Patents

Literature

51results about How to "Convenient stamping work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

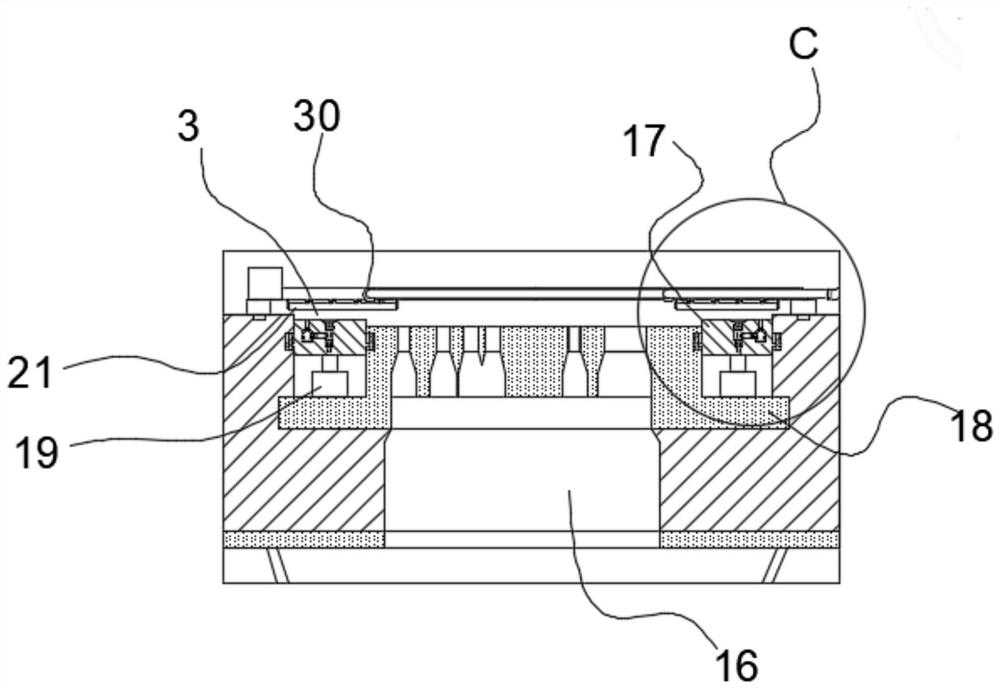

Device for punching parts

InactiveCN105728536AOvercoming elasticityFit closelyMetal-working feeding devicesStripping-off devicesPunchingEngineering

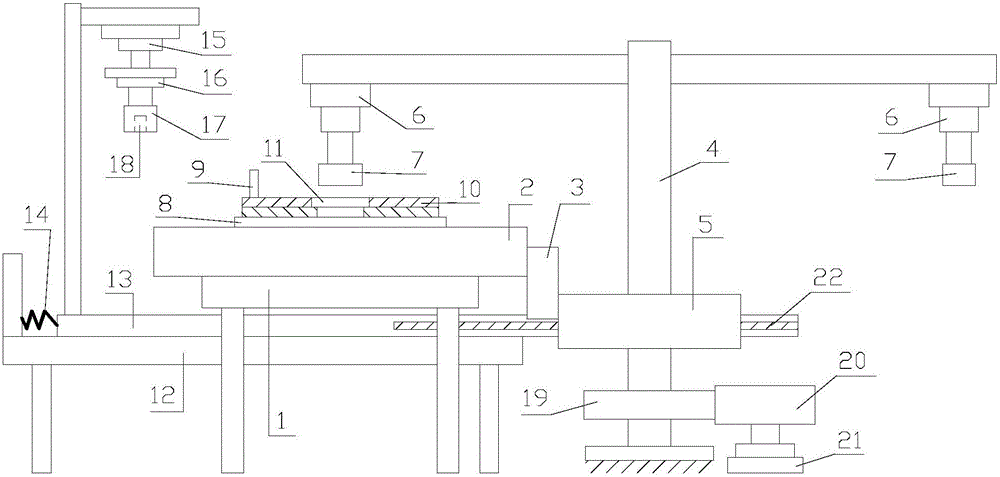

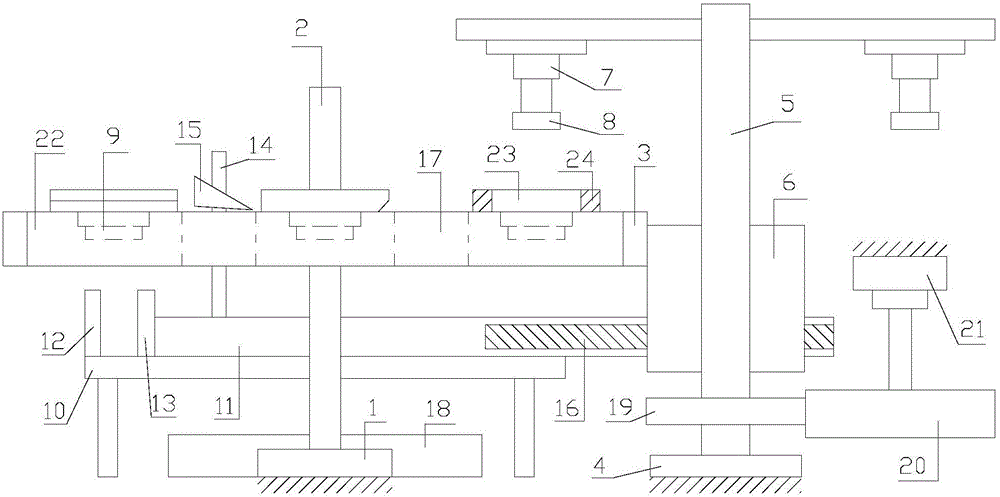

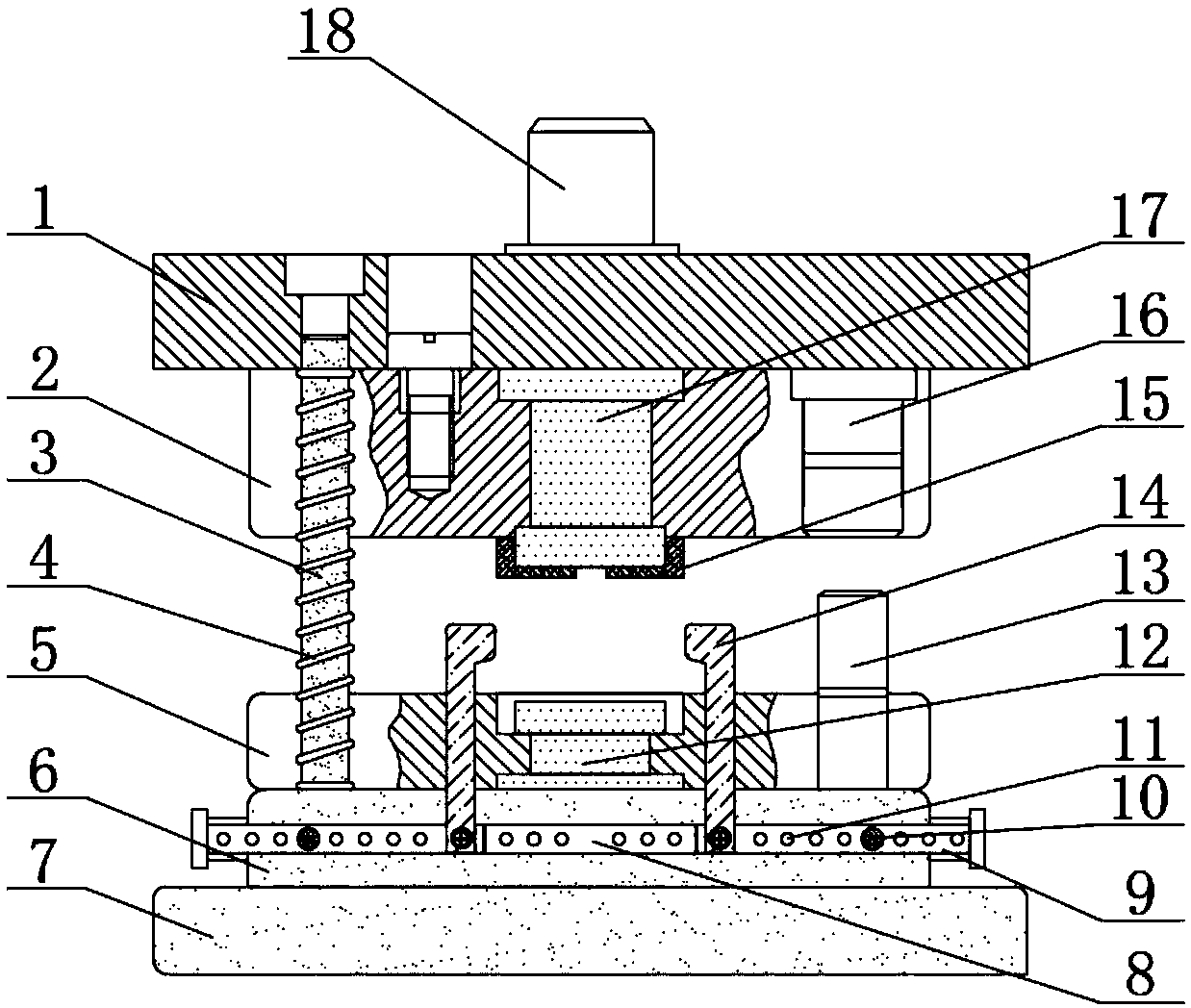

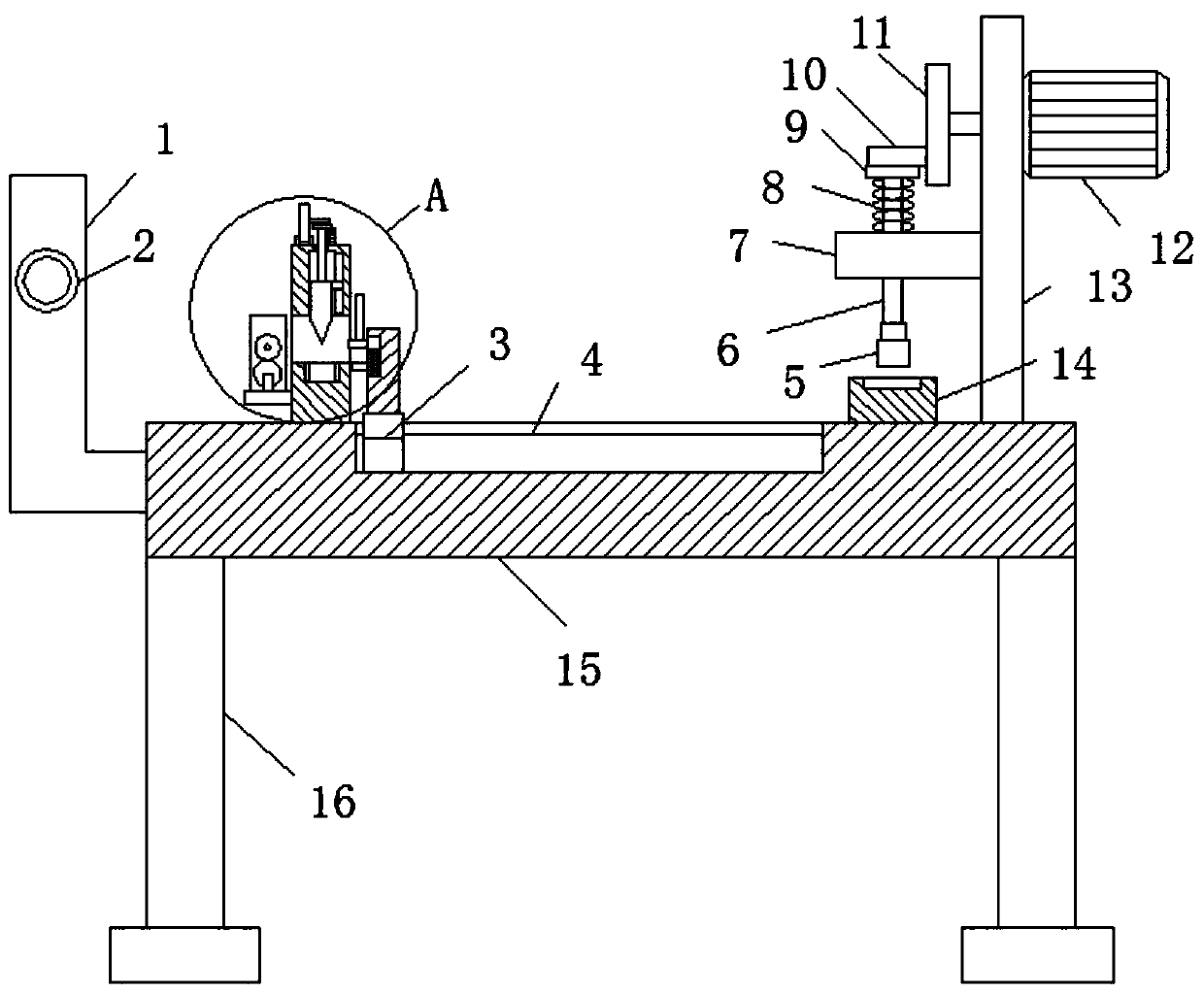

The invention discloses a device for stamping parts, which includes a transmission part, a plurality of molds, and a stamping part; the transmission part includes a support platform, a moving plate, and a rack; The channel is set horizontally; the moving plate is movably installed on the moving channel, and the moving plate is set horizontally; the rack is installed on the side of the moving plate, and the length direction of the rack is parallel to the length direction of the moving channel; multiple molds are arranged along the length of the moving channel The direction intervals are installed on the moving board, and the distance between any two adjacent moving boards is equal. The invention has good processing effect and high processing precision.

Owner:WUHU HONGFEI MACHINERY CO LTD

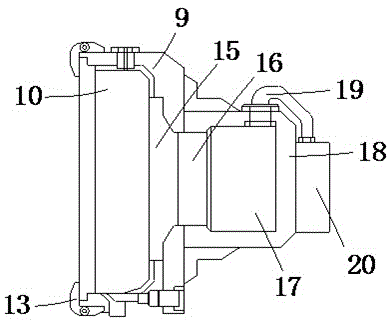

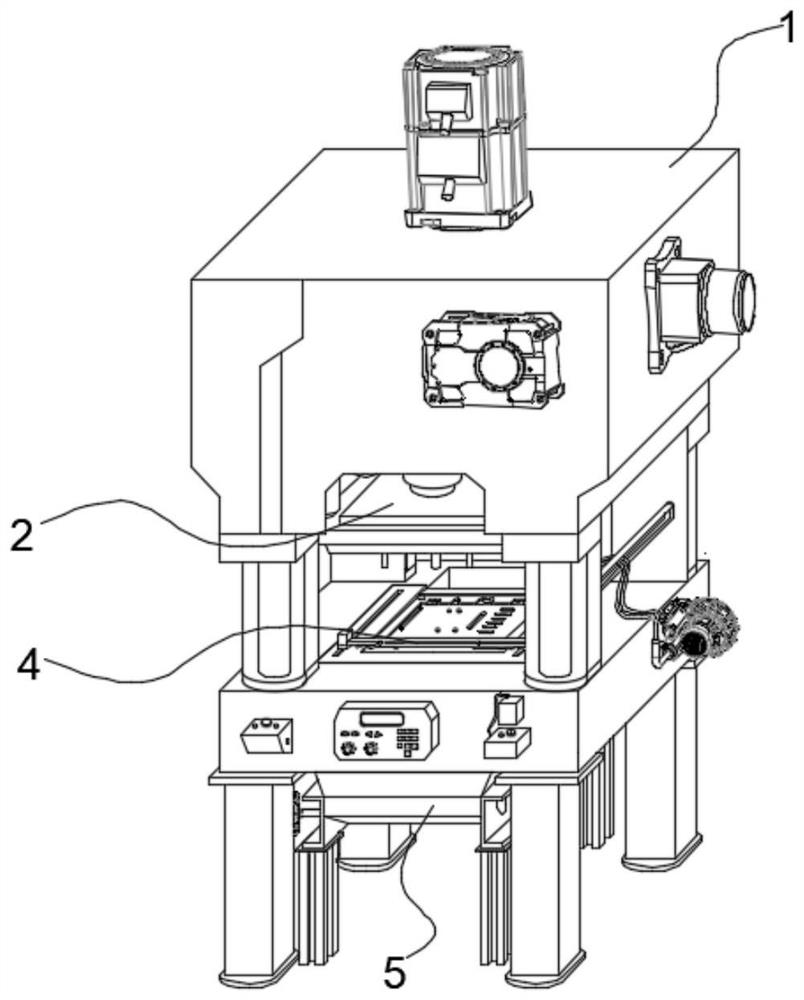

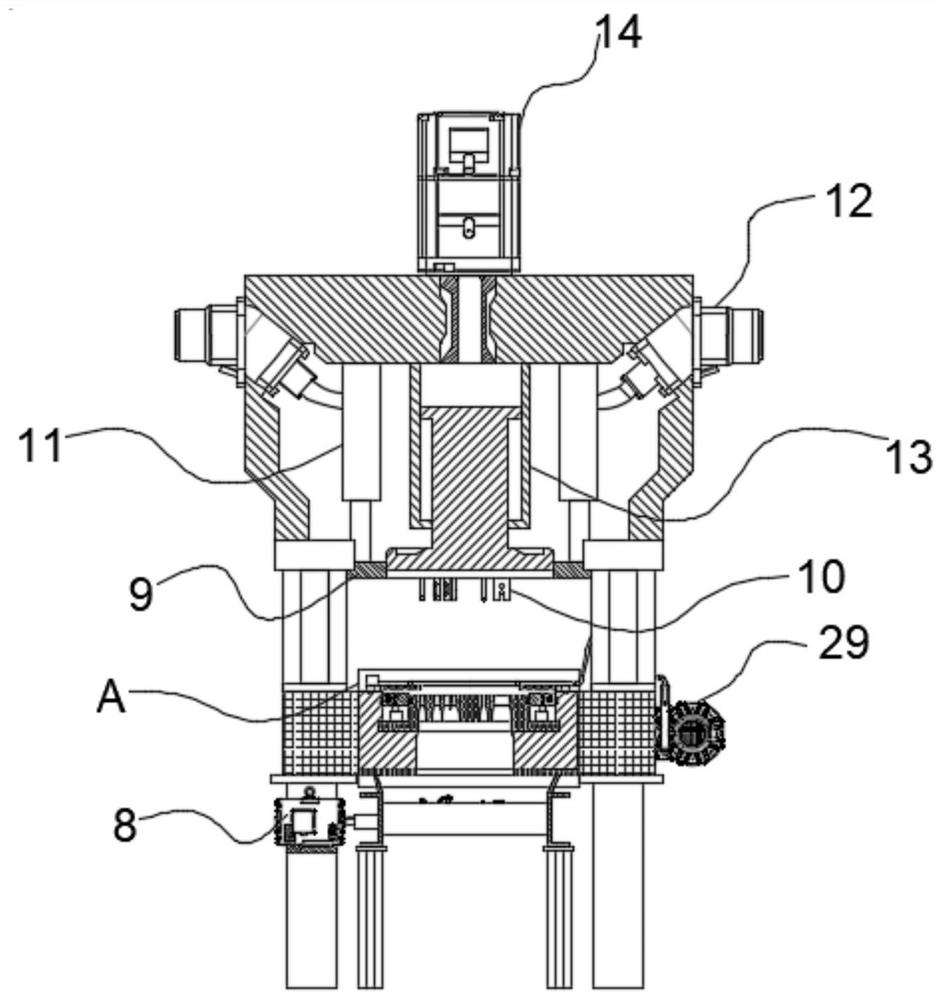

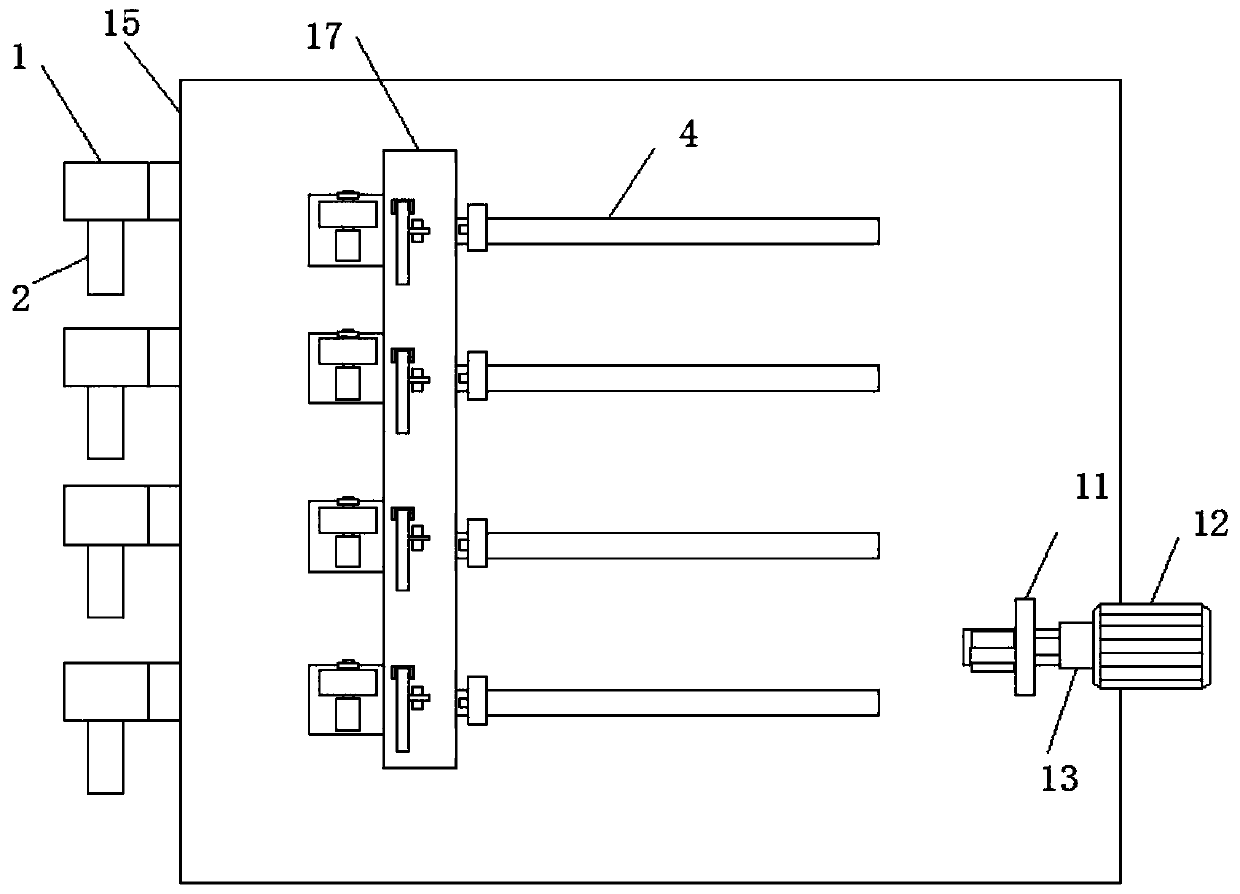

Device capable of continuously performing stamping machining

InactiveCN105750390ARealize automatic nestingFit closelyStripping-off devicesPressesMachine partsMachining

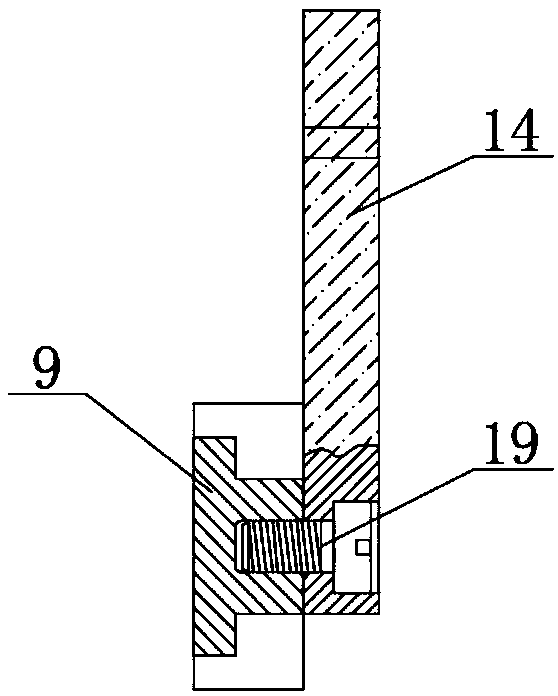

The invention discloses a device capable of continuously performing stamping machining. The device comprises a supporting part and a machining part, wherein the supporting part comprises a bracket, a supporting shaft, a turntable and a plurality of dies; the supporting shaft is mounted on the bracket in a rotating manner, and is vertically arranged; the turntable is mounted on the supporting shaft; a first wheel tooth is arranged on the circumferential surface of the turntable; the plurality of dies are mounted on the turntable, and uniformly surround the supporting shaft; the machining part comprises a support frame, a rotating shaft, a plurality of stamping mechanisms and a driving mechanism; the support frame and the rotating shaft are arranged on one side of the turntable; the rotating shaft is mounted on the support frame in the rotating manner, and is vertically arranged; a second wheel tooth matched with the first wheel tooth is locally arranged on the circumferential surface of the rotating shaft; when the rotating shaft rotates a cycle, the turntable rotates by an angle beta, wherein beta is an included angle of every two adjacent dies and the center of the turntable. The device has good stamping effects and high machining accuracy.

