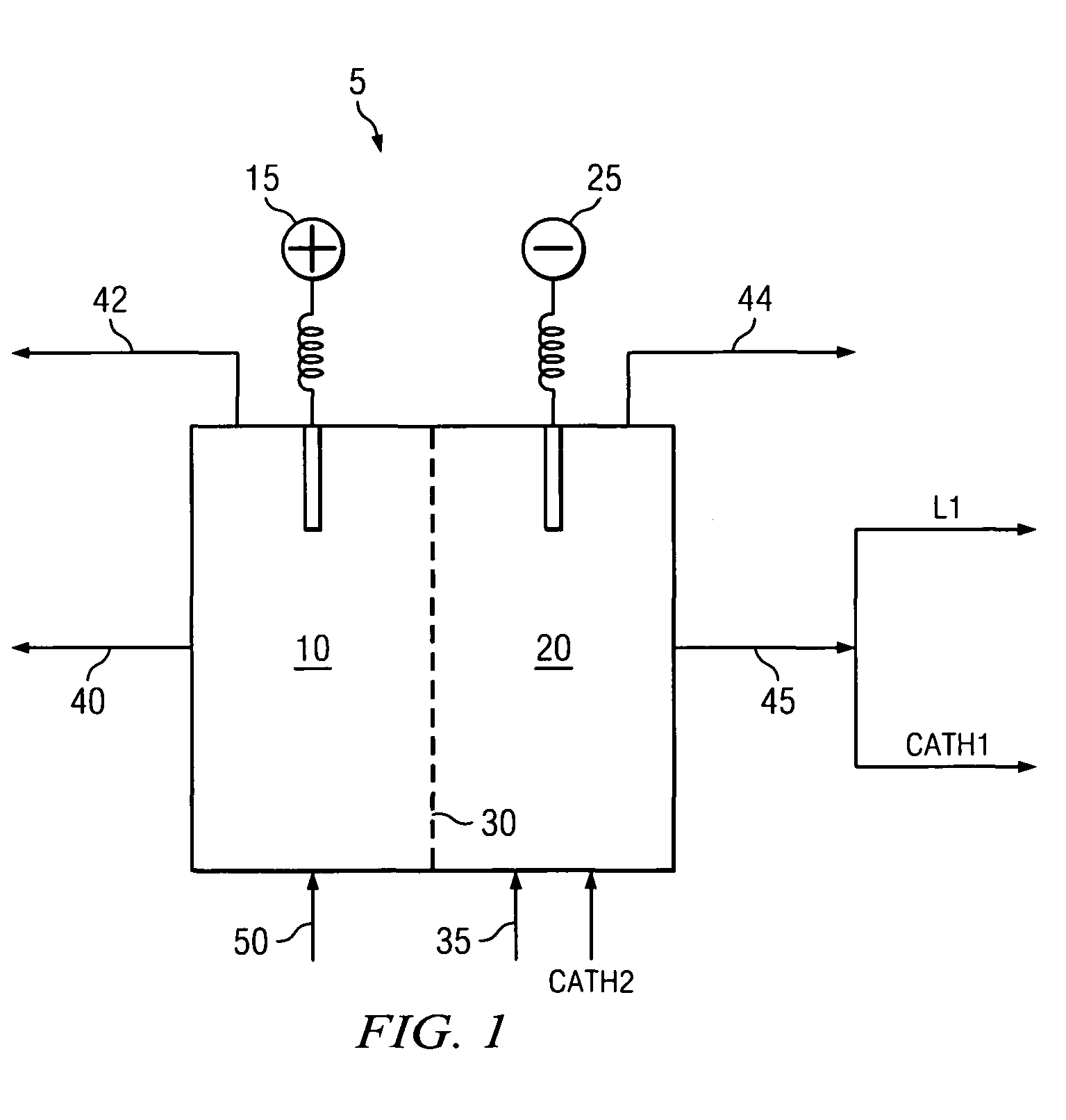

Method of concentrating an aqueous caustic alkali using a catholyte heat recovery evaporator

ActiveUS8317994B2Lower heating costsAmount of evaporationCellsWater/sewage treatmentMultiple-effect evaporatorEvaporation chamber

A method for concentrating an aqueous caustic alkali produced by a membrane cell process by using a single or multiple effect evaporator system in which the vapor flows in a counter direction to the aqueous caustic alkali flow and the heat recovered from the catholyte circulation line is used as part of the concentration process. In one embodiment, a catholyte heat recovery heat exchanger and evaporation chamber are located after the last effect of a multiple effect evaporator system. In another embodiment, the catholyte heat recovery heat exchanger and evaporation chamber are located prior to the single or multiple effect evaporator system. In yet another embodiment, the catholyte heat recovery process is used in conjunction with additional heat exchanger processes to further concentrate the final product as desired.

Owner:WESTLAKE VINYL CORP

Method for recovering low-temperature heat and application of the method to an aromatics complex

InactiveUS9908061B2Reduce consumptionLow operating pressureRefining to change hydrocarbon structural skeletonEvaporation with vapour compressionDistillationEngineering

A method for recovering heat available at low temperature in a process and its use in order to reduce the energy consumption of the said process, and application of this method to an aromatics complex in which the low-temperature heat is recovered at the head of distillation columns in the form of low-pressure steam and is reused to reboil other distillation columns in which the operating pressure has possibly been lowered.

