Electronic anti-counterfeiting device for wine transportation packaging box

An electronic anti-counterfeiting and packaging technology, applied in printing, stamping and other directions, can solve the problems of inconsistent seal position, troublesome, inability to detect well, and achieve the effect of reducing labor force and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

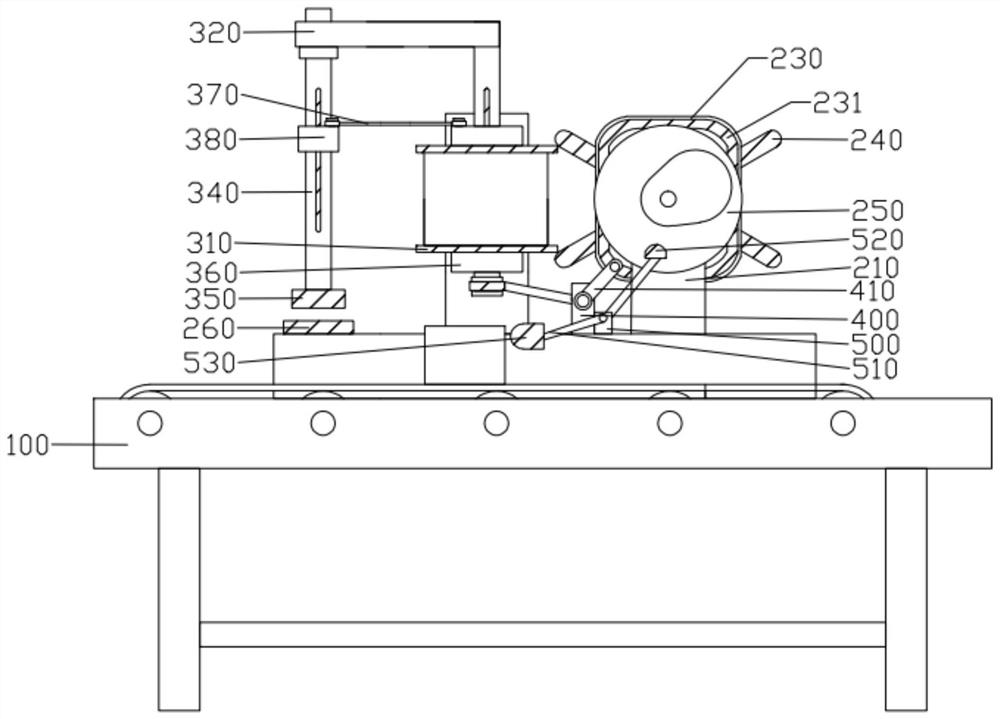

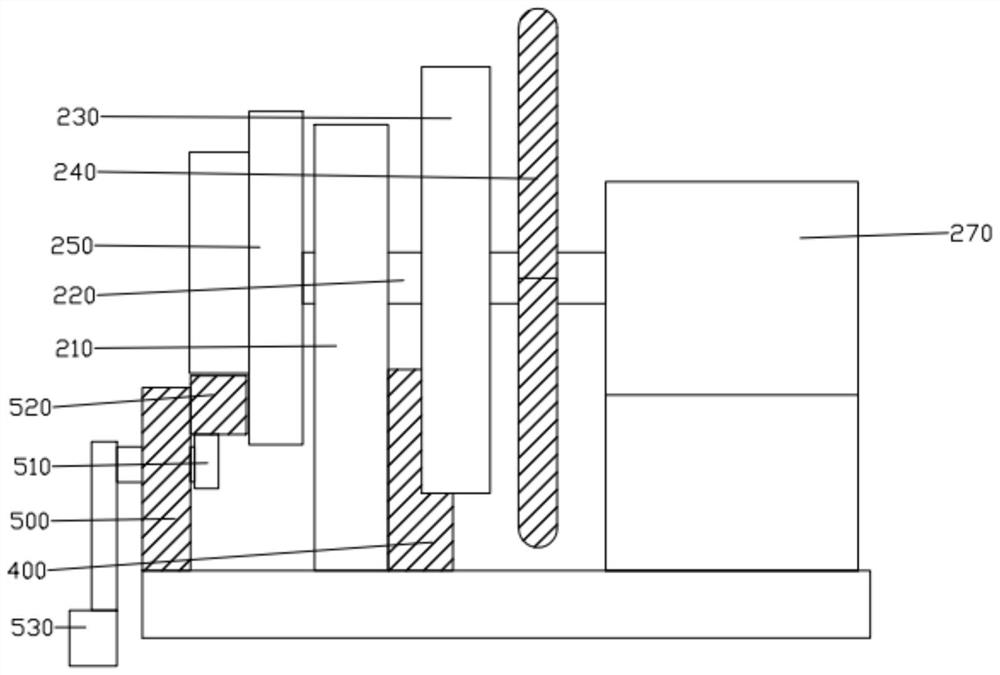

[0024] Embodiment one, by figure 1 , figure 2 , image 3 and Figure 4 Given, the present invention is an electronic anti-counterfeiting device for wine transport packaging boxes, including a transmission frame 100, the rear end of the transmission frame 100 is fixedly connected with a fixed frame 200, the right side of the fixed frame 200 is fixedly connected with a first support frame 210, the second The rear end of a support frame 210 is movably connected with a rotating rod 220, the rear end of the rotating rod 220 is fixedly connected with a draw-in slot plate 230, the front end of the draw-in slot plate 230 is provided with a draw-in slot 231, and the rear end of the rotating rod 220 is fixedly connected