Owner:WUHU HONGFEI MACHINERY CO LTD

System for carrying out punching on parts

InactiveCN105855348AIncrease movement speedReduce movement speedShaping toolsStripping-off devicesPunchingEngineering

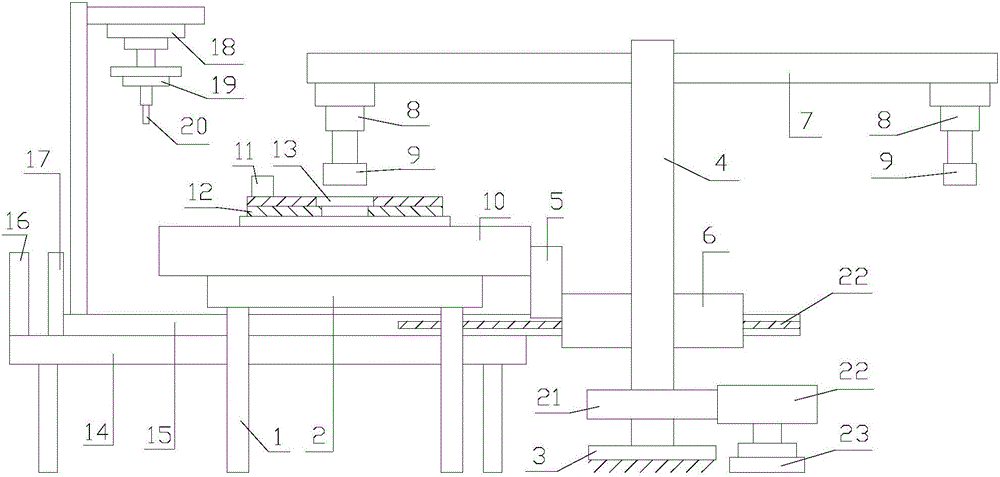

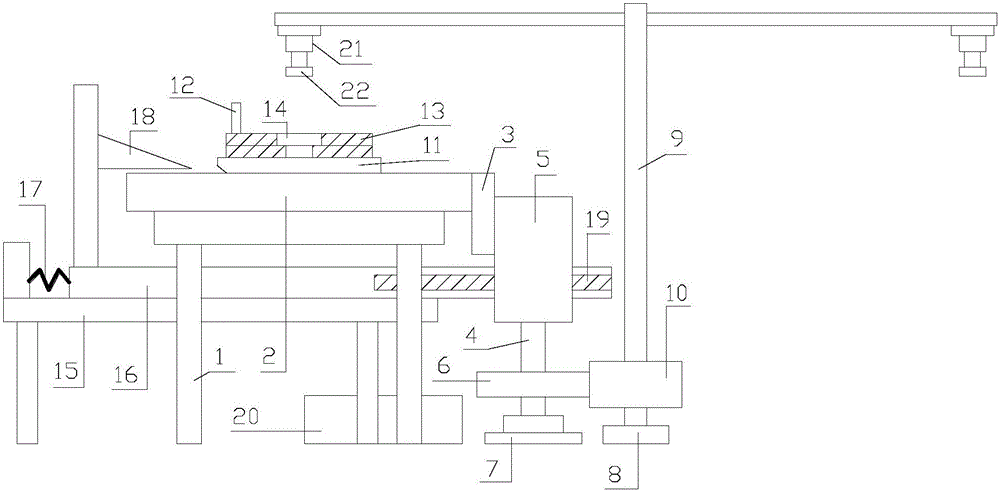

The invention discloses a system for stamping parts, including a bracket, a first moving plate, multiple molds, a mounting frame, a rotating shaft, two stamping parts, a driving mechanism, a thickness sensor, a first position sensor, The controller; guide rails are arranged on the bracket, and the guide rails are set along the horizontal direction; the first moving plate is movably installed on the guide rails, the first moving plate is set horizontally, and one side of the first moving plate is provided with the first wheel in continuous distribution Teeth; multiple molds are installed on the first moving plate at intervals along the length direction of the guide rail, and the distance between any two adjacent molds is equal; the mounting frame and the rotating shaft are all placed on the side of the first gear teeth away from the first moving plate On the side, the rotating shaft is rotatably installed on the mounting frame, the rotating shaft is arranged along the vertical direction, and a part of the circumferential surface of the rotating shaft is provided with second gear teeth matched with the first gear teeth. The invention has good processing effect and high processing precision.

Owner:WUHU HONGFEI MACHINERY CO LTD

System capable of stamping work-pieces continuously

InactiveCN105817515ARealize automatic nestingRealize receiptShaping toolsMetal-working feeding devicesEngineeringGear tooth

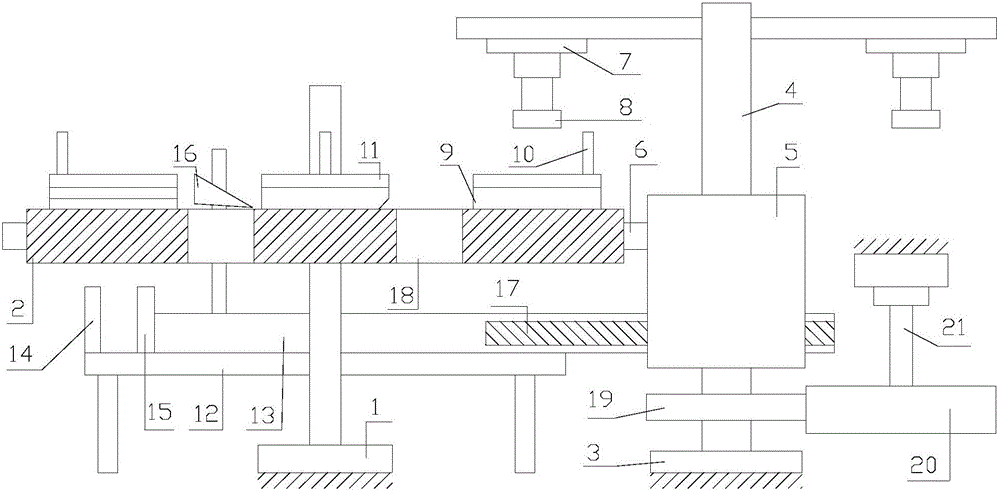

The invention discloses a system capable of continuously punching workpieces, which comprises a bracket, a support wheel, a plurality of molds, a mounting frame, a rotating shaft, a running wheel, a first punching mechanism, a second punching mechanism, a driving mechanism, a position sensor, a control The support wheel is installed on the bracket in rotation, the support wheel is set horizontally, and the circumferential surface of the support wheel is provided with the first gear teeth in continuous distribution; multiple molds are installed on the support wheel, and the rotation of the multiple molds on the support wheel The center is evenly distributed, and the included angle between two adjacent molds and the center of rotation of the supporting wheel is β; the rotating shaft is placed on one side of the supporting wheel, and the rotating shaft is connected to the mounting frame in rotation, the rotating shaft is set vertically, and the rotating wheel is installed on the rotating shaft , the axis of the runner coincides with the axis of the rotating shaft, the situation on the circumferential surface of the runner is provided with the second gear teeth matched with the first gear teeth, and the rotation angle of the support wheel is β every time the runner rotates one cycle. The invention has high processing effect and high processing precision.

Owner:WUHU HONGFEI MACHINERY CO LTD

Stamping die

The invention relates to the technical field of dies, in particular to a stamping die. The stamping die comprises a lower die plate and an upper die plate, wherein the upper surface of the lower template is fixedly provided with a fixed mold fixing plate, a sliding groove is formed in the front surface of the fixed mold fixing plate, sliding rods are arranged in the sliding groove, and limiting clamping plates are fixedly arranged on one sides, close to the interior of the sliding groove, of the outer surfaces of the sliding rods. According to the stamping die, the sliding groove is formed inthe side wall of the fixed mold fixing plate of the mold body, two sets of limiting devices are installed inside the sliding groove, each limiting device is composed of a sliding rod and a limiting clamping plate, and the mounting position of the sliding groove is adjusted through adjusting pin holes and fixing pins which are formed in the outer side walls of the sliding rods, so that the distancebetween the two limiting clamping plates is adjusted, the distance of the two limiting clamping plates is slightly larger than the width of the punching raw materials, the offset of the stamping rawmaterials is controlled within an allowable range, and therefore the error of the stamping size is reduced, and the qualified rate of products is improved.

Owner:昆山西诺巴精密模具有限公司

Device for machining workpieces

InactiveCN105855347AFlexible adjustmentIngenious structural designShaping toolsMetal-working feeding devicesEngineeringPunching

The invention discloses a device for processing a workpiece, which includes a bracket, a first moving plate, a rack, multiple molds, a support shaft, a first runner, a second runner, a driving mechanism, a mounting frame, and a rotating shaft , two stamping mechanisms; a chute is provided on the bracket, and the chute is set horizontally; the first moving plate is movably installed on the chute; the rack is installed on the side of the first moving plate, and the length direction of the rack is in line with the chute The length direction of the chute is parallel; multiple molds are installed on the first moving plate at intervals along the length direction of the chute, and the distance between any two adjacent molds is equal; the support shaft is placed on the side of the rack away from the first moving plate , the support shaft is arranged along the vertical direction; the first runner and the second runner are installed on the support shaft, and the axes of the first runner and the second runner coincide with the axis of the support shaft. The invention has high processing precision and good processing effect.

Owner:WUHU HONGFEI MACHINERY CO LTD

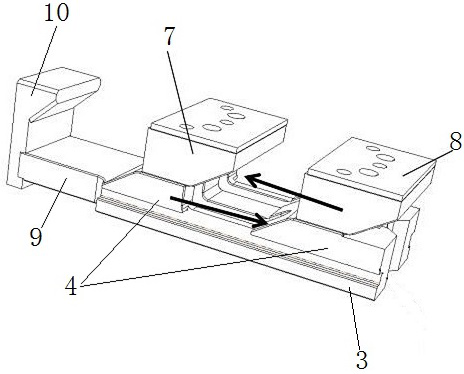

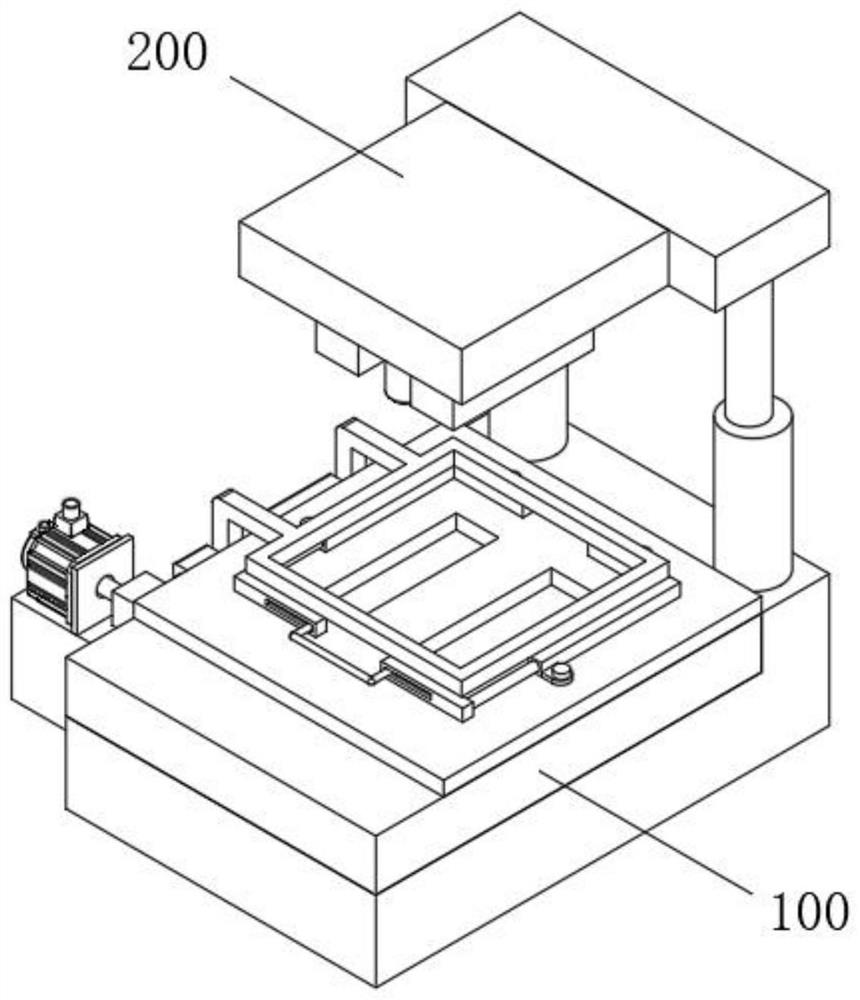

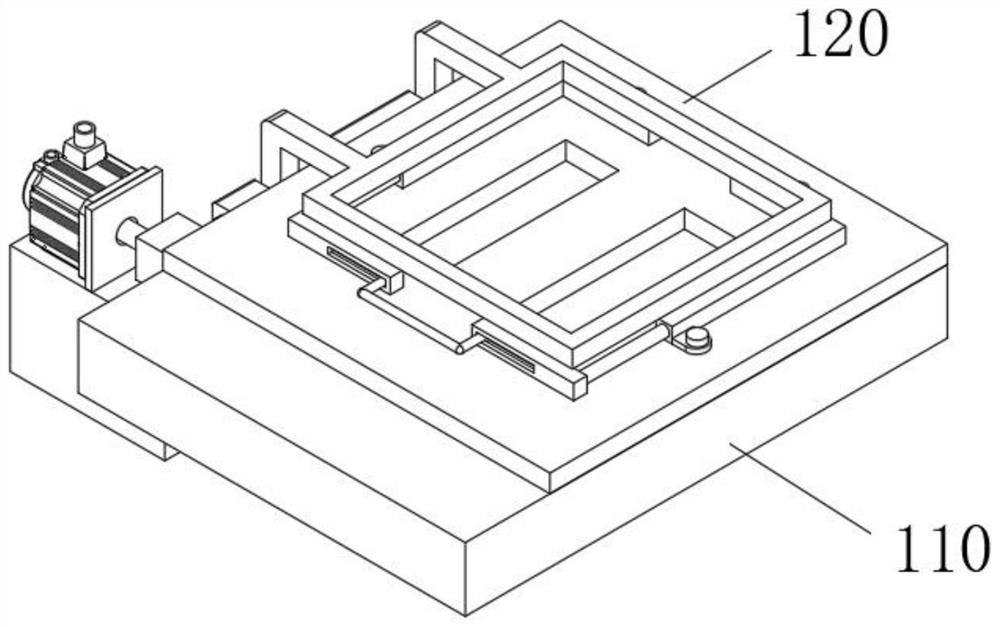

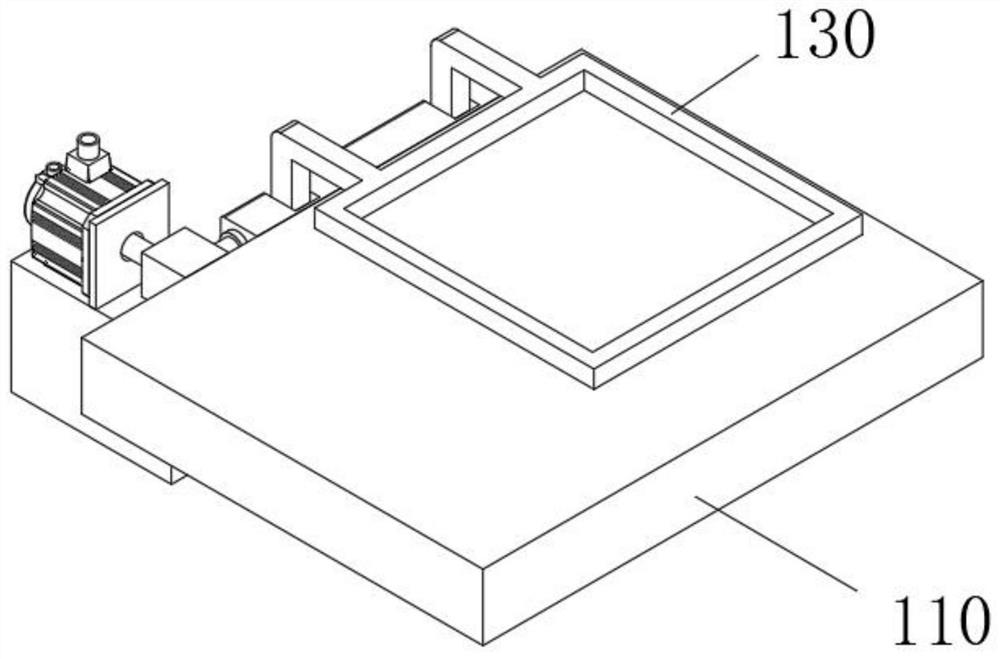

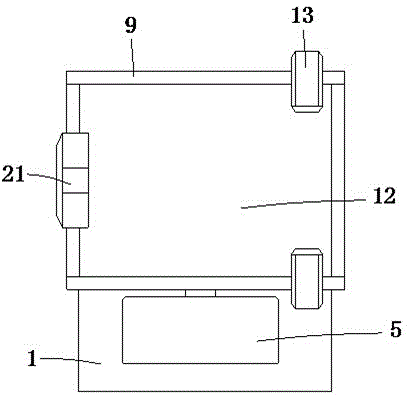

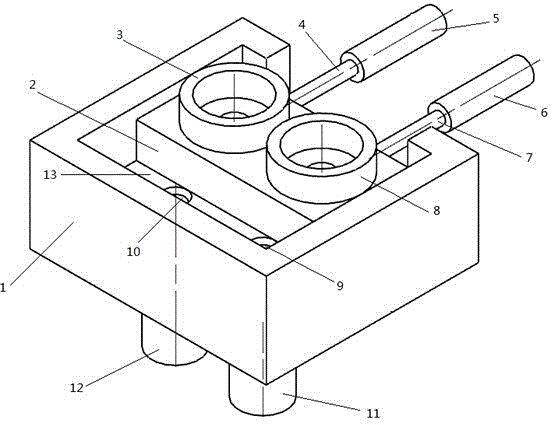

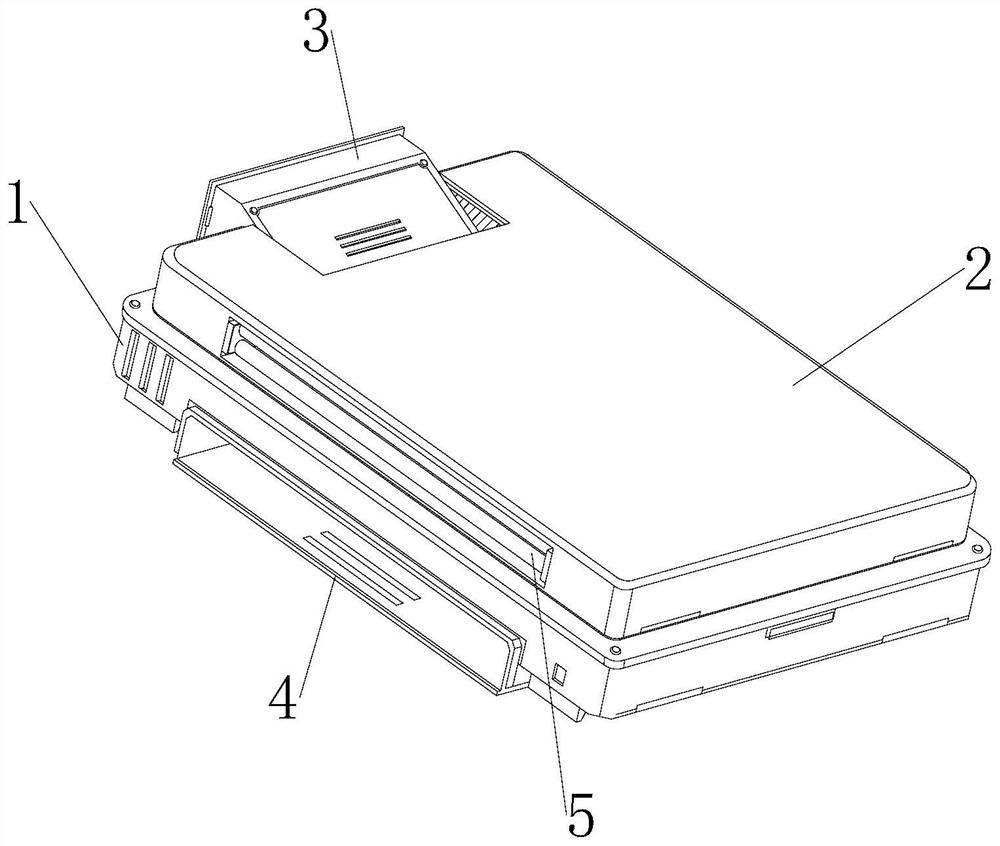

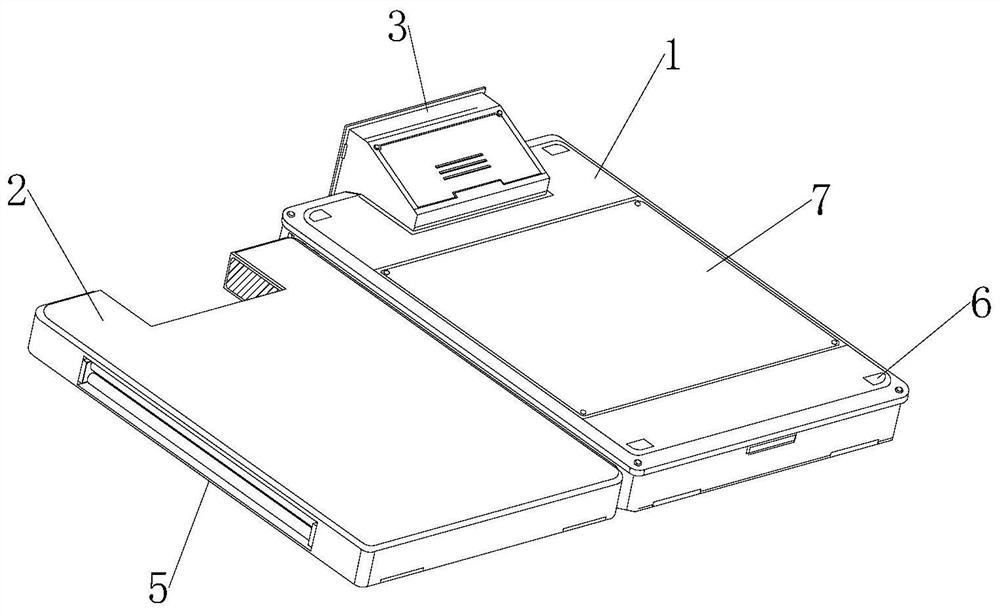

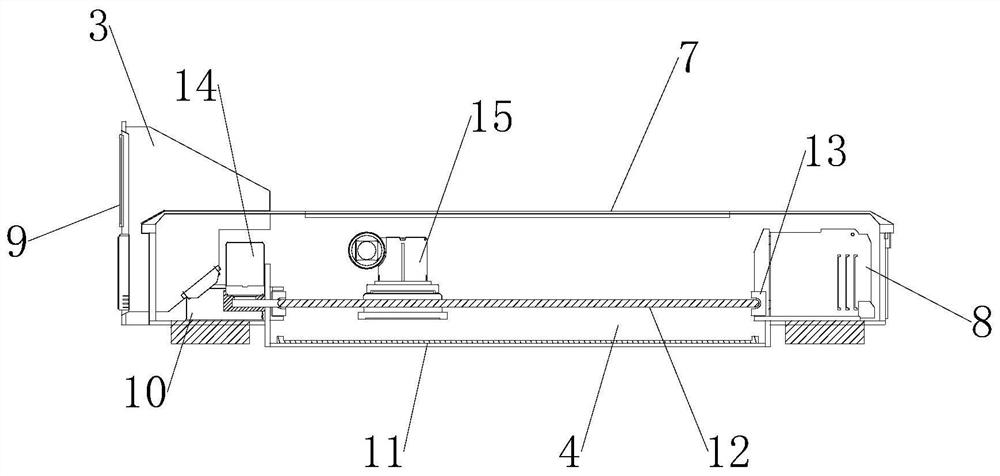

Die holder device capable of sliding

ActiveCN104438602AEasy to pick and place materials and stamping operationsShorten the timeShaping toolsEjection devicesSlide plateIndustrial engineering