Owner:AXENS SA

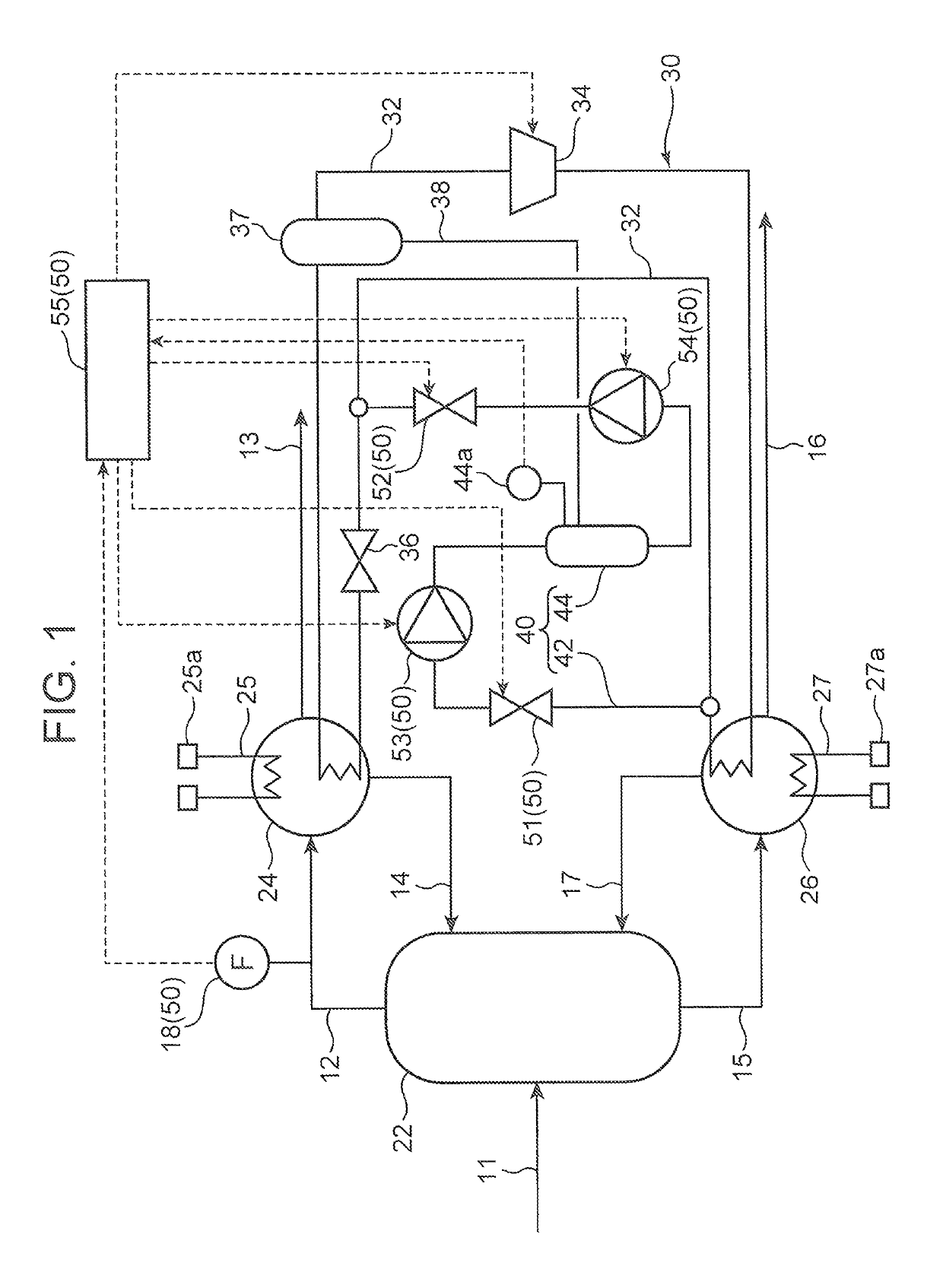

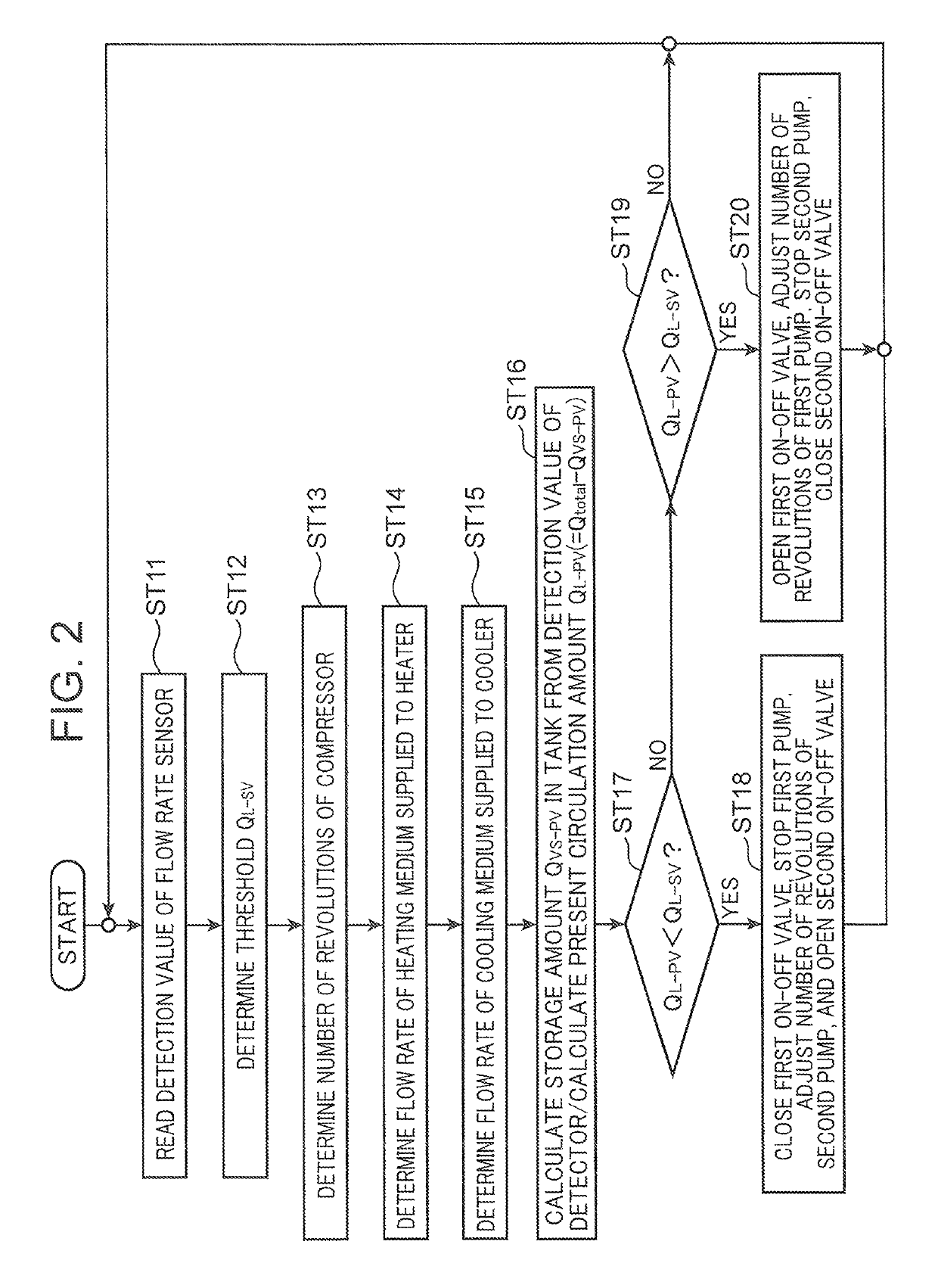

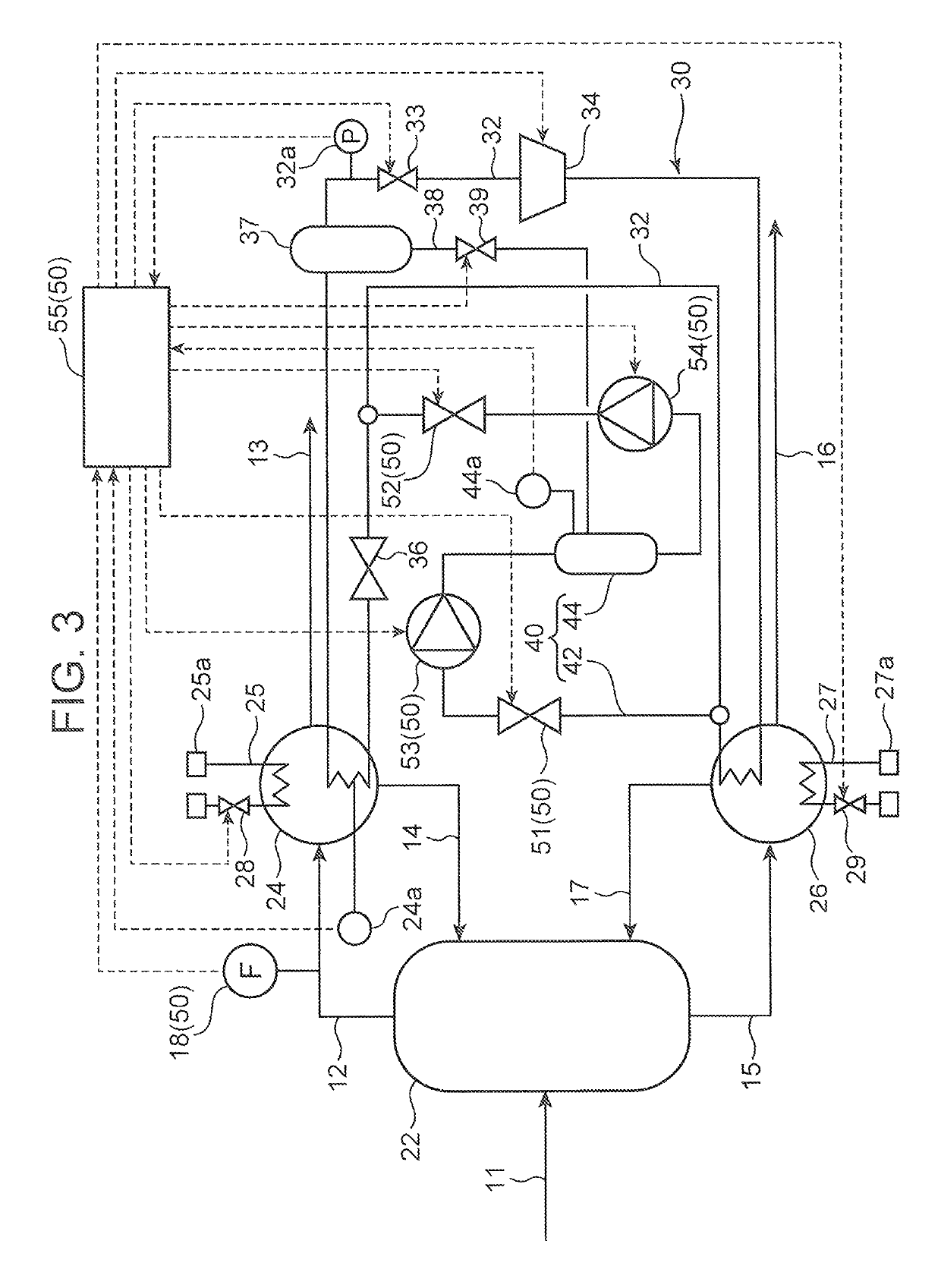

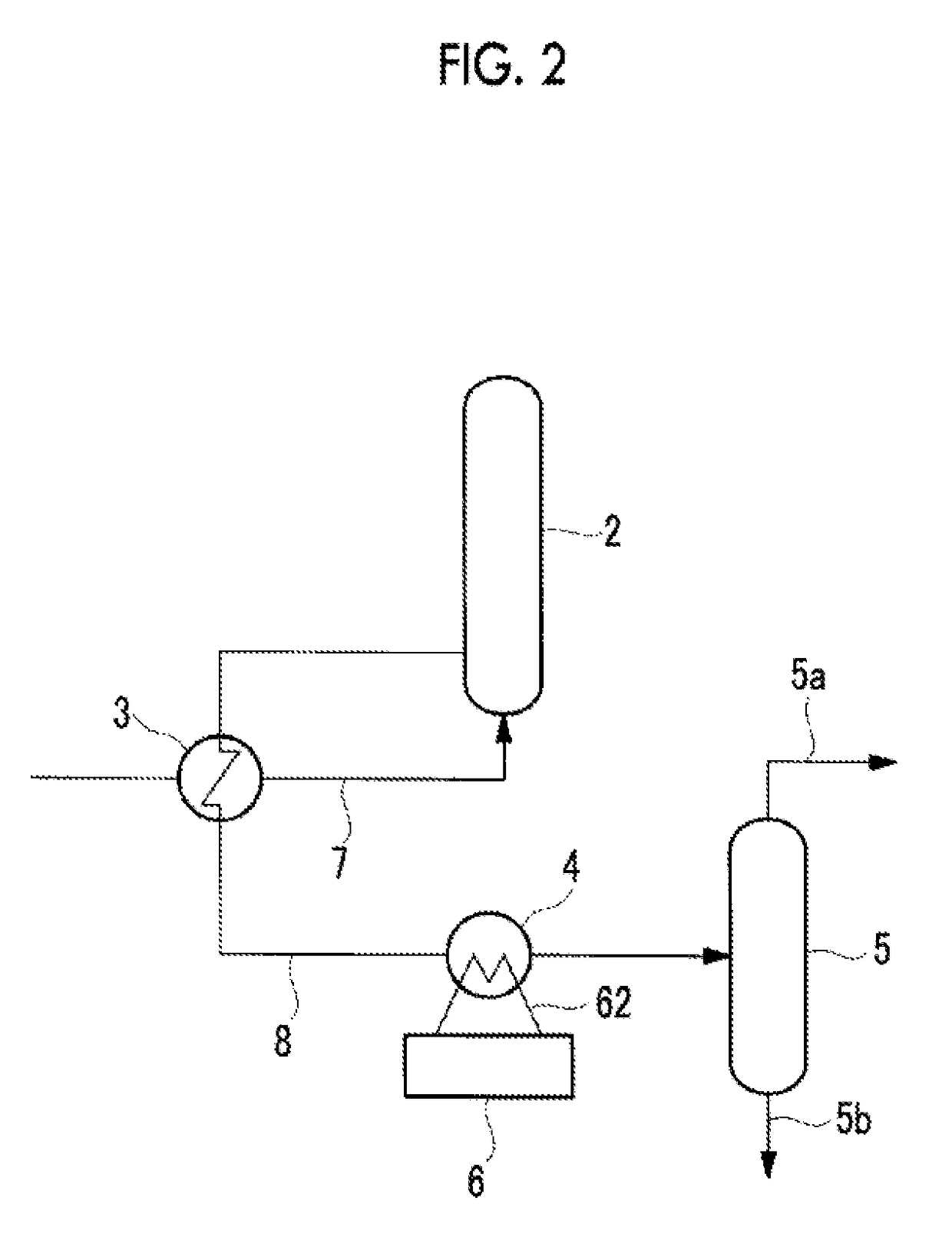

Distillation apparatus

ActiveUS10272358B2Efficient collectionEfficient thermal energyDistillation regulation/controlEnergy recuperation in distillationDistillationLiquid state

A distillation apparatus includes a separator, a cooler, a heater, and a heat collection circuit. The heat collection circuit includes a circulation channel, a compressor, an expanding mechanism, a storing section capable of storing a working medium in a liquid state, and a circulation-amount adjusting section that adjusts a circulation amount of the working medium. The circulation-amount adjusting section adjusts an outflow amount of the working medium, which is stored in the storing section, to the circulation channel or an inflow amount of the working medium, which is circulating in the circulation channel, to the storing section such that the circulation amount increases or decreases according to an increase or a decrease in a flow rate of the first output fluid.

