Testing system of electronic element with pins

A technology for electronic components and test systems, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of high production cost, low production efficiency of electronic components, and high labor intensity, saving labor and manual cleaning. process, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

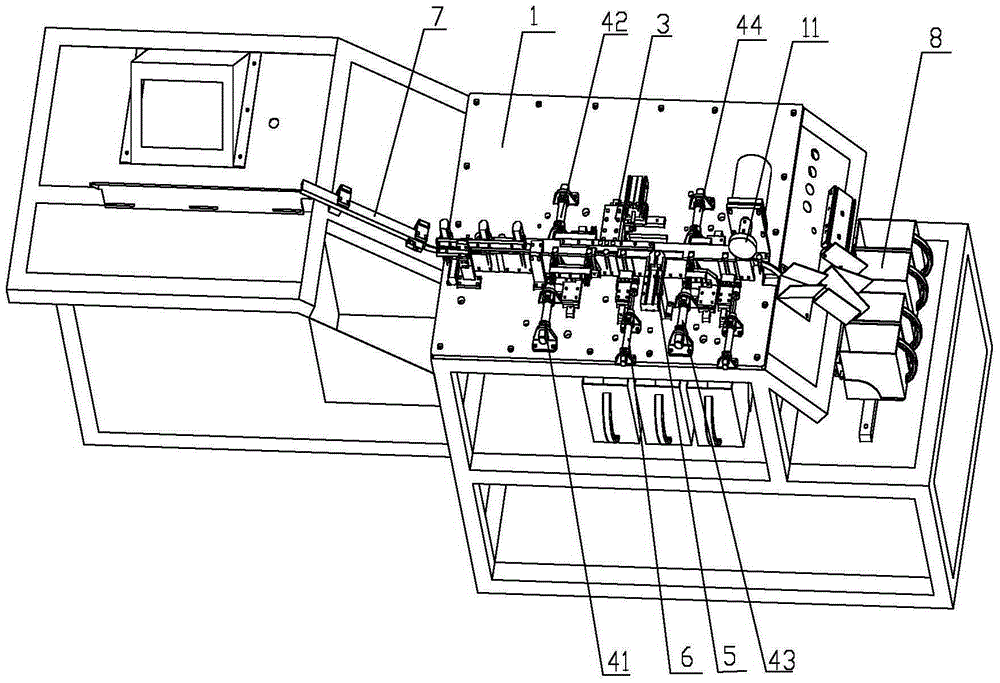

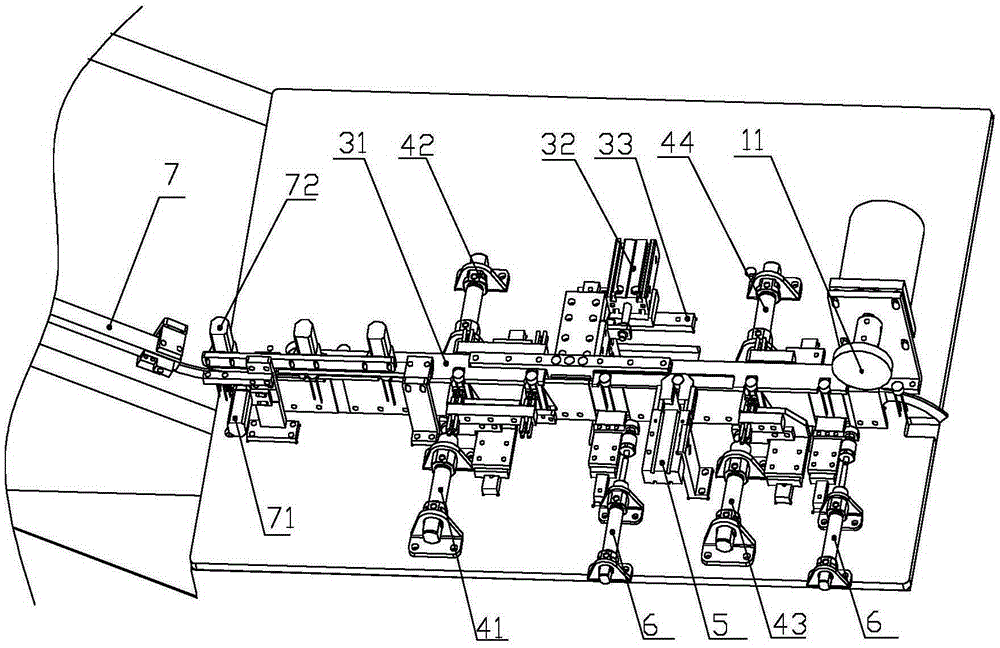

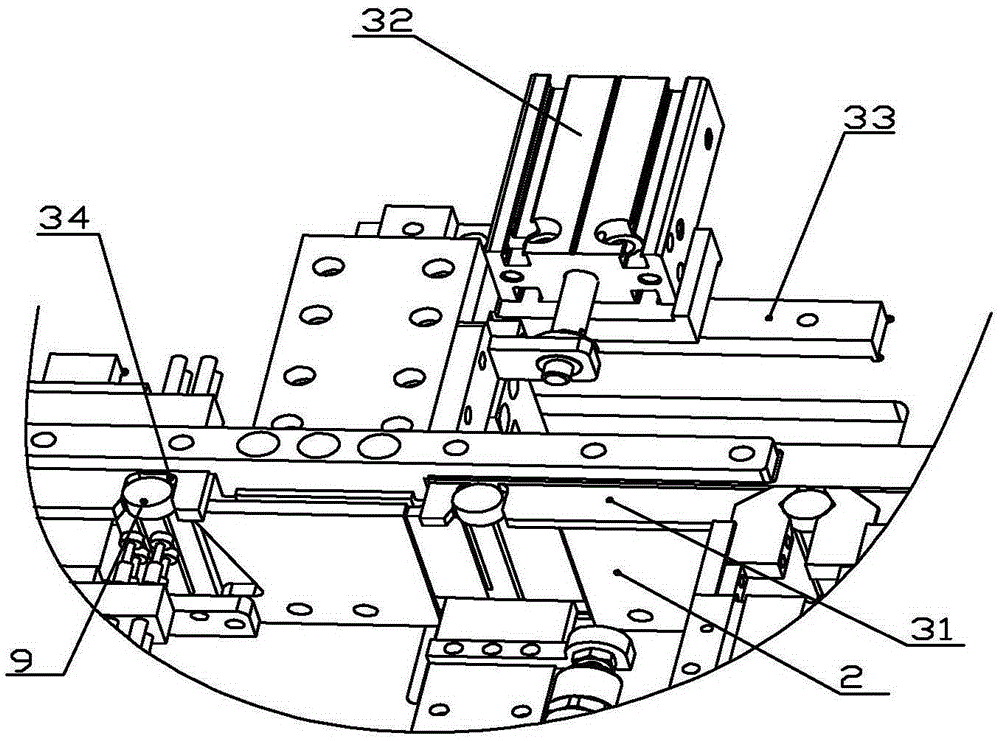

[0031] Such as figure 1 and figure 2 As shown, an electronic component testing system with a pin 93 includes a frame 1, a track 2, a transmission mechanism 3, a testing mechanism 41, a testing mechanism 42, a testing mechanism 43, a testing mechanism 44, a marking machine 5, a sixth Cylinder 6, feeding plate 7, material receiving box 8 and control system, track 2 is linear, fixedly connected on frame 1, transmission mechanism 3 is arranged on one side of track 2, along the transmission direction of electronic component 9 The arrangement is: 2 testing mechanisms 4, the sixth cylinder 6, a marking machine 5, 2 testing mechanisms 4 and the sixth cylinder 6 are arranged in sequence. The marking machine 5 is fixedly connected to the frame 1, the marking machine 5 is opposite to the notch 34, the marking machine 5 and the head of the electronic component 9 are located on the same plane, and the marking machine 5 marks the head of the electronic component 9 . The testing mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com