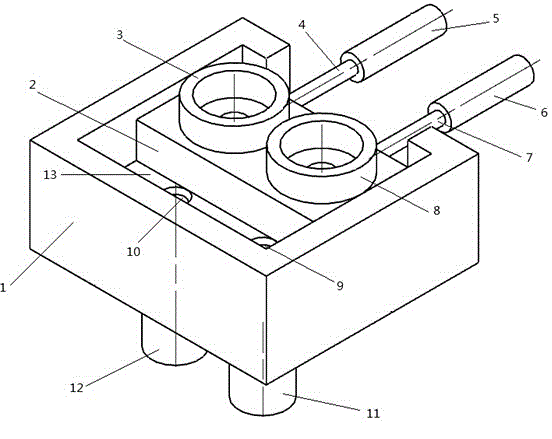

The invention discloses a die holder device capable of sliding. The die holder device includes a cuboid die holder. A cuboid groove is formed in the center of the upper portion of the die holder. A sliding plate which slides left and right in the cuboid groove is arranged in the cuboid groove. A first outer die sleeve and a second outer die sleeve are arranged in parallel in the front-back direction on the surface of the sliding plate. Punching dies are placed in the first outer die sleeve and the second outer die sleeve. A notch is formed in the right side face of the cuboid groove. A first drive mechanism and a second drive mechanism are arranged in parallel in the front-back direction on the right side face of the die holder. Two vertical through holes are formed in parallel in the front-back direction in the bottom surface of the left of the die holder, and a first ejector beam and a second ejector beam are arranged in the two through holes respectively. According to the die holder device, the sliding plate provided with multi-station dies is moved out of the position underneath a slide block through an air cylinder so that the working procedures of feeding and discharging can be performed; meanwhile, a hydraulic cylinder ejecting device is arranged underneath the die holder; accordingly, quick, safe and efficient punching production can be achieved.

Owner:泰州浙华机械精锻有限公司

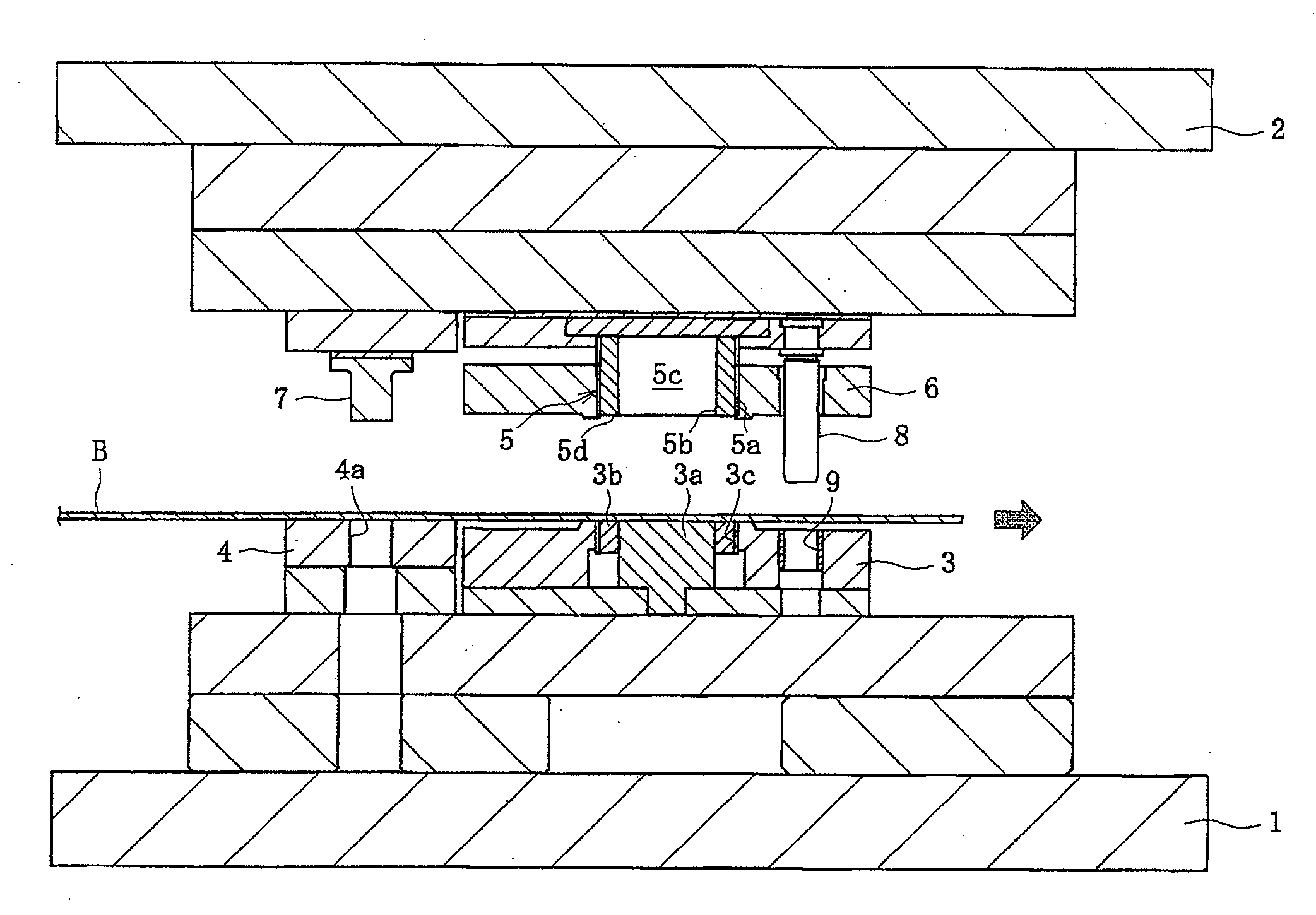

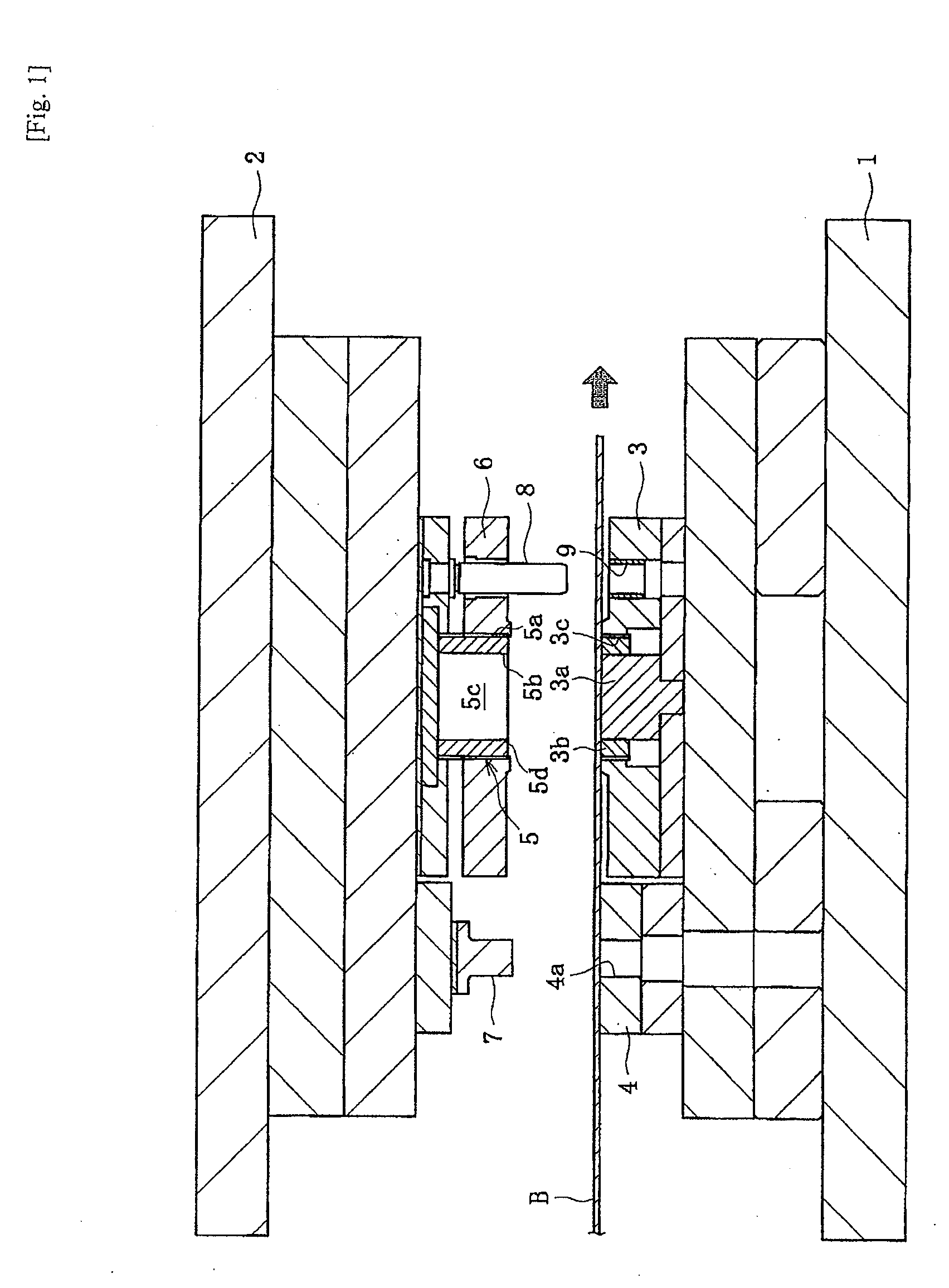

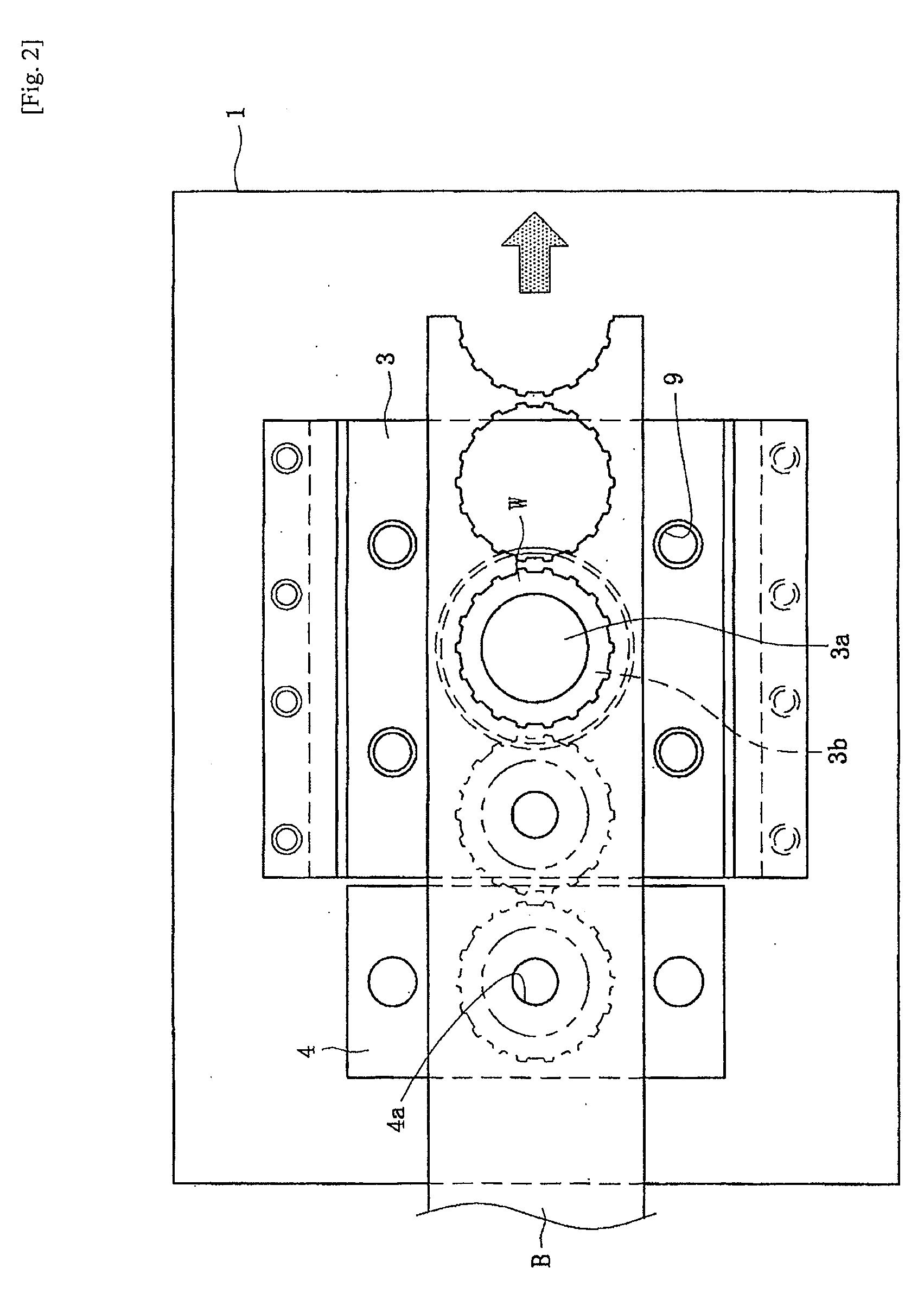

Punch working apparatus and method

InactiveUS20080110308A1Good sheared surfaceAvoid interferenceStripping-off devicesMetal working apparatusPunchingEngineering

Embodiment, punch working apparatus has a first mold frame on which a die is mounted, a second mold frame movable toward and away from the first mold frame and a punch mounted on the first mold frame for simultaneously performing both outer and inner circumferential punching works on a sheet material between the frames, the punch containing resulted scraps in a space defined therewithin. A sub-punch is also provided, and punches an aperture having a predetermined configuration at a position of the sheet material that ends up as part of the scrap formed by and contained within the punch.