Owner:KOBE STEEL LTD

Method and apparatus for sweetening and/or dehydrating a hydrocarbon gas, in particular a natural gas

ActiveUS9273261B2Efficient separationEffective maintenanceGas treatmentDispersed particle separationSyngasProduct gas

Owner:SIME

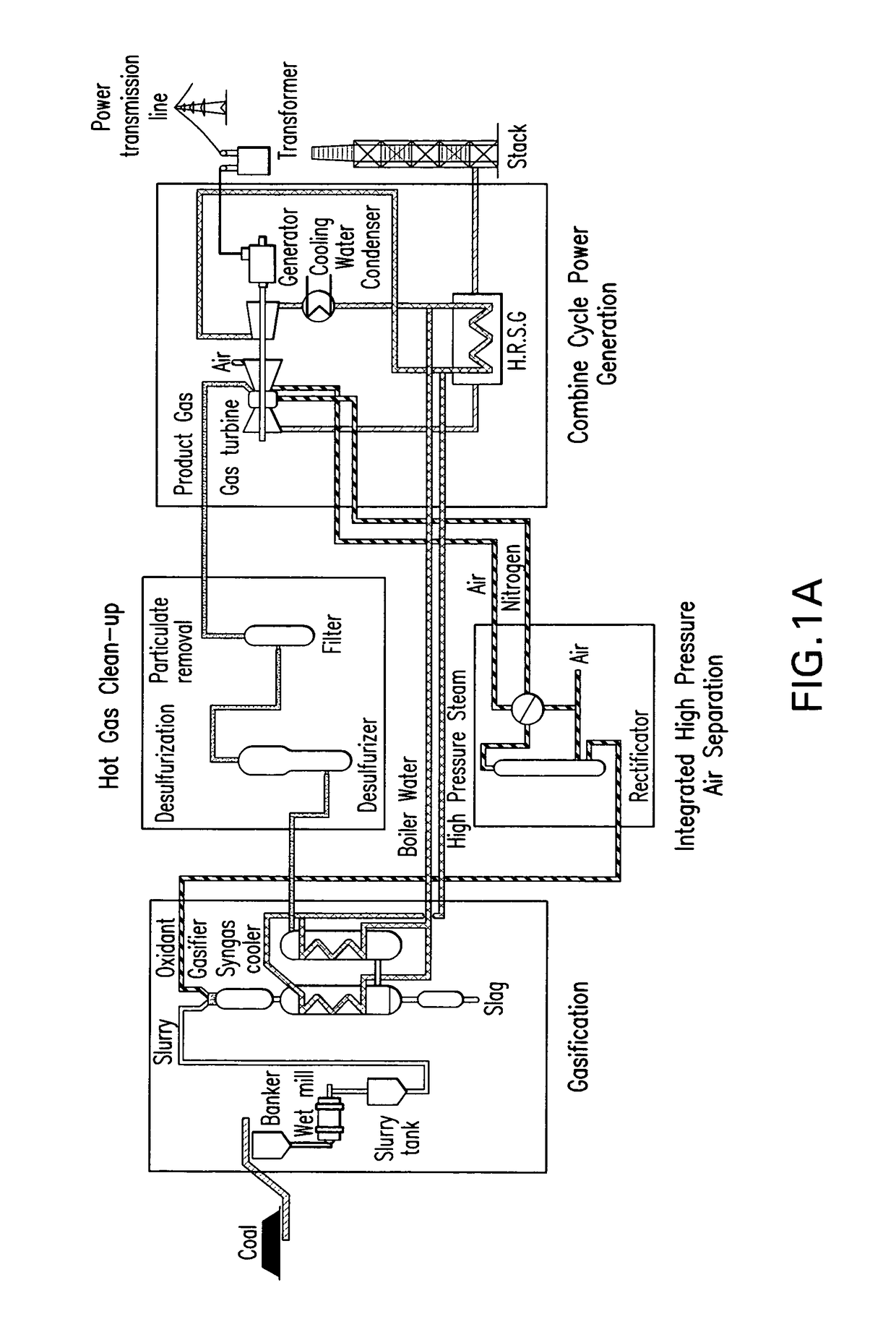

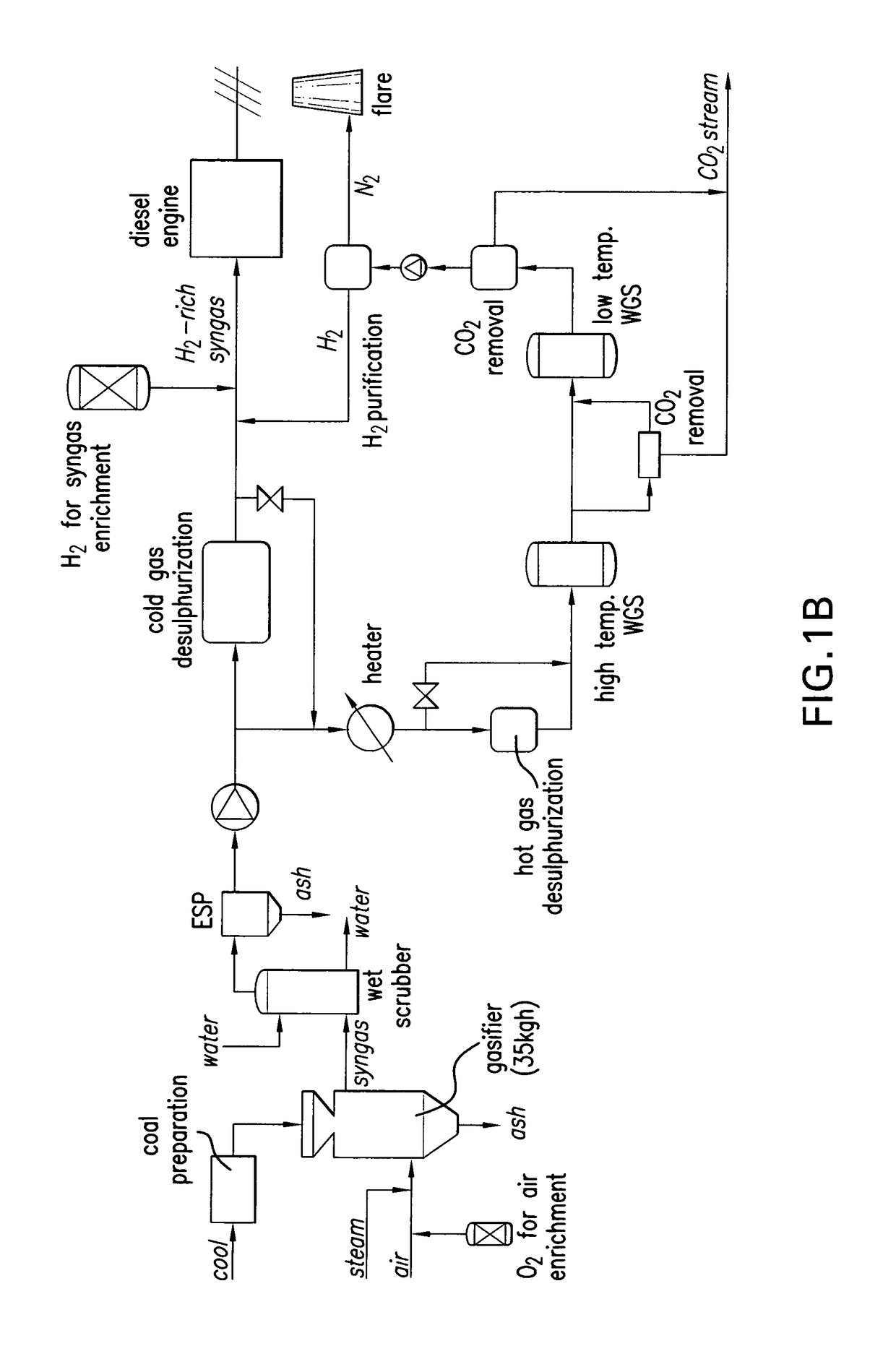

Methanol plant and gasoline synthesis plant

ActiveUS9790154B2Save on fuel costsGeneral water supply conservationSeawater treatmentGasolineFresh water

Provided is a methanol plant that can obtain fresh water from sea water by using, in a seawater desalination device, the exhaust heat discharged in a step for producing methanol from natural gas. The methanol plant is provided with: a heat exchanger (4) that recovers into a thermal medium (for example, seawater) the exhaust heat discharged from a step for producing methanol from a feed stock (for example, natural gas); and a seawater desalinization device (6) that obtains freshwater from seawater using the exhaust heat recovered by means of the thermal medium.

Owner:MITSUBISHI HEAVY IND ENG LTD

System for recovering waste heat

ActiveUS9574829B2Improve energy efficiencyRecuperative heat exchangersEvaporation with vapour compressionDistillationThermal water