with a dial The movable frame 240, the toggle frame 240 is located at the rear end of the slot plate 230, the front end of the rotating rod 220 is fixedly connected with a turntable 250, the left side of the fixed frame 200 is provided with an ink cartridge 260, and t...

Embodiment 2

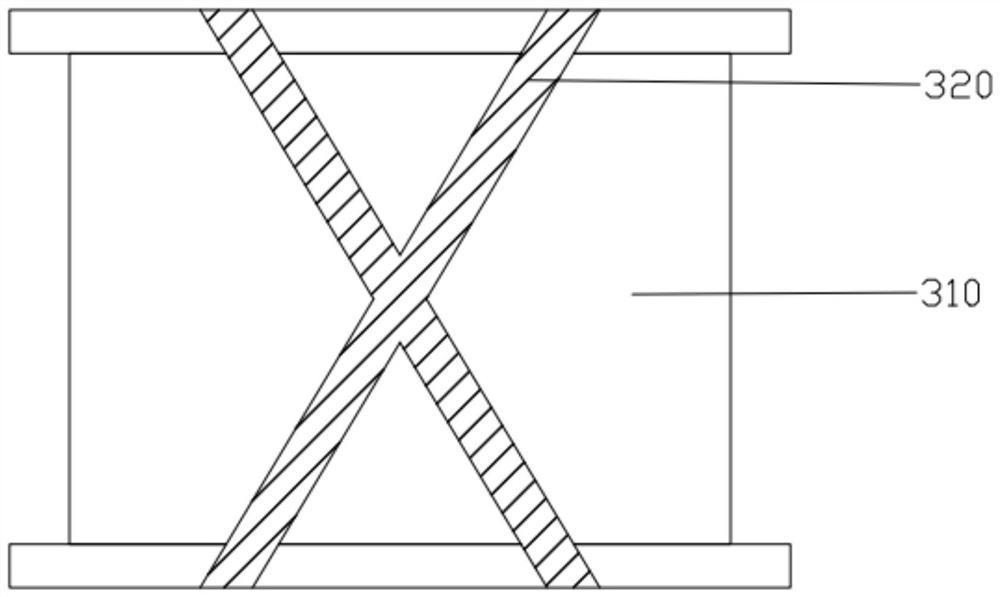

[0027] Embodiment two, by figure 1 and figure 2 Given, the shape of the slot plate 230 is set in an “X” shape, and the width of the toggle groove 330 matches the width of the slot plate 230. Through the above structure, the slot plate 230 can be better engaged in the toggle The inside of the groove 330 can better perform the work of stirring the stirring roller 310 .

Embodiment 3

[0028] Embodiment three, by figure 1 Given, the upper and lower sides of the front end of the second support frame 300 are fixed limit blocks 360, and the toggle roller 310 is located on the opposite side of the two sets of fixed limit blocks 360. By being provided with the fixed limit blocks 360, it is possible to toggle The position of the roller 310 is fixed, and the auxiliary toggle roller 310 works better

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com