Owner:FCC KK

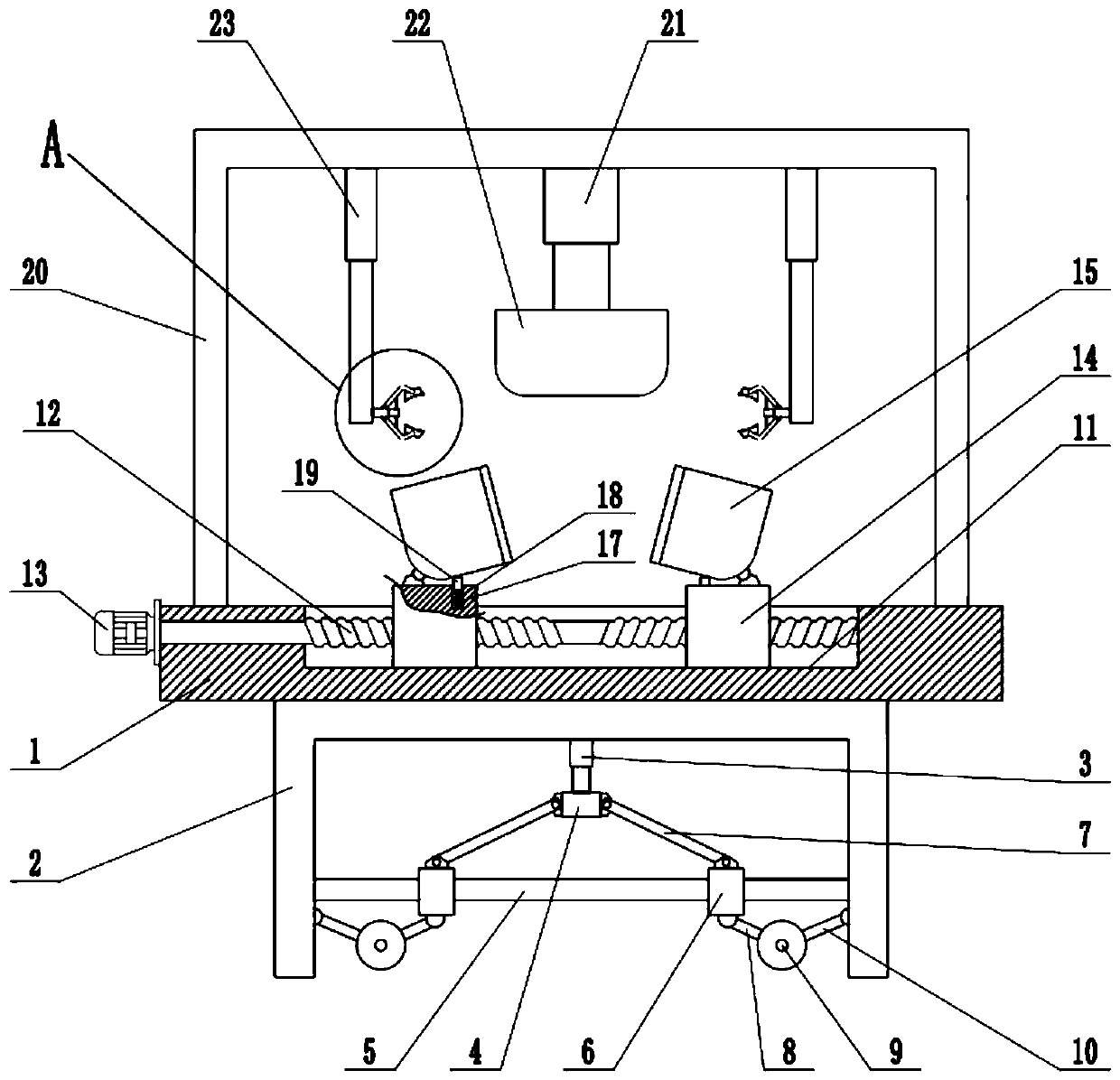

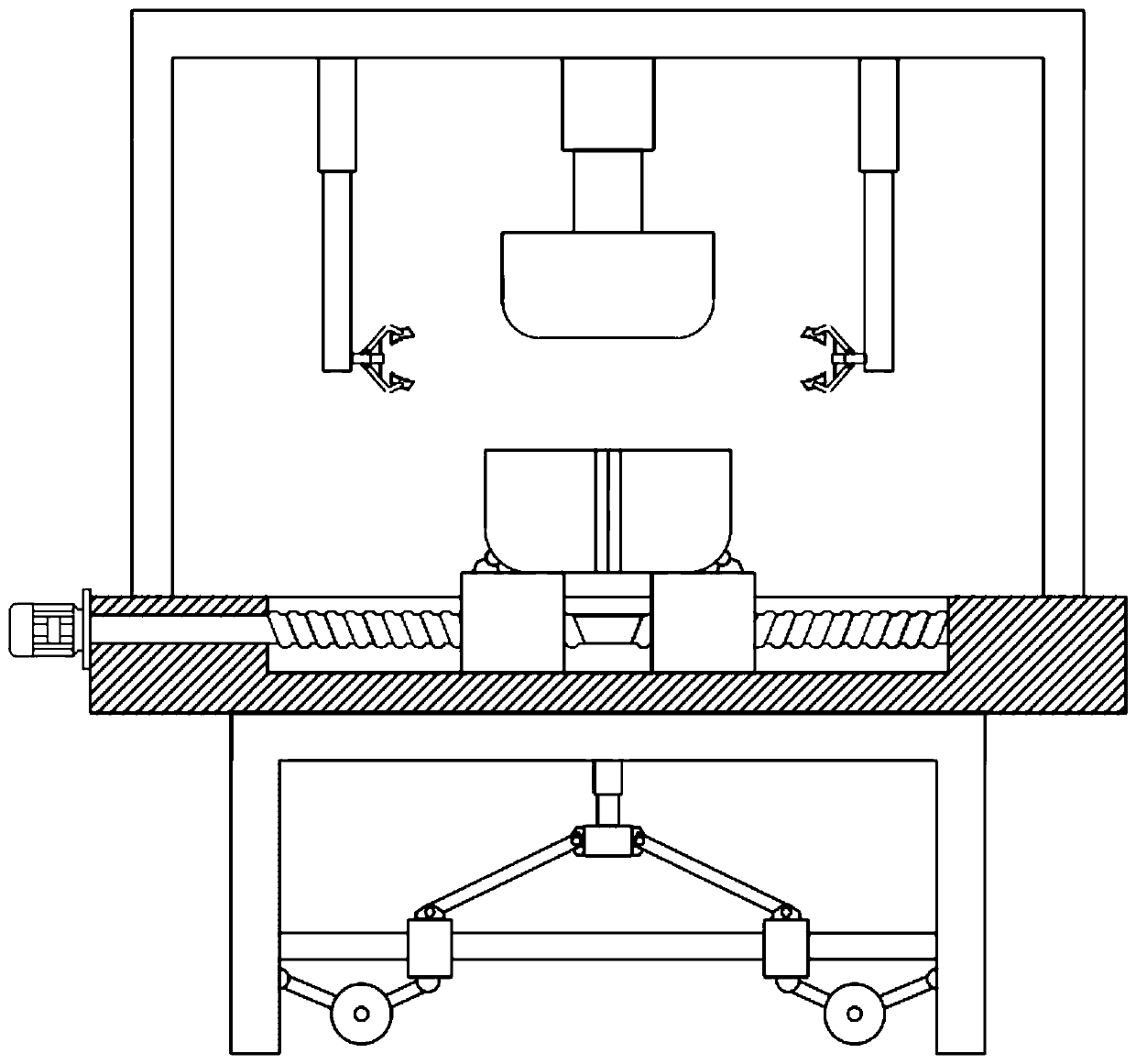

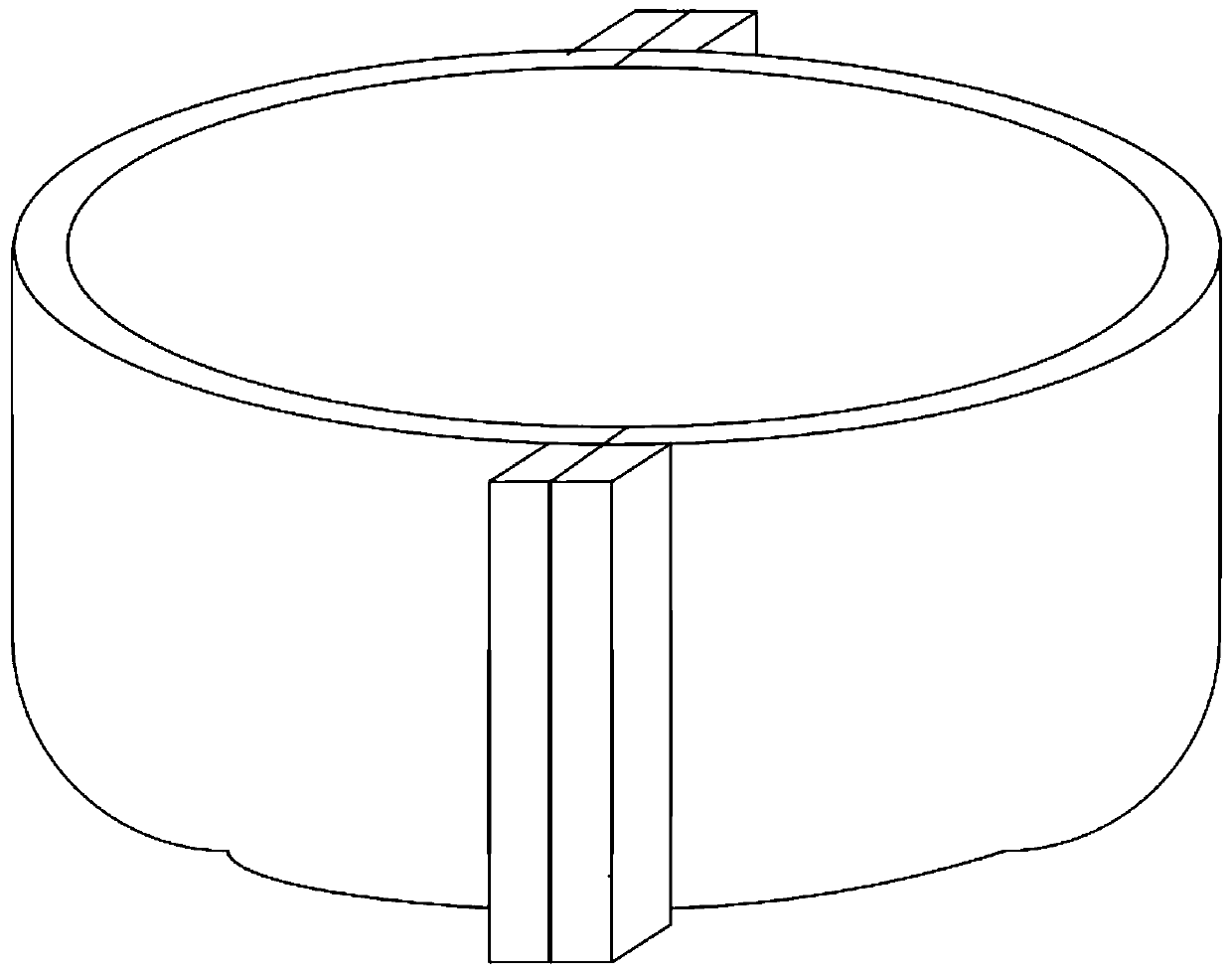

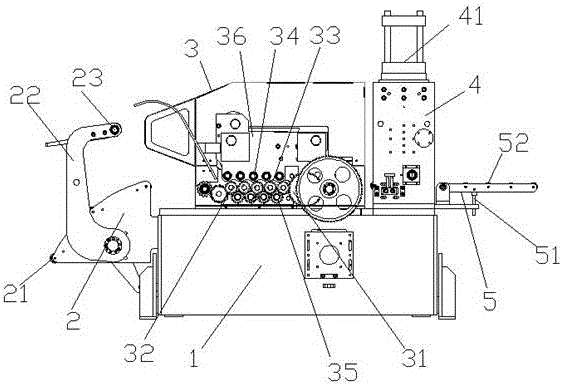

Automatic punching machine special for rice cooker inner container

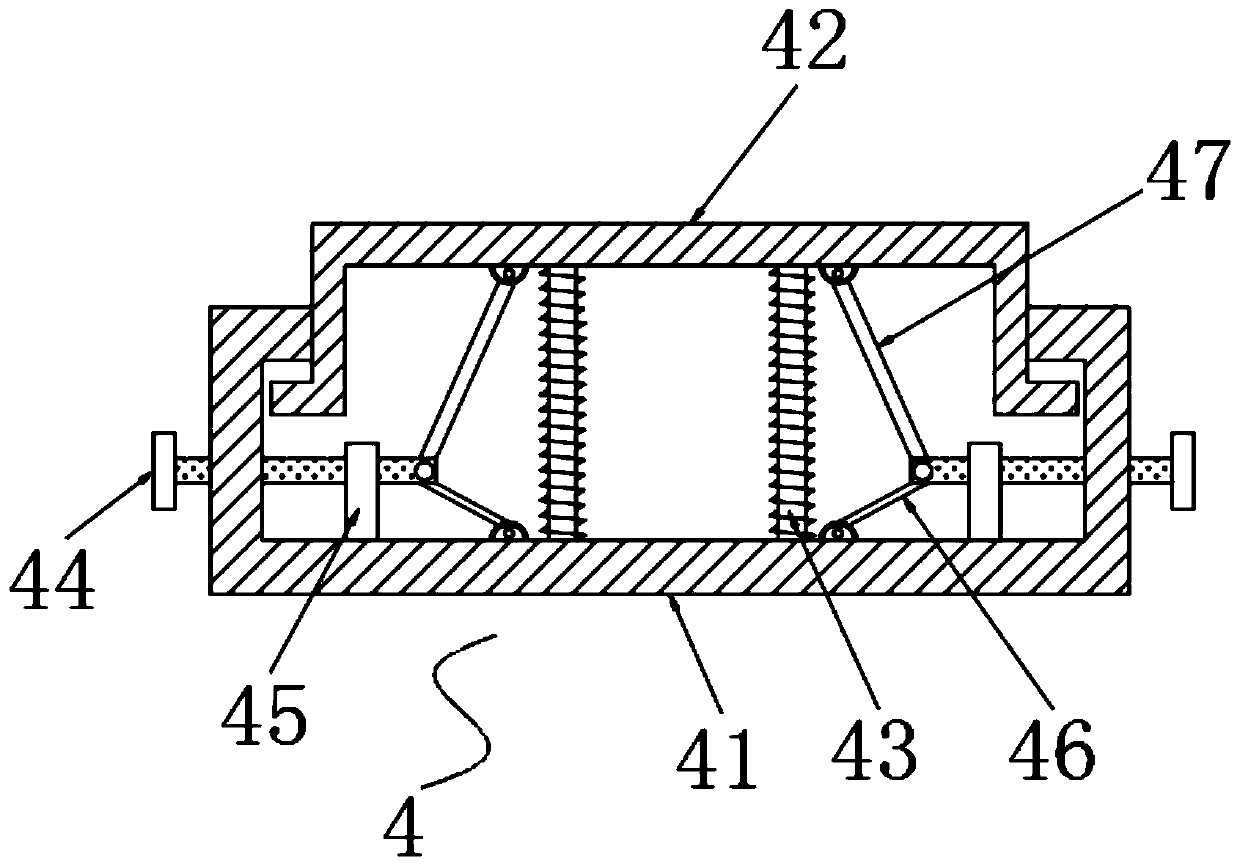

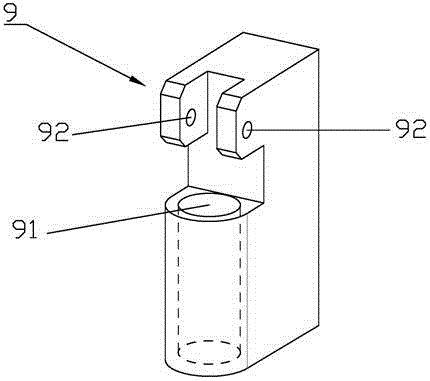

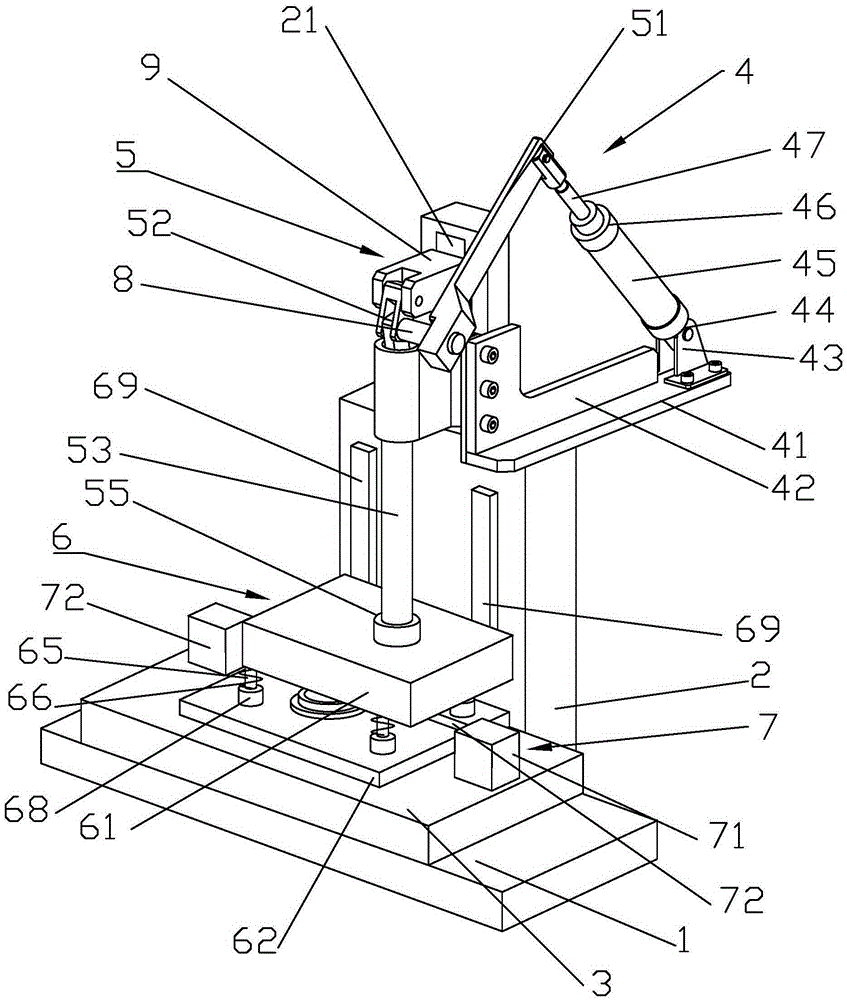

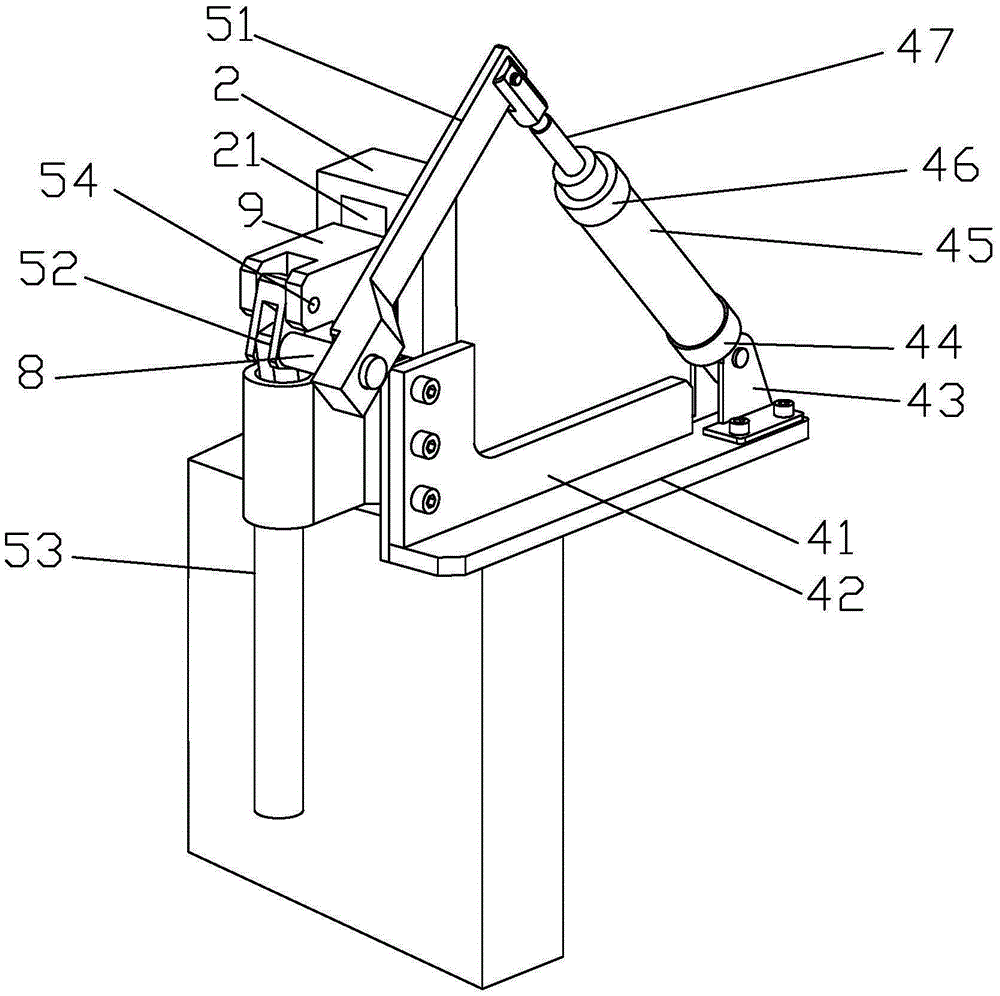

ActiveCN110180964AFast clamping speedEasy to removeShaping toolsMetal-working feeding devicesPunchingEngineering

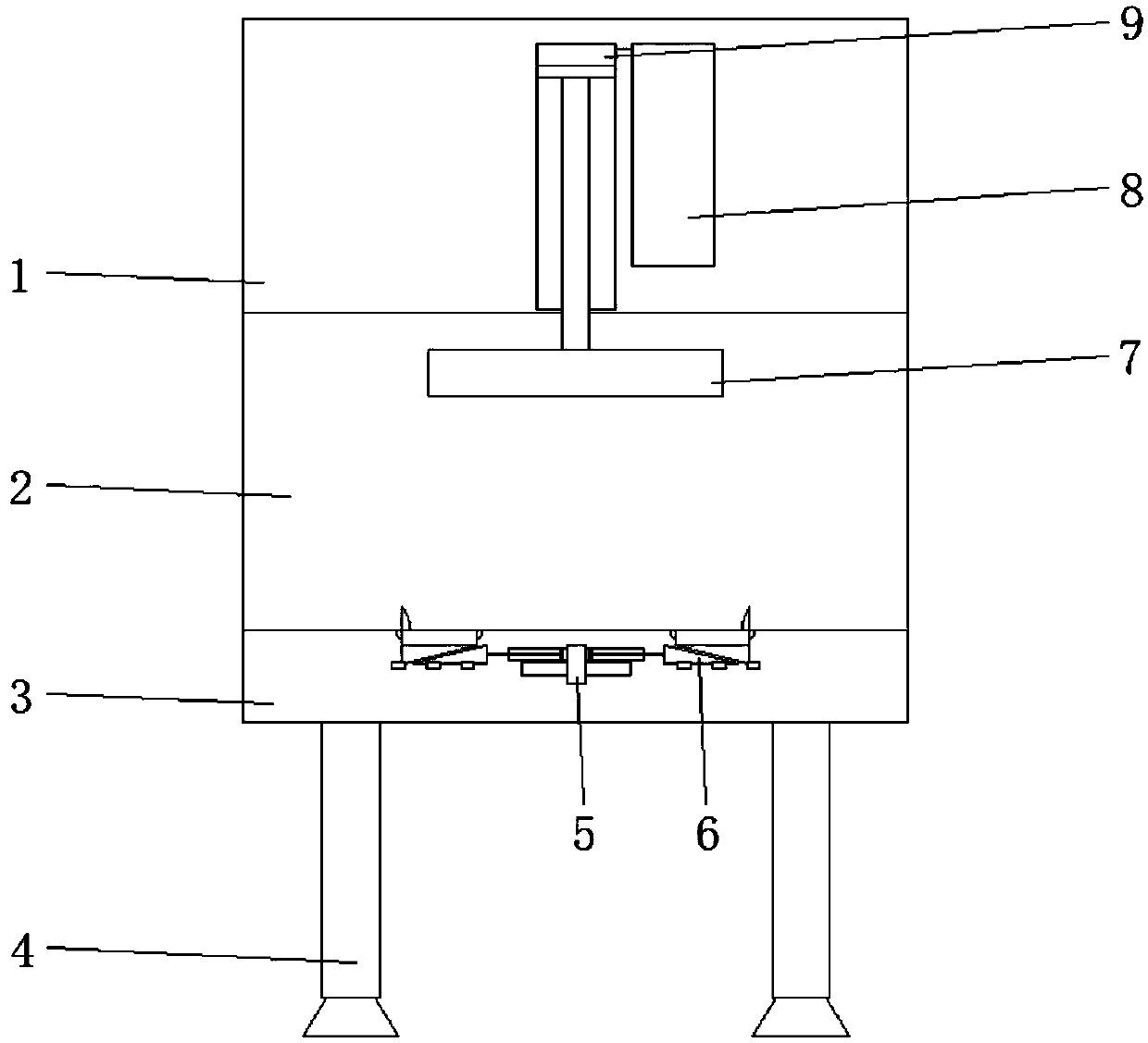

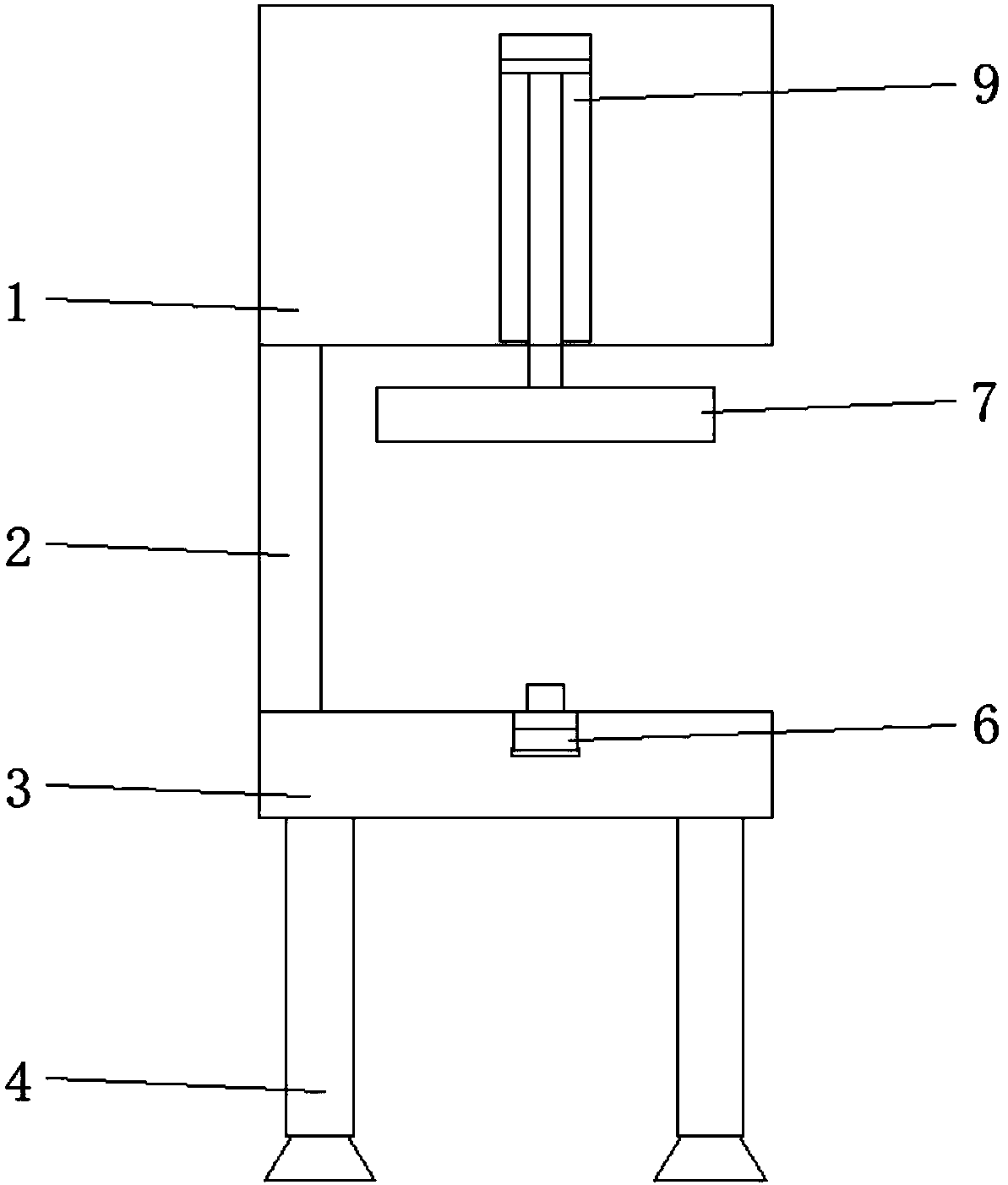

The invention relates to the field of rice cooker producing and machining equipment, in particular to an automatic punching machine special for a rice cooker inner container. The automatic punching machine special for the rice cooker inner container comprises a workbench, lower dies, a fixing frame, a second telescopic mechanism and an upper die; the upper surface of the workbench is provided witha sliding groove, a double-way screw is installed in the sliding groove and sleeved with supporting blocks, and the supporting blocks are in threaded connection with the double-way screw; the lower dies are hinged to the supporting blocks; and the fixing frame is fixedly connected to the upper surface of the workbench, the second telescopic mechanism is installed on the top of the fixing frame, and the upper die is fixedly connected to the lower end of the second telescopic mechanism. A to-be-punched part is clamped by a clamping mechanism, therefore, the to-be-punched part keeps stable, andthe clamping speed is high; punching operation is completed through cooperation of the lower dies and the upper die; the lower dies keep an inclination state through springs and ejection rods, therefore, people can conveniently take down the punched rice cooker inner container, and the assembling and disassembling speed is high; and a moving mechanism is arranged, and therefore the device can be conveniently pushed to move.