Owner:SK PICGLOBAL CO LTD

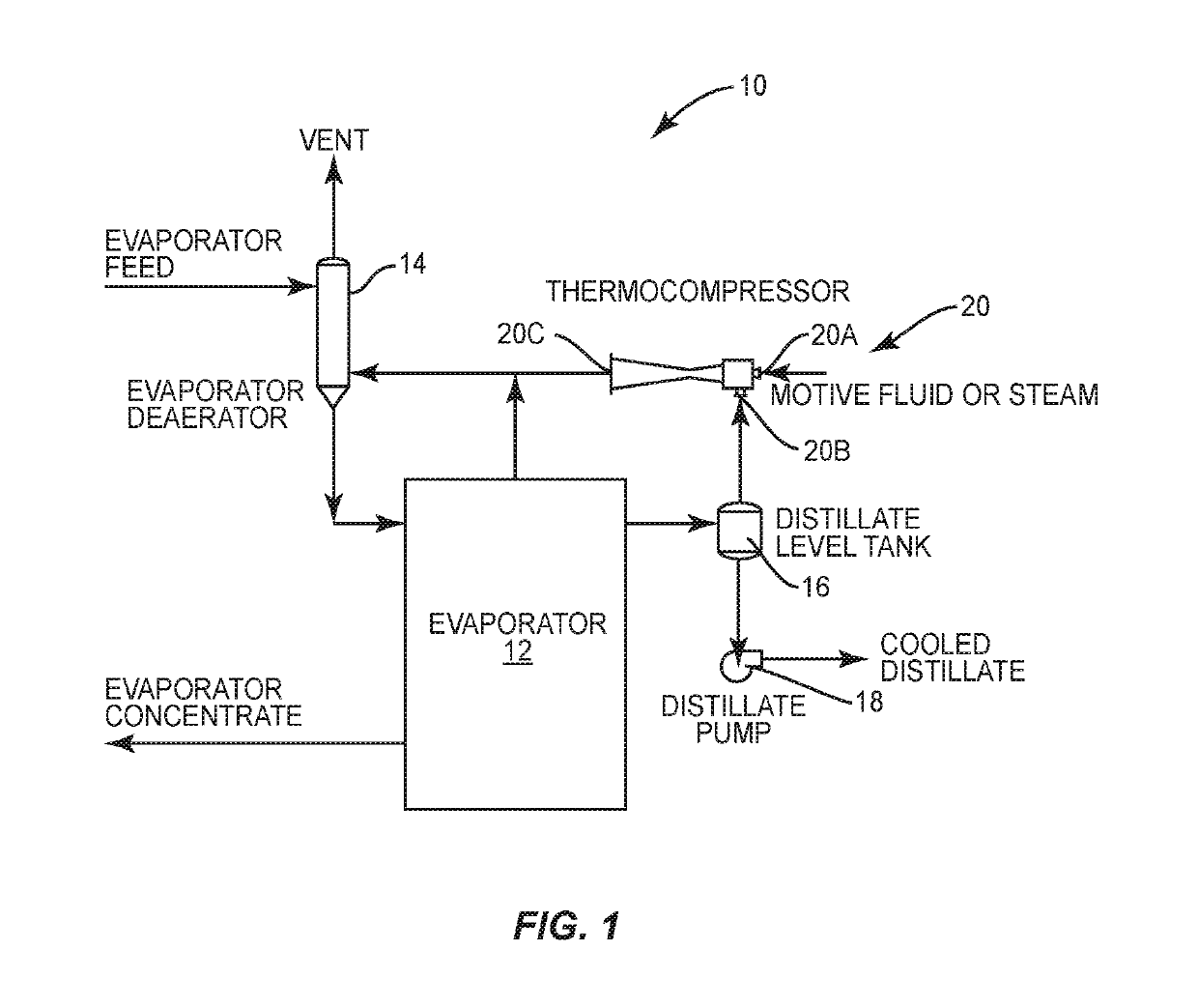

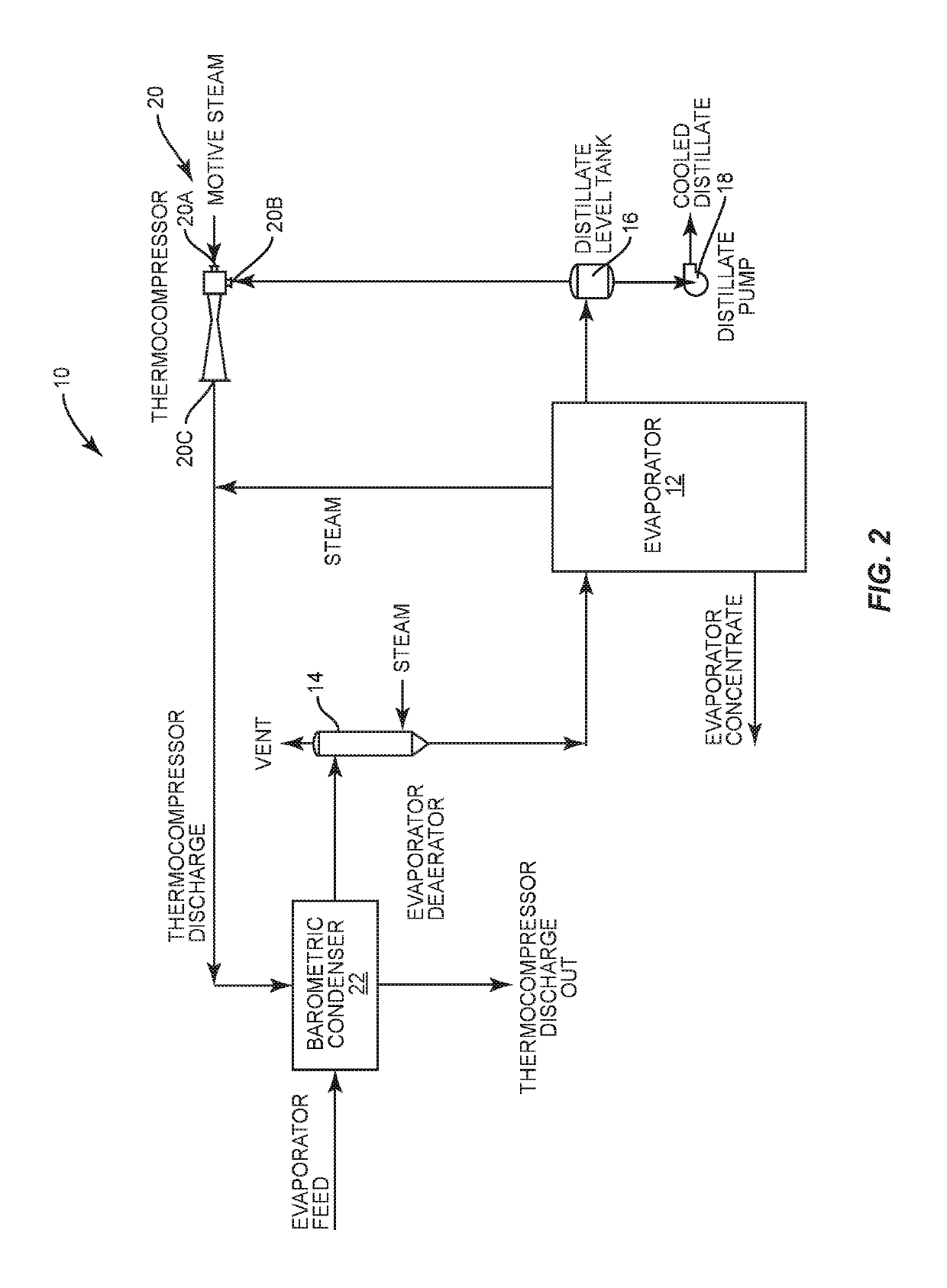

System and process for preheating evaporator feedwater

InactiveUS10434435B2Liquid degasification with auxillary substancesEvaporation with vapour compressionEvaporationEngineering

An evaporation system employs a thermocompressor to recover heat associated with a distillate produced by an evaporator and to use the recovered heat to preheat evaporator feedwater. In one example, the thermocompressor produces a thermocompressor discharge that is directed into the deaerator, contacting and preheating the evaporator feedwater passing therethrough. In another example, the thermocompressor discharge is directed through a barometric condenser which contacts evaporator feedwater therein and condenses and in the process preheats the evaporator feedwater.

