Building lamp top cover stamping equipment

A technology of stamping equipment and top cover, which is applied in the field of stamping equipment for the top cover of architectural lamps, to achieve the effects of saving manpower, avoiding stamping failure, and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

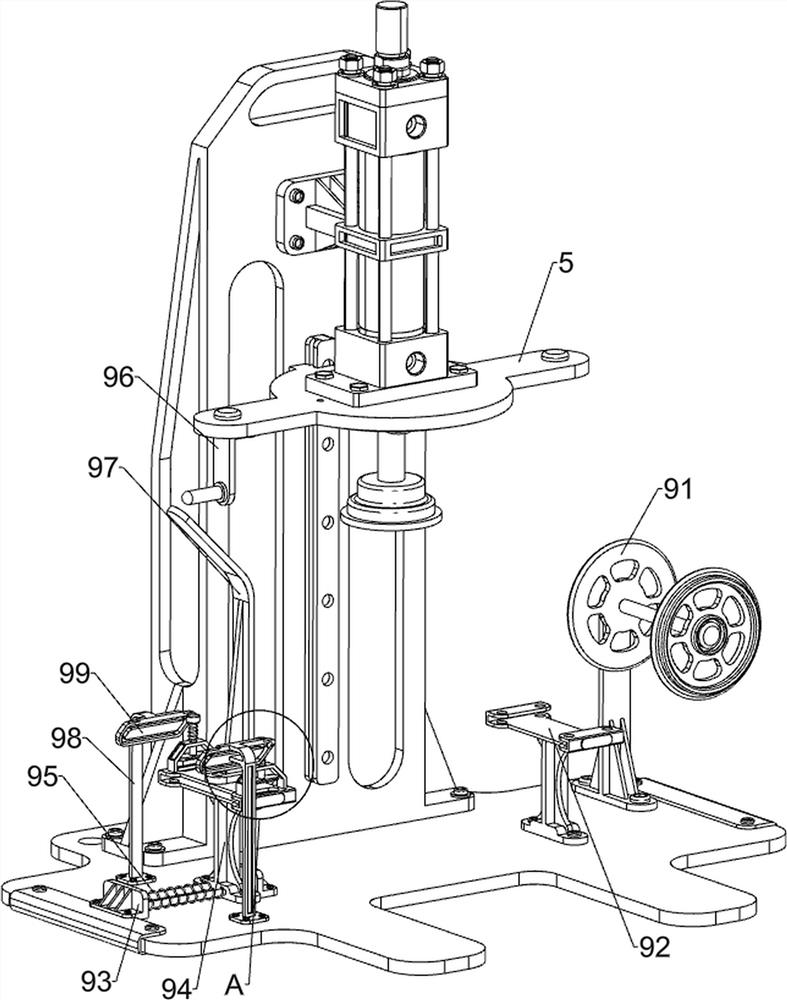

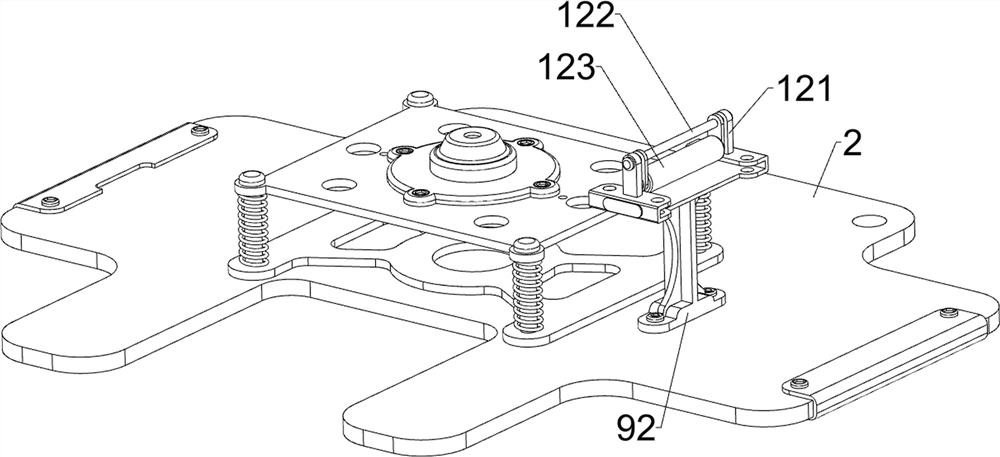

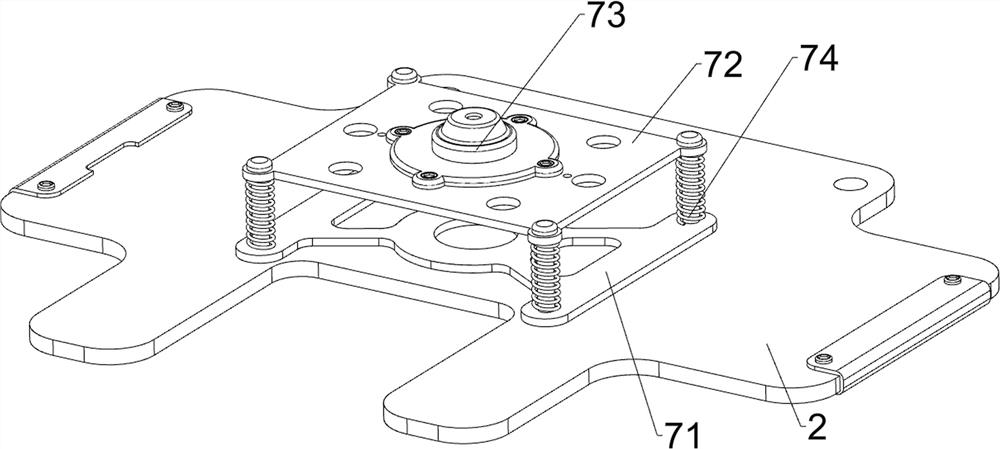

[0032] A stamping equipment for the top cover of architectural lamps, refer to figure 1 and figure 2 As shown, it includes a chassis 1, a bottom plate 2, a mounting table 3, a hydraulic cylinder 4, a first mold 5, a guide rail frame 6, a buffer mechanism 7 and a limit mechanism 8. The top of the chassis 1 is fixed with a bottom plate 2 through bolts, and the bottom plate 2 The rear side of the top is fixed with a mounting table 3 by bolts, and a hydraulic cylinder 4 is arranged on the front side of the upper part of the mounting table 3. The hydraulic cylinder 4 can provide power for the stamping work. 5. The top cover can be punched out. A guide rail frame 6 is arranged in the middle of the front side of the mounting table 3. The first mold 5 is slidably connected with the guide rail frame 6. The bottom plate 2 is provided with a buffer mechanism 7. A limiting mechanism 8 is connected, and the limiting mechanism 8 can clamp the top cover material.

[0033] refer to image...

Embodiment 2

[0037] On the basis of Example 1, refer to figure 1 , Figure 5 , Image 6 and Figure 7 As shown, it also includes a feeding mechanism 9, which can feed the top cover material. The feeding mechanism 9 includes a receiving rack 91, a first guide groove plate 92, a guide seat 93, and a second guide groove. Plate 94, first return spring 95, contact post 96, first wedge plate 97, mounting bracket 98, second wedge plate 99, mounting bracket 910, clamping plate 911 and second return spring 912, the top right side of bottom plate 2 passes through The material receiving rack 91 is fixedly connected with the bolts, and the first guide groove plate 92 is fixedly connected with the top right side of the bottom plate 2 by bolts. A guide seat 93 is provided. The right side of the guide seat 93 is slidably provided with a second guide groove plate 94. Two first return springs 95 are connected between the lower left side of the second guide groove plate 94 and the left side of the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com