Owner:磐安途舛信息科技有限公司

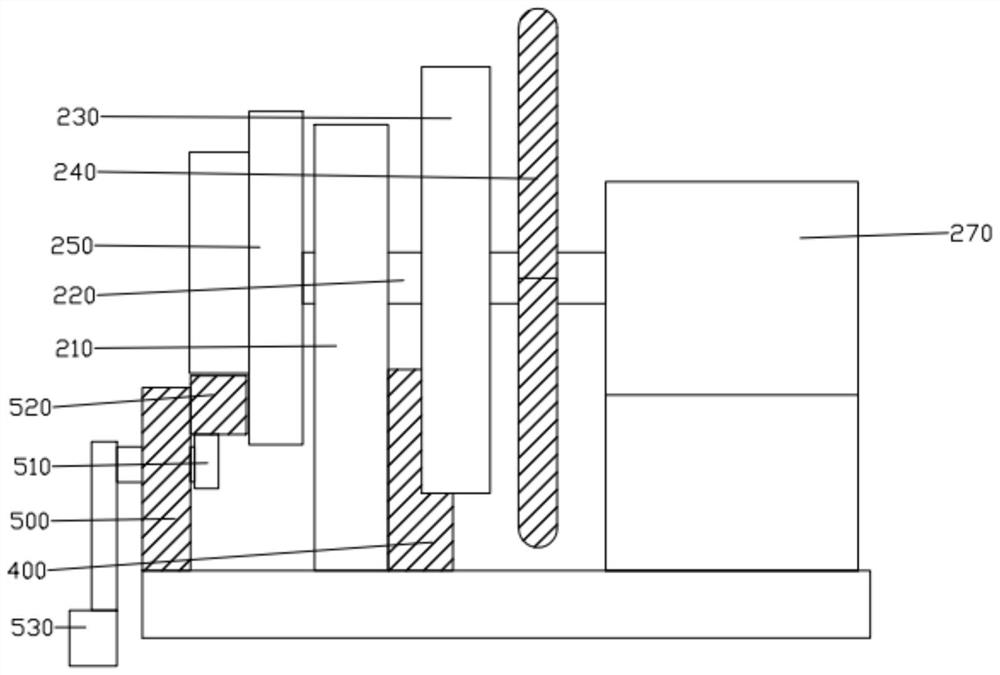

Stamping device for machining JYW800 steel material of vehicle

PendingCN111451344AGuaranteed stamping accuracyConvenient unloading workShaping toolsMetal-working feeding devicesStamping processTelescopic cylinder

The invention discloses a stamping device for machining a JYW800 steel material of a vehicle, and relates to the technical field of steel material machining, in particular to the technical field of machining of the JYW800 steel material. The stamping device comprises a machine frame, feet and a control panel. The feet are fixedly installed on the lower surface of the machine frame. The control panel is embedded in the front side of the machine frame. An adjusting base is arranged on the upper surface of the machine frame. The position, located on one side of the adjusting base, of the upper surface of the machine frame is fixedly provided with a stand column. A telescopic cylinder is fixedly installed at the top end of the stand column. The stamping device is scientific and reasonable in structure and convenient to operate; by means of the adjusting base, the height adjustment of a lower die holder can be realized, convenience is provided for stamping work of operators, and the stamping device can adapt to uses at different heights; and by means of a fixing mechanism, the to-be-machine steel material can be fixed and is prevented from displacement in the stamping process, and the stamping precision is ensured.

Owner:JINGYE STEEL CO LTD

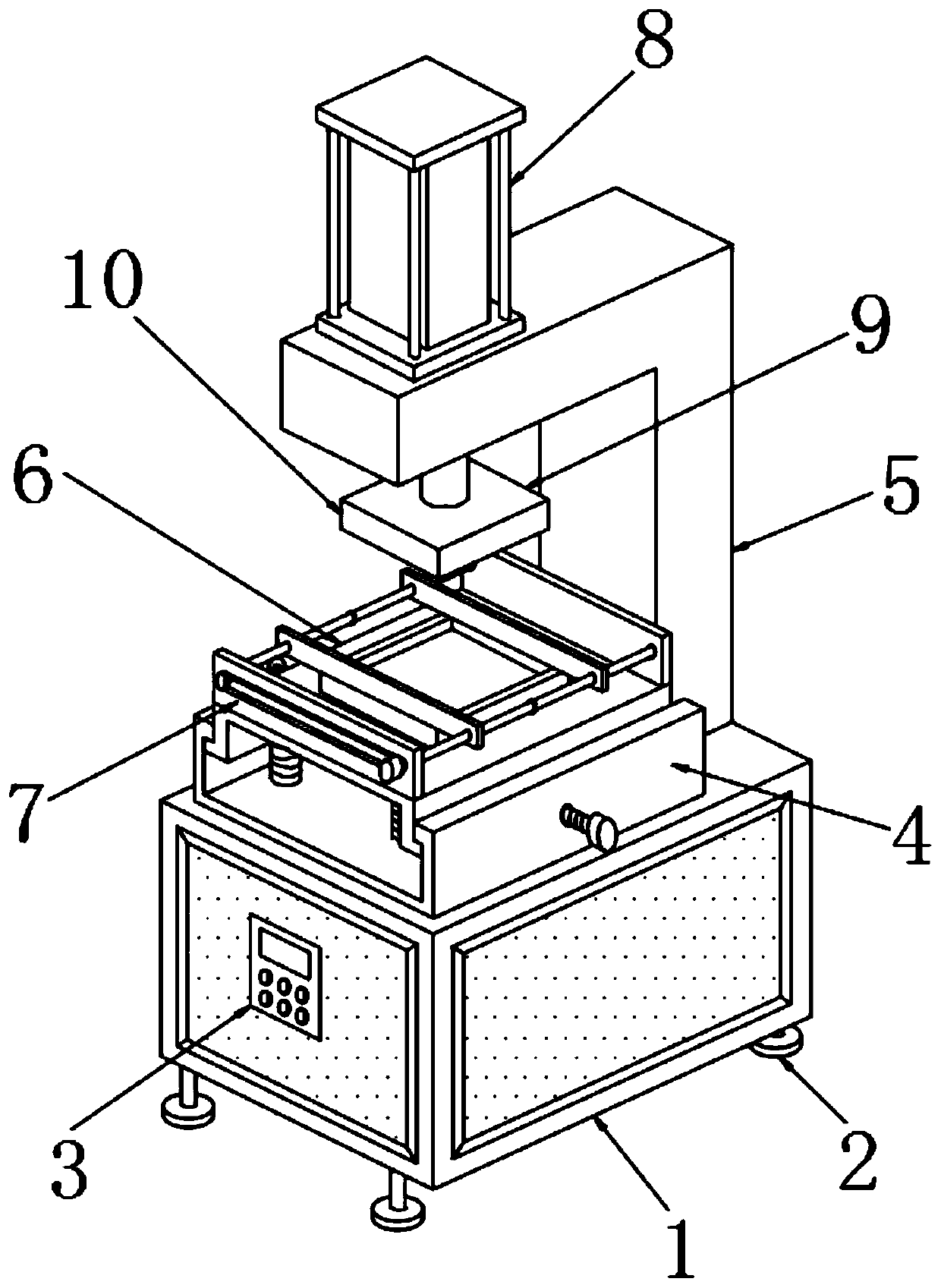

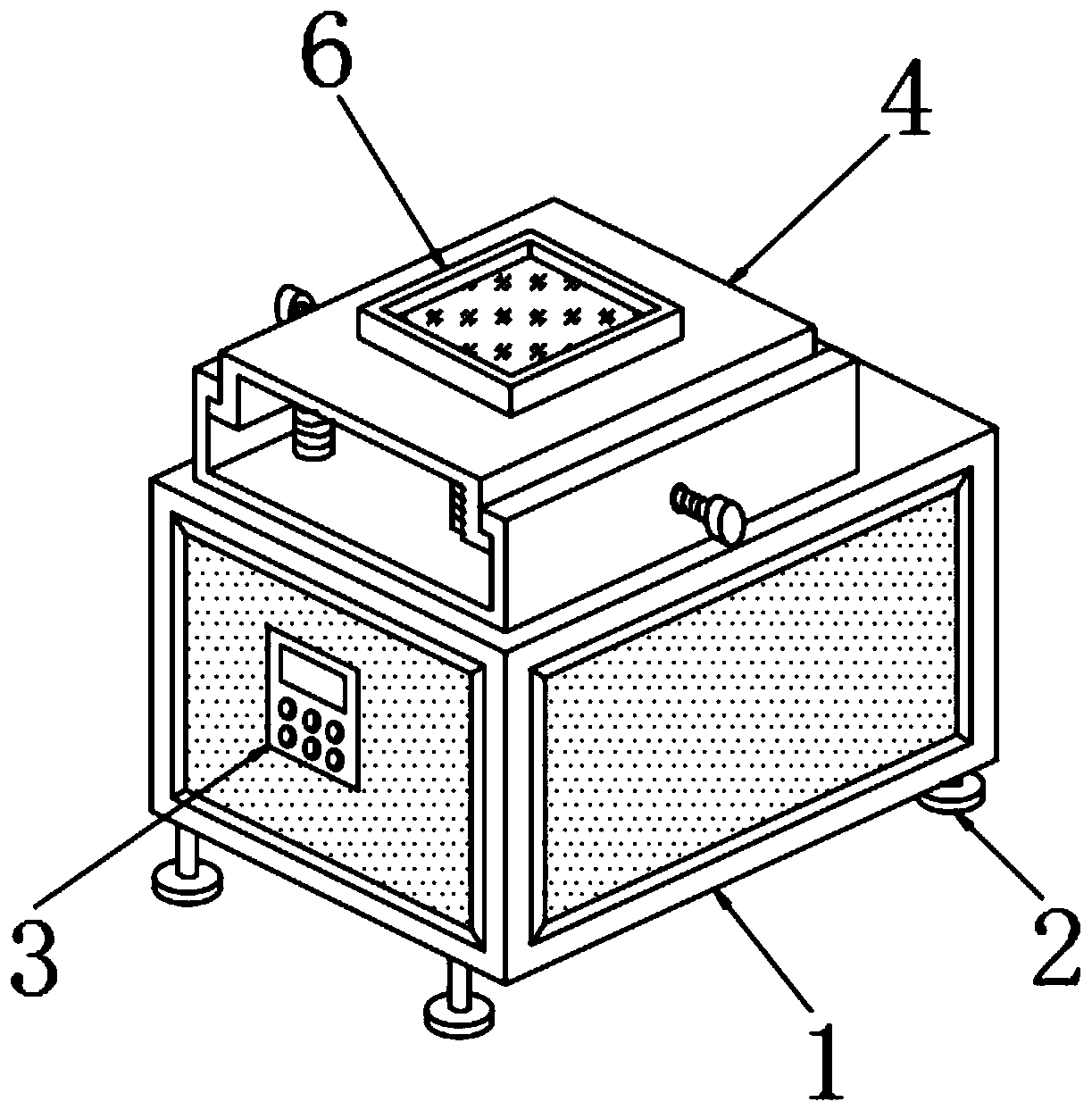

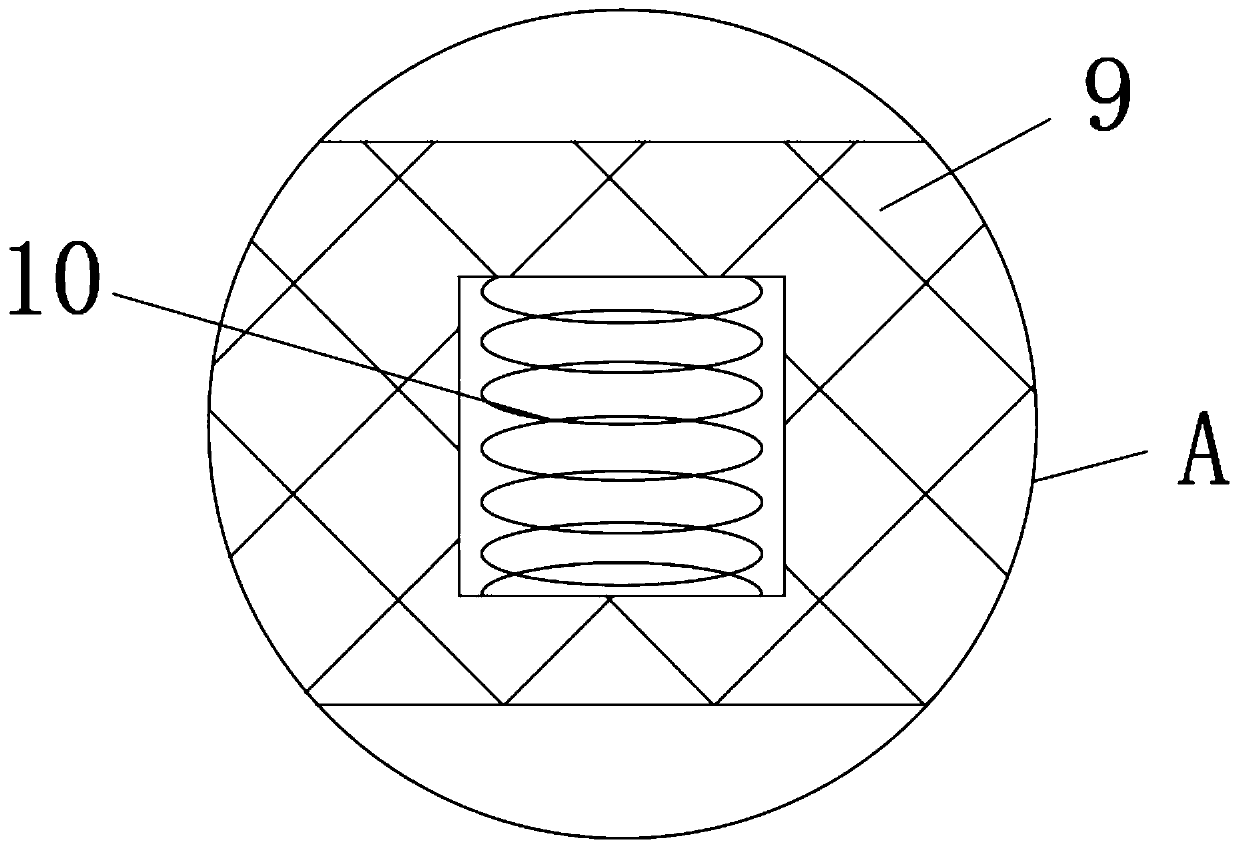

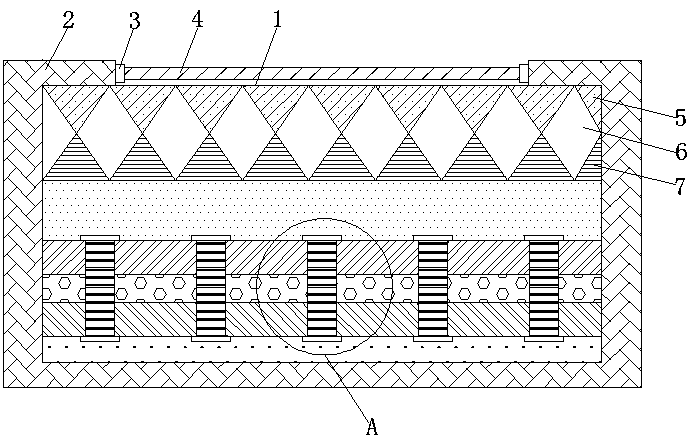

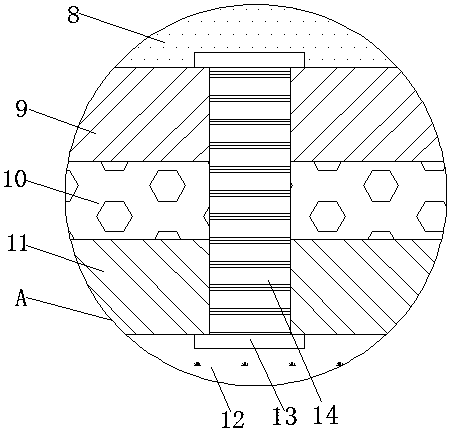

Stamping equipment applied to motor stator and rotor sheet production

ActiveCN105429385AIncrease productivitySimple structureManufacturing stator/rotor bodiesEngineeringUltimate tensile strength

The invention discloses stamping equipment applied to motor stator and rotor sheet production. The stamping equipment comprises a stamping engine base and a stamping engine body; a stamping apparatus comprises a stamping driving mechanism, a stamping transmission mechanism and a stamping assembly; the stamping driving mechanism is connected with the stamping transmission mechanism; the stamping transmission mechanism is connected with the stamping assembly; the stamping assembly comprises a stamping base, a stamping plate, a telescopic spring and a telescopic rod; the stamping base is glidingly mounted on the stamping engine body; the stamping plate is positioned below the stamping base; the stamping plate is mounted on a stamping platform; the telescopic rod is arranged between the stamping base and the stamping plate; and the telescopic spring is arranged on the telescopic rod. The stamping apparatus drives the whole equipment to move through the stamping driving mechanism; the stamping operation is performed by the stamping assembly under the drive of the stamping transmission mechanism; and the stamping equipment is simple in structure, good in stamping effect, safe, reliable and capable of improving the production efficiency of the stator and rotor sheet processing, lowering the labor intensity of workers and greatly improving the quality of products.