Owner:VEOLIA WATER TECH INC

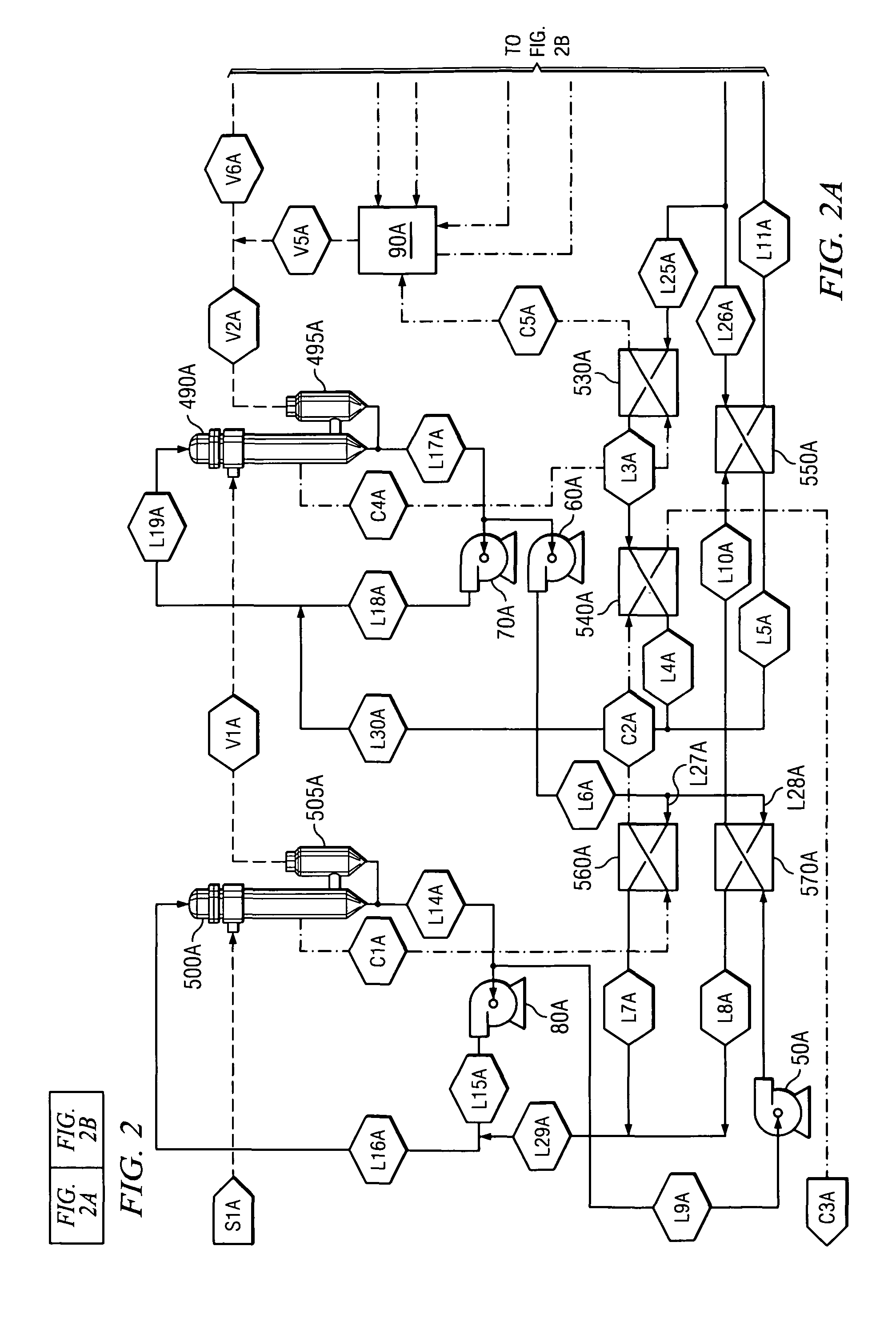

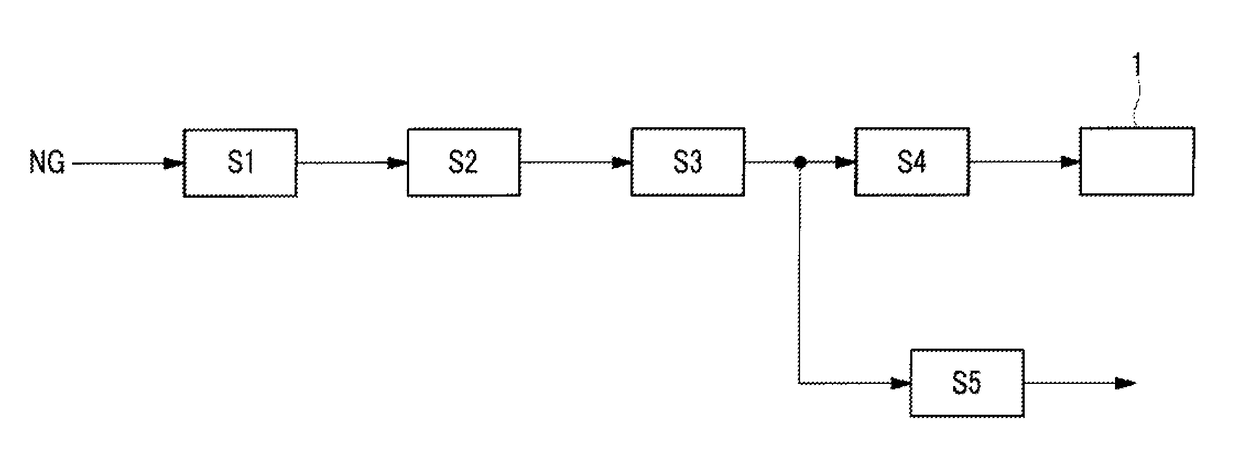

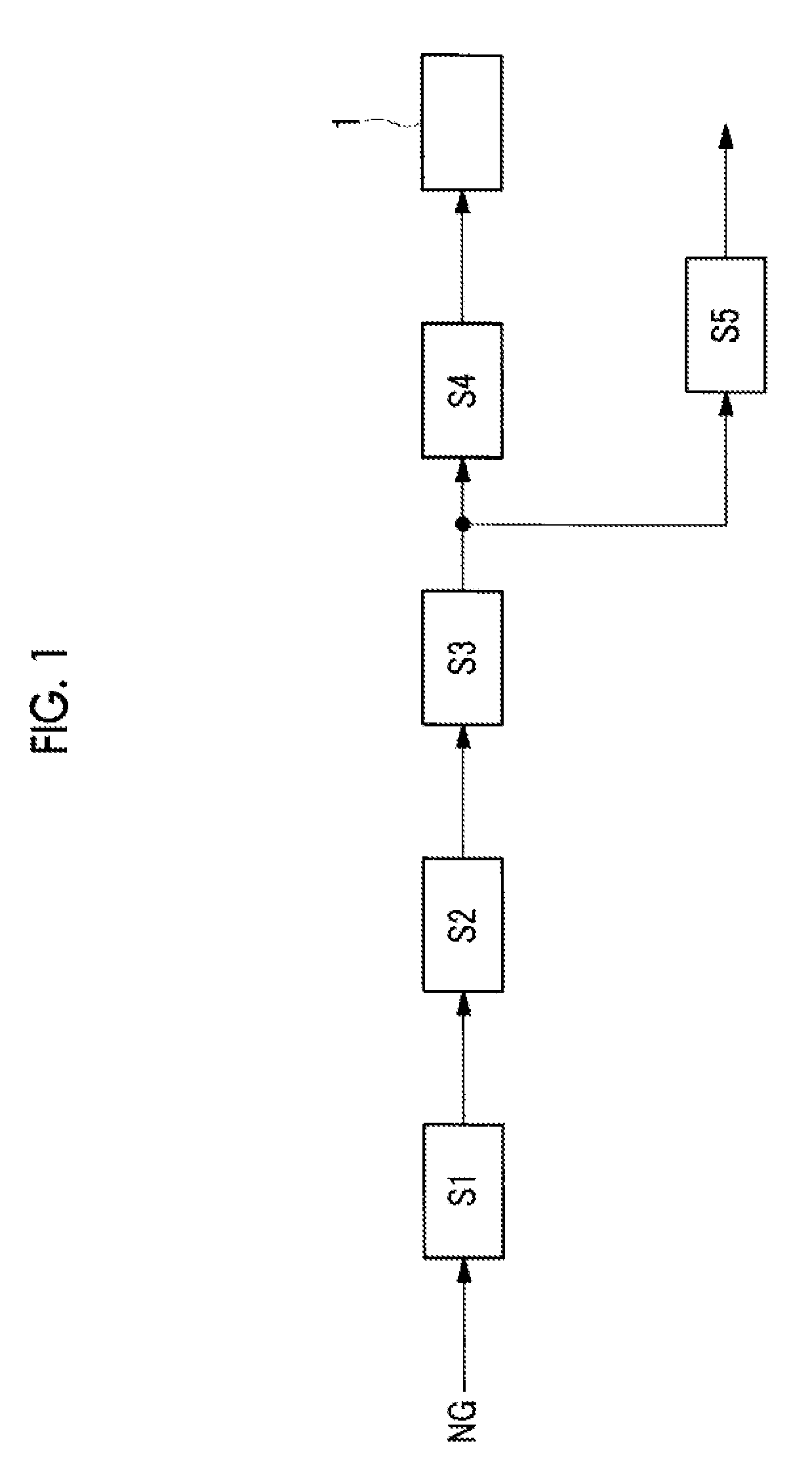

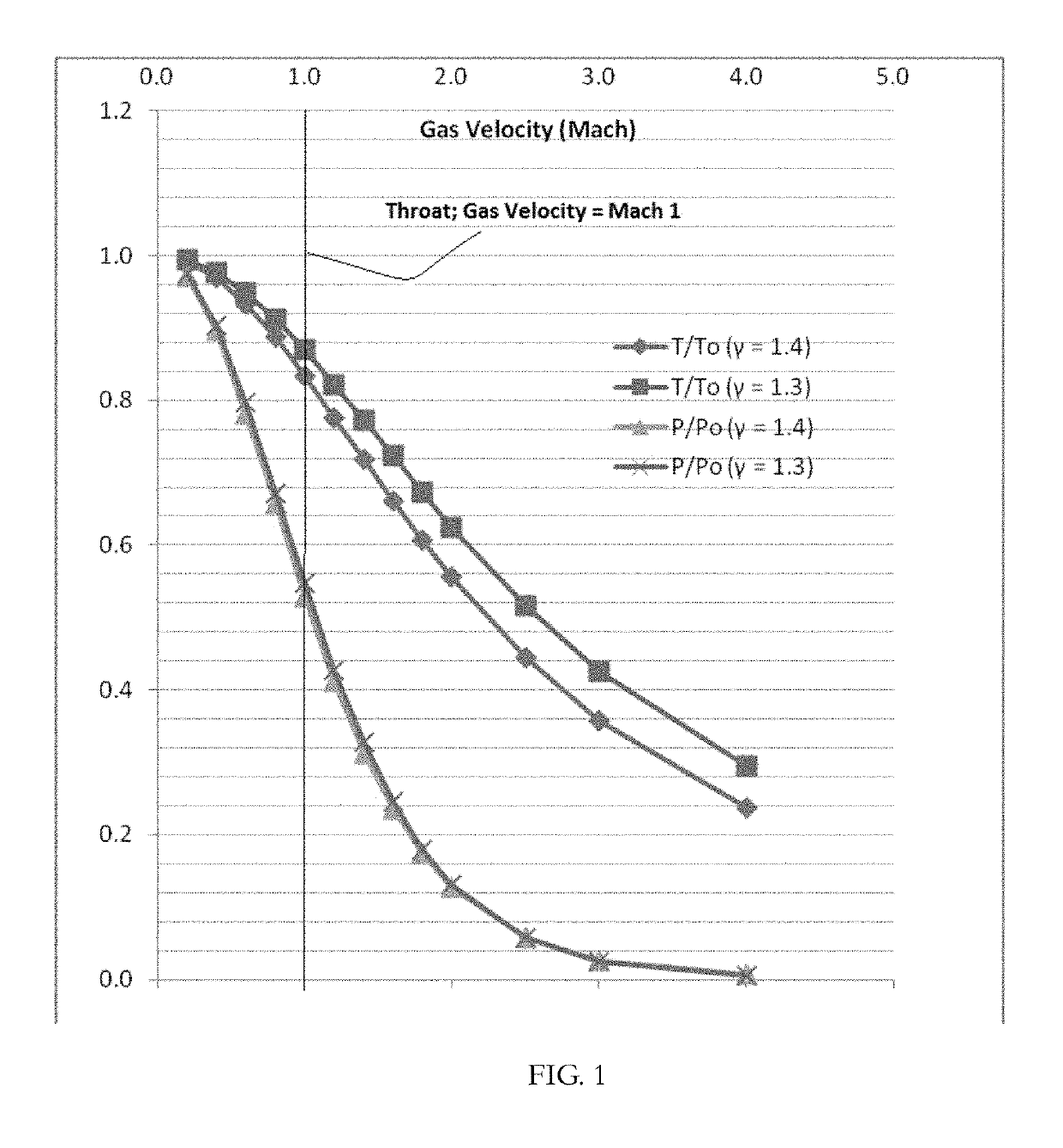

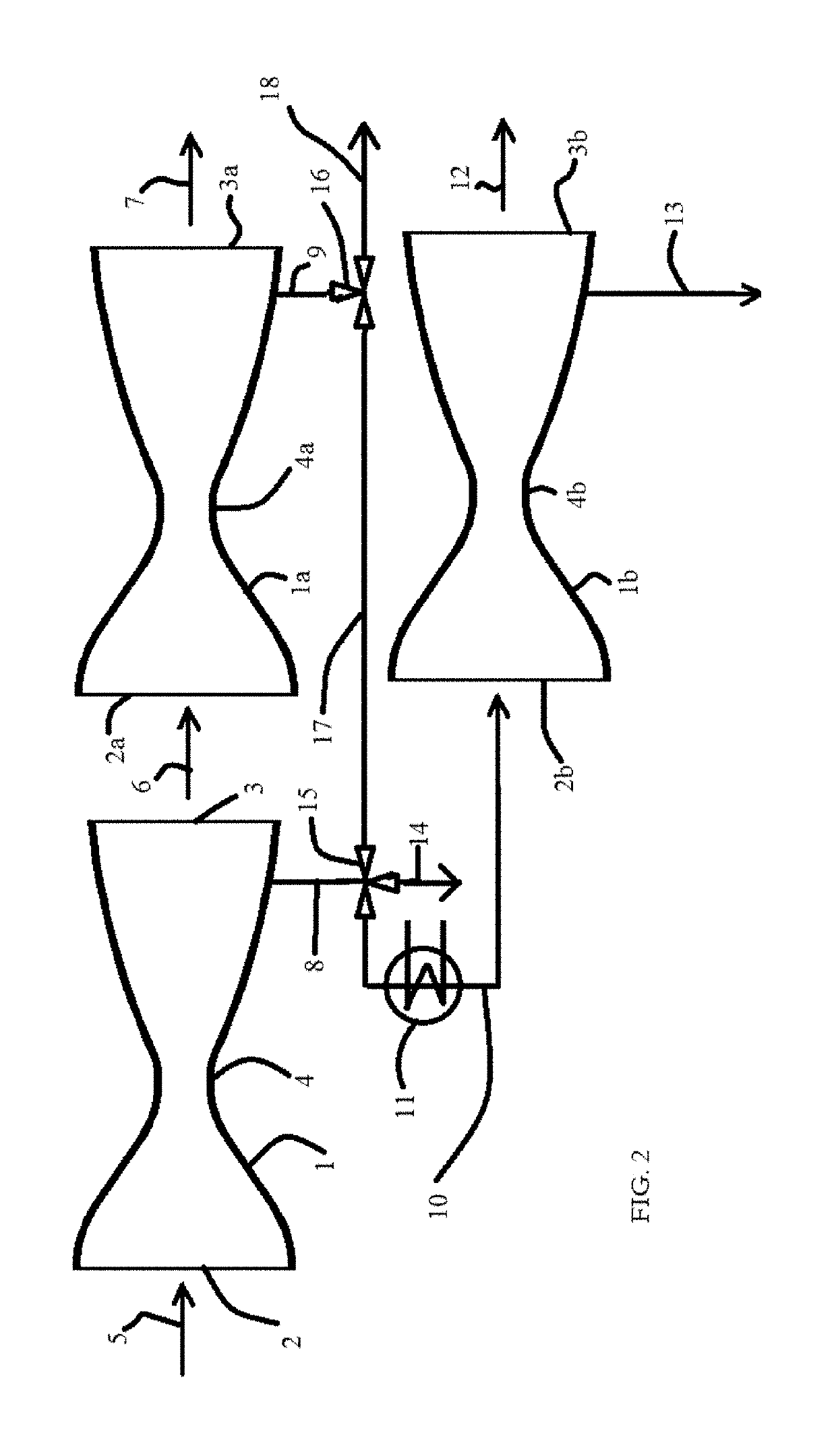

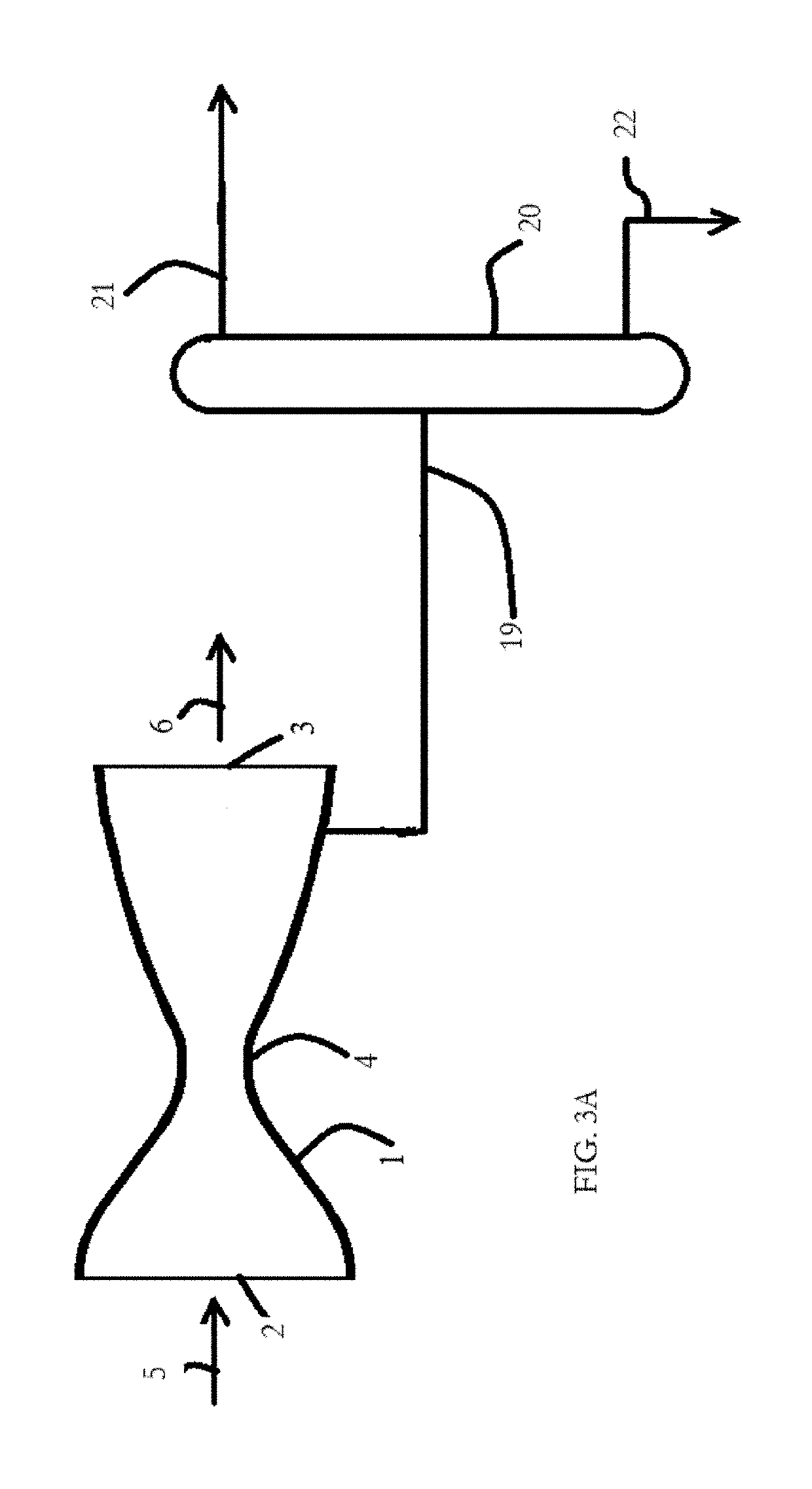

Supersonic separation of hydrocarbons

ActiveUS10436506B2Lower temperature and pressureIncrease probabilitySolidificationLiquefactionFractionationPropane

Selective recovery of C2 to C4 hydrocarbons is achieved through the use of a converging-diverging nozzle, or de Laval nozzle. The vapor stream comprising C2 to C4 hydrocarbons is fed into an inlet of a de Laval nozzle having a throat. The vapor stream may have an initial temperature of between 0° C. and 100° C., and an initial pressure of between 200 psig and 500 psig. In the de Laval nozzle, the vapor stream expands after passing through the throat of the de Laval nozzle, producing a vapor stream having reduced temperature and pressure. Then, C2 to C4 hydrocarbons condense from the reduced-temperature vapor stream as liquid droplets, which may be recovered. Fractionation of C2 to C4 hydrocarbons by means of a de Laval nozzle is possible; the technique allows selective recovery of a stream enriched in propene from a mixture of propane and propene.