Owner:南通捷越机电有限公司

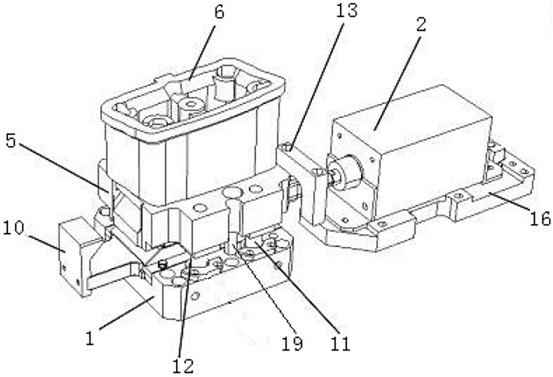

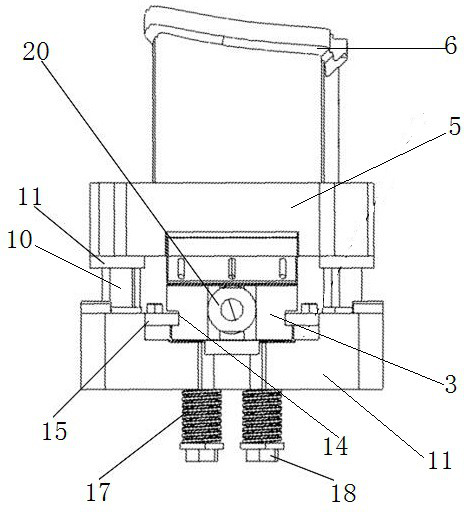

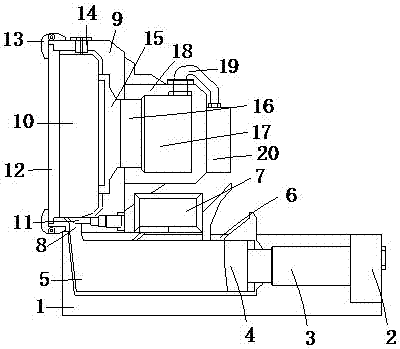

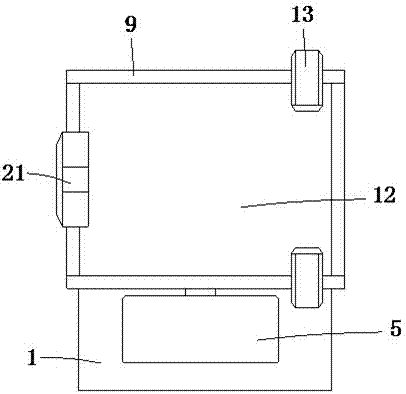

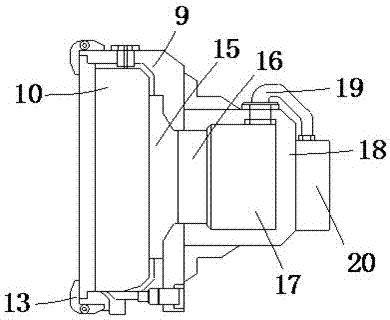

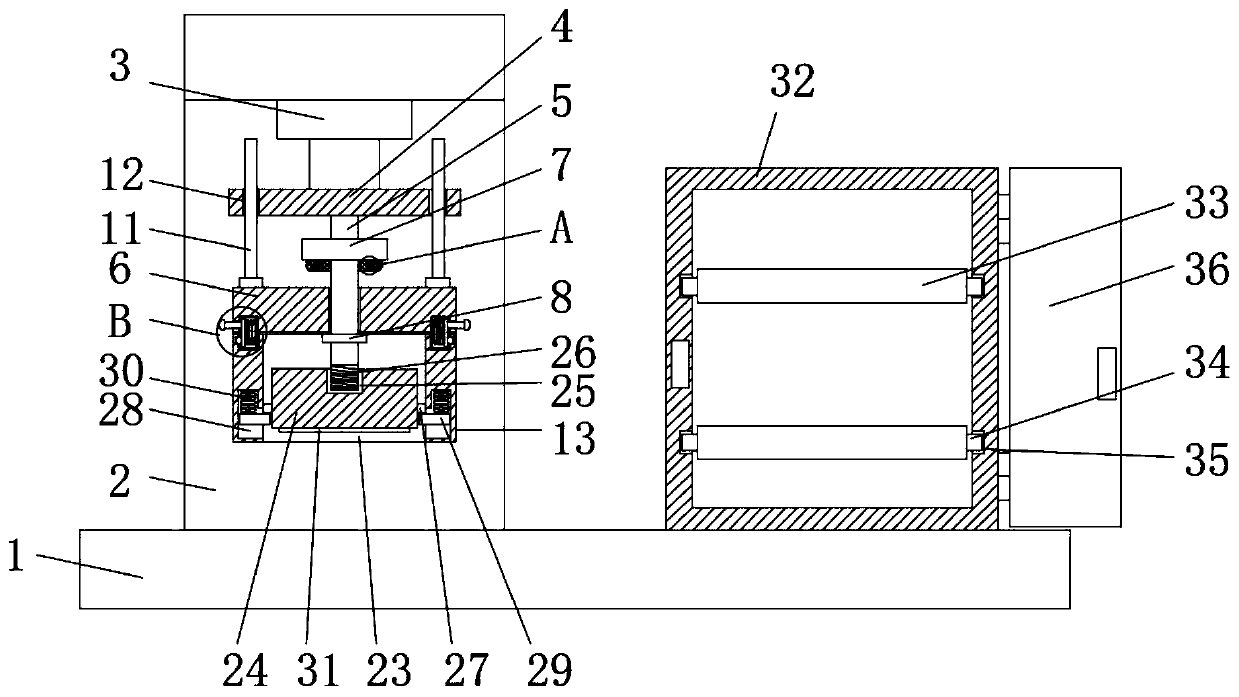

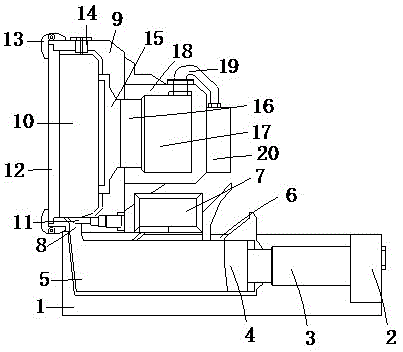

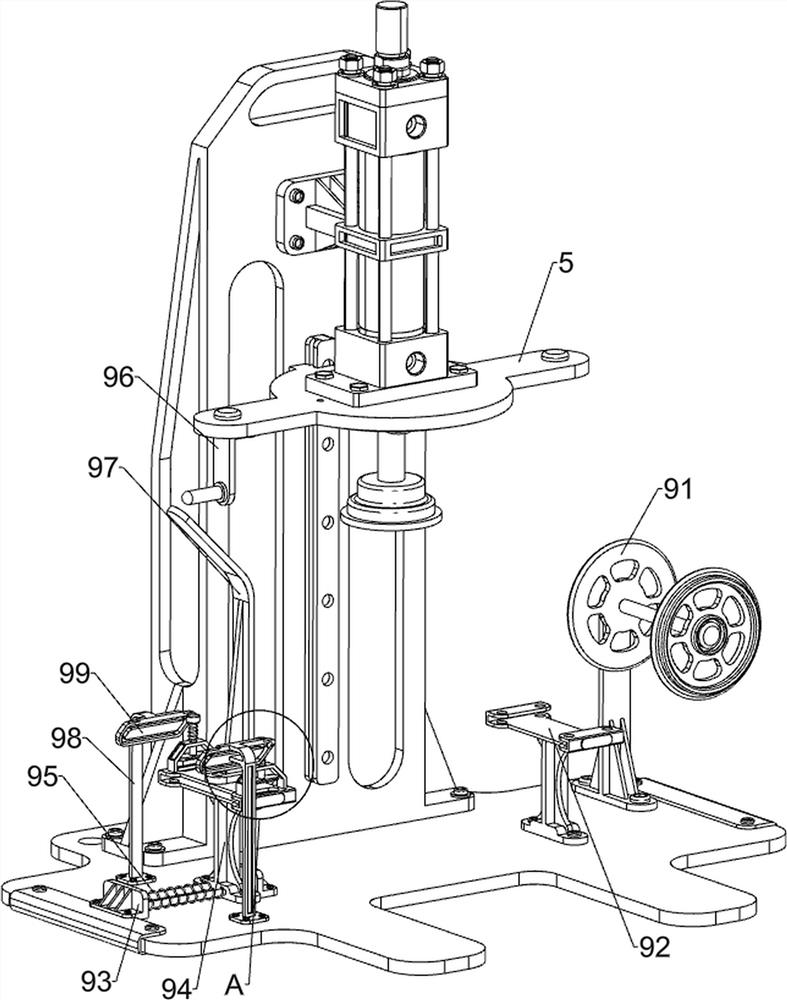

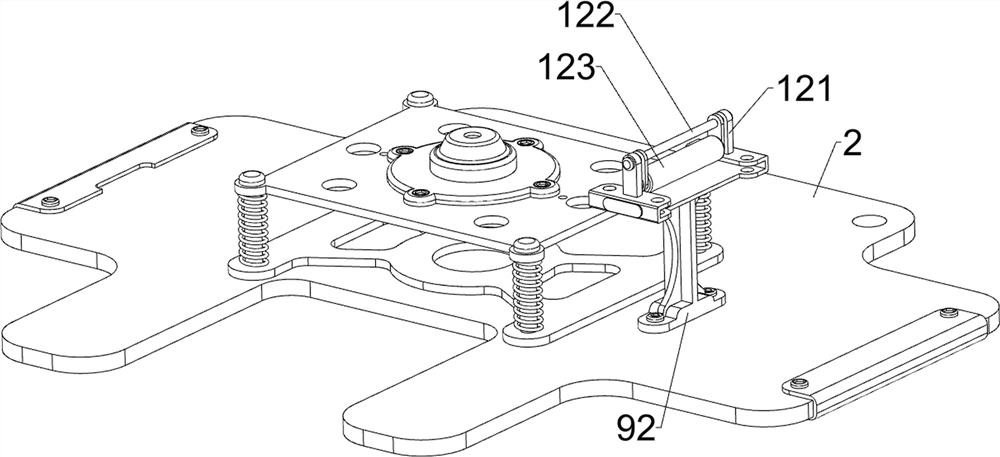

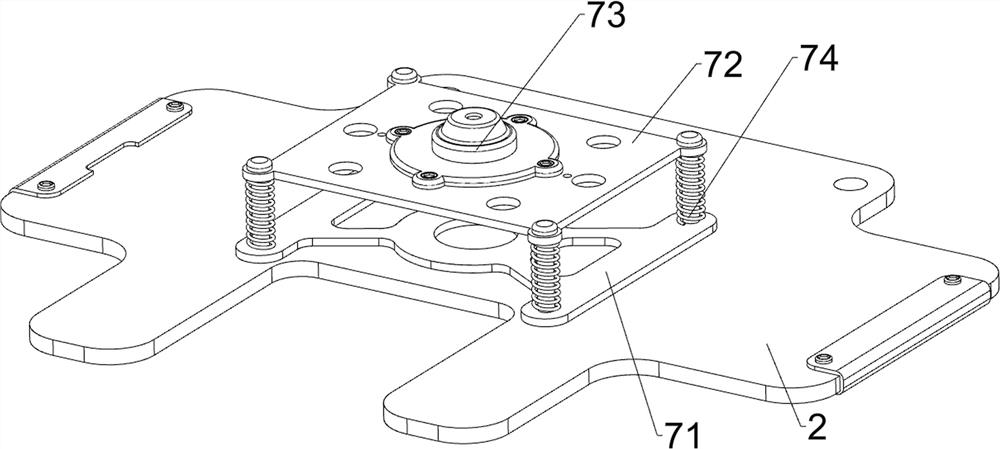

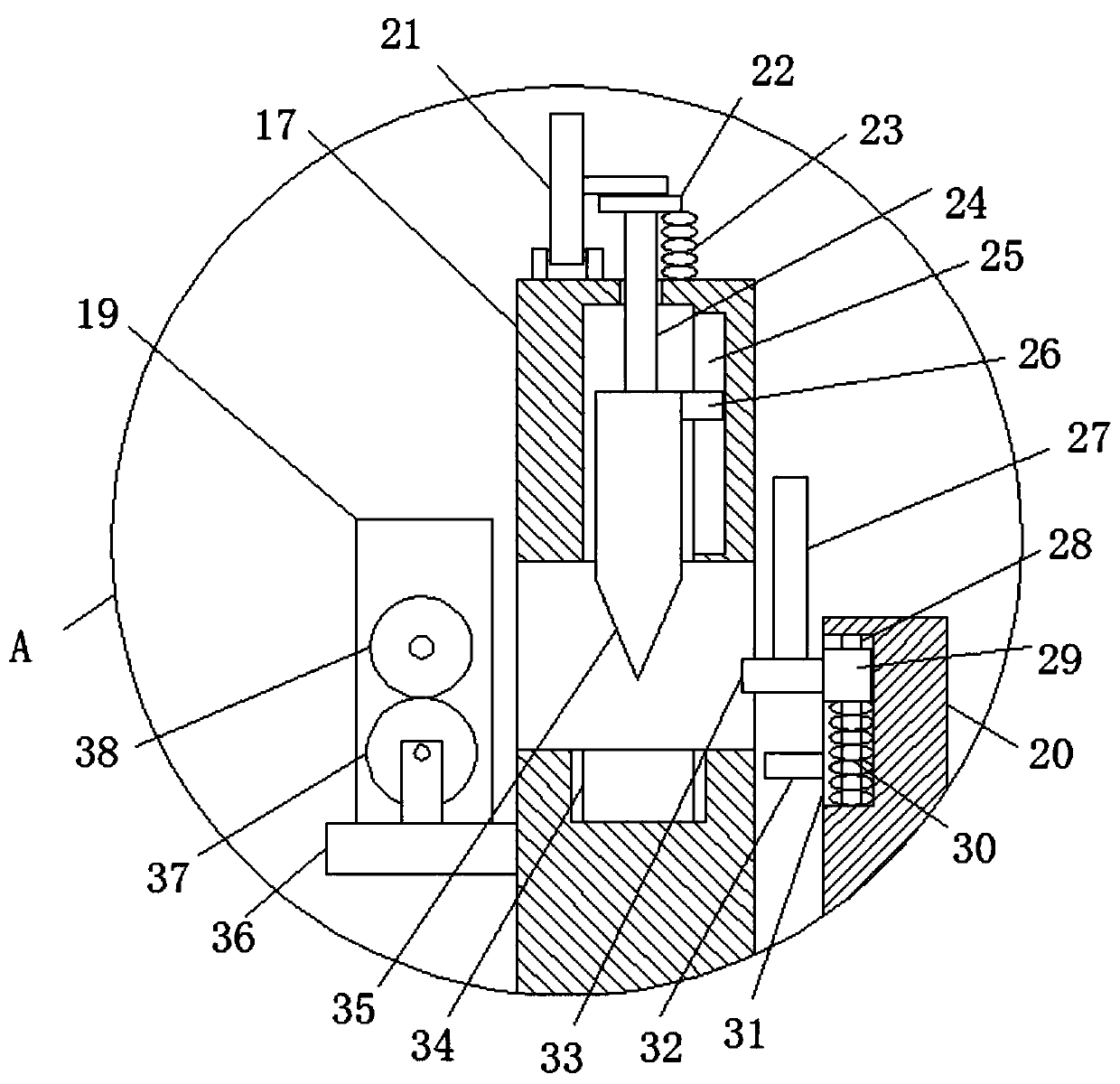

Punching machine

InactiveCN108655243AConvenient stamping workMetal-working feeding devicesPress ramPunch pressEngineering

The invention relates to the technical field of punching, in particular to a punching machine. The punching machine comprises a base, a punching mechanism, a loading mechanism, a linkage mechanism anda power mechanism; the punching mechanism is arranged above the base; the loading mechanism and the power mechanism are arranged on the right side of the base; the punching mechanism is connected toan output end of the power mechanism; the punching mechanism comprises a fixed plate, an upper template and a lower template; the fixed plate is arranged above the base; the upper template is connected above the fixed plate; a rotating shaft is arranged on the base; the lower template is arranged above the rotating shaft; one end of the linkage mechanism is connected to an output end of the powermechanism, and the other end is connected to the lower template; the loading mechanism comprises a first rotating shaft, a second rotating shaft and a belt; a limiting mechanism is arranged on the punching mechanism; the limiting mechanism comprises a limiting plate, a slide block and a spring; the limiting plate is connected above the fixed plate; a chute is formed in the fixed plate; the slide block is arranged in the chute; and the spring is arranged between the slide block and the limiting plate.

Owner:钱培玉

Lifting clamp for punch and manufacturing process thereof

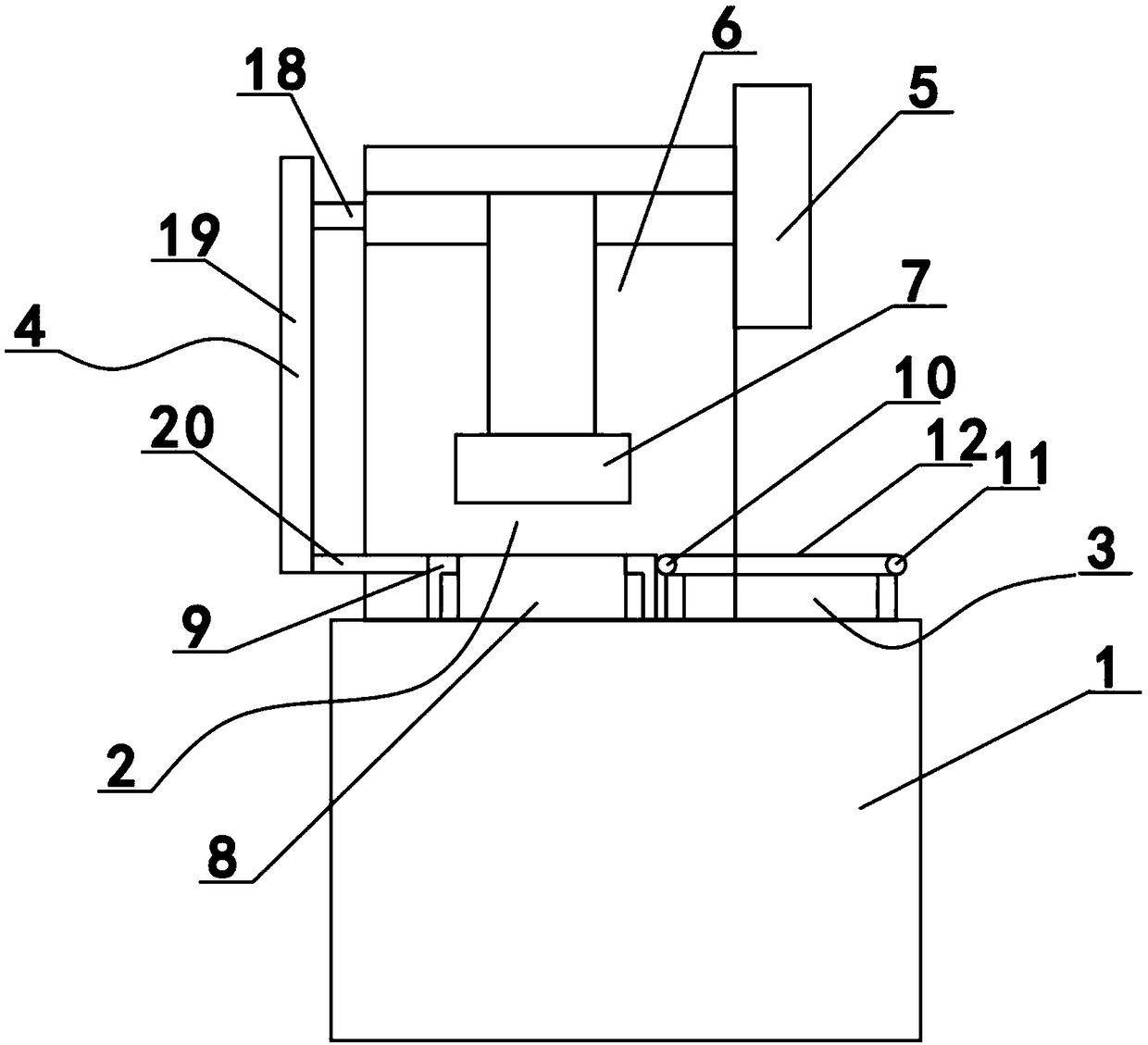

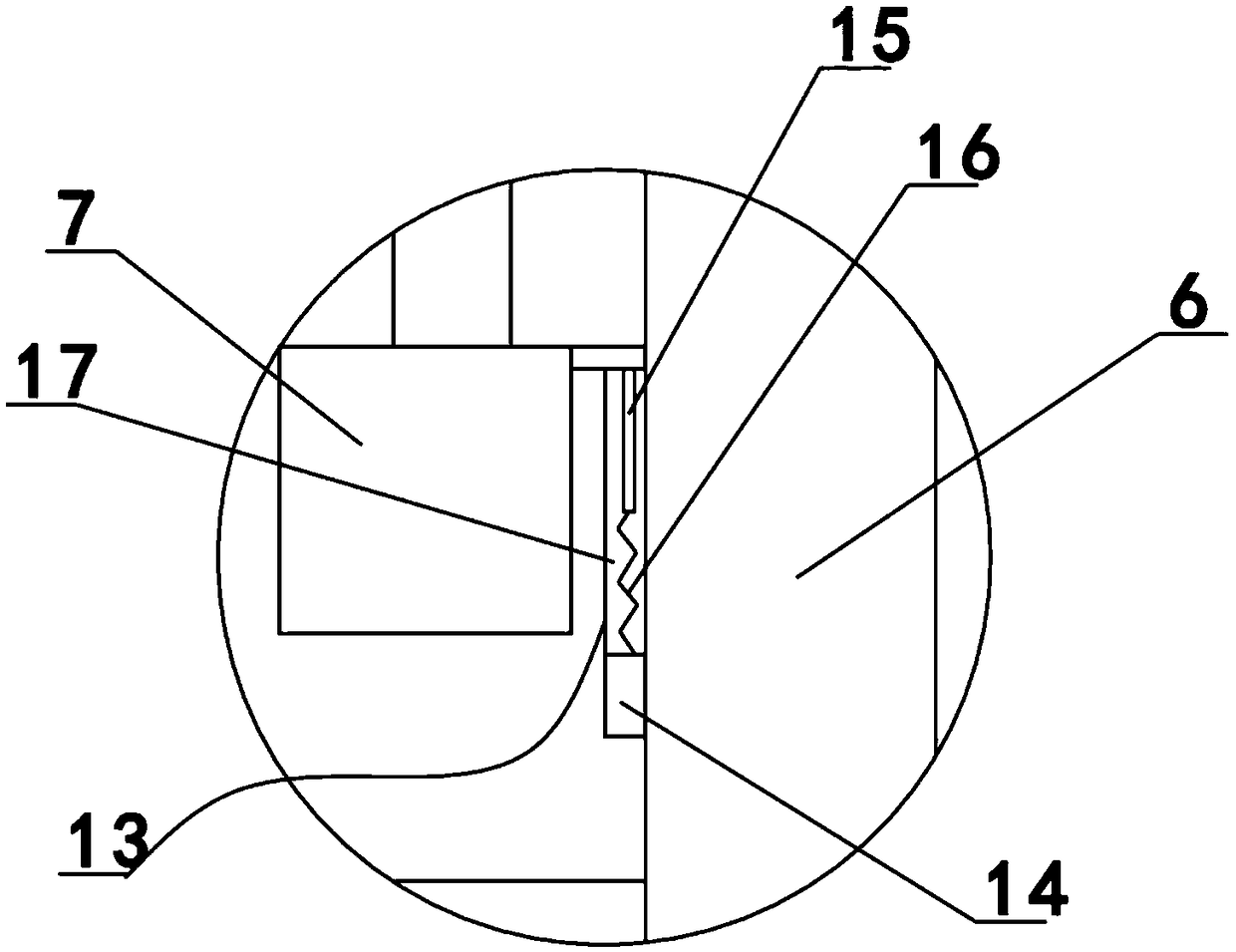

The invention discloses a lifting clamp for a punch and a manufacturing process thereof. The lifting clamp comprises a punching box, a back plate, a mounting plate, supporting columns, a middle partition plate and lifting clamp bodies; the back plate is mounted at the rear end of the upper end of the mounting plate; the punching box is mounted at the upper end of the back plate; a hydraulic cylinder is mounted in the middle inside the punching box; the middle partition plate is mounted in the middle inside the mounting plate; the lifting clamp bodies are mounted at the two ends of the middle partition plate correspondingly; lifting hydraulic cylinders are mounted at the ends, close to the middle partition plate, of the lifting clamp bodies; lifting hydraulic oil pumps are mounted below thelifting hydraulic cylinders; piston connection rods are slidably mounted inside the lifting hydraulic cylinders; movable triangular prisms are mounted at the output ends of the piston connection rods; lifting triangular prisms are mounted on the sides, away from the lifting hydraulic cylinders, of the movable triangular prisms; and lifting blocks are mounted at the upper ends of the lifting triangular prisms. After punching, punched raw materials are convenient to taken out through the lifting clamp bodies, and large deformation of the raw materials is avoided.

Owner:天津普越金属制品有限公司

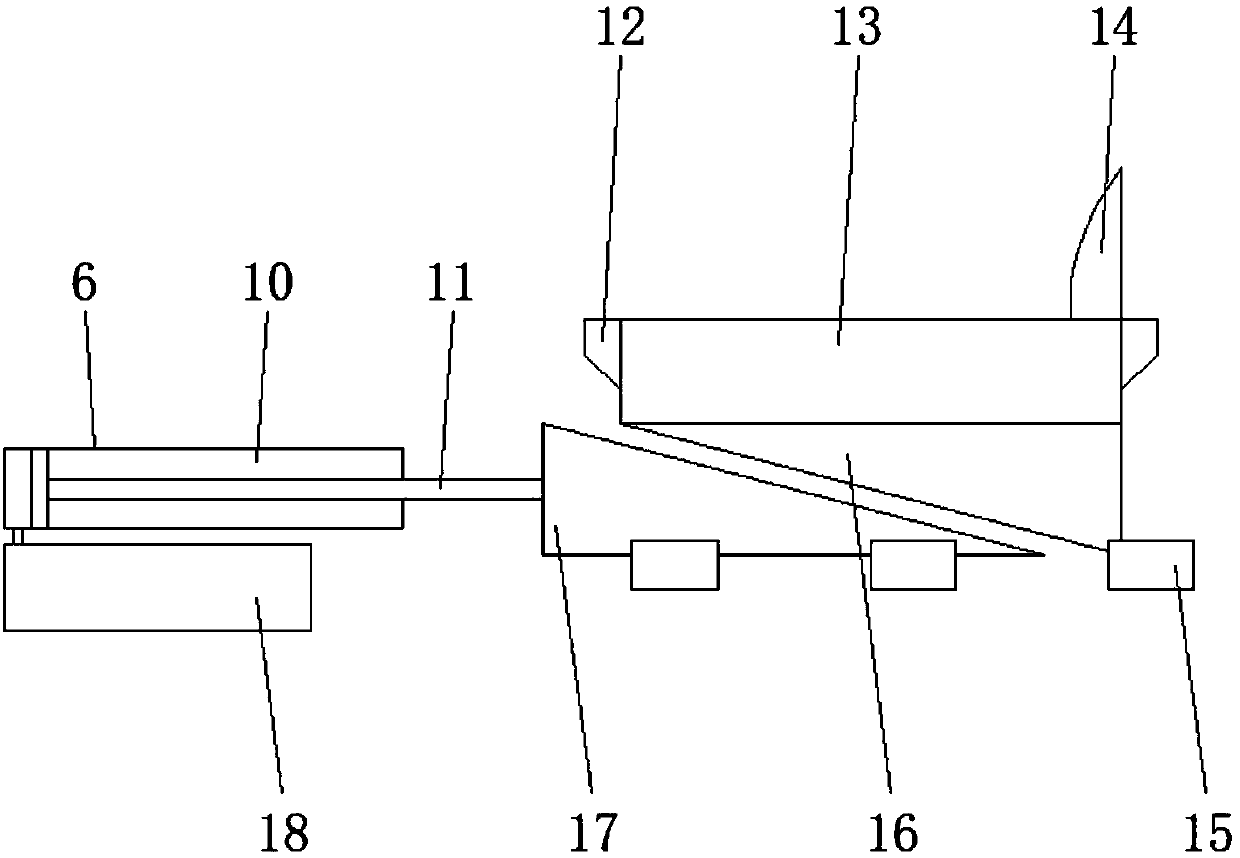

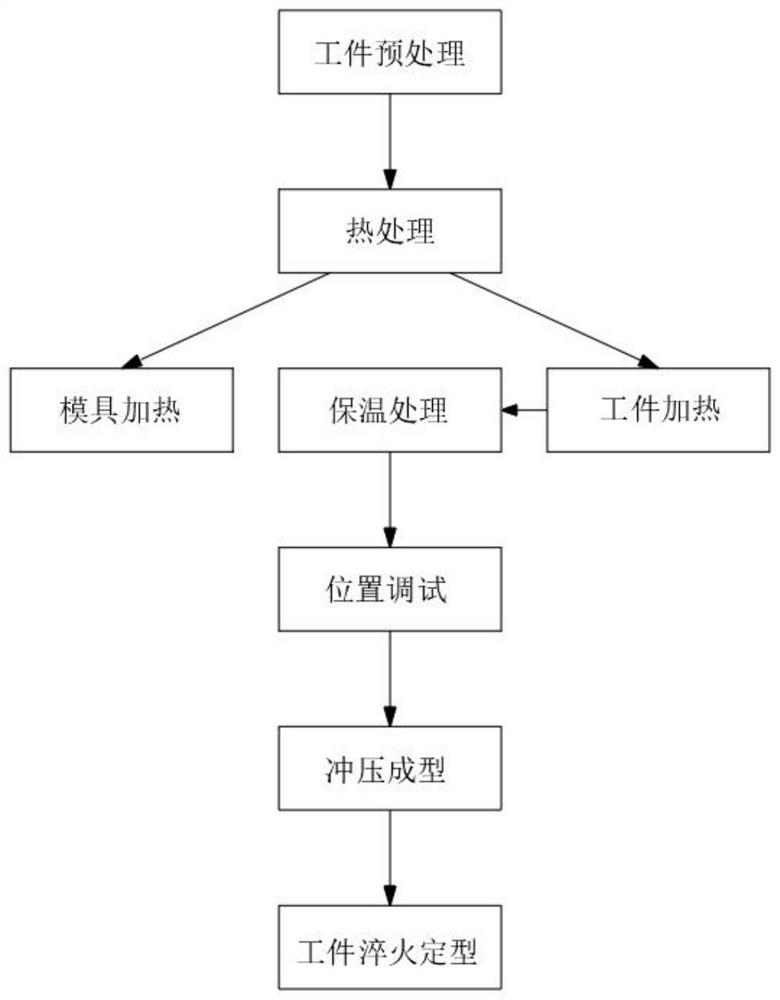

Rapid stamping and shaping process for automobile door frame

PendingCN112756450APrevent surface oxidation from detachmentAvoid destructionShaping toolsLiquid surface applicatorsStampingOxidation resistant

The invention discloses a rapid stamping and shaping process for an automobile door frame. The rapid stamping and shaping process comprises the following steps that a workpiece is pretreated, impurities attached to the surface of a plate are cleaned with a cleaning agent, it is guaranteed that the surface of the plate is clean and tidy, after the plate is dried, the surface of the workpiece is evenly coated with an anti-oxidation coating, and according to the size of a part needing to be stamped, the plate is cut to obtain a metal blank; heating is carried out, a stamping die is heated, the metal blank is heated to 900 DEG C-1100 DEG C, an electric heating mode is adopted for heating, temperature rising is fast, efficiency is high, and heat preservation is carried out on the workpiece after heating; and the initial position of a lower die base is debugged according to the position of an upper die base, so that the upper die base corresponds to the lower die base. The process is simple in step, convenient to operate, reasonable in design of punch forming process parameters and good in using effect, and a punch forming product which is smooth in surface, good in geometric shape and excellent in mechanical performance can be manufactured easily, conveniently and rapidly in a high-quality mode.