Owner:EASTMAN CHEM CO

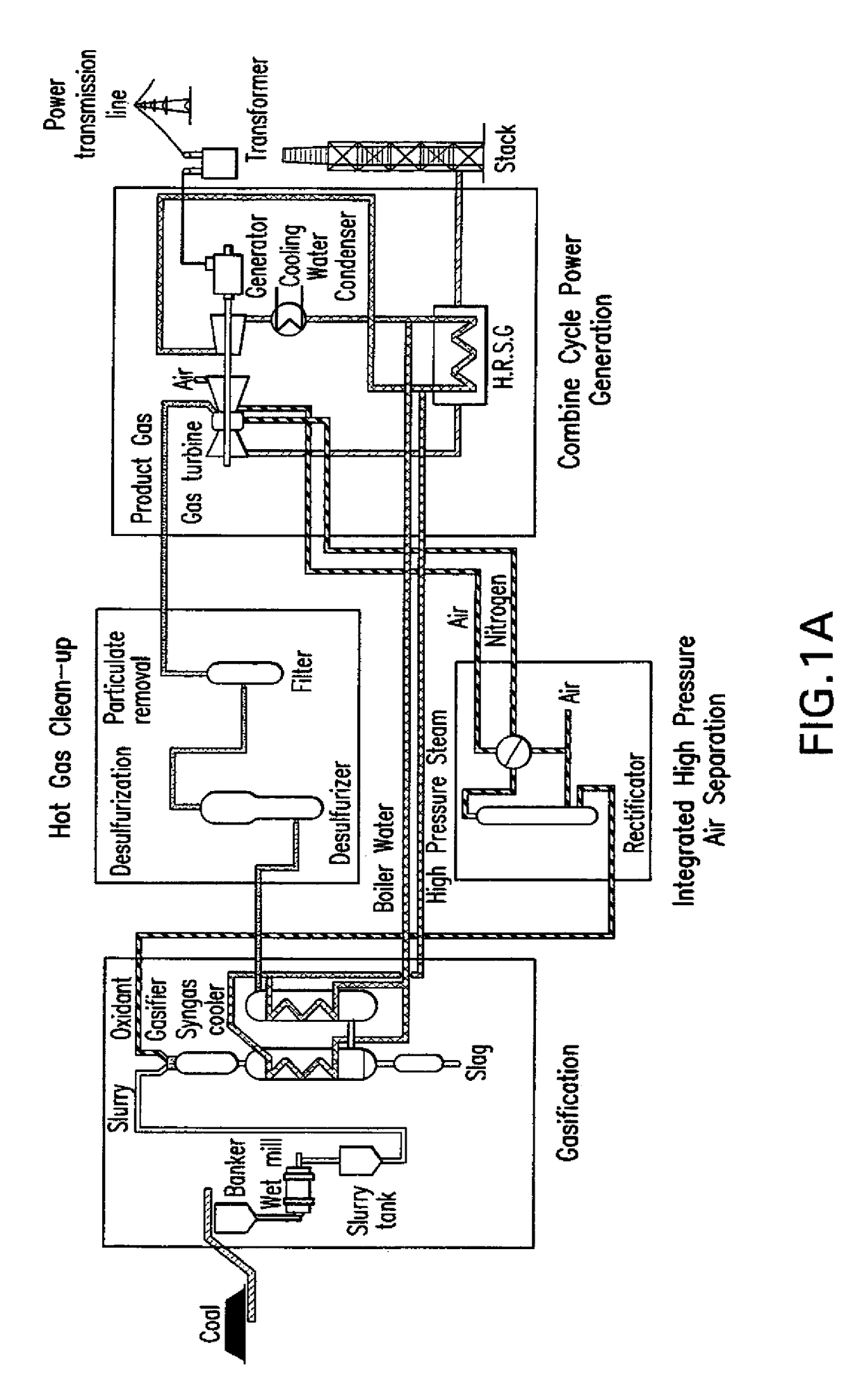

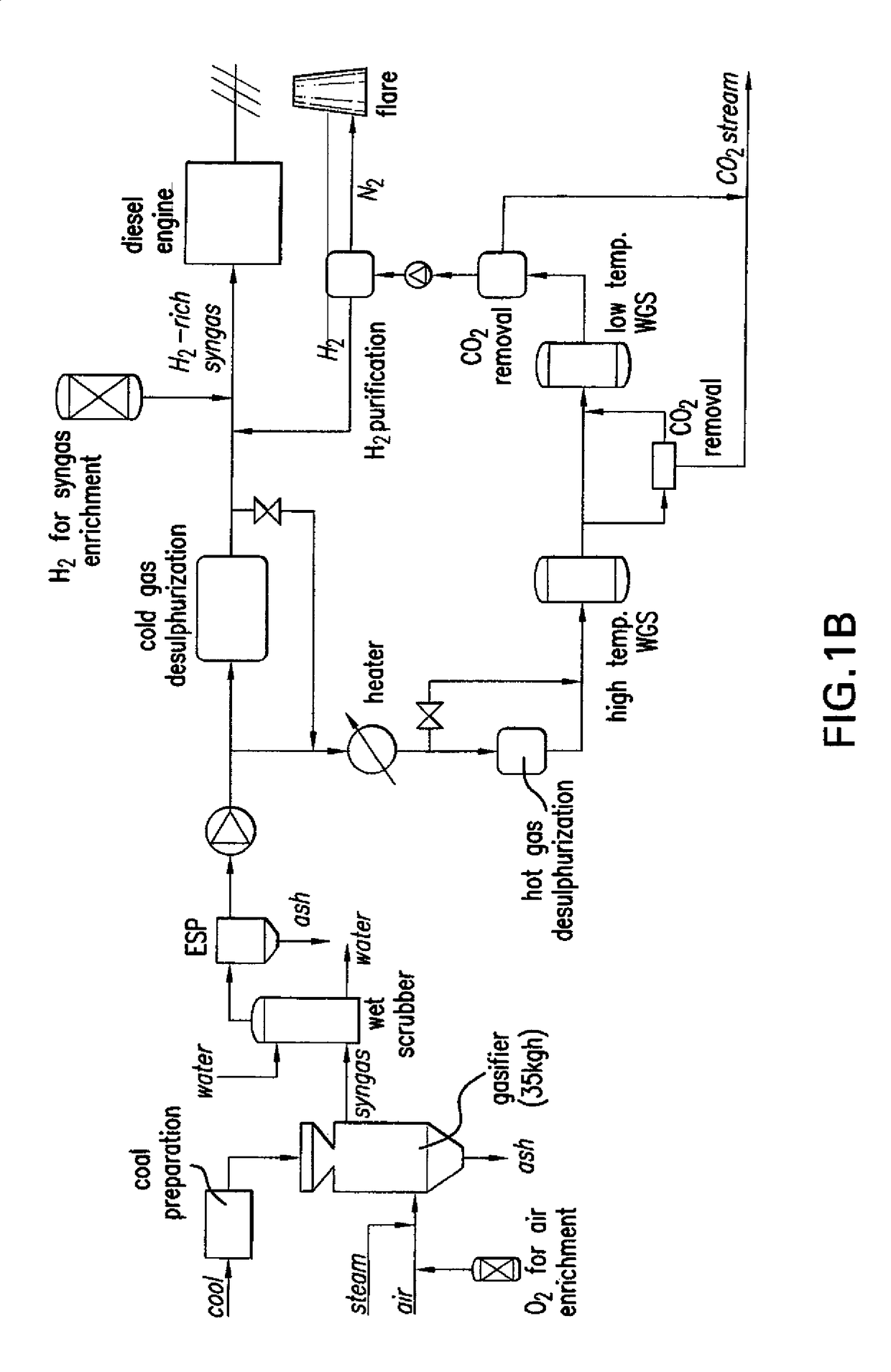

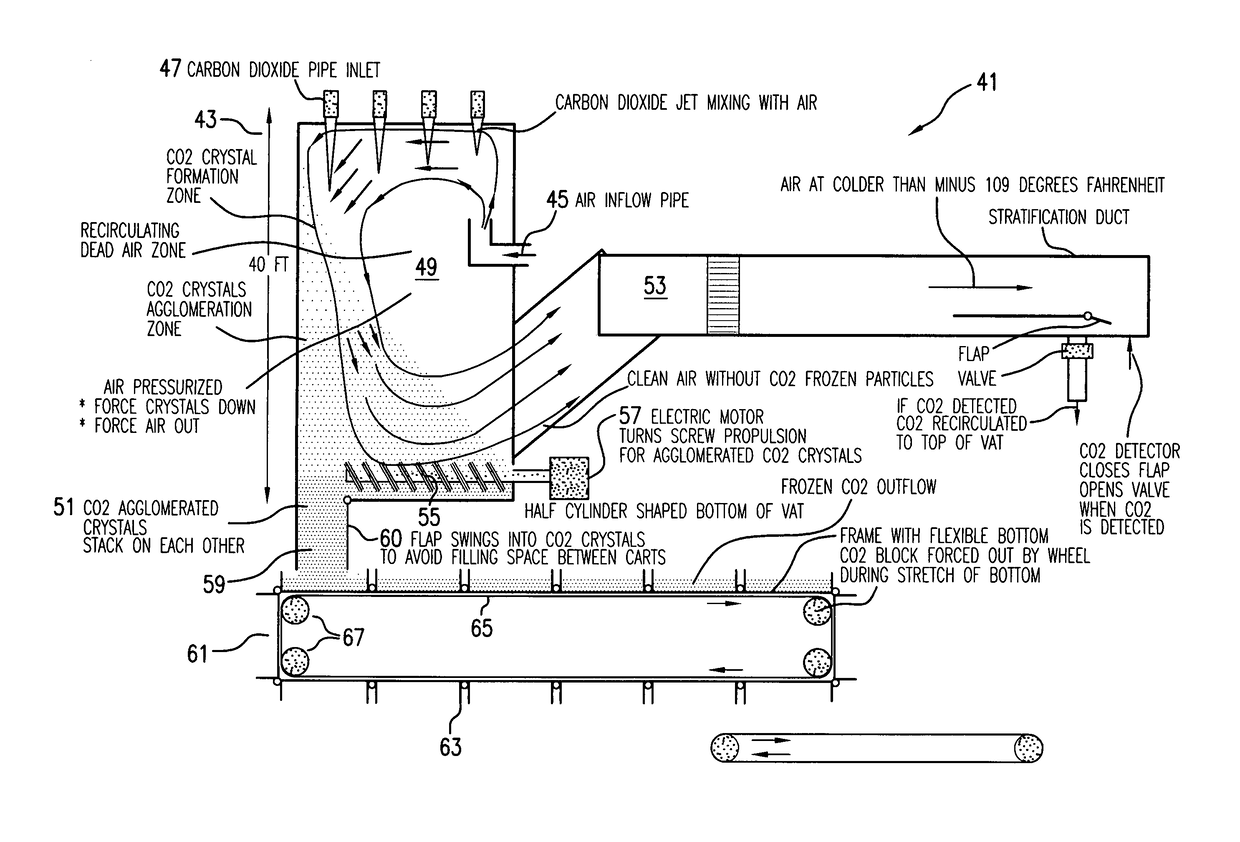

Method and apparatus for removing carbon dioxide gas from coal combustion power plants

The invention relates to a method and apparatus for removing CO2 gas emissions from a coal combustion power plant, comprising a means for physically removing the CO2 gas from the coal, and then using a turbo compressor and turbo expander device to produce super chilled air, which can then be mixed with the CO2 gas to form frozen CO2 crystals which can agglomerate together to form dry ice blocks, wherein the ice blocks can be easily transported and stored, and / or used for commercial purposes (such as for the beverage industry). The heating (compression) and cooling (expansion) processes preferably generate additional energy which can then be used to offset the substantial costs associated with separating the CO2 gas from the coal.

Owner:ENIS BEN M +1

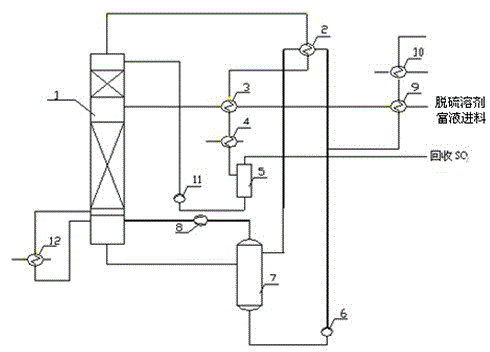

A new energy-saving process of heat pump distillation for desulfurization solvent in renewable flue gas desulfurization

ActiveCN104083885BIncrease profitReduce distillation energy consumptionDispersed particle separationSeparation machinesFractionating columnSolvent

The invention provides a novel heat pump distillation energy saving process for a desulfurization solvent in regenerable flue gas desulfurization. The novel heat pump distillation energy-saving process comprises the following steps that A, SO2 is separated from a pregnant solution of an SO2-containing desulfuration solvent at a desulfuration section in a distillation tower through distillation, and a barren liquor at the bottom of the distillation tower is sent to a flash tower, and is flashed in the flash tower; B, flashing steam generated by the flashing is sent to a compressor, and is compressed by using a compressor to act; and C, steam output from the compressor is sent to the bottom in the distillation tower, and forms raising steam required by the distillation together with vaporized water, the raising steam and the pregnant solution falling from the upper part of the distillation tower reversely flow for performing mass and heat transfer to complete the distillation process, part of flashed barren liquor and the steam discharged from the top of the distillation tower are exchanged with heat, and the barren liquor returns to the flashing tower after the steam heat is recycled, the left flashed barrel liquor and the desulfurization solvent pregnant solution entering the distillation tower are exchanged with the heat, and cooled to 40-55 DEG C through water cooling after the heat of the barren liquor is recycled so as to be sent to a desulfurization section for being recycled. When the distillation is performed by adopting the heat pump distillation process, energy can be saved more than 70 percent in comparison with that of a conventional distillation method.