Owner:安徽瑞卓汽车部件有限公司

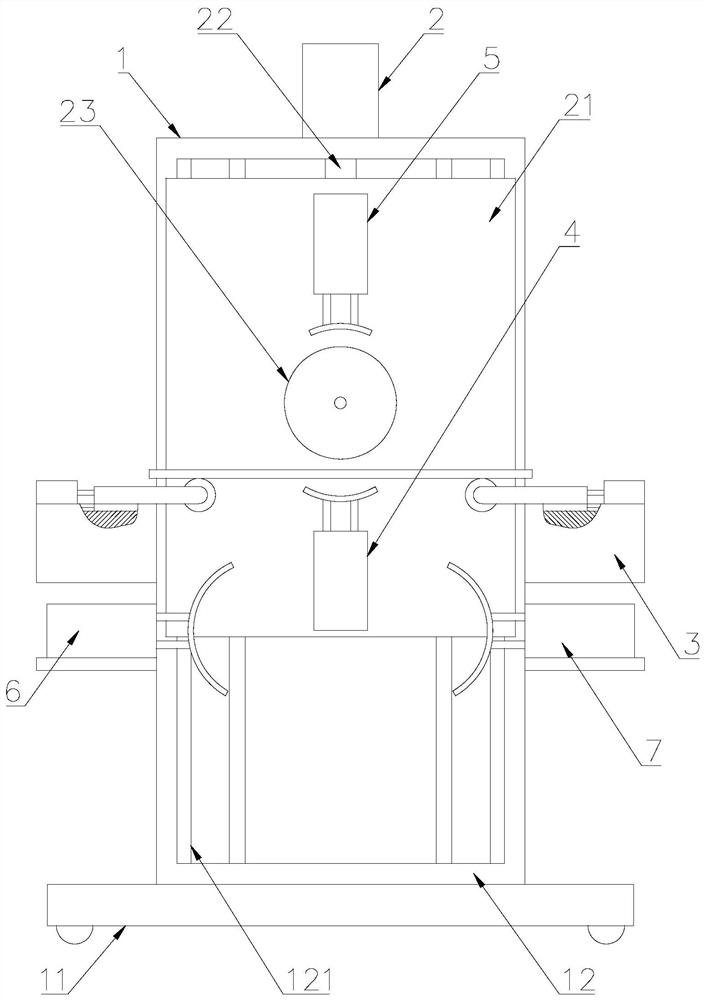

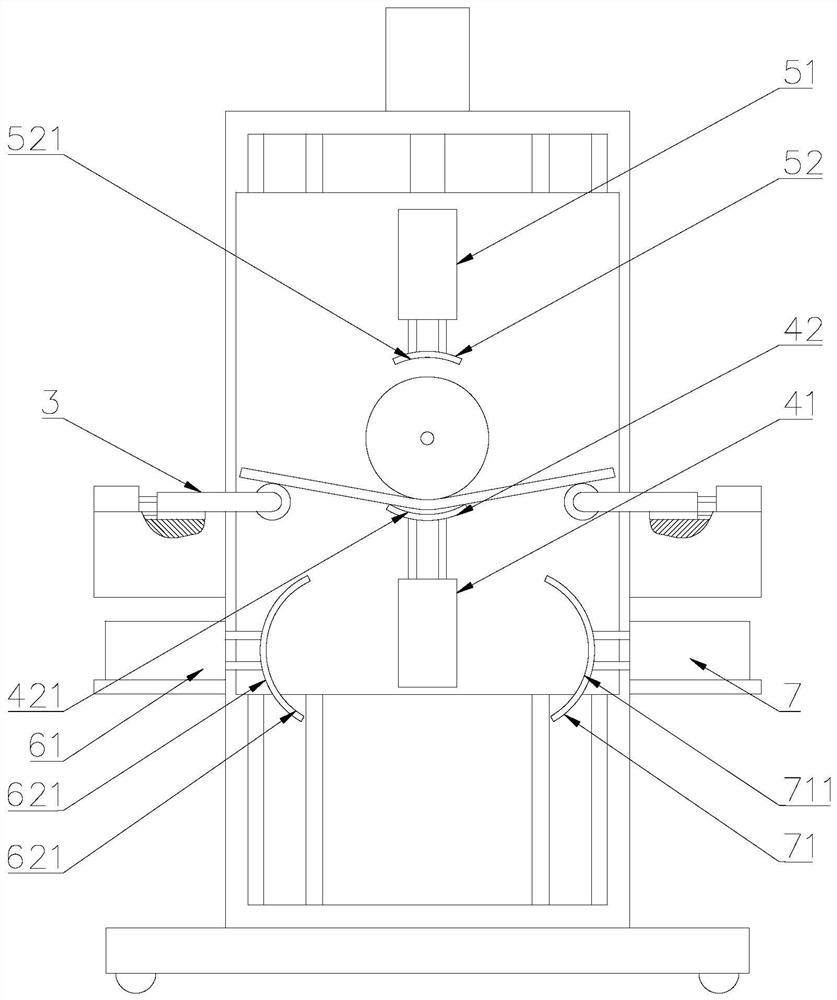

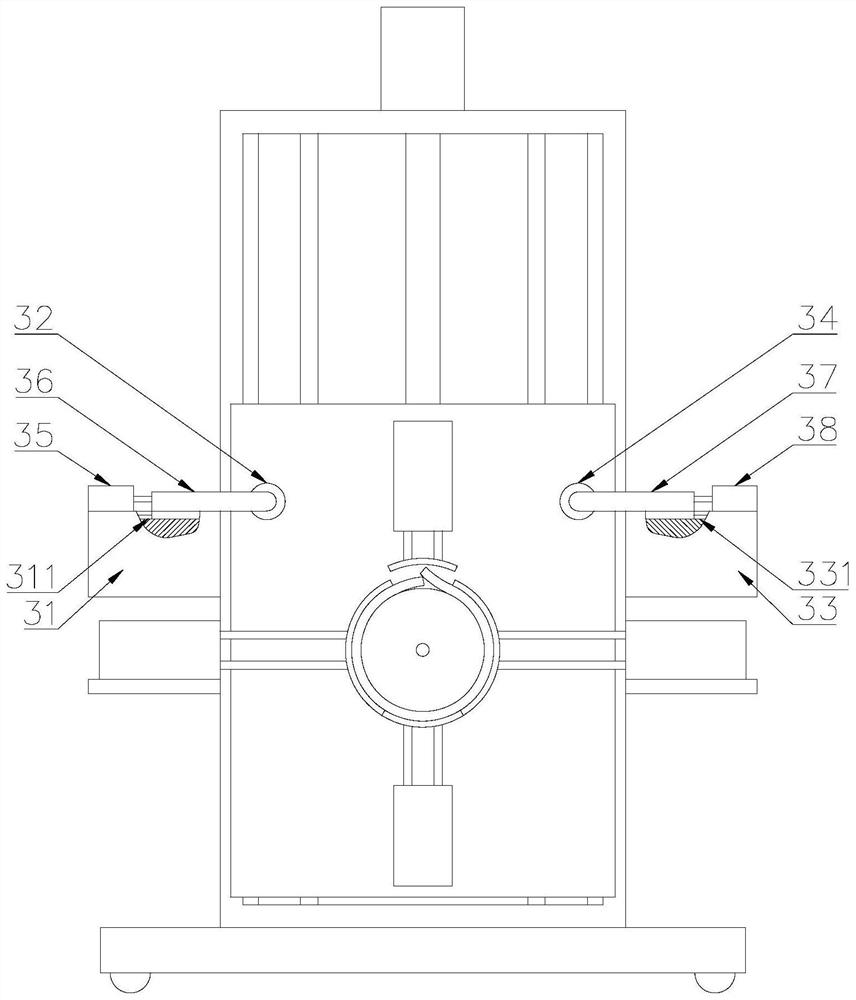

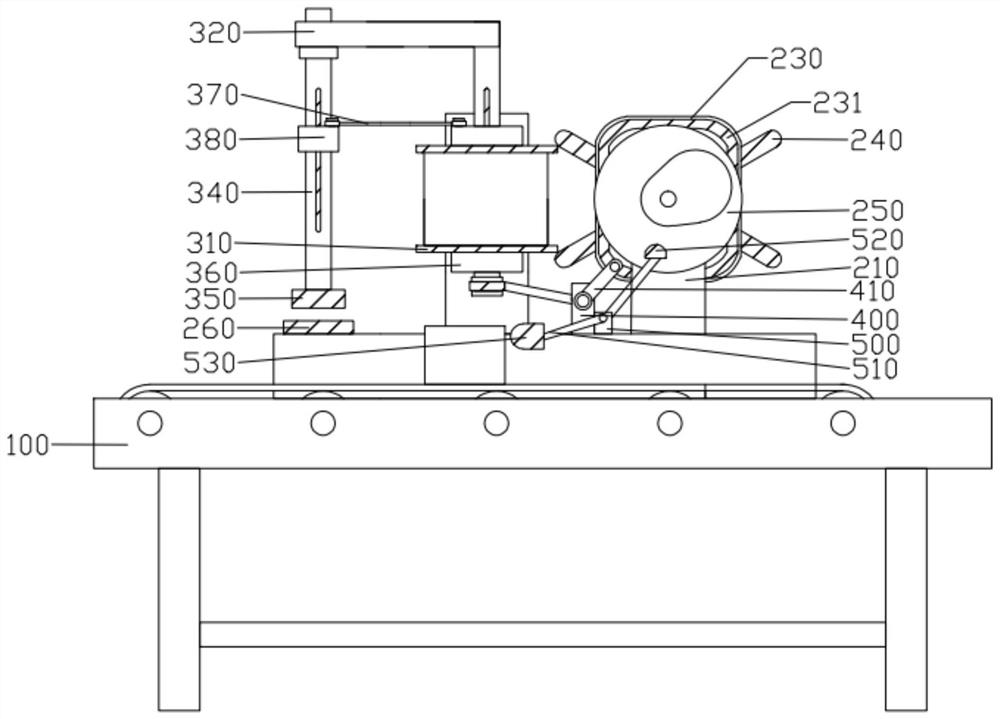

Vertical bamboo board cylinder forming machine

ActiveCN113043398AAvoid reducing molding effectStable structureCane mechanical workingWood stock bendingMolding machineStructural engineering

The invention relates to the technical field of bamboo cylinder processing, in particular to a vertical bamboo board cylinder forming machine. The vertical bamboo board cylinder forming machine comprises a rack, a lifting adjusting mechanism, a supporting mechanism, a first forming assembly, a second forming assembly, a third forming assembly and a fourth forming assembly, wherein the lifting adjusting mechanism, the supporting mechanism, the first forming assembly, the second forming assembly, the third forming assembly and the fourth forming assembly are arranged on the rack respectively; the lifting adjusting mechanism comprises a lifting frame, a lifting oil cylinder and a heating die head; the supporting mechanism comprises a first mounting frame, a first heating roller, a second mounting frame and a second heating roller; the first forming assembly comprises a first oil cylinder and a first hot pressing plate; the second forming assembly comprises a second oil cylinder and a second hot pressing plate; the third forming assembly comprises a third oil cylinder and a third hot pressing plate; and the fourth forming assembly comprises a fourth oil cylinder and a fourth hot pressing plate. According to the vertical bamboo board cylinder forming machine, cracking of a bamboo board in the cylinder forming process and a formed bamboo cylinder is avoided, the mechanical property of the bamboo cylinder is improved, and the processing efficiency is improved while the fitting property of the bamboo board and a core die is improved.

Owner:FUJIAN ZHENGBIAO BAMBOO CO LTD

Electronic anti-counterfeiting device for wine transportation packaging box

The invention relates to the technical field of carton anti-counterfeiting, and discloses an electronic anti-counterfeiting device for a wine transportation packaging box. The device comprises a conveying frame, the rear end of the conveying frame is fixedly connected with a fixing frame, the right side of the fixing frame is fixedly connected with a first supporting frame, and the rear end of the first supporting frame is movably connected with a rotating rod. A clamping groove plate is fixedly connected to the rear end of the rotating rod, a clamping groove is formed in the front end of the clamping groove plate, a shifting frame is fixedly connected to the rear end of the rotating rod and located at the rear end of the clamping groove plate, a rotating disc is fixedly connected to the front end of the rotating rod, an ink box is arranged on the left side of the fixing frame, and a driving motor is installed at the rear end of the fixing frame. According to the device, ink dipping and sealing work can be better carried out, through automatic ink dipping and sealing, the working efficiency can be effectively improved, the labor force of workers is effectively reduced, and better sealing work can be better carried out on the wine packaging boxes in an auxiliary mode.

Owner:杭州展虹科技有限公司

Cutter block switching structure of stamping die

InactiveCN114160673ASmooth movementConvenient stamping workShaping toolsVehicle componentsStructural engineeringMechanical engineering

According to the cutter block switching structure of the stamping die, the driving slotting cutter is driven by the air cylinder to be pulled rightwards so that the two slotting cutter blocks can move rightwards, the driven slotting cutter and the match grinding base plate move leftwards relatively to fall onto an extension plate on the left side of the slotting cutter block on the left side and a gap between the left slotting cutter block and the right slotting cutter block correspondingly, and therefore the mounting plate moves downwards through the guide mechanism; a safety limiting screw penetrating through the mounting plate and the base is used for limiting the top end of the mounting plate, so that the position of the top end of the cutter block is limited, a slotting tool is cooperatively driven to limit the bottom end of the cutter block, the position of the cutter block is fixed, and stamping work is better conducted; and the switching is more stable.

Owner:FUZHEN TECH RES ANHUI

Casting equipment for automotive metal parts

The invention discloses a casting device for automotive metal accessories. The casting device comprises a casting table base, a punching cavity, a casting table, a casting cavity and an accessory casting template bearing plate, wherein the punching cavity is formed in an inner cavity on the left side of the casting table base; the casting cavity is formed in an inner cavity on the left side of the casting table; the accessory casting template bearing plate is arranged on the left side of the casting cavity; a casting template fixing nut is further arranged at the top of the casting cavity; and an ejector plate is further arranged on the right side of the casting cavity. Through the adoption of a hydraulic punching type perfusion technology in the casting device for the automotive metal accessories, the casting cavity is filled with a casting solution from bottom to top, so that not only can the problem of shortage of castings occurring during a traditional casting technology be effectively avoided, but also the casting speed can be also effectively increased. Through the mounting of the accessory casting template bearing plate, casting templates of the accessories can be freely replaced according to the production and processing requirements of the accessories, so that the applicability of the casting device is effectively improved.

Owner:无锡市顺盛电力装备有限公司

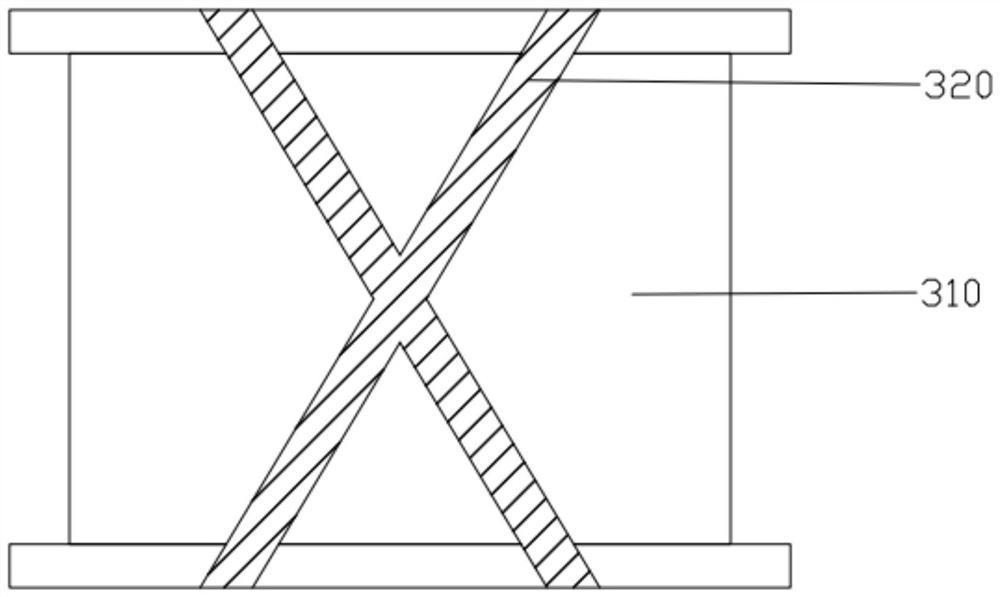

Double-stroke pressing device applied to workpiece machining

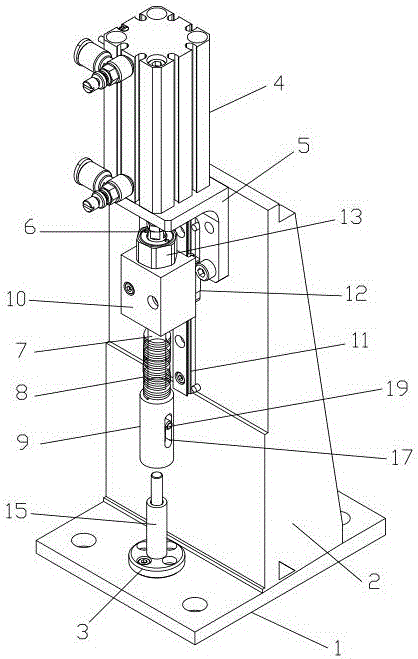

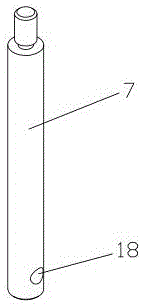

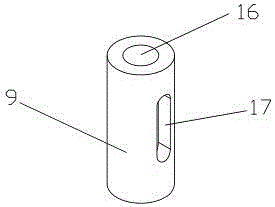

InactiveCN106552877AImprove processing qualitySolve the compression problemMetal-working feeding devicesShaping safety devicesGas cylinderEngineering

The invention discloses a double-stroke pressing device applied to workpiece machining. The device comprises a bottom plate, a support and a workbench; the support and the workbench are fixedly mounted on the bottom plate; a double-stroke pressing mechanism is arranged on the support and comprises a gas cylinder driving assembly and a pressing assembly; the gas cylinder driving assembly comprises a driving gas cylinder, a gas cylinder mounting seat and a piston rod; the driving gas cylinder is arranged on the gas cylinder mounting seat and is connected with a piston rod; the piston rod is connected with the pressing assembly; the pressing assembly comprises a pressing shaft, a pressing spring, a pressing sleeve and a connecting block; the upper end of the pressing shaft is connected with the connecting block; the lower end of the pressing shaft is connected with the pressing sleeve; and the pressing shaft is sleeved with the pressing spring. The device is simple in structure, scientific, convenient, high in pertinence, high in automation degree and high in machining efficiency, the workpiece machining quality is substantially improved, the labor intensity of workers is reduced, the production cost is reduced, and the problem about pressing during workpiece machining is well solved.

Owner:王梅春

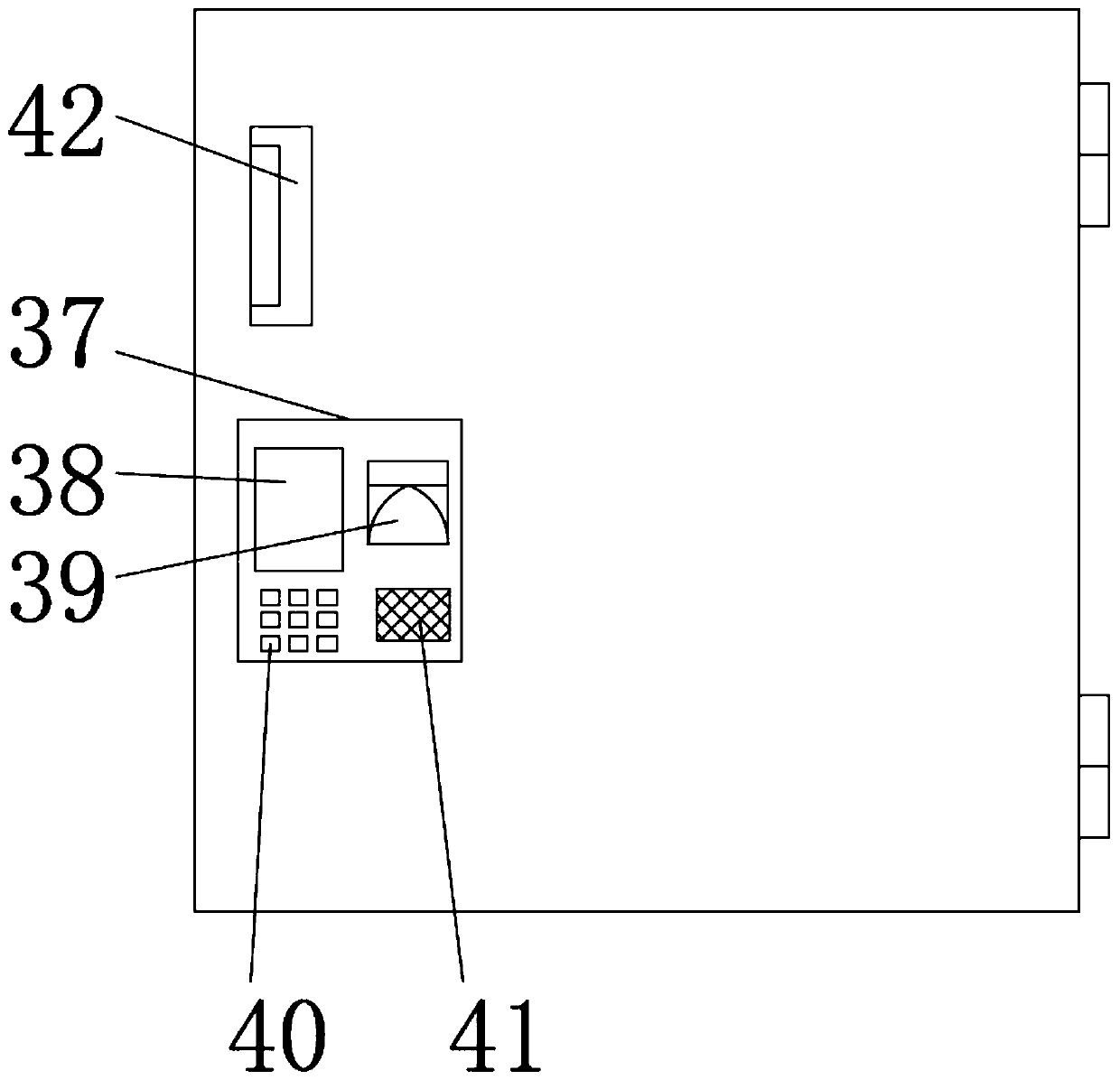

Stamping device for financial and economic management and using method thereof

InactiveCN111421974APlay a protective effectQuality improvementStampingStampingIndustrial engineering

The invention provides a stamping device for financial and economic management and a using method thereof, and relates to the technical field of stamping. The stamping device for financial and economic management comprises a fixing table, a fixing frame is fixedly connected to one side of the top of the fixing table, an electric push rod is arranged at the inner top end of the fixing frame, a lifting table is arranged at the driving end of the electric push rod, a connecting rod is fixedly connected to the bottom of the lifting table, a protective cover is connected to the outer surface of theconnecting rod in a nested and sliding mode, and the whole structure not only can carry out stable and cyclic stamping work, but also can cope with stamping of multiple files, meanwhile, the stampingquality can be guaranteed through the arrangement of a positioning sleeve, through arrangement that a detachable stamping structure is matched with a storage box, so that a stamp can be well protected, the stamping device not only can flexibly replace different stamps for operation, but also plays role in protecting stamps from being lost, and a good auxiliary effect is achieved for stamping forfinancial and economic management.

Owner:潘攀 +1

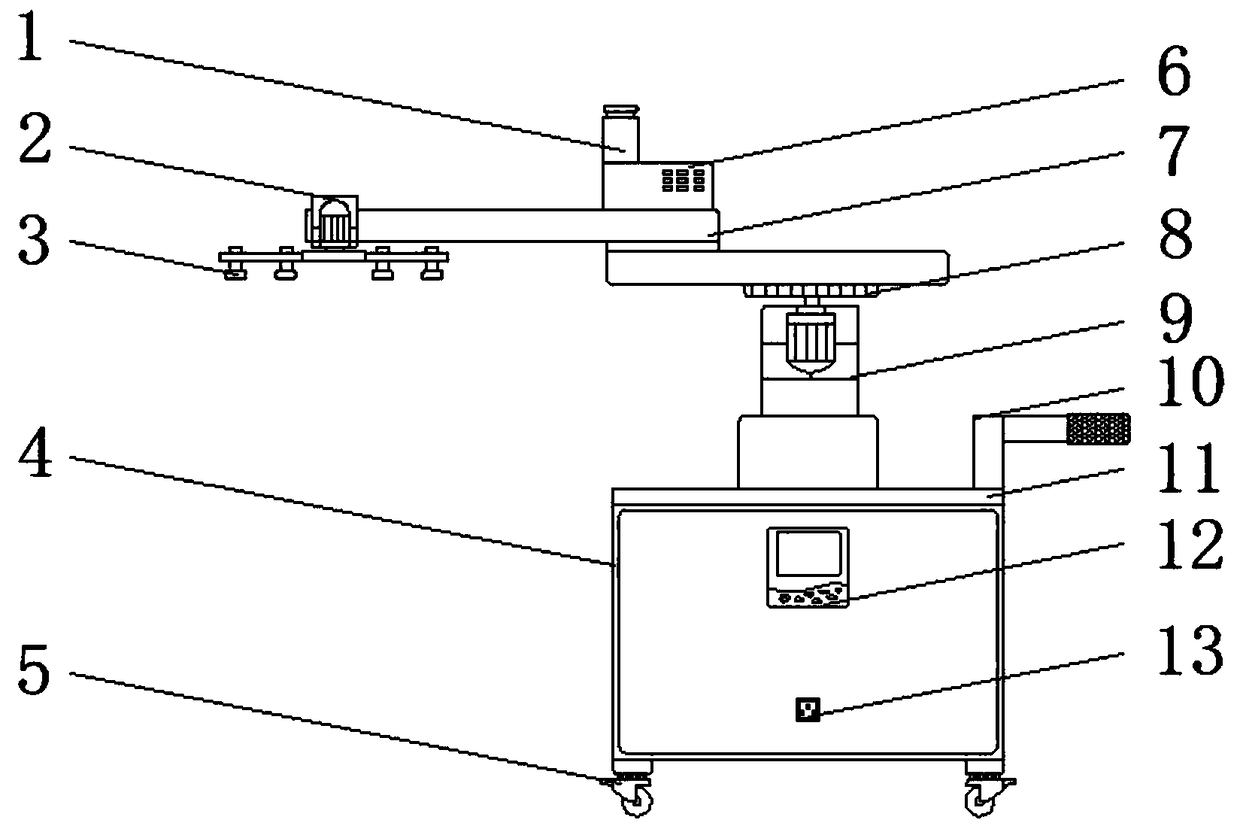

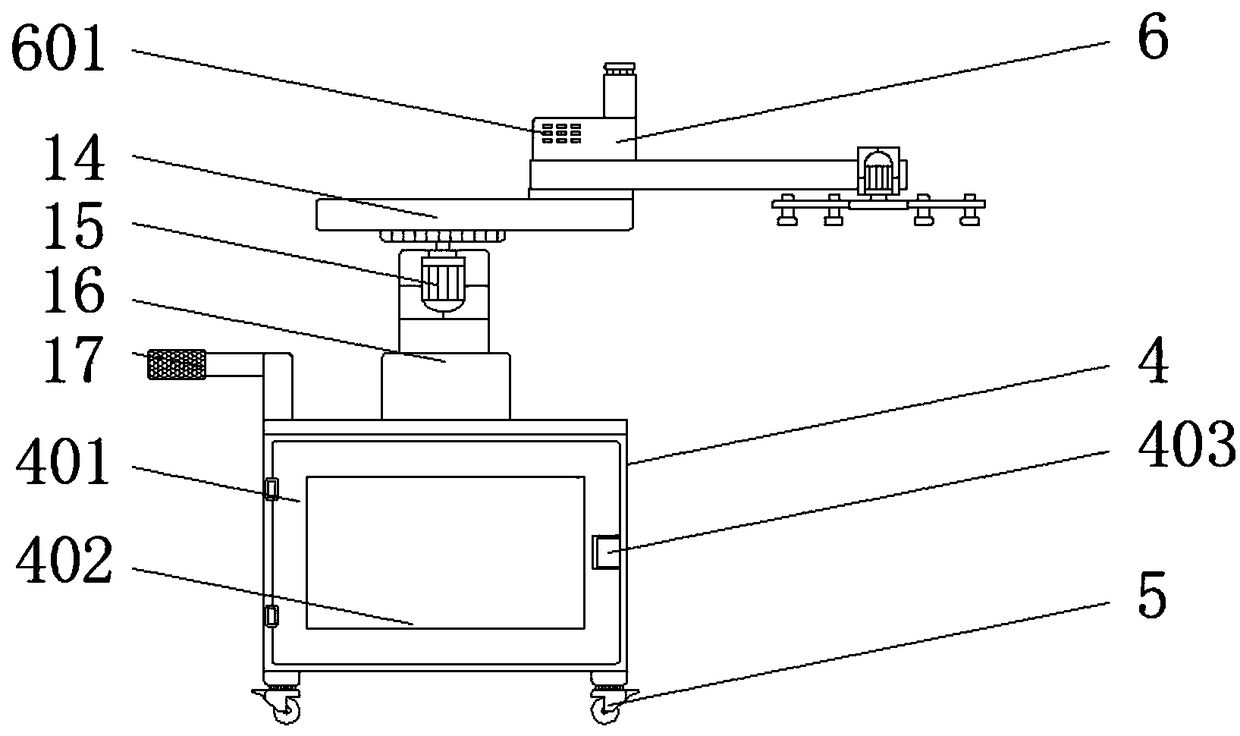

Automatic feeding device for stamping manufacturing process

The invention discloses an automatic feeding device for the stamping manufacturing process. The automatic feeding device comprises an electromagnetic chuck, a machine case and a sliding platform cylinder. A supporting seat is fixedly installed at the top of the machine case, an electric cylinder is fixedly installed at the top of the supporting seat, and a protective shell is fixedly installed atthe top of the electric cylinder. A first motor is fixedly installed on the interior of a positioning plate, the electromagnetic chuck is fixedly installed at the output end of the first motor, a chipbox is fixedly installed at the top of the positioning plate, and an electronic module box is fixedly installed at the top of chip box. A handrail is fixedly installed at the top of the supporting seat, and the handrail is located on one side of the electric cylinder. A control panel is fixedly installed on the surface of the machine case, a supply hub is fixedly installed on the surface of the machine case, and the supply hub is located at the bottom of the control panel. The automatic feeding device for the stamping manufacturing process has the advantages of high working efficiency and simple operation in the using process of the automatic feeding device by arranging a series of structures.

Owner:宁波市拓欧金属制品有限公司

High-precision stamping die limiting structure capable of preventing materials from deviating

PendingCN113426908AAvoid shakingEasy to hold and secureMetal-working feeding devicesPositioning devicesStampingStructural engineering

The invention relates to the technical field of stamping dies, in particular to a high-precision stamping die limiting structure capable of preventing materials from deviating. The high-precision stamping die limiting structure comprises a stamping device and a limiting mechanism installed in the stamping device. In the high-precision stamping die limiting structure capable of preventing the materials from deviating, the clamping device is arranged so that the side face of a stamping part can be conveniently and stably clamped, the stamping part is prevented from deviating, the clamping length can be conveniently adjusted through sliding between a sliding block and a limiting rod, the stamping part can be accurately clamped, after the length is adjusted, the sliding block is automatically reset through the elastic force effect of a sliding rod spring, meanwhile, clamping work of the stamping part is stabilized, a fixing frame is arranged, through the rotation relation of a rotating block and the fixing frame, the fixing frame can conveniently limit and fix the top face of the stamping part, and through an arranged buffer block, and the upper surface of the stamping part can be conveniently fixed before a stamping module makes contact with the stamping part, and shaking of the stamping part is avoided.

Owner:方国保

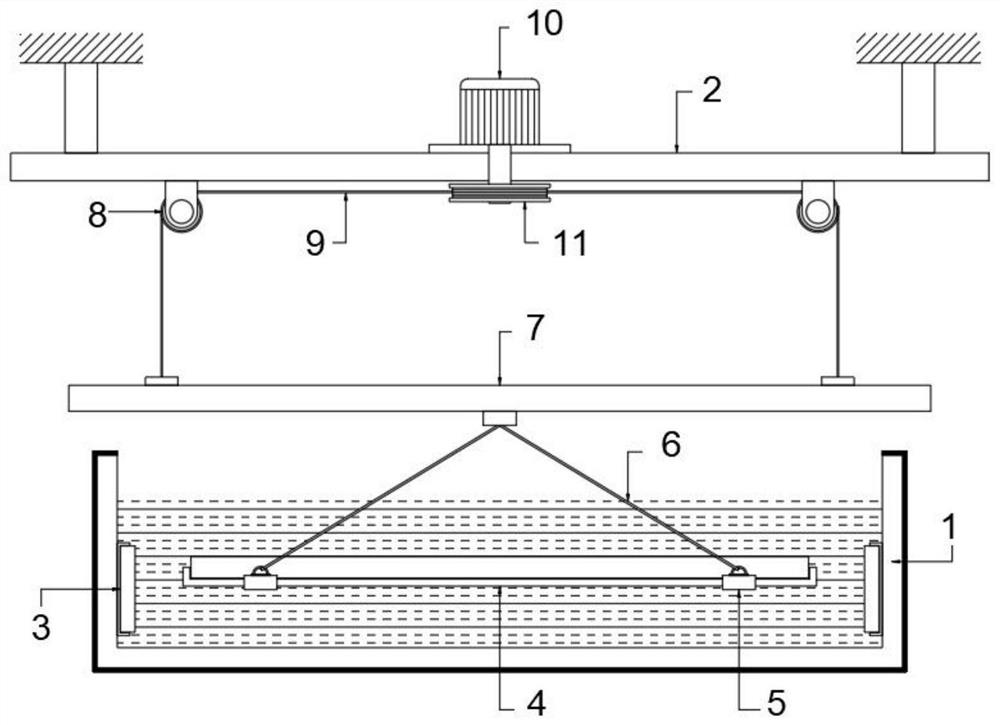

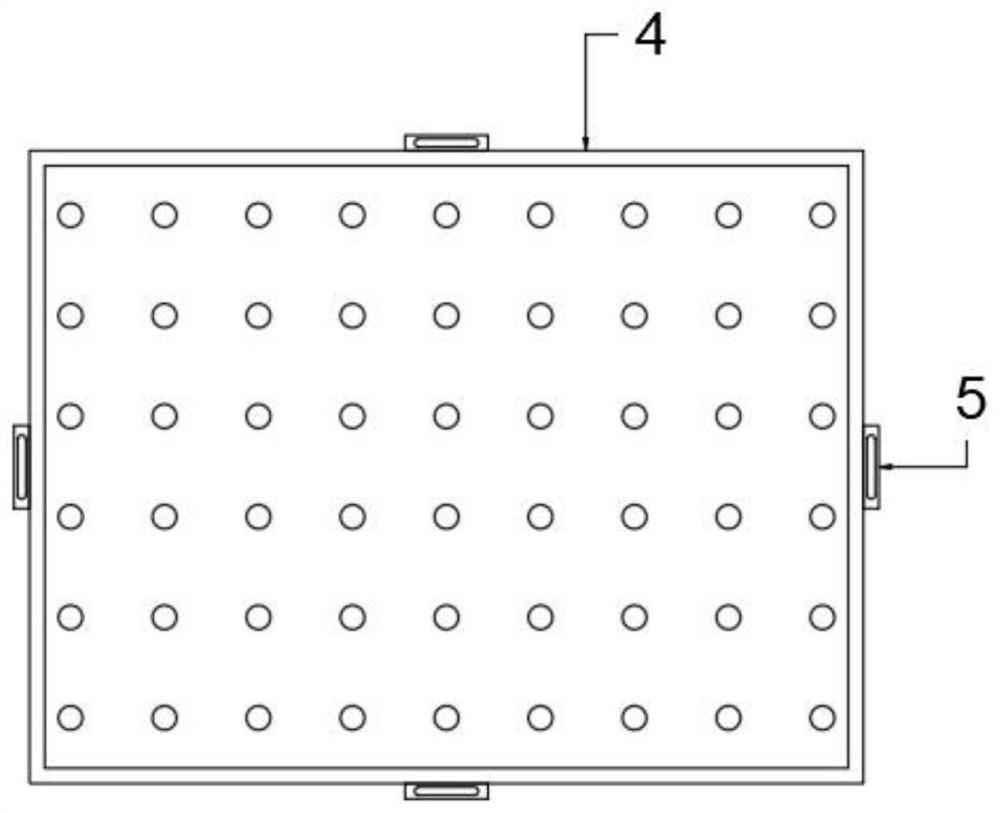

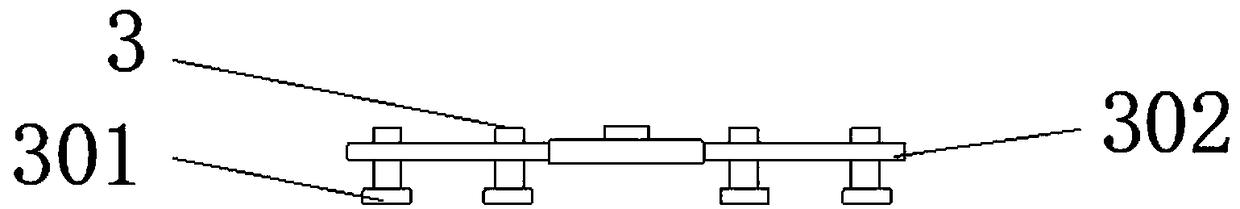

Sheet leveling and conveying device

InactiveCN106391898AConvenient stamping workImprove pass rateMetal-working feeding devicesPositioning devicesPunchingThin sheet

The invention discloses a sheet leveling and conveying device comprising a leveling base and a conveying rolling frame; the conveying rolling frame is hinged at one end of the leveling base; two sides of the other end of the leveling base are provided with arc-shaped feeding supporting plates; a plurality of first guide rollers are arranged between the two arc-shaped feeding supporting plates; the leveling base is provided with a leveling roller mounting shell located between the conveying rolling frame and each arc-shaped feeding supporting plate; a row of driving rollers is arranged inside the leveling roller mounting shell in which two fixed plates are arranged; and a row of driven rollers located above the driving rollers is arranged between the two fixed plates. In such a way, according to the sheet leveling and conveying device disclosed by the invention, sheets are clamped between each of the plurality of driving rollers and each of the plurality of driven rollers and conveyed so as to be leveled, and then, the sheets are conveyed to a punching machine block by block after being cut by using a cutter, so that the punching work of the punching machine is favorably realized, and the product percent of pass and work efficiency are increased.

Owner:常熟市威成自动化科技有限公司

Casting device for automotive metal accessories

The invention discloses a casting device for automotive metal accessories. The casting device comprises a casting table base, a punching cavity, a casting table, a casting cavity and an accessory casting template bearing plate, wherein the punching cavity is formed in an inner cavity on the left side of the casting table base; the casting cavity is formed in an inner cavity on the left side of the casting table; the accessory casting template bearing plate is arranged on the left side of the casting cavity; a casting template fixing nut is further arranged at the top of the casting cavity; and an ejector plate is further arranged on the right side of the casting cavity. Through the adoption of a hydraulic punching type perfusion technology in the casting device for the automotive metal accessories, the casting cavity is filled with a casting solution from bottom to top, so that not only can the problem of shortage of castings occurring during a traditional casting technology be effectively avoided, but also the casting speed can be also effectively increased. Through the mounting of the accessory casting template bearing plate, casting templates of the accessories can be freely replaced according to the production and processing requirements of the accessories, so that the applicability of the casting device is effectively improved.

Owner:无锡市顺盛电力装备有限公司

A slidable lower mold base device

ActiveCN104438602BShorten the timeEasy to pick and placeShaping toolsEjection devicesHydraulic cylinderStamping

The invention discloses a slidable lower mold base device, which comprises a cuboid lower mold base, a cuboid-shaped groove is arranged in the center of the upper part of the lower mold base, and a sliding plate sliding left and right is arranged in the cuboid-shaped groove , the surface of the sliding plate is provided with a first mold jacket and a second mold jacket arranged side by side, a stamping die is placed inside the first mold jacket and the second mold jacket; a gap is provided on the right side of the cuboid groove, and The right side of the mold base is provided with a first driving mechanism and a second driving mechanism arranged side by side; the bottom surface of the left part of the lower mold base is provided with two vertical through holes arranged side by side, and the two through holes are respectively A first ejector rod and a second ejector rod are provided. The invention relies on the cylinder to remove the sliding plate with the multi-station mold from the bottom of the slider to carry out the loading and unloading process. At the same time, a hydraulic cylinder jacking device is installed under the mold base, which can realize fast, safe and high-efficiency stamping production.

Owner:泰州浙华机械精锻有限公司

Building lamp top cover stamping equipment

PendingCN114632878AAvoid stamping failureConvenient stamping workMetal-working feeding devicesCleaning using toolsHydraulic cylinderStamping

The invention relates to top cover stamping equipment, in particular to building lamp top cover stamping equipment. According to the building lamp top cover stamping equipment, top cover materials can be fixed and then stamped. According to the technical scheme, the building lamp top cover stamping equipment comprises a machine box, a bottom plate, a mounting table, a hydraulic cylinder, a first mold and the like, the bottom plate is arranged on the front side of the top of the machine box, the mounting table is arranged on the rear side of the top of the bottom plate, and the hydraulic cylinder capable of providing power for stamping work is arranged on the front side of the upper portion of the mounting table; a first die capable of punching a top cover is arranged at the bottom of a telescopic rod of the hydraulic cylinder. And the first limiting plate and the second limiting plate are matched to clamp the top cover material, so that the top cover material cannot move, the punching failure can be avoided, and the punching work can be better carried out.

Owner:吴志雄

Stamping device for guard plate of computer case

ActiveCN112059015AGood cleaning effectImprove work efficiencyMetal-working feeding devicesStripping-off devicesElectric machineryComputer case

The invention discloses a stamping device for a guard plate of a computer case. The stamping device for the guard plate of the computer case comprises a machine shell, a stamping assembly, a fixing assembly, a dust removal assembly and a conveying belt, wherein the stamping assembly is used for punching and stamping forming of an outer plate; the fixing assembly is arranged below the stamping assembly; the dust removal assembly is slidably connected to a workbench; the conveying belt is arranged at the bottom of the workbench; a first driving motor is connected to the left side of the conveying belt; baffles are arranged on the two sides and the rear side of the conveying belt respectively; the top ends of the baffles are attached to the bottom of the workbench; and the conveying belt is used for conveying waste generated by stamping to a waste box.

Owner:JIANGHAI POLYTECHNIC COLLEGE

A pressure-resistant special stamping protective film

InactiveCN106739377BExpand coverageImprove protectionSynthetic resin layered productsCoatingsTectorial membraneSurface layer

Owner:无锡市玉西薄膜有限公司

Workbench for TV wire harness processing

ActiveCN109980484BConvenient interceptionQuick measureLine/current collector detailsTelevision connectorsStructural engineeringTelevision set

The invention relates to the technical field of television accessory production, and discloses a workbench for television wire harness processing. The workbench comprises a transverse plate, wherein astrip-shaped block is fixedly connected to the upper end of the transverse plate; a plurality of through holes which are uniformly distributed are formed in the left side of the strip-shaped block, and rectangular grooves are formed in the upper sides of the through holes respectively; a shearing mechanism is arranged in each rectangular groove; a plurality of T-shaped sliding grooves which are uniformly distributed are formed in the upper end of each transverse plate; T-shaped sliding blocks are arranged in the T-shaped sliding grooves in a sliding mode, and mounting blocks are fixedly connected to the upper ends of the T-shaped sliding blocks; a clamping mechanism is arranged on one side of the mounting block; a stand column is fixedly connected to the upper side of the right end of thetransverse plate; and a stamping mechanism is arranged on one side of the stand column. According to the workbench, wires can be rapidly cut by workers in batches when the television wire harness isproduced, and the workers can conveniently stamp the wire harness connectors on the same workbench, so that the production speed of the wire harness is accelerated.

Owner:MAANSHAN HETIAN ELECTRONICS INTELLIGENCE CONTROL SYST CO LTD

Accounting office seal all-in-one machine

ActiveCN111775579ACompact structure and combined installationEasy to carryStampingStructural engineeringIndustrial engineering

The invention discloses an accounting office seal all-in-one machine, and belongs to the technical field of accounting. The accounting office seal all-in-one machine comprises a seal box and a paper rolling box; seal bins are arranged on the left side and the right side of the seal box in a penetrating mode, paper frames are embedded into the lower ends of the inner sides of the seal bins, brake boxes are arranged at the rear ends of the seal bins, and the brake boxes are connected with the seal box in a clamped mode; and a pair of sliding seats are symmetrically arranged at the front end andthe rear end of the inner side of each seal bin, the sliding seats are connected with the inner walls of the seal bins in a sliding mode, a circle of annular rack rail is arranged between the two sliding seats and in each brake box respectively, the annular rack rail between the two sliding seats is transversely arranged at the upper ends of the paper frames, the annular rack rail in each brake box is longitudinally arranged, a transverse shaft motor is fixed outside the sliding seat at the front end, and the transverse shaft motor is rotationally connected with the annular rack rail between the sliding seats. According to the seal all-in-one machine, automatic sealing and paper discharging work of files can be completed through assembly of the seal box and the paper rolling box, so that the review efficiency of an accountant when reviewing a large number of files is improved, the machine is convenient to carry, and the applicability of the all-in-one machine is improved.

Owner:JIANGXI COLLEGE OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com