Owner:CHENGDU HUAXITANG ENVIRONMENTAL PROTECTION TECH CO LTD

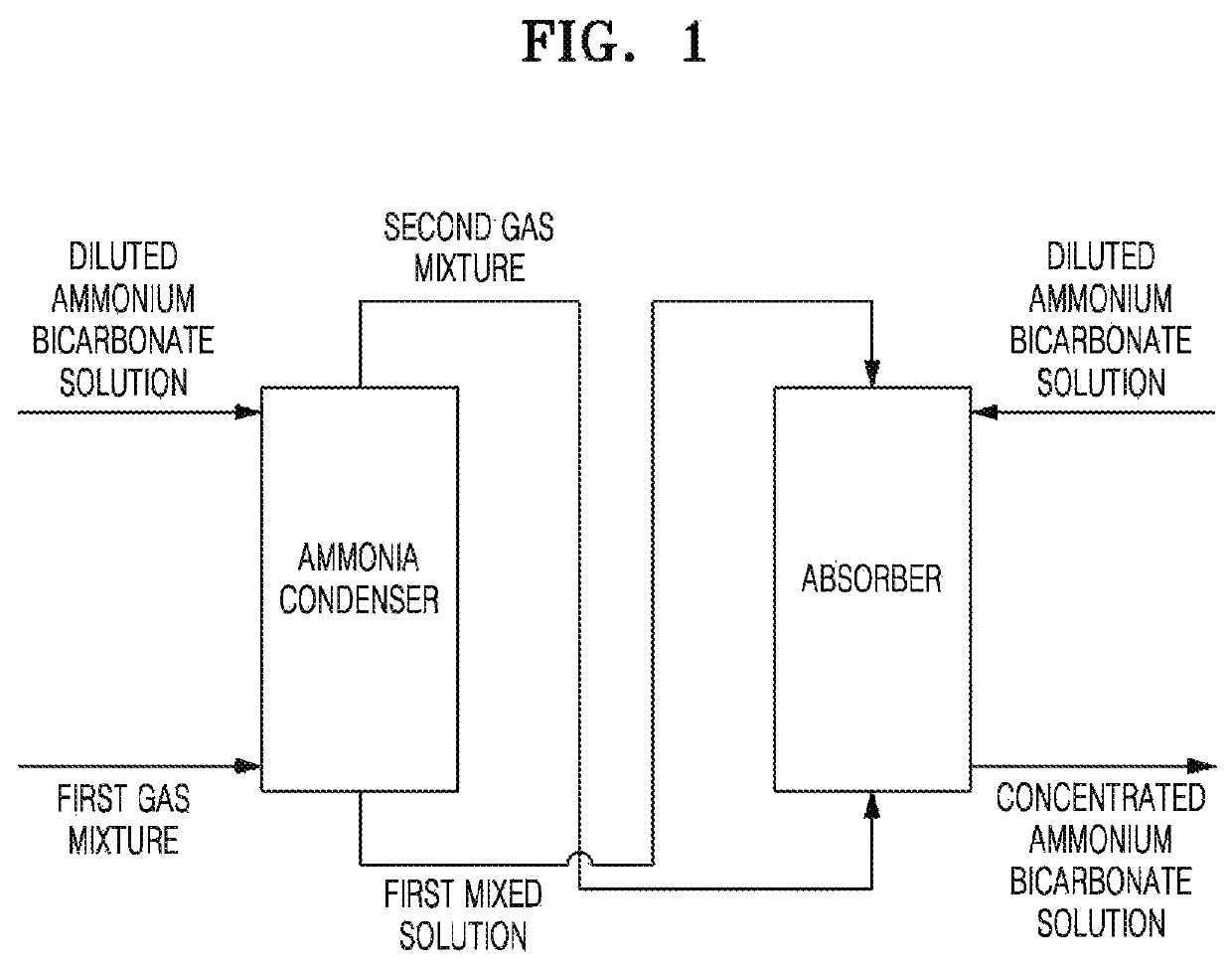

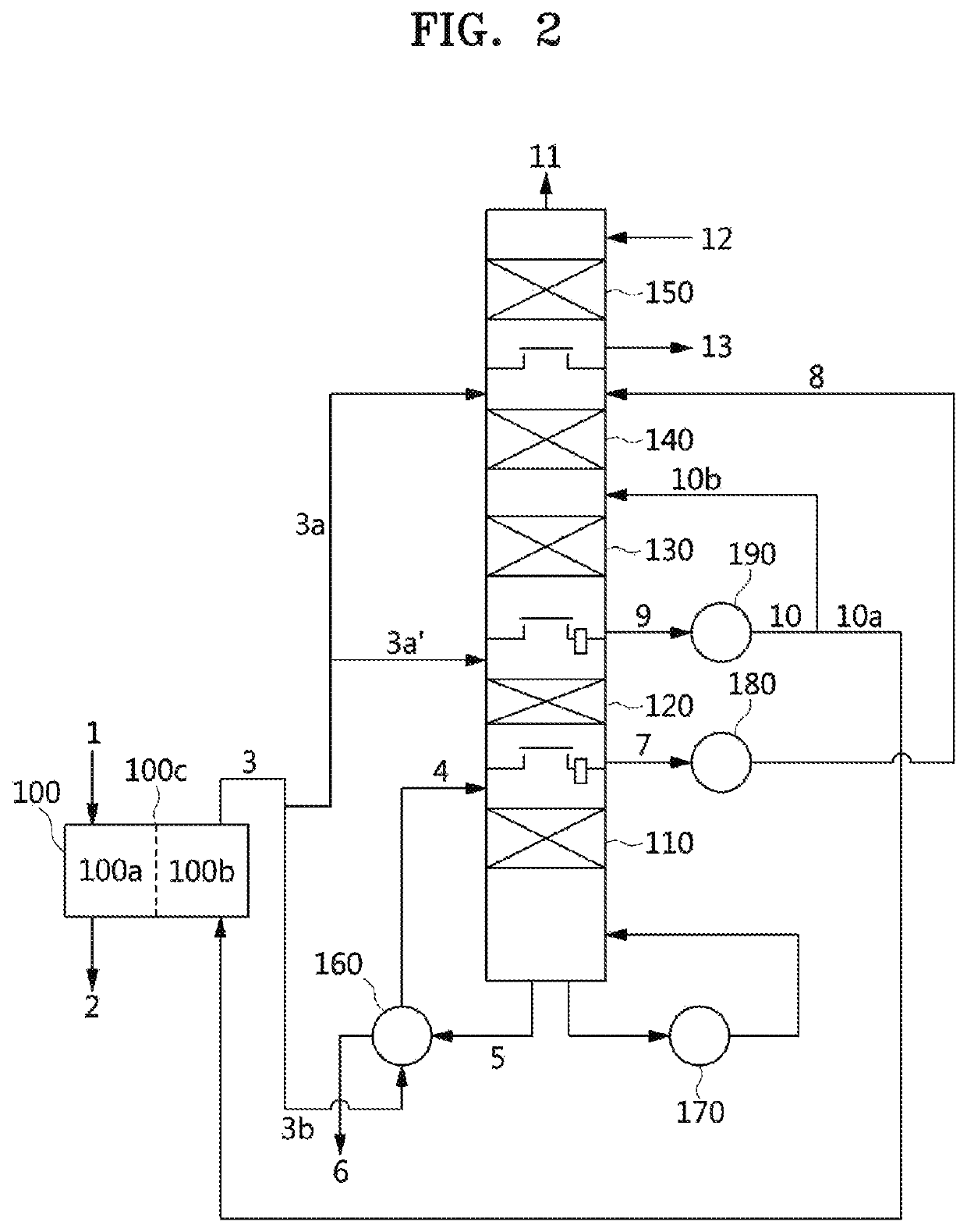

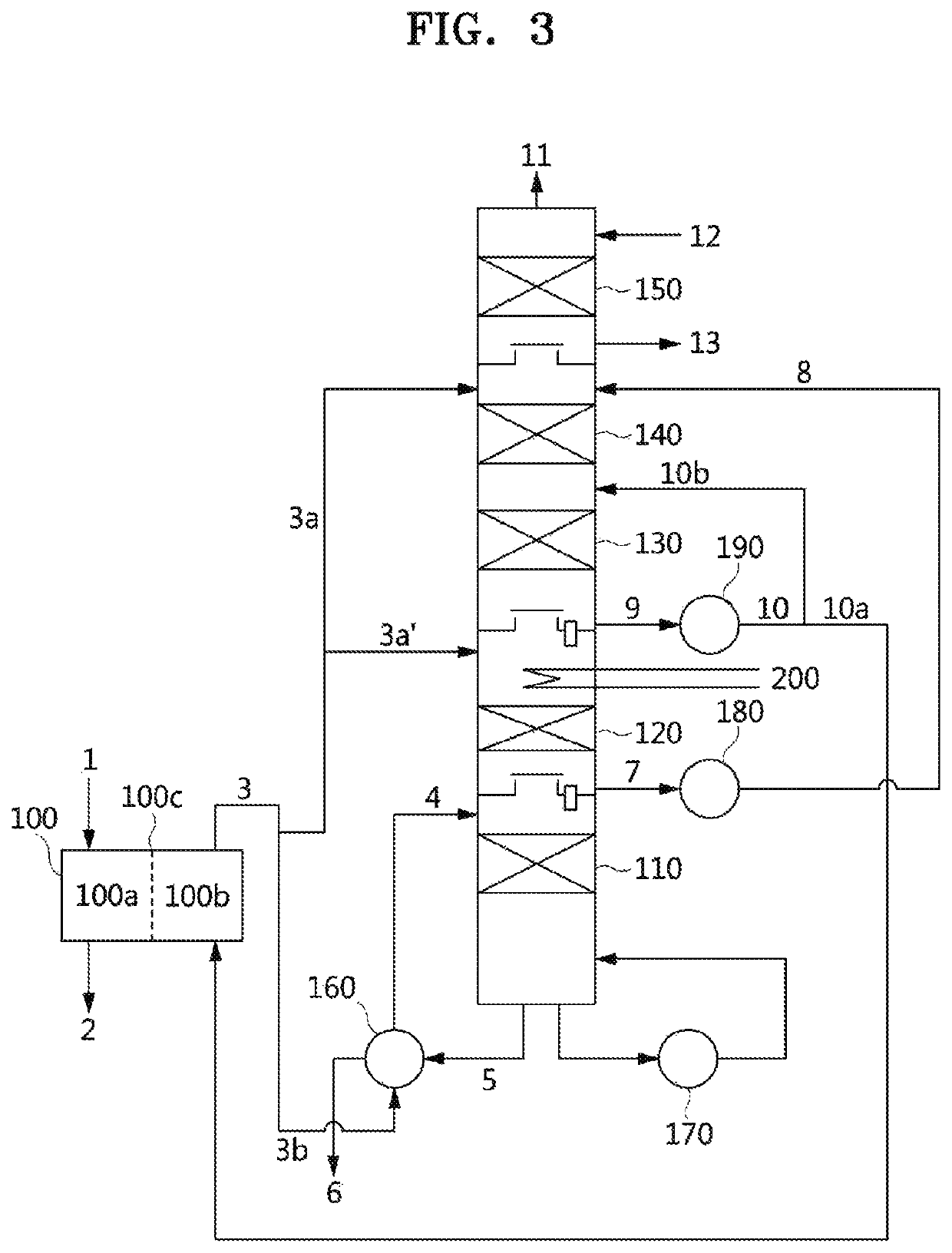

Recovery method for ammonium bicarbonate solution

ActiveUS10682609B2Continuous regenerationQuantity minimizationSemi-permeable membranesGas treatmentDistillationPhysical chemistry

A method of regenerating an ammonium bicarbonate solution includes supplying a diluted ammonium bicarbonate solution to an upper portion of a distillation unit, an upper portion of an ammonia condenser, and an upper portion of an absorber; distilling the diluted solution to discharge a first gas mixture, supplying the first gas mixture to a lower portion of the ammonium condenser; bringing the first gas mixture into contact with the diluted solution to be separated into a first mixed solution and a second gas mixture, supplying the first mixed solution to the upper portion of the absorber, and supplying the second gas mixture to a lower portion of the absorber; and bringing the second gas mixture into contact with the diluted solution supplied to the upper portion of the absorber and the first mixed solution supplied to the upper portion of the absorber to recover a concentrated ammonium bicarbonate solution.

Owner:BENIT M CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com